ASTM D346-90(1998)

(Practice)Standard Practice for Collection and Preparation of Coke Samples for Laboratory Analysis

Standard Practice for Collection and Preparation of Coke Samples for Laboratory Analysis

SCOPE

1.1 This practice covers procedures for the collection and reduction of samples of coke to be used for physical tests, chemical analyses, and the determination of total moisture.

1.2 The values given in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.>

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 346 – 90 (Reapproved 1998)

Standard Practice for

Collection and Preparation of Coke Samples for Laboratory

Analysis

This standard is issued under the fixed designation D 346; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Coke, especially run of oven coke or foundry coke, or both, is a difficult material to sample. It is

imperative that every sample be collected and handled carefully and conscientiously and in strict

accordance with the standard procedure described herein.

Gross samples of not less than the quantities designated in this practice must be taken, whether the

coke to be sampled consists of a few tons or several hundred tons.

1. Scope caution must be exercised in all stages of sampling, from

system specifications and equipment procurement to equip-

1.1 This practice covers procedures for the collection and

ment acceptance testing and actually taking the final sample.

reduction of samples of coke to be used for physical tests,

3.2 This practice also provides an analysis sample of coke

chemical analyses, and the determination of total moisture.

from the gross or divided sample. The analysis samples can be

1.2 The values given in SI units are to be regarded as the

used to determine the value of the coke represented, its ability

standard. The values given in parentheses are for information

to meet specifications, as well as for other purposes.

only.

1.3 This standard does not purport to address the safety

4. Place of Sampling

concerns associated with its use. It is the responsibility of the

4.1 Sample coke while it is being loaded into or unloaded

user of this standard to establish appropriate safety and health

from railroad cars, ships, barges, or trucks, or when discharged

practices and determine the applicability of regulatory limita-

from supply bins, grab buckets, belt conveyers, or other coke

tions prior to use.

conveying equipment. Sample close to the point of interest.

2. Referenced Documents

5. Collection of Gross Sample

2.1 ASTM Standards:

5.1 Collect increments regularly, systematically, and with

D 167 Test Method for Apparent and True Specific Gravity

such frequency, so that the entire quantity of coke sampled will

and Porosity of Lump Coke

2 be represented proportionately in the gross sample, and a gross

D 293 Test Method for the Sieve Analysis of Coke

sample of the required amount will be collected. The standard

D 2013 Method of Preparing Coal Samples for Analysis

2 gross sample shall equal or exceed the quantities given in Table

D 2234 Practice for Collection of a Gross Sample of Coal

1.

D 3038 Test Method for Drop Shatter Test for Coke

2 5.1.1 The quantity of sample to be taken will depend on the

D 3302 Test Method for Total Moisture in Coal

2 size of the coke being sampled and the amount of information

D 3402 Test Method for Tumbler Test for Coke

to be obtained from the sample.

3. Significance and Use 5.1.1.1 The size of the sieve analysis sample is governed by

the homogeneity of the coke being sampled. The quantities

3.1 This practice may be used to provide a representative

given in Table 1 represent the minimum quantity to be

sample of the coke from which it is collected. Because of the

collected. The sieve analysis sample will supply sufficient coke

variability of coke and the wide variety of sampling equipment,

for any subsequent physical tests and laboratory analysis. Total

moisture of the coke should not be determined on the sieve

This practice is under the jurisdiction of ASTM Committee D05 on Coal and analysis sample.

Coke and is the direct responsibility of Subcommittee D05.23 on Sampling.

5.1.1.2 For the drop shatter test, a minimum of 75 kg (165

Current edition approved Sept. 28, 1990. Published January 1991. Originally

lb) of coke retained on 50-mm (2-in.) square mesh sieve if

published as D 346 – 32 T. Last previous edition D 346 – 78.

furnace coke is being processed, or 140 kg (300 lb) of coke

Annual Book of ASTM Standards, Vol 05.05.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

