EN 13163:2012+A2:2016

(Main)Thermal insulation products for buildings - Factory made expanded polystyrene (EPS) products - Specification

Thermal insulation products for buildings - Factory made expanded polystyrene (EPS) products - Specification

This European Standard specifies the requirements for factory made expanded polystyrene products, with or without rigid or flexible facings or coatings, which are used for the thermal insulation of buildings. The products are manufactured in the form of boards or rolls or other preformed ware (flat, tapered, tongue and grooves, shiplap, profiled etc.).

Products covered by this standard are also used for sound insulation and in prefabricated thermal insulation systems and composite panels; the performance of systems incorporating these products is not covered.

This standard describes product characteristics and includes procedures for testing, evaluation of conformity, marking and labelling.

This standard does not specify the required class or level of a given property to be achieved by a product to demonstrate fitness for purpose in a particular application. The classes and levels required for a given application are to be found in regulations or non-conflicting standards.

Products with a declared thermal resistance lower than 0,25 m²⋅K/W or a declared thermal conductivity at 10 °C greater than 0,060 W/(m⋅K) are not covered by this standard.

This standard does not cover in-situ insulation products (covered by EN 16025-1 and -2), products intended to be used for the insulation of building equipment and industrial installations (covered by EN 14309), products intended to be used in civil engineering applications (covered by EN 14933) and products intended to be used in beam and block systems in floors (covered by EN 15037-4).

Wärmedämmstoffe für Gebäude - Werkmäßig hergestellte Produkte aus expandiertem Polystyrol (EPS) - Spezifikation

Produits isolants thermiques pour le bâtiment - Produits manufacturés en polystyrène expansé (EPS) - Spécification

Toplotnoizolacijski proizvodi za stavbe - Proizvodi iz ekspandiranega polistirena (EPS) - Specifikacija

Ta evropski standard določa zahteve za proizvode iz ekspandiranega polistirena (EPS) s trdno ali prožno površinsko prevleko ali lakom ali brez, ki se uporabljajo za toplotno izolacijo stavb. Proizvodi so izdelani v obliki plošč ali kolutov ali v drugih oblikah (ploščati, konusni, z utori in jezički, s prekrivnimi deli, profilirani itd.).

Proizvodi iz tega standarda se uporabljajo tudi za zvočno izolacijo ter v predizdelanih sistemih toplotne izolacije in vezanih ploščah; lastnosti sistemov iz teh proizvodov niso opisane.

Ta standard opisuje lastnosti proizvodov ter zajema postopke za preskušanje, vrednotenje skladnosti, označevanje in etiketiranje.

Ta standard ne določa zahtevanega razreda ali ravni določene lastnosti, ki jo mora proizvod doseči, da se dokaže njegova primernost namenu za posamezno vrsto uporabe. Zahtevani razredi in ravni za posamezno uporabo so določeni v uredbah ali standardih, ki niso v nasprotju s tem standardom.

Proizvodi z deklarirano toplotno upornostjo, nižjo od 0,25 m²⋅K/W, ali deklarirano toplotno prevodnostjo, višjo od 0,060 W/(m⋅K) pri 10 °C, v tem standardu niso zajeti.

Ta standard ne zajema izolacijskih proizvodov, izdelanih na kraju samem (zajeti so v standardu EN 16025-1 in -2), za izolacijo gradbene opreme in industrijskih napeljav (zajema jih standard EN 14309), proizvodov za inženirske objekte (zajema jih standard EN 14933) ter proizvodov za nosilne in blokovne sisteme v tleh (zajema jih standard EN 15037-4).

General Information

- Status

- Published

- Publication Date

- 01-Nov-2016

- Technical Committee

- CEN/TC 88 - Thermal insulating materials and products

- Drafting Committee

- CEN/TC 88/WG 2 - Coordinating group

- Current Stage

- 9093 - Decision to confirm - Review Enquiry

- Start Date

- 04-May-2022

- Completion Date

- 11-Feb-2026

Relations

- Effective Date

- 19-Jan-2023

- Effective Date

- 19-Jan-2023

- Effective Date

- 09-Feb-2026

- Effective Date

- 04-Feb-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Overview

EN 13163:2012+A2:2016 specifies requirements for factory-made expanded polystyrene (EPS) products used for the thermal insulation of buildings. It applies to EPS manufactured as boards, rolls or other preformed ware (flat, tapered, tongue-and-groove, shiplap, profiled, etc.), with or without rigid or flexible facings or coatings. The standard defines product characteristics, testing procedures, evaluation of conformity, and marking and labelling requirements. Note: the performance of entire systems incorporating EPS (e.g., cladding systems) is not covered.

