EN 12418:2000+A1:2009

(Main)Masonry and stone cutting-off machines for job site - Safety

Masonry and stone cutting-off machines for job site - Safety

This European Standard applies to transportable masonry and stone cutting-off machines stationary during work, principally used on job site building construction for cutting-off stones, other mineral construction materials and composite materials having at least one supporting surface. The power for the tool rotation is supplied by electrical or internal combustion prime motor. This European Standard deals with all significant hazards pertinent to masonry and stone cutting-off machines for job site (see clause 4), when they are used as intended and under the conditions foreseen by the manufacturer. This European Standard specifies the appropriate technical measures to eliminate or reduce risks arising from the significant hazards.

These machines are designed for use with rotating diamond cutting-off wheels with a continuous rim and/or segmented rim.

This European Standard does not apply to:

- metal cutting-off machines;

- wood and timber sawing machines;

- machines with a feed or descent mechanism other than manual, or with a pedal;

- mobile machines on a trolley travelling on the ground;

- hand-held portable grinding and cutting-off machines;

- hand-held portable grinding and cutting-off machines mounted on a support to be used in a fixed position.

This European Standard does not cover the operation of transportable masonry and stone cutting-off machines in potential explosive atmospheres.

This European Standard covers electrical hazards making reference to relevant European Standards (see 5.2).

Those hazards that are relevant for all mechanical, electrical, hydraulic, pneumatic and other equipment of machinery and that are dealt with in standards for common use are not covered by this European Standard. Reference to pertinent standards of this kind is made where such standards are applicable and so far necessary.

In this standard, the masonry and stone cutting-off machines for job site construction are called: "cutting-off machines" or "machines", and

Steintrennmaschinen für den Baustelleneinsatz - Sicherheit

Diese Europäische Norm gilt für transportable Steintrennmaschinen, die während des Einsatzes stationär sind, und die hauptsächlich auf Baustellen zum Trennen von Steinen und anderen mineralischen Bau-materialien sowie Verbundwerkstoffen verwendet werden, die mindestens eine Auflagefläche besitzen. Die Antriebsenergie für die Drehbewegung des Werkzeugs wird durch elektrischen oder Verbrennungsmotor zur Verfügung gestellt. Diese Europäische Norm behandelt alle signifikanten Gefährdungen, die auf Steintrenn-maschinen für den Baustelleneinsatz zutreffen, wenn sie bestimmungsgemäß und entsprechend den Empfehlungen des Herstellers verwendet werden (siehe Abschnitt 4). Diese Norm spezifiziert die entsprechenden Maßnahmen zur Beseitigung oder Verminderung der Risiken, die von den signifikanten Gefährdungen ausgehen.

Diese Maschinen sind zum Einsatz mit rotierenden segmentierten Diamanttrennscheiben und Diamant-trennscheiben mit geschlossenem Rand vorgesehen.

Diese Europäische Norm gilt nicht für:

- Metalltrennmaschinen;

- Holztrennmaschinen;

- Maschinen, deren Vorschub oder Absenkmechanismus anders als manuell oder über ein Pedal gesteuert wird;

- mobile Maschinen auf einem Fahrwerk, das auf dem Boden fährt;

- handgeführte, tragbare Schleif und Trennmaschinen;

- auf einer Tragvorrichtung montierte handgeführte, tragbare Schleif und Trennmaschinen zur Anwendung in einer festen Position.

Diese Europäische Norm behandelt nicht den Einsatz von transportablen Steintrennmaschinen in explosions-gefährdeten Bereichen.

Diese Europäische Norm behandelt elektrische Gefährdungen durch Verweis auf relevante Europäische Normen (siehe 5.2).

Die Gefährdungen, die für alle mechanischen, elektrischen, hydraulischen, pneumatischen Einrichtungen von Maschinen relevant sind und in entsprechenden allgemeinen Normen behandelt werden, umfasst diese Europäische Norm nicht. Soweit erforderlich, wird auf anwendbare Normen dieser Art verwiesen.

(...)

