EN 13480-5:2012

(Main)Metallic industrial piping - Part 5: Inspection and testing

Metallic industrial piping - Part 5: Inspection and testing

This part of EN 13480 describes the requirements for inspection and testing to be performed on individual spools or piping systems, including supports, designed in accordance with EN 13480-3 and fabricated and installed in accordance with EN 13480-4.

Metallische industrielle Rohrleitungen - Teil 5: Prufüng

Dieser Teil der EN 13480 beschreibt die Anforderungen an die Prüfungen, die bei Fertigung und Verlegung nach EN 13480-4 an einzelnen, nach EN 13480-3 ausgelegten vorgefertigten Baugruppen (Spools) oder Rohrleitungssystemen einschließlich Halterungen durchzuführen sind.

Tuyauteries industrielles métalliques - Partie 5: Inspection et contrôle

La présente partie de la norme européenne spécifie les exigences relatives à l'inspection et au contrôle tels que définis dans prEN 13480-1:1999, à exécuter sur les éléments de tuyauteries préfabriqués ou sur les réseaux de tuyauteries, supports compris, conçus conformément à prEN 13480-3 et à prEN 13480-6, et fabriqués et installés conformément à prEN 13480-4.

Kovinski industrijski cevovodi - 5. del: Pregled in preskušanje

Ta del tega evropskega standarda določa zahteve za pregled in preskušanje industrijskih cevovodov, kot določa standard EN 13480-1:2012, ki ju je treba izvesti na posameznih navitjih cevnih sistemov, vključno z nosilci, ki so konstruirani v skladu s standardoma EN 13480-3:2012 in EN 13480-6:2012 (če je to potrebno) ter izdelani in vgrajeni v skladu s standardom EN 13480-4:2012.

General Information

- Status

- Withdrawn

- Publication Date

- 26-Jun-2012

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 267 - Industrial piping and pipelines

- Drafting Committee

- CEN/TC 267/WG 8 - Maintenance of EN 13480 series

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 28-Jun-2017

- Completion Date

- 11-Feb-2026

- Directive

- 97/23/EC - Pressure equipment

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 20-Jun-2012

- Effective Date

- 08-Jun-2022

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Refers

EN 13480-6:2012 - Metallic industrial piping - Part 6: Additional requirements for buried piping - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

Institut za varilstvo d.o.o. (Welding Institute)

Slovenia's leading welding institute since 1952. ISO 3834, EN 1090, pressure equipment certification, NDT personnel, welder qualification. Only IIW Au

Sponsored listings

Frequently Asked Questions

EN 13480-5:2012 is a standard published by the European Committee for Standardization (CEN). Its full title is "Metallic industrial piping - Part 5: Inspection and testing". This standard covers: This part of EN 13480 describes the requirements for inspection and testing to be performed on individual spools or piping systems, including supports, designed in accordance with EN 13480-3 and fabricated and installed in accordance with EN 13480-4.

This part of EN 13480 describes the requirements for inspection and testing to be performed on individual spools or piping systems, including supports, designed in accordance with EN 13480-3 and fabricated and installed in accordance with EN 13480-4.

EN 13480-5:2012 is classified under the following ICS (International Classification for Standards) categories: 23.040.01 - Pipeline components and pipelines in general. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 13480-5:2012 has the following relationships with other standards: It is inter standard links to EN 13480-5:2002/A1:2011, EN 13480-5:2002, EN 13480-5:2017, EN ISO 17635:2010, EN 13480-2:2012, EN 14917:2009+A1:2012, EN 13480-6:2012, EN ISO 17640:2010, EN ISO 5817:2007, EN ISO 9712:2012, EN ISO 25457:2008, EN 13480-4:2012, EN 13480-1:2012, EN 13480-3:2012, EN 378-2:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 13480-5:2012 is associated with the following European legislation: EU Directives/Regulations: 2014/68/EU, 97/23/EC; Standardization Mandates: M/071. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 13480-5:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