Key exclusions:

- Products with declared thermal resistance < 0.25 m²·K/W or declared thermal conductivity at 10 °C > 0.060 W/(m·K)

- In-situ insulation (see EN 16025-1/-2)

- Insulation for building equipment/industrial installations (EN 14309)

- Civil engineering applications (EN 14933)

- Beam and block floor systems (EN 15037-4)

Key topics and technical requirements

SIST EN 13163 covers a comprehensive set of technical properties and test methods, including:

- Thermal performance: declaration of thermal resistance and thermal conductivity (λ) at 10 °C and procedures for declared values.

- Dimensional tolerances: length, width, thickness, squareness and flatness classes.

- Mechanical properties: compressive stress at 10% deformation, bending strength, tensile strength perpendicular to faces, shear behaviour, compressive creep and cyclic loading behaviour.

- Durability and serviceability: dimensional stability, deformation under load/temperature, freeze–thaw resistance, water absorption and water vapour transmission.

- Acoustic and dynamic properties: dynamic stiffness and suitability for sound insulation.

- Safety and environmental: reaction to fire classification (as placed on the market), continuous glowing combustion, and release of dangerous substances.

- Quality & conformity: Product Type Determination (PTD), Factory Production Control (FPC), Assessment and Verification of Constancy of Performance (AVCP), marking and labelling (including Annex ZA relating to the Construction Products Regulation).

Practical applications and users

Who uses SIST EN 13163:

- EPS manufacturers - for product specification, factory production control and CE marking.

- Specifiers, architects and engineers - to select compliant EPS products for roofs, walls, floors, prefabricated panels and composite panels.

- Test laboratories and certification bodies - to perform required tests, PTD and AVCP procedures.

- Regulators and procurement teams - to verify conformity with EU/ national requirements.

Typical applications:

- Thermal insulation of building envelopes (roof, wall, floor)

- Prefabricated thermal insulation systems and composite panels

- Acoustic insulation uses where EPS properties are relevant

Related standards

- EN 16025-1 / EN 16025-2 - in-situ insulation

- EN 14309 - insulation for building equipment and industrial installations

- EN 14933 - civil engineering insulation

- EN 15037-4 - beam and block floor systems

- Annex ZA of EN 13163 - links to the EU Construction Products Regulation (CPR)

Keywords: SIST EN 13163, EPS, expanded polystyrene, thermal insulation, thermal conductivity, thermal resistance, factory-made EPS, product specification, CE marking, conformity, reaction to fire.

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 13163:2012+A2:2016 is a standard published by the European Committee for Standardization (CEN). Its full title is "Thermal insulation products for buildings - Factory made expanded polystyrene (EPS) products - Specification". This standard covers: This European Standard specifies the requirements for factory made expanded polystyrene products, with or without rigid or flexible facings or coatings, which are used for the thermal insulation of buildings. The products are manufactured in the form of boards or rolls or other preformed ware (flat, tapered, tongue and grooves, shiplap, profiled etc.). Products covered by this standard are also used for sound insulation and in prefabricated thermal insulation systems and composite panels; the performance of systems incorporating these products is not covered. This standard describes product characteristics and includes procedures for testing, evaluation of conformity, marking and labelling. This standard does not specify the required class or level of a given property to be achieved by a product to demonstrate fitness for purpose in a particular application. The classes and levels required for a given application are to be found in regulations or non-conflicting standards. Products with a declared thermal resistance lower than 0,25 m²⋅K/W or a declared thermal conductivity at 10 °C greater than 0,060 W/(m⋅K) are not covered by this standard. This standard does not cover in-situ insulation products (covered by EN 16025-1 and -2), products intended to be used for the insulation of building equipment and industrial installations (covered by EN 14309), products intended to be used in civil engineering applications (covered by EN 14933) and products intended to be used in beam and block systems in floors (covered by EN 15037-4).