Scies de chantier à tronçonner les matériaux - Sécurité

Rezalniki kamenja na gradbiščih - Varnost

General Information

- Status

- Withdrawn

- Publication Date

- 24-Mar-2009

- Withdrawal Date

- 10-Feb-2026

- Technical Committee

- CEN/TC 151 - Construction equipment and building material machines - Safety

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 15-Dec-2021

- Completion Date

- 11-Feb-2026

- Directive

- Harmonized Standard2006/42/EC - Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on machinery, and amending Directive 95/16/EC (recast)OJ Ref: C 214, C 214, C 214, C 214, C 214, C 214, C 214, C OJ Date: 08-Sep-2009

Not Harmonized98/37/EC - Machinery

Relations

- Effective Date

- 18-Jan-2023

- Effective Date

- 28-Jan-2009

- Effective Date

- 22-Dec-2021

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Refers

EN 12096:1997 - Mechanical vibration - Declaration and verification of vibration emission values - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 12418:2000+A1:2009 is a standard published by the European Committee for Standardization (CEN). Its full title is "Masonry and stone cutting-off machines for job site - Safety". This standard covers: This European Standard applies to transportable masonry and stone cutting-off machines stationary during work, principally used on job site building construction for cutting-off stones, other mineral construction materials and composite materials having at least one supporting surface. The power for the tool rotation is supplied by electrical or internal combustion prime motor. This European Standard deals with all significant hazards pertinent to masonry and stone cutting-off machines for job site (see clause 4), when they are used as intended and under the conditions foreseen by the manufacturer. This European Standard specifies the appropriate technical measures to eliminate or reduce risks arising from the significant hazards. These machines are designed for use with rotating diamond cutting-off wheels with a continuous rim and/or segmented rim. This European Standard does not apply to: - metal cutting-off machines; - wood and timber sawing machines; - machines with a feed or descent mechanism other than manual, or with a pedal; - mobile machines on a trolley travelling on the ground; - hand-held portable grinding and cutting-off machines; - hand-held portable grinding and cutting-off machines mounted on a support to be used in a fixed position. This European Standard does not cover the operation of transportable masonry and stone cutting-off machines in potential explosive atmospheres. This European Standard covers electrical hazards making reference to relevant European Standards (see 5.2). Those hazards that are relevant for all mechanical, electrical, hydraulic, pneumatic and other equipment of machinery and that are dealt with in standards for common use are not covered by this European Standard. Reference to pertinent standards of this kind is made where such standards are applicable and so far necessary. In this standard, the masonry and stone cutting-off machines for job site construction are called: "cutting-off machines" or "machines", and

This European Standard applies to transportable masonry and stone cutting-off machines stationary during work, principally used on job site building construction for cutting-off stones, other mineral construction materials and composite materials having at least one supporting surface. The power for the tool rotation is supplied by electrical or internal combustion prime motor. This European Standard deals with all significant hazards pertinent to masonry and stone cutting-off machines for job site (see clause 4), when they are used as intended and under the conditions foreseen by the manufacturer. This European Standard specifies the appropriate technical measures to eliminate or reduce risks arising from the significant hazards. These machines are designed for use with rotating diamond cutting-off wheels with a continuous rim and/or segmented rim. This European Standard does not apply to: - metal cutting-off machines; - wood and timber sawing machines; - machines with a feed or descent mechanism other than manual, or with a pedal; - mobile machines on a trolley travelling on the ground; - hand-held portable grinding and cutting-off machines; - hand-held portable grinding and cutting-off machines mounted on a support to be used in a fixed position. This European Standard does not cover the operation of transportable masonry and stone cutting-off machines in potential explosive atmospheres. This European Standard covers electrical hazards making reference to relevant European Standards (see 5.2). Those hazards that are relevant for all mechanical, electrical, hydraulic, pneumatic and other equipment of machinery and that are dealt with in standards for common use are not covered by this European Standard. Reference to pertinent standards of this kind is made where such standards are applicable and so far necessary. In this standard, the masonry and stone cutting-off machines for job site construction are called: "cutting-off machines" or "machines", and

EN 12418:2000+A1:2009 is classified under the following ICS (International Classification for Standards) categories: 91.220 - Construction equipment. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 12418:2000+A1:2009 has the following relationships with other standards: It is inter standard links to EN 12418:2000, EN 12418:2000/prA1, EN 12418:2021, EN 60335-2-41:2003, EN 60335-1:2002, EN 61029-1:2000, EN 12096:1997, EN ISO 13732-1:2008, EN ISO 12100-2:2003, EN 13218:2002, EN ISO 20643:2008, EN ISO 12100-1:2003, EN ISO 11201:1995, EN ISO 14120:2015, EN ISO 12241:2008. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 12418:2000+A1:2009 is associated with the following European legislation: EU Directives/Regulations: 2006/42/EC, 98/37/EC; Standardization Mandates: M/079, M/396. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

EN 12418:2000+A1:2009 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Steintrennmaschinen für den Baustelleneinsatz - SicherheitScies de chantier à tronçonner les matériaux - SécuritéMasonry and stone cutting-off machines for job site - Safety91.220Gradbena opremaConstruction equipmentICS:Ta slovenski standard je istoveten z:EN 12418:2000+A1:2009SIST EN 12418:2000+A1:2009en01-maj-2009SIST EN 12418:2000+A1:2009SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 12418:2000+A1

