EN 15684:2012

(Main)Building hardware - Mechatronic cylinders - Requirements and test methods

Building hardware - Mechatronic cylinders - Requirements and test methods

This European Standard specifies requirements for performance and testing of Mechatronic Cylinders and their keys and/or electronic keys.

It applies to cylinders for such locks designed to be normally used in buildings. It also applies to cylinders for use with other hardware products such as exit devices, door operators, etc. or monitoring facilities and alarm systems.

It establishes categories of use based on performance tests and grades of security based on design requirements and on performance tests that simulate attack.

This European standard includes assessment of additional features when they are included in the cylinder design.

This European standard does not cover any other element of a security system, other than those directly involved in the control of a cylinder.

The suitability of cylinders for use on fire or smoke-door assemblies is determined by fire performance tests conducted in addition to the performance testing specified by this European standard; see Annex A.

Schlösser und Baubeschläge - Mechatronische Schließzylinder - Anforderungen und Prüfverfahren

Diese Europäische Norm legt Anforderungen an die Leistung und Prüfverfahren für mechatronische Zylinder und deren Schlüssel und/oder elektronischen Schlüssel fest. Sie gilt für Schließzylinder von Schlössern, die dafür ausgelegt sind, üblicherweise in Gebäuden verwendet zu werden. Sie gilt ebenfalls für Schließzylinder, die mit anderen Produkten wie beispielsweise Fluchttür-verschlüssen, Türautomatikanlagen usw. oder Überwachungseinrichtungen und Alarmanlagen verwendet werden. Sie legt auf Leistungsprüfungen basierende Gebrauchsklassen sowie Sicherheitsklassen fest, die auf Konstruktionsanforderungen und Leistungsprüfungen, die Angriffe simulieren, beruhen. Die vorliegende Europäische Norm enthält eine Beurteilung zusätzlicher Eigenschaften, wenn sie Bestandteil der Schließzylinderkonstruktion sind. Die vorliegende Europäische Norm behandelt keine anderen Elemente eines Sicherheitssystems, als die-jenigen, die unmittelbar mit der Bedienung eines Schließzylinders verbunden sind. Die Eignung von Schließzylindern für die Verwendung an Feuerschutz- oder Rauchschutztüren wird durch Prüfungen der Feuerwiderstandsfähigkeit bestimmt, die zusätzlich zu den in der vorliegenden Europäischen Norm geforderten Prüfungen der Funktionsfähigkeit durchzuführen sind, siehe Anhang A.

Quincaillerie pour le bâtiment - Cylindres mécatroniques - Exigences et méthodes d'essai

La présente Norme européenne spécifie les exigences de performance et d'essai des cylindres

mécatroniques et de leurs clés et/ou de leurs clés électroniques.

Elle s'applique aux cylindres de serrures conçues pour être normalement utilisées dans les bâtiments. Elle

s'applique également aux cylindres compatibles avec d'autres produits de quincaillerie tels que dispositifs de

sortie de secours, actionneurs de porte, etc. ou avec des installations de surveillance et des systèmes

d'alarme.

Elle définit des catégories d'utilisation basées sur des essais de performance et des niveaux de sécurité

basés sur des exigences de conception et sur des essais de performance simulant une effraction.

La présente Norme européenne contient une évaluation de caractéristiques supplémentaires lorsqu’elles sont

intégrées dans la conception du cylindre.

La présente Norme européenne ne couvre aucun élément d’un système de sécurité autre que ceux

directement mis en jeu dans la manoeuvre d’un cylindre.

L'aptitude des cylindres à être utilisés sur des blocs-portes coupe-feu ou pare-fumées est déterminée par des

essais de performance au feu réalisés en complément des essais de performance requis par la présente

Norme européenne, voir l’Annexe A.

Stavbno okovje - Mehatronski cilindri - Zahteve in preskusni postopki

Ta evropski standard določa zahteve za delovanje in preskušanje mehatronskih cilindrov ter njihovih ključev in/ali elektronskih ključev. Uporablja se za cilindre za ključavnice, ki so namenjene normalni uporabi v stavbah. Uporablja se tudi za cilindre za uporabo z drugim okovjem, kot so izhodne naprave, naprave za odpiranje vrat itd., ali z napravami za spremljanje in alarmnimi sistemi. Določa kategorije uporabe na podlagi preskusov delovanja in varnostnih stopenj na podlagi zahtev glede zasnove in preskusov delovanja, ki simulirajo napad. Ta evropski standard zajema oceno dodatnih lastnosti, kadar so vključene v zasnovo cilindra. Ta evropski standard ne zajema drugih elementov varnostnega sistema, ki niso neposredno vključeni v nadzor cilindra. Ustreznost cilindrov za uporabo pri sestavih požarnih ali dimnih vrat se določi s preskusi delovanja med požarom, ki se izvajajo poleg preskušanja delovanja, opredeljenega v tem evropskem standardu; glej dodatek A.