This European Standard specifies the requirements for factory made expanded polystyrene products, with or without rigid or flexible facings or coatings, which are used for the thermal insulation of buildings. The products are manufactured in the form of boards or rolls or other preformed ware (flat, tapered, tongue and grooves, shiplap, profiled etc.). Products covered by this standard are also used for sound insulation and in prefabricated thermal insulation systems and composite panels; the performance of systems incorporating these products is not covered. This standard describes product characteristics and includes procedures for testing, evaluation of conformity, marking and labelling. This standard does not specify the required class or level of a given property to be achieved by a product to demonstrate fitness for purpose in a particular application. The classes and levels required for a given application are to be found in regulations or non-conflicting standards. Products with a declared thermal resistance lower than 0,25 m²⋅K/W or a declared thermal conductivity at 10 °C greater than 0,060 W/(m⋅K) are not covered by this standard. This standard does not cover in-situ insulation products (covered by EN 16025-1 and -2), products intended to be used for the insulation of building equipment and industrial installations (covered by EN 14309), products intended to be used in civil engineering applications (covered by EN 14933) and products intended to be used in beam and block systems in floors (covered by EN 15037-4).

EN 13163:2012+A2:2016 is classified under the following ICS (International Classification for Standards) categories: 91.100.60 - Thermal and sound insulating materials. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13163:2012+A2:2016 has the following relationships with other standards: It is inter standard links to EN 13163:2012+A1:2015, EN 13163:2012+A1:2015/FprA2, ISO 16269-6:2005, EN ISO 11925-2:2026, EN 13172:2012, EN 12089:2013, EN 13793:2003, EN 12429:1998, EN ISO 16534:2020, EN ISO 11925-2:2020, EN 13820:2003, EN ISO 16535:2019, EN 12090:2013, EN 1607:2013, EN ISO 29466:2022. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13163:2012+A2:2016 is associated with the following European legislation: EU Directives/Regulations: 305/2011; Standardization Mandates: M/103. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13163:2012+A2:2016 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Toplotnoizolacijski proizvodi za stavbe - Proizvodi iz ekspandiranega polistirena (EPS) - SpecifikacijaWärmedämmstoffe für Gebäude - Werkmäßig hergestellte Produkte aus expandiertem Polystyrol (EPS) - SpezifikationProduits isolants thermiques pour le bâtiment - Produits manufacturés en polystyrène expansé (EPS) - SpécificationThermal insulation products for buildings - Factory made expanded polystyrene (EPS) products - Specification91.100.60Thermal and sound insulating materialsICS:Ta slovenski standard je istoveten z:EN 13163:2012+A2:2016SIST EN 13163:2013+A2:2017en,fr,de01-januar-2017SIST EN 13163:2013+A2:2017SLOVENSKI

STANDARDSIST EN 13163:2013+A1:20151DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13163:2012+A2

November 2016 ICS 91.100.60 Supersedes EN 13163:2012+A1:2015

English Version

Thermal insulation products for buildings - Factory made expanded polystyrene (EPS) products - Specification

Produits isolants thermiques pour le bâtiment - Produits manufacturés en polystyrène expansé (EPS) - Spécification

Wärmedämmstoffe für Gebäude - Werkmäßig hergestellte Produkte aus expandiertem Polystyrol (EPS) - Spezifikation This European Standard was approved by CEN on 6 October 2012 and includes Amendment 1 approved by CEN on 15 December 2014 and Amendment 2 approved by CEN on 11 July 2016.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2016 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13163:2012+A2:2016 E SIST EN 13163:2013+A2:2017

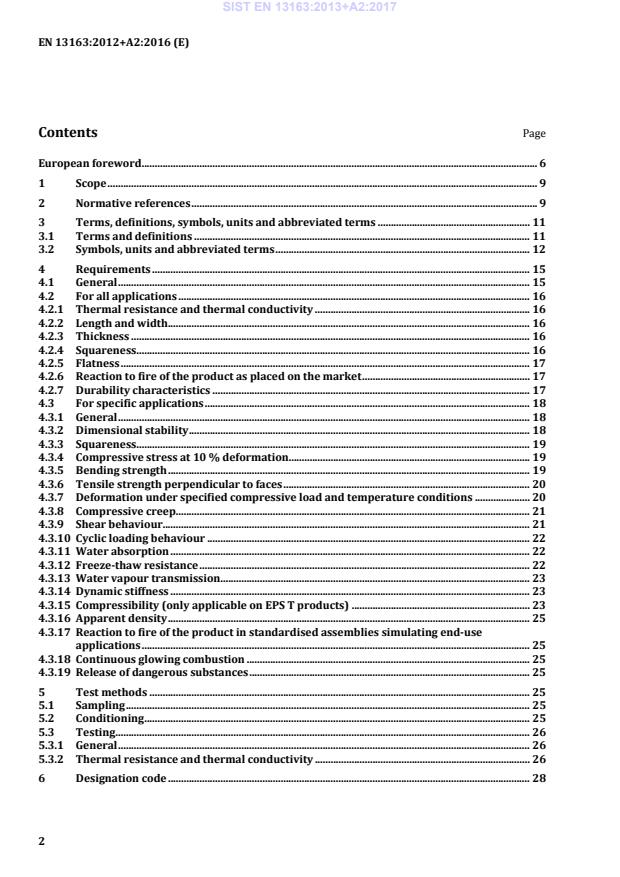

Determination of the declared values of thermal resistance and thermal conductivity . 32 A.1 General . 32 A.2 Input data . 32 A.3 Declared values . 32 A.3.1 General . 32 A.3.2 Case where thermal resistance and thermal conductivity are declared . 32 A.3.3 Case where thermal resistance is declared . 33 Annex B (normative)