March 2009 ICS 91.220 Supersedes EN 12418:2000English Version

Masonry and stone cutting-off machines for job site - Safety

Scies de chantier à tronçonner les matériaux - Sécurité

Steintrennmaschinen für den Baustelleneinsatz - SicherheitThis European Standard was approved by CEN on 3 May 2000 and includes Amendment 1 approved by CEN on 15 February 2009.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2009 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 12418:2000+A1:2009: ESIST EN 12418:2000+A1:2009

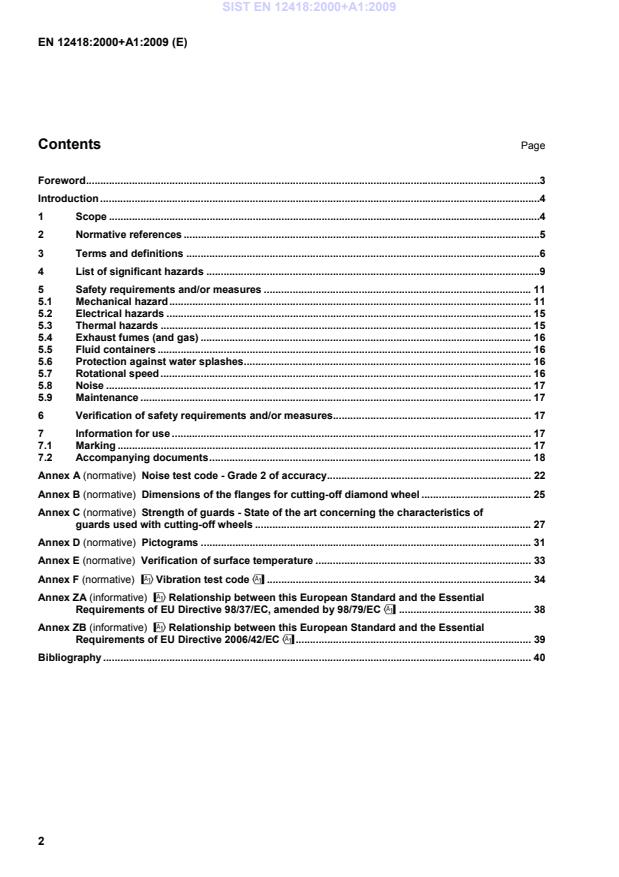

Noise test code - Grade 2 of accuracy. 22Annex B (normative)

Dimensions of the flanges for cutting-off diamond wheel . 25Annex C (normative)

Strength of guards - State of the art concerning the characteristics of guards used with cutting-off wheels . 27Annex D (normative)

Pictograms . 31Annex E (normative)

Verification of surface temperature . 33Annex F (normative)

!Vibration test code" . 34Annex ZA (informative)

!Relationship between this European Standard and the Essential Requirements of EU Directive 98/37/EC, amended by 98/79/EC" . 38Annex ZB (informative)

!Relationship between this European Standard and the Essential Requirements of EU Directive 2006/42/EC" . 39Bibliography . 40 SIST EN 12418:2000+A1:2009

metal cutting-off machines; wood and timber sawing machines; machines with a feed or descent mechanism other than manual, or with a pedal; mobile machines on a trolley travelling on the ground; hand-held portable grinding and cutting-off machines; hand-held portable grinding and cutting-off machines mounted on a support to be used in a fixed position. This European Standard does not cover the operation of transportable masonry and stone cutting-off machines in potential explosive atmospheres. This European Standard covers electrical hazards making reference to relevant European Standards (see 5.2). Those hazards that are relevant for all mechanical, electrical, hydraulic, pneumatic and other equipment of machinery and that are dealt with in standards for common use are not covered by this European Standard. Reference to pertinent standards of this kind is made where such standards are applicable and so far necessary. In this standard, the masonry and stone cutting-off machines for job site construction are called: "cutting-off machines" or "machines", and cutting-off wheels are also called: "tools“. This standard applies primarily to the machines which are manufactured after the date of approval of the standard by CEN. SIST EN 12418:2000+A1:2009

Figure 1 — Sketches of the different types of cutting-off machines SIST EN 12418:2000+A1:2009

Cutting-off machine with internal combustion engine Cutting-off machine with electric motor 1 frame (incorporating the water tank) 2 legs (demountable or otherwise) 3 cutting head 4 cutting-off wheel