General Information

- Status

- Withdrawn

- Publication Date

- 30-Oct-2012

- Withdrawal Date

- 08-Feb-2026

- Technical Committee

- CEN/TC 33 - Doors, windows, shutters and building hardware

- Drafting Committee

- CEN/TC 33/WG 4 - Building hardware

- Current Stage

- 9960 - Withdrawal effective - Withdrawal

- Start Date

- 25-Nov-2020

- Completion Date

- 11-Feb-2026

Relations

- Replaced By

EN 15684:2020 - Building hardware - Mechatronic cylinders - Requirements and test methods - Effective Date

- 02-Dec-2020

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Effective Date

- 09-Feb-2026

- Refers

EN 1906:2012 - Building hardware - Lever handles and knob furniture - Requirements and test methods - Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

- Effective Date

- 28-Jan-2026

Get Certified

Connect with accredited certification bodies for this standard

ICC Evaluation Service

Building products evaluation and certification.

QAI Laboratories

Building and construction product testing and certification.

Aboma Certification B.V.

Specialized in construction, metal, and transport sectors.

Sponsored listings

Frequently Asked Questions

EN 15684:2012 is a standard published by the European Committee for Standardization (CEN). Its full title is "Building hardware - Mechatronic cylinders - Requirements and test methods". This standard covers: This European Standard specifies requirements for performance and testing of Mechatronic Cylinders and their keys and/or electronic keys. It applies to cylinders for such locks designed to be normally used in buildings. It also applies to cylinders for use with other hardware products such as exit devices, door operators, etc. or monitoring facilities and alarm systems. It establishes categories of use based on performance tests and grades of security based on design requirements and on performance tests that simulate attack. This European standard includes assessment of additional features when they are included in the cylinder design. This European standard does not cover any other element of a security system, other than those directly involved in the control of a cylinder. The suitability of cylinders for use on fire or smoke-door assemblies is determined by fire performance tests conducted in addition to the performance testing specified by this European standard; see Annex A.

This European Standard specifies requirements for performance and testing of Mechatronic Cylinders and their keys and/or electronic keys. It applies to cylinders for such locks designed to be normally used in buildings. It also applies to cylinders for use with other hardware products such as exit devices, door operators, etc. or monitoring facilities and alarm systems. It establishes categories of use based on performance tests and grades of security based on design requirements and on performance tests that simulate attack. This European standard includes assessment of additional features when they are included in the cylinder design. This European standard does not cover any other element of a security system, other than those directly involved in the control of a cylinder. The suitability of cylinders for use on fire or smoke-door assemblies is determined by fire performance tests conducted in addition to the performance testing specified by this European standard; see Annex A.

EN 15684:2012 is classified under the following ICS (International Classification for Standards) categories: 91.190 - Building accessories. The ICS classification helps identify the subject area and facilitates finding related standards.

EN 15684:2012 has the following relationships with other standards: It is inter standard links to EN 15684:2020, EN 60068-2-29:1993, EN 60529:1991, EN IEC 60068-2-2:2025, EN 60068-2-6:2008, EN IEC 61000-4-2:2025, EN IEC 60068-2-1:2025, EN 60068-2-30:2005, EN 1906:2012, EN 1634-2:2008, EN 1634-3:2004, EN 1303:2005, EN ISO 15482:1999, EN 636:2003, EN ISO 15480:2019. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

EN 15684:2012 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Stavbno okovje - Mehatronski cilindri - Zahteve in preskusni postopkiSchlösser und Baubeschläge - Mechatronische Schließzylinder - Anforderungen und PrüfverfahrenQuincaillerie pour le bâtiment - Cylindres mécatroniques - Exigences et méthodes d'essaiBuilding hardware - Mechatronic cylinders - Requirements and test methods91.190Stavbna opremaBuilding accessoriesICS:Ta slovenski standard je istoveten z:EN 15684:2012SIST EN 15684:2014en,fr,de01-januar-2014SIST EN 15684:2014SLOVENSKI