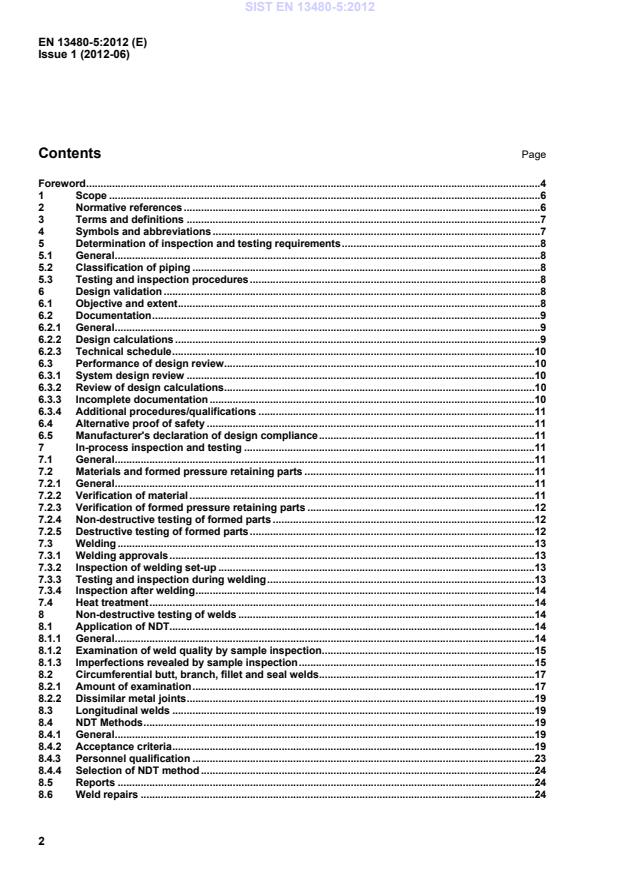

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Kovinski industrijski cevovodi - 5. del: Pregled in preskušanjeMetallische industrielle Rohrleitungen - Teil 5: PrufüngTuyauteries industrielles métalliques - Partie 5: Inspection et contrôleMetallic industrial piping - Part 5: Inspection and testing77.140.75Jeklene cevi in cevni profili za posebne nameneSteel pipes and tubes for specific useICS:Ta slovenski standard je istoveten z:EN 13480-5:2012SIST EN 13480-5:2012en,fr,de01-oktober-2012SIST EN 13480-5:2012SLOVENSKI

STANDARDSIST EN 13480-5:2002/A1:2011SIST EN 13480-5:20021DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13480-5

June 2012 ICS 23.040.01 Supersedes EN 13480-5:2002English Version

Metallic industrial piping - Part 5: Inspection and testing

Tuyauteries industrielles métalliques - Partie 5: Inspection et contrôle

Metallische industrielle Rohrleitungen - Teil 5: Prufüng This European Standard was approved by CEN on 8 May 2012.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2012 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13480-5:2012: ESIST EN 13480-5:2012

Inspection of safety systems . 33 Annex Y (informative)

History of EN 13480-5 . 34 Annex ZA (informative)

Relationship between this European Standard and the Essential Requirements of EU Pressure Equipment Directive (97/23/EC) . 35

For relationship with EU Directive(s), see informative Annex ZA, which is an integral part of this document.

This European Standard EN 13480 for metallic industrial piping consists of eight interdependent and not dissociable Parts which are: Part 1: General; Part 2: Materials; Part 3: Design and calculation; Part 4: Fabrication and installation; Part 5: Inspection and testing; Part 6: Additional requirements for buried piping; CEN/TR 13480-7, Guidance on the use of conformity assessment procedures; Part 8: Additional requirements for aluminium and aluminium alloy piping. Although these Parts may be obtained separately, it should be recognised that the Parts are inter-dependant. As such the manufacture of metallic industrial piping requires the application of all the relevant Parts in order for the requirements of the Standard to be satisfactorily fulfilled. This European Standard will be maintained by a Maintenance MHD working group whose scope of working is limited to corrections and interpretations related to EN 13480.

The contact to submit queries can be found at http://portailgroupe.afnor.fr/public_espacenormalisation/CENTC267WG8/index.htm. A form for submitting questions can be downloaded from the link to the MHD website. After subject experts have agreed an answer, the answer will be communicated to the questioner. Corrected pages will be given specific issue number and issued by CEN according to CEN Rules. Interpretation sheets will be posted on the website of the MHD.