!Product type determination" (!PTD") and factory production control (FPC) . 34 B.1 !Product type determination" and factory production control . 34 B.2 Indirect testing for factory production control . 39 B.2.1 General . 39 B.2.2 Compressive stress at 10 % deformation . 39 B.2.3 Thermal conductivity . 40 B.2.4 Thickness effect . 41 B.2.5 Dynamic stiffness . 41 Annex C

(normative)

Product classification . 42 Annex D (normative)

Multi layered EPS products . 44 D.1 General . 44 D.2 Requirements . 44 D.2.1 For all applications. 44 D.2.2 For specific applications . 45 D.3 Test methods . 45 D.4 Evaluation of conformity . 45 Annex E (informative)

Verification of the reaction to fire classification of raw materials . 46 E.1 General . 46 E.2 Material covered by this annex . 46 E.3 Preparation of samples . 46 E.4 !Product type determination" for EPS raw material . 46 E.5 Factory Production Control for EPS raw material . 47 E.5.1 General . 47 E.5.2 Testing frequency . 47 E.6 Certification of conformity for EPS raw material . 47 E.6.1 Bodies involved in the evaluation of conformity procedure . 47 E.6.2 Test specimens . 47 E.6.3 !Product type determination" . 47 E.7 Continuous surveillance of EPS raw material . 48 E.7.1 Production . 48 E.7.2 Factory production control . 48 E.8 Material certificate for EPS raw material. 48 E.9 Requirement for raw material supply . 49 E.9.1 Declaration for the raw material supply . 49 E.9.2 Labelling. 49 Annex F (informative)

Additional properties . 50 SIST EN 13163:2013+A2:2017

!Clauses of this European Standard addressing the provisions of the EU Construction Products Regulation" . 54 Bibliography . 65

Tables Table 1 — Classes of dimensional tolerances . 17 Table 2 — Dimensional stability under specified temperature or specified temperature and humidity conditions . 18 Table 3 — Levels for compressive stress at 10 % deformation. 19 Table 4 — Levels for bending strength . 20 Table 5 — Levels of deformation under specified compressive load and temperature conditions . 21 Table 6 — Levels for dynamic stiffness . 23 Table 7 — Classes for thickness tolerances . 24 Table 8 — Levels for compressibility . 24 Table 9 — Test methods, test specimens and conditions . 27 Table A.1 — Values for k for one sided 90 % tolerance interval with a confidence level of 90 % . 33 Table B.1 — Number of tests for !PTD" and minimum product testing frequencies . 34 Table B.2 — Minimum product testing frequencies for the reaction to fire characteristics . 37 Table C.1 — Classification of EPS products . 42 Table C.2 — Classification EPS products with acoustical properties . 43 Table E.1 — Testing frequency of raw material . 48 Table F.1 — Correlation between bending strength and shear strength . 51 Table F.2 —Tabulated values of water vapour diffusion resistance index and water vapour permeability . 52 Table ZA.1 — Relevant clauses for factory made expanded polystyrene and intended use . 55 Table ZA.2 — Systems of AVCP . 56 Table ZA.3.1 — Assignment of AVCP tasks for factory made expanded polystyrene products under system 1 for reaction to fire and system 3 (see Table ZA.2) . 57 Table ZA.3.2 — Assignment of AVCP tasks for factory made expanded polystyrene products under system 3 (see Table ZA.2) . 58 Table ZA.3.3 — Assignment of AVCP tasks for factory made expanded polystyrene products under combined system 4 for reaction to fire and system 3 (see Table ZA.2) . 59 SIST EN 13163:2013+A2:2017