STANDARD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 15684

October 2012 ICS 91.190 English Version

Building hardware - Mechatronic cylinders - Requirements and test methods

Quincaillerie pour le bâtiment - Cylindres mécatroniques - Exigences et méthodes d'essai

Schlösser und Baubeschläge - Mechatronische Schließzylinder - Anforderungen und Prüfverfahren This European Standard was approved by CEN on 23 September 2012.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2012 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 15684:2012: ESIST EN 15684:2014

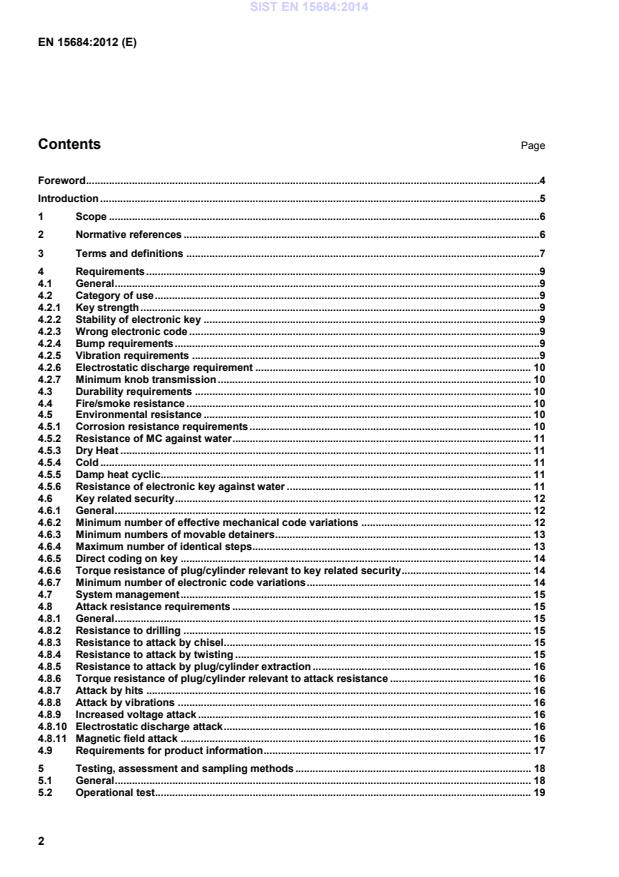

2 Contents Page Foreword .4Introduction .51 Scope .62 Normative references .63 Terms and definitions .74 Requirements .94.1 General .94.2 Category of use .94.2.1 Key strength .94.2.2 Stability of electronic key .94.2.3 Wrong electronic code .94.2.4 Bump requirements .94.2.5 Vibration requirements .94.2.6 Electrostatic discharge requirement . 104.2.7 Minimum knob transmission . 104.3 Durability requirements . 104.4 Fire/smoke resistance . 104.5 Environmental resistance . 104.5.1 Corrosion resistance requirements . 104.5.2 Resistance of MC against water . 114.5.3 Dry Heat . 114.5.4 Cold . 114.5.5 Damp heat cyclic. 114.5.6 Resistance of electronic key against water . 114.6 Key related security . 124.6.1 General . 124.6.2 Minimum number of effective mechanical code variations . 124.6.3 Minimum numbers of movable detainers . 134.6.4 Maximum number of identical steps. 134.6.5 Direct coding on key . 144.6.6 Torque resistance of plug/cylinder relevant to key related security . 144.6.7 Minimum number of electronic code variations . 144.7 System management . 154.8 Attack resistance requirements . 154.8.1 General . 154.8.2 Resistance to drilling . 154.8.3 Resistance to attack by chisel . 154.8.4 Resistance to attack by twisting . 154.8.5 Resistance to attack by plug/cylinder extraction . 164.8.6 Torque resistance of plug/cylinder relevant to attack resistance . 164.8.7 Attack by hits . 164.8.8 Attack by vibrations . 164.8.9 Increased voltage attack . 164.8.10 Electrostatic discharge attack . 164.8.11 Magnetic field attack . 164.9 Requirements for product information . 175 Testing, assessment and sampling methods . 185.1 General . 185.2 Operational test . 19SIST EN 15684:2014

Suitability for use on fire/smoke resistant doors . 38Annex B (normative)

Tool sets for attack resistance tests. 39Annex C (normative)

Table of test procedures . 42Annex D (informative)