EN ISO 15609-2:2001+A1:2003, Specification and qualification of welding procedures for metallic materials — Welding procedure specification — Part 2: Gas welding (ISO 15609-2:2001) EN ISO 17635:2010, Non-destructive testing of welds — General rules for metallic materials (ISO 17635:2010) EN ISO 17638:2009, Non-destructive testing of welds — Magnetic particle testing (ISO 17638:2003) EN ISO 17640:2010, Non-destructive testing of welds — Ultrasonic testing — Techniques, testing levels, and assessment (ISO 17640:2010) EN ISO 23277:2009, Non-destructive testing of welds — Penetrant testing of welds — Acceptance levels (ISO 23277:2006) EN ISO 23278:2009, Non-destructive testing of welds — Magnetic particle testing of welds — Acceptance levels (ISO 23278:2006) EN ISO 23279:2010, Non-destructive testing of welds — Ultrasonic testing — Characterization of indications in welds (ISO 23279:2010) CEN ISO/TR 15608:2005, Welding — Guidelines for a metallic materials grouping system (ISO/TR 15608:2005) 3 Terms and definitions For the purposes of this Part of this European Standard, the terms and definitions given in EN 13480-1:2012 shall apply. 4 Symbols and abbreviations For the purposes of this Part of this European Standard, the symbols given in EN 13480-1:2012 apply together with the following abbreviations: LT

Leak test; NDT Non-destructive testing; MT

Magnetic particle testing; PT

Penetrant testing; RT

Radiographic testing; UT

Ultrasonic testing; VT

Visual examination; PWHT Post-weld heat treatment. SIST EN 13480-5:2012

The design validation includes the pressure walls to the first joint with other pressurised components. It also includes the interaction with components directly connected to the piping, but does not include validation of the components themselves. The design validation shall be performed to verify that the piping meets the requirements of this European Standard with regard to materials, design details and dimensions, and that the requirements of procedures and personnel can be met during fabrication. Where the design of parts has already been validated in accordance with this European Standard, and where an appropriate certificate or assessment report is available, a further design validation shall not be required.

6.2.1 General Documentation shall be provided to demonstrate compliance with this European Standard and shall include construction drawings, parts lists, design calculations and the technical schedule for fabrication/installation. 6.2.2 Design calculations 6.2.2.1 Where calculations are performed by hand or with the aid of a computer, the following minimum data shall be provided: explanation of notations; calculation input data, including material details; reference number of the standard including the edition and reference number of the formula; full traceability of the calculations performed; results of intermediate formulae; calculated minimum thickness or the calculated stress compared with the design stress; corrosion, wastage and other allowances where applicable; thickness tolerances; the selected thickness. 6.2.2.2 Where stress analysis is carried out by numerical methods, e.g. finite element method, boundary element method or other design methods, it shall be documented. Documentation shall include at least the following data: explanation of notations; details of the computer program; assumptions for calculation; calculation input data; graphs for the geometric model, including boundary and compatibility conditions; stresses, displacements and strains, where necessary; the stresses in the most critical areas; calculation of stress intensities compared with the design stress.

of NDT personnel; Procedures for finishing, e.g. cleaning, painting, insulation etc. 6.4 Alternative proof of safety If the design proposed by the manufacturer has not been prepared by a method acceptable under the requirements of EN 13480-3:2012, then the manufacturer shall supply all the necessary information in support of the alternative design approach. This may consist of mathematical analysis, proof test data, operating experience or any other data the manufacturer considers relevant to support this method of design. The documents submitted shall be reviewed to ensure that the design of the piping is as safe as that provided by this European Standard and include the principles given in 6.3. 6.5 Manufacturer's declaration of design compliance After validation of the design has shown that the design requirements of this European Standard have been fulfilled, the piping manufacturer shall prepare a declaration that the design is in compliance with the requirements of this European Standard.

NOTE A specimen of the manufacturer’s declaration of design compliance is given in CEN/TR 13480-7:2002. A list of the relevant drawings shall be attached to the declaration. 7 In-process inspection and testing 7.1 General Examinations and tests specified in EN 13480-5:2012 shall be carried out by personnel trained for the method used. European Standards or written procedures (where necessary) detailing the method and acceptance criteria shall be available. 7.2 Materials and formed pressure retaining parts 7.2.1 General The testing and inspection specified below shall be restricted to parts formed during the fabrication process, especially induction bending. Formed bought out standardized parts and components shall not be a part of this requirement. 7.2.2 Verification of material A verification shall be performed that materials are in accordance with the specified material standard or purchase order.