5 electric motor (or engine) 6 handle for moving the cutting head 7 foot pedal for lowering the cutting head (if any) 8 cutting-off wheel guard 9 moveable table including material stop for supporting materials to be cut 10 water splash deflector 11 table guiding tracks 12 water supply system 13 front stop of the table 14 cutting depth stop (for types 1 and 2 machines) Figure 2 — Examples of cutting-off machines SIST EN 12418:2000+A1:2009

HazardsRelevant subclauses

4.1 Crushing hazard 5.1.1, 5.1.2, 5.1.3, 5.1.4, 5.1.5, 5.1.6, 5.1.7, 5.1.8, 5.1.9, 5.1.10, 7.2.1

4.2 Shearing hazard 5.1.1, 5.1.2, 5.1.3, 5.1.5, 5.1.6, 5.1.8, 5.1.9, 5.1.10

4.3 Cutting and severing hazard 5.1.1, 5.1.2, 5.1.3, 5.1.6, 5.1.8, 5.1.9, 5.1.10

4.4 Entanglement hazard 5.1.1, 5.1.2, 5.1.3, 5.1.6, 5.1.8, 5.1.9, 5.1.10

4.5 Drawing-in or trapping hazard 5.1.1, 5.1.2, 5.1.3, 5.1.6, 5.1.9, 5.1.10

(continued) SIST EN 12418:2000+A1:2009

Hazards Relevant subclauses 4.6 Impact hazard 5.1.1, 5.1.2, 5.1.3, 5.1.5, 5.1.6, 5.1.7, 5.1.8, 5.1.9, 5.1.10, 7.2.1

4.7 Fluid ejection hazard 5.6

4.8 Hazards caused by ejection of parts (material/work pieces) 5.1.1, 5.1.2, 5.1.3, 5.1.6, 5.1.7, 5.1.8, 5.1.9, 5.1.10, 5.7, 7.2.1

4.9 Hazards caused by loss of stability (machinery and machine parts) 5.1.4, 5.1.5, 5.1.9, 7.2.1

4.10 Slip, trip and fall hazard in relationship with machinery 5.5, 7.2.1

4.11 Hazards caused by electrical contact direct or indirect 5.2, 7.2.1

4.12 Hazards resulting in burns and/or scalds, by possible contact of persons, by flames or explosions and also by radiation of heat sources 5.3, 7.2.1

4.13 Health-damaging effects by hot or cold work environment and by noise 5.8, 7.2.1

4.14 Hazards resulting from contact with or inhalation of harmful fluids, gases, mists, fumes and dusts 5.4, 5.5, 5.9, 7.2.1

4.15 Hazards caused by fire and/or explosion 7.2.1

4.16 Unhealthy postures or excessive efforts 5.1.5, 5.1.7, 5.1.8, 7.2.1.3

4.17 Hazards caused by inadequate local lighting 7.2.1

4.18 Hazards caused by human errors 5.1.2, 5.2.1, 7.1, 7.2.1

4.19 Hazard combinations 5.1.1, 7.1, 7.2.1

4.20 Hazard caused by failure of energy supply (of energy and/or control circuits) 5.1.10, 5.2, 7.2.1

4.21 Hazards caused by failure/disorder of control system 5.1.9, 5.1.10, 5.2, 7.2.1

4.22 Hazards caused by errors of fitting 7.1, 7.2.1

4.23 Hazards caused by temporarily missing and/or incor-rectly positioned safety related measures/means as:

4.23.1 Guards of all kinds 7.2.1

4.23.2 Safety related protection devices of all kinds 7.2.1

4.23.3 Starting and stopping devices 7.2.1

4.23.4 Information on safety signs and tags 7.1.3

4.23.5 Information and warnings of all kinds 7.1, 7.2.1

4.23.6 Essential equipment and accessories for safe ad-justment and/or maintenance 5.1.8.2, 7.2.1 SIST EN 12418:2000+A1:2009