Installation instructions . 44Bibliography . 45 SIST EN 15684:2014

4 Foreword This document (EN 15684:2012) has been prepared by Technical Committee CEN/TC 33 “Doors, windows, shutters, building hardware and curtain walling”, the secretariat of which is held by AFNOR. This European Standard shall be given the status of a national standard, either by publication of an identical text or by endorsement, at the latest by April 2013, and conflicting national standards shall be withdrawn at the latest by April 2013. Attention is drawn to the possibility that some of the elements of this document may be the subject of patent rights. CEN [and/or CENELEC] shall not be held responsible for identifying any or all such patent rights. According to the CEN/CENELEC Internal Regulations, the national standards organisations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom. SIST EN 15684:2014

Mechanically performance of the mechatronic cylinder are based on EN 1303:2005. Mechatronic Cylinder can technically be described in three main designs: a cylinder with both electrically and mechanically operated locking parts; a cylinder with electrically operated locking part and a key for mechanically rotating the plug; a cylinder with electrically operated locking part and with manual operated opening/closing function. Increasingly such Mechatronic Cylinders (MCs) form a part of the security system of a building and may involve the use of electrical locking and controlling elements.

The performance tests incorporated in this European Standard are considered to be reproducible and as such will provide a consistent and objective assessment of the performance of these devices throughout CEN Member States.

It is assumed that mechatronic cylinders will conform to the legal regulations i.e. of the Electromagnetic Compatibility (EMC) - Directive 2004/108EG, The Low Voltage (LV) - Directive 2006/95/EG, Radio & Telecommunications Terminal Equipment (R&TTE) - Directive 1999/5/EC and other relevant directives concerning electronic apparatus.

On occasions there may be a need for additional functions within the design of the cylinder. Purchasers should satisfy themselves that the products are suitable for their intended use. This is particularly important when the operation of such additional functions is safety-related. Accordingly, this European Standard includes assessment of such features when they are included in the cylinder design.

6 1 Scope This European Standard specifies requirements for performance and testing of Mechatronic Cylinders and their keys and/or electronic keys.

It applies to cylinders for such locks designed to be normally used in buildings. It also applies to cylinders for use with other hardware products such as exit devices, door operators, etc. or monitoring facilities and alarm systems.

It establishes categories of use based on performance tests and grades of security based on design requirements and on performance tests that simulate attack. This European Standard includes assessment of additional features when they are included in the cylinder design. This European Standard does not cover any other element of a security system, other than those directly involved in the control of a cylinder.

The suitability of cylinders for use on fire or smoke-door assemblies is determined by fire performance tests conducted in addition to the performance testing specified by this European Standard; see Annex A.

2 Normative references The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies. EN 636:2003, Plywood Specifications EN 1303:2005, Building hardware — Cylinders for locks — Requirements and test methods

EN 1634-1, Fire resistance and smoke control tests for door, shutter and openable window assemblies and elements of building hardware — Part 1: Fire resistance tests for doors, shutters and openable windows EN 1634-2, Fire resistance and smoke control tests for door, shutter and openable window assemblies and elements of building hardware — Part 2: Fire resistance characterisation test for elements of building hardware EN 1634-3, Fire resistance and smoke control tests for door and shutter assemblies, openable windows and elements of building hardware — Part 3: Smoke control test for door and shutter assemblies

EN 1670:2007, Building hardware — Corrosion resistance — Requirements and test methods EN 1906, Building hardware Lever handles and knob furniture Requirements and test methods EN 60068-2-1, Environmental testing — Part 2-1: Tests — Test A: Cold (IEC 60068-2-1) EN 60068-2-2, Environmental testing — Part 2-2: Tests — Test B: Dry heat (IEC 60068-2-2) EN 60068-2-6:2008, Environmental testing — Part 2-6: Tests — Test Fc: Vibration (sinusoidal)

(IEC 60068-2-6:2007) EN 60068-2-29:1993, Environmental testing — Part 2: Tests — Test Eb and guidance: Bump

(IEC 60068-2-29:1987) SIST EN 15684:2014

degree of functionality intended to provide a record of mechatronic cylinder and/or its electronic key events that will identify the individual credential used to operate the mechatronic cylinder 3.2 attack unauthorised attempt to open a mechatronic cylinder by various techniques (destructive and or non-destructive techniques) 3.3 cam component of the cylinder to provide the movement necessary to effect locking 3.4 cylinder device, usually distinct from its associated lock or latch, operated by a key 3.5 effective differ difference between cylinders of similar design, achieved only by the movable detainer, which enables each cylinder to be operated only by its own key