7.2.4 Non-destructive testing of formed parts All formed parts shall be subject to non-destructive testing.

The examination shall include, if appropriate: wall thickness measurements; dimensional checks (ovality, angle of bend etc.); hardness tests; ultrasonic examination for volumetric (internal) imperfections in longitudinal and transversal direction; examination for surface or near surface imperfections (magnetic particle or penetrant examination); replicas of the surface structure in the tension zone (in case life monitoring is required for creep range applications); on each component or batch of identical components (dependent on the material and piping category). Material, heat treatment conditions, heat treatment lot, degree of deformation shall be considered in the definition of the batch. 7.2.5 Destructive testing of formed parts Testing shall be performed to verify the heat treatment of the formed parts, and shall include: tensile test; hot tensile test (where items are being used in the creep range); notch impact test; micrographs (e.g. 9 % or 12 % Cr steels); other tests specified in EN 13480-2:2012 or in a European Standard for base material. One set of test per cast, wall thickness range and heat treatment lot shall be performed for piping of piping category II and III. The tests shall be performed on test pieces from the end of the component itself, or from test pieces placed together with the components in the heat treatment furnaces.

EN ISO 15609-2:2001+A1:2003, established for all welding activities including tack welds and temporary attachment welds; Approval of all WPS to EN 13480-4:2012; Appropriate and current approval of all welders in accordance with EN 287-1:2004+A2:2006 and all welding operators in accordance with EN 1418:1997. 7.3.2 Inspection of welding set-up Prior to carrying out any welding, each weld preparation shall be visually inspected. The inspection shall verify compliance with the drawing and WPS, by ensuring the following: the correct materials are used; dimensions are within tolerance, including position, alignment, and orientation of branches, nozzles, attachments and anchors, etc.; cleanliness and freedom from imperfections which may give rise to defects in the completed joint; nozzles, branches etc., properly fit the curvature of the pipe; tack welds that are to be incorporated into the final weld are free from cracks or other defects. 7.3.3 Testing and inspection during welding The following testing and inspection shall be carried out, where appropriate, at suitable stages during the welding operation to verify that the specified WPS is being followed for: a) correct preheat; b) correct welding process; c) correct welding consumables; d) correct electrical characteristics; e) correct interpass temperature and cleaning; f) other requirements of the WPS; g) all tack welds and temporary attachments are welded in accordance with an approved WPS. SIST EN 13480-5:2012

d) Where a welded joint is to be subsequently formed or heat treated, the required NDT shall be carried out on the weld in the final condition. If a weld will not be accessible for examination after heat treatment or forming, the parties involved shall agree on a suitable alternative;

e) NDT-method used and acceptance criteria for all NDT shall be in accordance with Table 8.4-1; f) In case of austenitic base or filler material, the method for surface testing shall be PT. 8.1.1.2 Arc strikes and contact points with fused material shall be ground smooth and subjected to surface examination appropriate to the material used. 8.1.1.3 Surface condition and preparation for non-destructive testing

The following criteria shall be met: a) RT: surface dressing is required where ripples or weld surface irregularities will interfere with the interpretation of the radiographs;

Figure 8.1-1 — Flow diagram of additional testing required when imperfections have been revealed SIST EN 13480-5:2012

For piping operating at 100 C or more, at least 10 % of socket welds should be radiographed to confirm that an adequate expansion gap has been achieved. f) For the selection of the appropriate NDT method for volumetric testing, see Table 8.4-4. SIST EN 13480-5:2012

Surface testing Volumetric testing Surface testing Volumetric testing Surface testingSurface testing VT % en b mm MT/PT c%

RT/UT %

Branch diameteren mm MT/PT c %

Branch diameterenb

mm RT/UT %

en

mm MT/PT% en

mm MT/PT % 1.1 1.2 8.1 I 100 n/a n/a 5 All n/a

All n/a All n/a All n/a II n/a n/a 5 III n/a n/a 10 10 > DN 100> 15 10 10 10 1.3, 1.4 2.1, 2.2 4.1, 4.2 8.2, 8.3 9.1, 9.2, 9.3 10.1, 10.2 I 100 30