5 Safety requirements and/or measures Machinery shall comply with the safety requirements and/or measures of this clause and in addition with !EN ISO 12100-1:2003" and !EN ISO 12100-2:2003" for hazards which are relevant but not significant and which are not dealt with in this standard. For the application of !EN ISO 13857", EN 953, and EN 60204-1 the manufacturer shall carry out an adequate risk assessment for the requirements thereof where choice is necessary. NOTE This specific risk assessment should be part of the general risk assessment relating to the hazards not covered by this standard. Covering each significant hazard is sufficient for covering combinations of hazards. 5.1 Mechanical hazard 5.1.1 General As components and parts have to be manually handled, all the accessible parts, with the exception of the cutting-off wheel, shall be free of sharp parts and burrs which could generate hazards when setting, using, handling, and maintaining the machine. Burrs resulting from, for example, manufacturing, casting or welding shall be eliminated and sharp edges shall be smoothed. 5.1.2 Protection against moving parts 5.1.2.1 Transmission parts Rotating transmission parts, for example, couplings and belt drives for drive shafts and mechanical water pumps shall be provided with fixed guards to prevent contact. These guards shall comply with !EN 953". Fixed guards shall be held in position either by welding or by mounting them in such a way that they can be opened or removed only with the aid of tools or keys. !These guards shall comply with EN 953 and 5.3.2.2 of EN ISO 12100-2:2003." !deleted text" 5.1.2.2 Connection between the cutting head and the frame For type 1 machines (see 3.2) with a swinging moveable cutting head, the cutting head, as far as it is not lockable, shall return automatically to rest position when released. In this case the area between the cutting head and the frame of the machine shall be protected to avoid any shearing hazard. This can be done either by design (taking into account the minimum distances given in EN 349:1993) or by enclosing the shearing area with guards. 5.1.2.3 Moving parts involved in the working process (protection against contact with the cutting-off wheel and its fixing devices) The safety measures to be taken shall be adapted according to the type of machines (see 3.2). SIST EN 12418:2000+A1:2009

Figure 3a b) The rear edge of the cutting-off wheel guard shall be located, at least, as low as the horizontal plane passing by the lowest point of the flange. The foregoing condition shall be fulfilled when the cutting head is in the highest position. The rear angle of the guard α2 shall not be greater than the maximum upward angle α1 measured when the cutting head is in the highest position (see figure 3b).

Figure 3b Front of the machine Link joint of the cutting head Front of the machine Tangent at the lowest edge of the wheel flange SIST EN 12418:2000+A1:2009

5.1.2.3.2 Type 4 machines These machines are intended to be used only with continuous rim diamond cutting-off wheels. For this type of machine, where the cutting-off wheel fixing device is located below the table, the design shall be such that this fixing device is out of reach of the operator during the working procedure. The working area shall be protected by means of a water splash guard which can be fixed to a support fixed to the frame. This guard shall minimize water splash against the operator. 5.1.3 Minimum strength of the guards The guards of the cutting-off wheel (for type 1, 2 and 3 machines) shall be so designed to resist strains resulting from an accidental projection of a fragment of the cutting-off wheel. Brittleness of the guard material shall be taken into account. Permanent plastic deformation of the guard resulting from stresses shall be allowed. Guards shall remain attached to the cutting head in case of the projection of segments of the cutting-off wheel.

Annex C indicates the characteristics of guards which correctly fulfil their function. 5.1.4 Frame and legs 5.1.4.1 Stability of the machine The machine shall be stable in order to avoid overturning when operating or during handling the material to be cut on the table. This may be verified as follows: The machine without water (when the tank is located inside the frame of the machine), the cutting head and the table being secured, shall be inclined at an angle of 10° in all positions with respect to the vertical. It shall not overturn regardless of the position of the movable parts. 5.1.4.2 Connection of legs to frame Connection between legs and frame shall be so designed that any loss of the legs in particular when lifting the machine, is prevented. Disconnection shall only be possible by an intentional manual action. 5.1.5 Transport and handling The movable parts of the machine shall be either lockable or removable to avoid any risk of shearing or crushing e.g. during handling and carrying. NOTE For technical requirements relating to transport and lifting of the machine see !5.5.5" of

!EN ISO 12100-2:2003". SIST EN 12418:2000+A1:2009

EN 60529:1991) !therefore an inbuilt PRCD is not required". 5.2.2 Water pump Where water is supplied by an electrical pump for flushing the cutting-tool, the pump shall fulfil the relevant requirements of !EN 60335-1:2002" and !EN 60335-2-41:2003". 5.3 Thermal hazards 5.3.1 Handles and other surfaces which require continuous contact shall have a surface temperature not exceeding 43°C. 5.3.2 Controls and other parts of the machine which are contacted occasionally shall meet the limits as given in !EN ISO 13732-1:2008" according to the chosen material for a contact period up to 5 s, lowest curve. SIST EN 12418:2000+A1:2009

!EN ISO 13732-1:2008" for a contact period below 1 s. These areas shall be either located at a distance greater than 120 mm from the gripping areas, or they shall be protected by shields.

These shields shall be designed to reduce the heat transfer from the surface to the body of the operator. This may be achieved by a structured surface, ribs or special coating. 5.3.4 Test method The test method to verify the surface temperature of the machine is prescribed in annex E. The machine parts whose temperatures exceed the permissible limits of !EN ISO 13732-1:2008" for a contact time not exceeding 1 s and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...