Note 1 to entry: The number of effective differs is equal to the number of theoretical differs after deduction of the differs excluded by the manufacturer due to technical constraints and those differs excluded in accordance with the restraints of 4.8.4 3.6 electronic dummy key

electronic key which cannot electronically operate the mechatronic cylinder

Note 1 to entry: If applicable the electronic dummy key has the right mechanical code. SIST EN 15684:2014

8 3.7 electronic key

device containing information necessary to authorise operation of the (mechatronic) cylinder 3.8 key separate device corresponding to the cylinder, which can mechanically operate the cylinder 3.9 key way aperture extending along the whole or part of the length of the plug into which the key is inserted 3.10 knob

element of the cylinder for mechanical hand operation of the cylinder 3.11 mechatronic cylinder MC device with an integrated or a remote electronic system, which is to be used with a lock for the purpose of operating the lock and/or detaining elements after verifying the authorisation of an electronic key, and which can be replaced by a mechanical cylinder conforming to EN 1303 without replacing any door furniture 3.12 moveable detainer part of the mechanism of a cylinder, which should first be moved by the key into a pre-determined position before the key and/or plug can move 3.13 plug part of a cylinder that can be moved when the proper key is used 3.14 steps cuts in the surface of a bit or blade which operates movable detainers 3.15 thumb turn element of the cylinder for mechanical finger operation of the cylinder 3.16 time zone

degree of functionality intended to provide security by limiting the time that a valid credential will operate the MC 3.17 manufacturer entity or organisation that is legally responsible for putting the product on the market SIST EN 15684:2014

The structure of the following requirements and test procedures reflects the classification in accordance with Clause 6.

4.2 Category of use

4.2.1 Key strength

When tested in accordance with 5.4.1 the electronic key shall not break under the applied maximum torque of 2,5 Nm. After the test, the electronic key shall be capable of being removed from the MC and re-used to operate the same MC with a torque not exceeding 1,5 Nm. 4.2.2 Stability of electronic key

The electronic key shall be able to withstand a freefall from 1,5 m height, without loss of function and without the need to reassemble it. Compliance is checked by the test method given in 5.4.2.

4.2.3 Wrong electronic code

When using a electronic dummy key with the right mechanical code the MC shall be capable of resisting a torque on the key of 3,5 Nm (or the maximum torque that can be transmitted with the normal manufacturers key if less than 3,5 Nm) without loss of function.

Compliance is checked by the test method given in 5.10.5.3, however with a torque of 3,5 Nm. If a MC is equipped with a knob or thumb turn on the outside (replacing the key function) and this MC is not protected by a clutch to prevent damage in case of excessive torque being applied to the knob or thumb turn, the MC shall be capable of resisting a torque of 5 Nm (+5 %), without loss of function.

4.2.4 Bump requirements

The MC and its electronic keys shall be able to withstand bumps.

The MC shall conform to the requirements given in Table 1.

The MC and the electronic key may have temporary degradation or loss of function and/or data, but the MC shall remain in secured position. The loss of function and/or data shall be self-recoverable within 5 s.

Compliance is checked by the test methods given in 5.4.3.

4.2.5 Vibration requirements The MC and its electronic keys shall be able to withstand vibrations.

The MC shall conform to the requirements given in Table 1.

The MC and the electronic keys may have temporary degradation or loss of function and/or data, but the MC shall remain in secured position. The loss of function and/or data shall be self-recoverable within 5 s. The loss of function and/or data shall be self-recoverable within 5 s after the vibration test. SIST EN 15684:2014

10 Compliance is checked by the test methods given in 5.4.4.

Table 1 — Bump and Vibration requirements Test method Grade 1 1. Bump test EN 60068-2-29:1993 40 g (100 bumps / 3 directions) duration per bump 6 ms 3.a Vibrations EN 60068-2-6:2008 -Frequency range: 10 to 150 Hz -Displacement amplitude: 0,35 mm

-Acceleration amplitude: 5 g

-Duration of endurance in

sweep cycles for each axis: 5

-Cross-over frequency : 58 Hz to 62 Hz -Sweep rate: 1 octave per minute

4.2.6 Electrostatic discharge requirement

The MC and its electronic keys shall be able to withstand high voltage and static electricity. It shall conform to the requirements given in EN 61000-4-2 and conform to the specification in Table 9, grade 0.

The MC and the electronic keys may have temporary degradation or loss of function and/or data, but the electric blocking of the MC shall remain in secured position. The loss of function and/or data shall be self-recoverable within 5 s.

Compliance is checked by the test method given in 5.10.9.