5 10All e 10 All n/a All e 10 All e 5 > 30 10 10 II 30

510> 30 10 10 III 30

5 25All > DN 100> 15 10 All 25 All 25 > 30

25 d 3.1, 3.2, 3.3

5.1, 5.2, 5.3 5.4, 6.1, 6.2, 6.3, 6.4, 7.1, 7.2, 11 I 100 30

25 All 25 > DN 100> 15 25 All 25 All 10 > 30

25 II 30

25 > 30

25 d III 30 100 100 100 100 100 100 > 30 100

100d a

Material group, see CEN ISO/TR 15608:2005. b For the selection of the appropriate NDT-method for volumetric testing, see Table 8.4-4. c For ferritic materials preference shall be given to MT. d Additional testing for transverse defects from weld surface (see 8.4.4.2). e

Only if PWHT has been carried out. SIST EN 13480-5:2012

RT or UT b

% z 0,7 100 0 0

0,7 < z 0,85 100 10 10

0,85 < z 1,0

100 100 100 a for ferritic materials preference shall be given to MT. b see Table 8.4-3

8.4 NDT Methods 8.4.1 General The NDT methods specified in the following clauses shall be performed in accordance with written NDT procedures, and, where appropriate, with NDT instructions.

8.4.2 Acceptance criteria The acceptance criteria for the NDT techniques shall follow the European Standards in Table 8.4-1. Requirements for acceptance criteria for surface imperfections are given in Table 8.4-2 and additional requirements for acceptance criteria for internal imperfections detected by RT are given in Table 8.4-3.

Acceptance level 2 and additional requirements of Table 8.4-3 Ultrasonic Testing (UT) EN ISO 17640:2010, class B b EN ISO 11666:2010, c Acceptance level 2 d Penetrant Testing (PT) EN 571-1:1997 EN ISO 23277:2009,

Acceptance level 1 Magnetic Particle Testing (MT) EN ISO 17638:2009 EN ISO 23278:2009, Acceptance level 1 a

However, the maximum area for single exposure shall correspond to the requirements of EN 1435:1997+A2:2003, class A. b

Class A for material group 1.1, 1.2, 8.1 when category is I or II. c

For the characterization of indications EN ISO 23279:2010 may be used. d

Acceptance level 3 for material group 1.1, 1.2, 8.1 when category is I or II.

6520-1:2007,

Reference number Designation EN ISO 5817:2007 Reference number Category in accordance with

EN 13480-1:2012, Table 5.1-1 Additional requirements a IIIIII EN ISO 5817:2007, quality level1001-1064 Cracks (all) 1 Not permitted

2011-2017 2021-2024 Gas cavity (all) Shrinkage cavity (all) 3 to 5 B1) B C 1) When occurring at the surface,

- diameter = 2 mm and

- depth = 1 mm

with additional conditions that:

- it does not occur at a stop or restart

- it is not systematic on the same weld for

pressure welds or load carrying attachment

welds. 3011-3014 3021-3024 303 3041-3043 Slag inclusions (all) Flux inclusions (all) Oxide inclusions Metallic inclusions (all) 6 6 6 6,7 Not permitted shall be removed e. g. by grinding 4011-4013 Lack of fusion (all) 8 Not permitted

402 Lack of penetration 9 Not permitted If a full penetration weld is required 5011-5012 Undercut 11 B2) C C 2) t 16 mm :

h 0,5 mm for long

imperfections 6 mm t < 16 mm: h 0,3 mm for long

imperfections;

h 0,5 mm for

short imperfections t < 6 mm:

h < 0,3 mm for

short imperfections 5013 Shrinkage grove 21 B C C

502 Excessive weld metal 12 B C C Smooth transition is required.

Weld toe angle 120 503 Excessive convexity 13 C C C Same as for 502 504 Excess penetration 16 B C C

5041 Local excess penetration 17 B B C

506 Overlap 22 Not permitted

507 Linear misalignment 18

See EN 13480-4:2012 508 Angular misalignment -

See EN 13480-4:2012 509 Sagging 19 B B B

511 Incompletely filled groove 19 B B B

512 Excessive asymmetry of fillet welds 20 D D D

512 Excessive asymmetry of fillet welds 20 D D D

515 Root concavity 21 B B B Long imperfection: not permitted

(continued) SIST EN 13480-5:2012

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...