Figures Figure B.1 — Relationship between compressive stress at 10 % deformation and apparent density for indirect testing . 40 Figure F.1 — Example of a relationship between thermal conductivity (at 50 mm reference thickness and 10 °C mean temperature) apparent density for indirect testing of non infrared absorbing EPS . 53 Figure ZA.1 — #Example CE marking information$ . 64

is the prediction interval 1 b is the width mm b0 is a regression coefficient kPa b1 is a regression coefficient kPa·m³/kg c is the compressibility mm d is the thickness mm

is the water vapour permeability mg/(Pa„h„m) dB is the thickness under a load of 2 kPa after removal of an additional load of 48 kPa mm dL is the thickness under a load of 250 Pa mm dN is the nominal thickness of the product mm ds is the thickness of the test specimen mm SIST EN 13163:2013+A2:2017

is the water vapour diffusion resistance factor 1 n is the number of test results 1 a is the apparent density kg/m³ mean is the mean density kg/m³ R90/90=is the 90 % fractile with a confidence level of 90 % for the thermal resistance m²„K/W RD is the declared thermal resistance m²„K/W Ri is one test result of thermal resistance m²„K/W Rmean is the mean thermal resistance m²„K/W RU is the design value of thermal resistance m²„K/W s' is the dynamic stiffness MN/m³ 10 is the compressive stress at 10 % deformation kPa 10, mean is the mean compressive stress at 10 % deformation kPa 10, pred is the predicted compressive stress at 10 % deformation with a prediction interval of 90 % kPa b is the bending strength kPa SIST EN 13163:2013+A2:2017

is the shear strength kPa WdV is the water absorption by diffusion % Wlp is the long-term water absorption by partial immersion kg/m² Wlt is the long-term water absorption by total immersion % Wv is the additional water absorption % X0 is the initial deformation after 60 s from the beginning of the loading mm X=is the deformation at time t (total thickness reduction) mm Z is the water vapour resistance m²„h„Pa/mg

BS is the symbol of the declared level for bending strength CC (i1/i2/y) c is the symbol of the declared level for compressive creep CP is the symbol of the declared level for compressibility CS(10) is the symbol of the declared level for compressive stress at 10 % deformation DS(N) is the symbol of the declared class for dimensional stability under constant normal laboratory conditions DS(23,90); DS(70,-); DS(70,90) is the symbol of the declared level for dimensional stability under specified temperature and humidity conditions DLT(5) is the symbol of the declared level for dimensional stability under load and temperature conditions FTCD is the symbol of the declared class for freeze-thaw resistance when using samples prepared by water absorption by diffusion FTCI is the symbol of the declared class for freeze-thaw resistance when using samples prepared by long term water absorption by total immersion GM is the symbol of the declared level for shear modulus L is the symbol of the declared class for length tolerances SIST EN 13163:2013+A2:2017

TC is the symbol for the declared class for thickness tolerance of EPS T products$ TR is the symbol of the declared level for tensile strength perpendicular to faces W is the symbol of the declared class for width tolerance WD(V) is the symbol of the declared level for water absorption by diffusion WL(P) is the symbol of the declared level for long term water absorption by partial immersion WL(T) is the symbol of the declared level for long term water absorption by total immersion Z is the symbol of the declared water vapour resistance value Abbreviated terms used in this standard: EPS is Expanded PolyStyrene !PTD is Product Type Determination (previously named ITT for Initial Type Test)" FPC is Factory Production Control RtF is Reaction to Fire !AVCP is Assessment and Verification of Constancy of Performance (previously named attestation of conformity) DoP is Declaration of Performance ThIB is Thermal Insulation for Buildings VCP is Verification of Constancy of Performance (previously named evaluation of conformity)" 4 Requirements 4.1 General Product properties shall be assessed in accordance with Clause 5. To comply with this standard, products shall meet the requirements of 4.2, and the requirements of 4.3 as appropriate. NOTE Information on additional properties is given in Annex F. For multi-layered products, additional requirements are given in Annex D. One test result for a product property is the average of the measured values on the number of test specimens given in Table 9. SIST EN 13163:2013+A2:2017

for products of uniform thickness, the thermal resistance, RD, shall always be declared. The thermal conductivity, D, shall be declared where possible. Where appropriate, for products of non-uniform thickness (i.e. for sloped, tapered or shape moulded non flat products) only the thermal conductivity, D, shall be declared; — the declared thermal resistance, RD, and the declared thermal conductivity, D, shall be given as limit values representing at least 90 % of the production, determined with a confidence level of 90 %; — the statistical value of the thermal conductivity, 90/90, shall be rounded upwards to the nearest 0,001 W/(m„K) and declared as D in levels with steps of 0,001 W/(m„K); — the declared thermal resistance, RD, shall be calculated from the nominal thickness, dN, or dL in case of pr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...