4.2.7 Minimum knob transmission

If a MC is equipped with a knob on the outside and this MC is protected by a clutch to prevent damage in case of excessive torque being applied to the knob, the clutch shall be able to transmit a minimum torque of 1,5 Nm having been released 100 times within 20 min.

4.3 Durability requirements

When tested in accordance with 5.5, it shall be possible to operate the MC with a new original authorised electronic key with a torque not exceeding 1.5 Nm after the number of completed test cycles specified in 6.3. Compliance is checked by the test method given in 5.2.

4.4 Fire/smoke resistance

The MC shall conform to the requirements of Annex A.

4.5 Environmental resistance

4.5.1 Corrosion resistance requirements

After the corrosion test of 5.7.1, the MC shall operate, using a maximum torque on the electronic key of 1,5 Nm. Compliance is checked by the test method in 5.2. SIST EN 15684:2014

The MC and its electronic key shall be able to function correctly at different temperatures. It shall also be able to function correctly after being exposed to thermal shocks. See Tables 2 and 3 for environmental resistance MC and electronic keys.

Compliance is checked by the test methods of 5.7.3. 4.5.4 Cold

The MC and its electronic key shall be able to function correctly at different low temperatures. It shall also be able to function correctly after being exposed to thermal shocks. See Tables 2 and 3 for environmental resistance MC and electronic keys.

Compliance is checked by the test methods of 5.7.4.

4.5.5 Damp heat cyclic

The MC and its electronic keys shall be able to function correctly in an environment of high relative humidity. See Tables 2 and 3 for environmental resistance MC and electronic keys. Compliance is checked by the test method of 5.7.5. 4.5.6 Resistance of electronic key against water

The electronic keys shall be able to operate its MC after they have been exposed to water in accordance with the test described in 5.7.6.

Table 2 — Environmental resistance MC Requirement Test clause Grade 0

4.5.1 Corrosion resistance

5.7.1 - - Yes Yes Yes 4.5.2 Protection of MC against water

5.7.2 - - Yes Yes Yes 4.5.3 Dry heat

5.7.3 - +55° C, 16 h +55° C, 16 h +55° C, 16 h +65° C, 16 h 4.5.4 Cold

5.7.4 - +5° C, 16h +5° C,

16 h -10° C,

16 h -25° C,

16 h 4.5.5 Damp Heat (cyclic)

5.7.5 -

- - - +55° C, 6 cycles

12 Table 3 — Environmental resistance MC Key Requirement Test clause Grade0

3 4 4.5.6 Resistance of electronic key against water 5.7.6 - - Yes Yes Yes 4.5.3 Dry heat

5.7.3 - +55° C, 16 h +55° C, 16 h +55° C, 16 h +65° C, 16 h 4.5.4 Cold

5.7.4 - +5° C,

16 h +5° C,

16 h -10° C,

16 h -25° C,

16 h 4.5.5 Damp Heat (cyclic)

5.7.5 - - - - +55° C, 6 cycles

4.6 Key related security

4.6.1 General For classification of mechanical code variation (5th character), the following requirements shall be fulfilled: 4.6.2; 4.6.3; 4.6.4; 4.6.5; 4.6.6. For classification of electronic code variation (6th character), the following requirements shall be fulfilled: 4.6.5; 4.6.6; 4.6.7. In case of a double cylinder, it is assumed that the grades for both categories apply to the attack side/outside of the cylinder. This side shall have a proper indication/marking, either on the product or on the documents with the product. 4.6.2 Minimum number of effective mechanical code variations

The minimum number of effective mechanical code variations of the MC shall be as specified in Table 4.

Mechanical codes Correlation with EN 1303:2005 Torque resistance of plug/cylinder Grade A:

- no grade in EN 1303:2005

Grade B:

grade 1 of EN 1303:2005

2,5 Nm Grade C:

grade 2 of EN 1303:2005

5 Nm Grade D:

15 000

grade 3 of EN 1303:2005

15 Nm Grade E:

30 000

grades 4 or 5 of EN 1303:2005

15 Nm Grade F:

100 000

grade 6 of EN 1303:2005

15 Nm

Compliance is checked by the test method of 5.8.2. NOTE Grade A includes MCs without mechanical code variations. 4.6.3 Minimum numbers of movable detainers The minimum number of movable detainers shall be as specified in Table 5. Table 5 — Numbers of movable detainers

Min number of detainers Correlation with EN 1303:2005 Grade A:

- no grade in EN 1303:2005

Grade B:

2 grade 1 of EN 1303:2005

Grade C:

3 grade 2 of EN 1303:2005

Grade D:

5 grade 3 of EN 1303:2005

Grade E:

5 grades 4 or 5 of EN 1303:2005

Grade F:

6 grade 6 of EN 1303:2005

4.6.4 Maximum number of identical steps The choice of key steps for movable detainer operation, which have the same operating level, shall be as specified in Table 6. SIST EN 15684:2014

14 Table 6 — Maximum number of identical steps

Max numbers of identical steps Correlation with EN 1303:2005 Grade A:

- no grade in EN 1303:2005

Grade B:

100 % grade 1 of EN 1303:2005

Grade C:

70 % , max. 2 adjacent grade 2 of EN 1303:2005

Grade D:

60 % , max. 2 adjacent grade 3 of EN 1303:2005

Grade E:

60 % , max. 2 adjacent grades 4 or 5 of EN 1303:2005

Grade F:

60 % , max. 2 adjacent grade 6 of EN 1303:2005

NOTE The requirements as specified in Table 6 relate to one row only of movable detainers. 4.6.5 Direct coding on key Direct key coding shall not be used on electronic keys for key related security grades A to F. 4.6.6 Torque resistance of plug/cylinder relevant to key related security Torque resistance of plug/cylinder shall be classified in relation to mechanical code variations. When tested as in 5.8.3 the MC shall resist the torque in Table 4 without operating the cylinder. If the torque cannot be applied, the cylinder shall be deemed to have passed the test.

This requirement is not applicable if the requirement of 4.8.6 is applied. 4.6.7 Minimum number of electronic code variations

The minimum number of electronic codes (different keys) of the MC shall be as specified in Table 7.

Table 7 — Electronic codes

Electronic codes Grade A:

10 000 Grade B:

100 000 Grade C:

1 000 000 Grade D:

10 000 000 Grade E:

100 000 000

Communication shall be protected

This requirement shall be verified by the manufacturers declaration as described in 4.9. Grade F:

1 000 000 000

Communication shall be protected This requirement shall be verified by the manufacturers declaration as described in 4.9.

Compliance is checked by the test method of 5.8.4. SIST EN 15684:2014

The audit trail record shall be stored in a form of non-volatile memory or data shall otherwise be preserved during removal of power supply. The MC shall have time zoning capability as specified in Table 8. Table 8 — Audit trail and time zone Grade 0 No requirement Grade 1 Time zone without audit trail Grade 2 Audit trail capability without time zone Grade 3 Audit trail capability and time zone

Time zone and audit trail capability shall be protected against manipulation. Compliance is checked by the test method of 5.9. 4.8 Attack resistance requirements 4.8.1 General The MC shall conform to the requirements based on: Mechanical part without electronic lock (only MC); Electronic part with a electronic dummy key with right mechanical code; Both parts.

In case a MC is equipped with a knob or thumb turn on the attack side the MC should conform to the same performance (test requirements) in accordance with 5.10.4, using an appropriate tool for pulling a knob or thumb turn. When the knob or thumb turn can be removed with common tools and/or hitting in accordance with the chisel test given in 5.10.2, the test shall be performed without the knob or thumb turn.

The requirements for each grade are described in Table 9.

4.8.2 Resistance to drilling After testing in accordance with 5.10.1, the lock driving element of the cylinders shall not rotate without the correct key, using a maximum torque of 5 Nm. It is not necessary for the correct key to operate the cylinder after testing. 4.8.3 Resistance to attack by chisel After testing in accordance with 5.10.2, the lock driving element of the cylinders shall not rotate without the correct key, using a maximum torque of 5 Nm. It is not necessary for the correct key to operate the cylinder after testing. 4.8.4 Resistance to attack by twisting After testing in accordance with 5.10.3, the lock driving element of the cylinders shall not rotate without the correct key, using a maximum torque of 5 Nm. It is not necessary for the correct key to operate the cylinder after testing. SIST EN 15684:2014

16 4.8.5 Resistance to attack by plug/cylinder extraction After testing in accordance with 5.10.4, the cam of the cylinders shall not rotate manually with 5 Nm through 360°, or in the case of cylinders with restricted plug movement, to the maximum permitted by the design. It is not necessary for the correct key to operate the cylinder after testing. 4.8.6 Torque resistance of plug/cylinder relevant to attack resistance After testing in accordance with 5.10.5, the plug and/or cylinder in attack resistance grades 0, 1 and 2 shall not rotate using the applied torque.

It is not necessary for the correct key to operate the cylinder after testing. 4.8.7 Attack by hits When tested in accordance with 5.10.6 the MC and its electronic keys shall be able to withstand opening by hits within the time specified in Table 9. 4.8.8 Attack by vibrations When tested in accordance with 5.10.7 the MC and its electronic keys shall be able to withstand opening by vibrations within the time specified in Table 9. 4.8.9 Increased voltage attack

The MC and its electronic keys shall be able to withstand electrical attacks by using higher voltage than the normal supply voltage DC specified by the manufacturer. The MC or electronic key may have degradation or loss of function which is not recoverable, due to damage of equipment or software, or loss of data. The electric blocking of the MC shall remain in a locked position.

Compliance is checked by the test method given in 5.10.8.

4.8.10 Electrostatic discharge attack

The MC and its electronic keys should be able to withstand electrical attacks and manipulation using high voltage and static electricity specified in Table 9.

For grades 1 and 2 the MC or electronic key may have degradation or loss of function which is not recoverable, due to damage of equipment or software, or loss of data. The electric blocking of MC shall remain in locked position.

Compliance is checked by the test method given in 5.10.9.

4.8.11 Magnetic field attack

The MC and its electronic keys, shall in grade 1 and grade 2 be able to withstand attacks and manipulation using a magnetic field. It shall not be possible to move the electronic blocking element from a closed to an open position by a magnet

from any direction of the MC available after installation.

The MC shall withstand 2 min of attack by a maximum 0,6 T magnet.

The MC or electronic key may have degradation or loss of function which is not recoverable, due to damage of equipment or software, or loss of data. The electric blocking of the MC shall remain in locked position.

Compliance is checked by the test method given in 5.10.10.

Grade 0 Grade 1 Grade 2 4.8.2 Resistance to drilling 5.10.1 Effective time No requirements 3 min 5 min Total time 5 min 10 min 4.8.3 Resistance to attack by chisel 5.10.2 Number of blows No requirements 30 blows 40 blows 4.8.4 Resistance to attack by twisting 5.10.3 Number of twists No requirements 20 twists 30 twists 4.8.5 Resistance to attack by plug/cylinder extraction 5.10.4 Time No requirements 3 min 5 min Force 10 kN 15 kN 4.8.6 Torque resistance of plug/cylinder 5.10.5. Test 5.10.5.2 No requirements 20 Nm 30 Nm Test 5.10.5.3 key break or minimum 5 Nm key break or minimum 7 Nm 4.8.7 Attack by hits 5.10.6 Effective time No requirements 3 min 5 min 4.8.8 Attack by vibrations 5.10.7 Effective time No requirements 3 min 5 min 4.8.9 Increased voltage attack test 5.10.8 Voltage No requirements Normal supply voltage + 6 V by a max. of 600 mA Normal supply voltage + 48 V by a max. of 600 mA 4.8.10 Electrostatic discharge attack test 5.10.9 Contact 8 kV 8 kV 8 kV Air 15 kV 21 kV 21 kV 4.8.11 Magnetic field attack test 5.10.10 Time No requirements 2 min 2 min

NOTE Grade 0 represents the requirements of 4.2 Category of use. 4.9 Requirements for product information A MC and its electronic keys manufactured to this European Standard shall have clear and detailed instructions in its product documentation and/or product information for its installation operation and maintenance. These instructions shall at least include the following: a) The limitations on its intended use, such as the limitation of the rated voltage, temperature range, environment and allowed back set, etc. b) The following warning in a prominent position: "The product should not be modified in any way except in accordance with those modifications described in the instructions."’ SIST EN 15684:2014

18 c) Installation and fixing instructions to ensure that the MC can achieve the performance requirements in this document, including any restriction in use, for example conditions under which the MC and its electronic key could be rendered inoperable. See Annex D. d) Maintenance and operation instructions to ensure that the MC and its electronic key continues to achieve the performance declared by the manufacturer for a reasonably economic working life. e) A list of all elements that are tested and approved for use with this MC and which may be packaged separately, e.g. cylinder accessories, etc. f) Information about the following product features: 1) time zone possibilities (like number of time profiles, special time functions);

2) the quality of time zones (for example recurring (daily, weekly) or calendar);

3) authorisation process for an access modification (code, master card.); 4) audit trails: quantity, with or without time-stamp, authorised access, denied access also, access programming; 5) what happens with the access during and after the removal of main power;

6) battery change: how long the data are been protected;

7) b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...