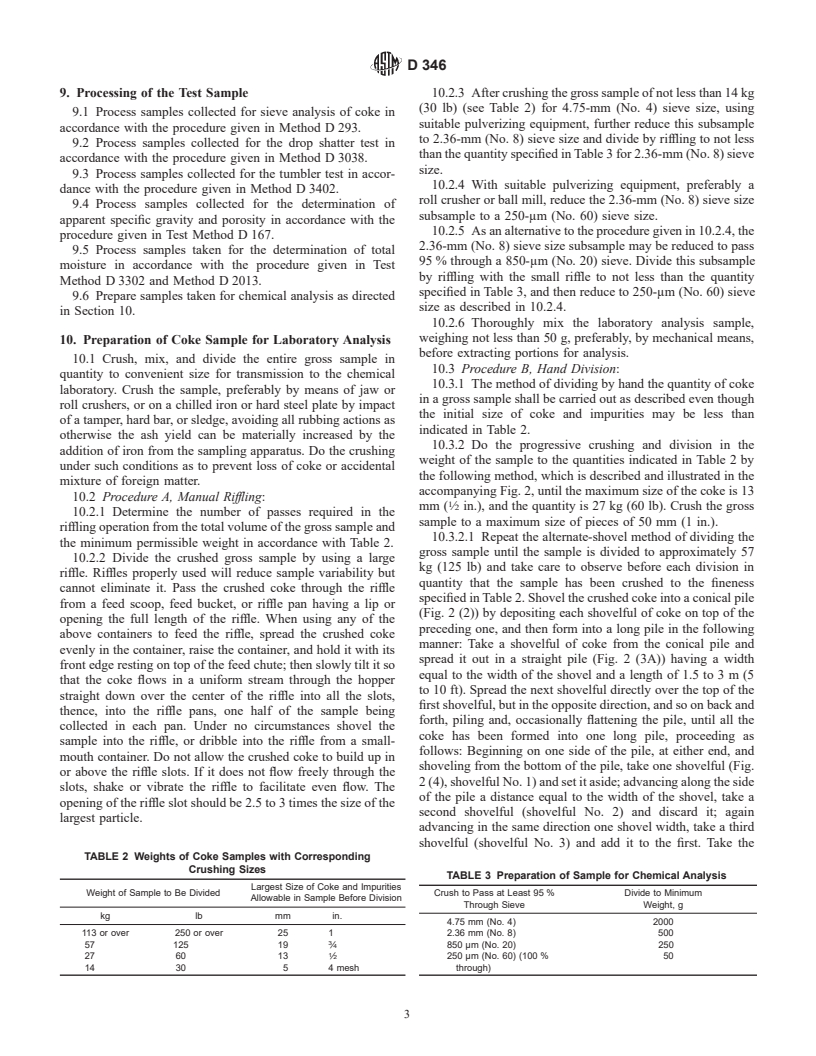

D 346

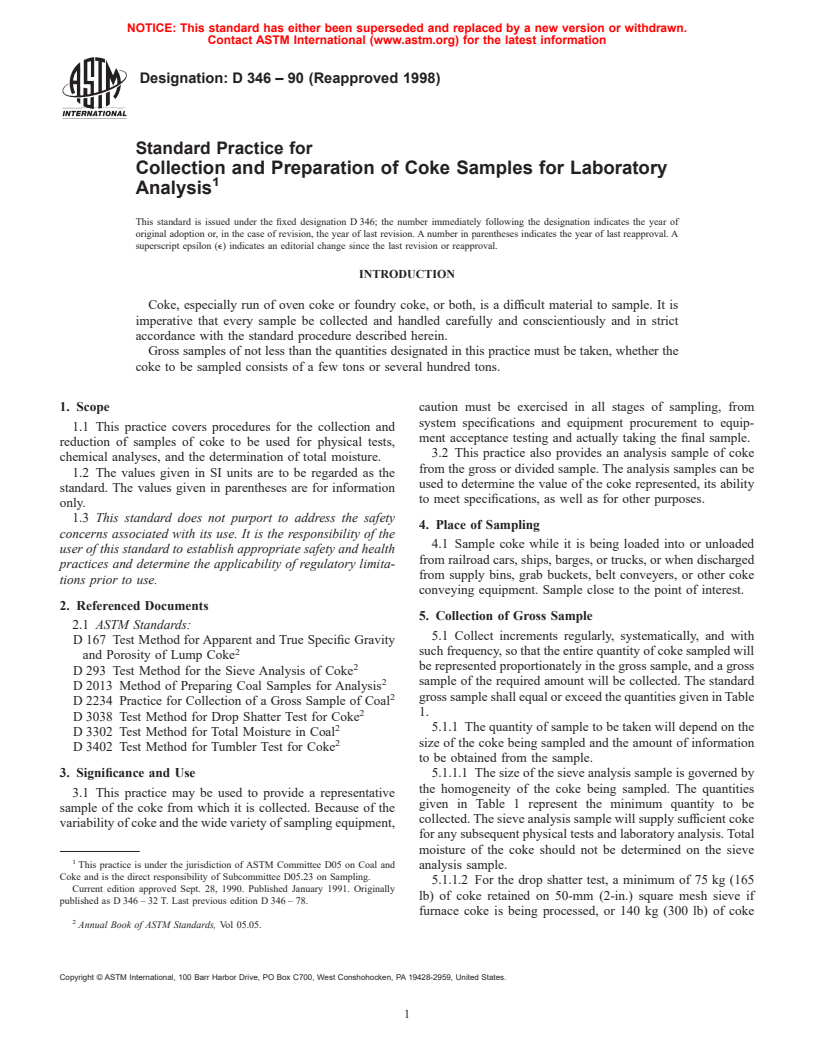

TABLE 1 Minimum Gross Sample Weights of Coke, kg (lb)

Foundry Coke Furnace Coke

A

Usage Coke Breeze

Run of Oven Sized Run of Oven Sized

Sieve analysis (size consist) 364 (800) 227 (500) 227 (500) 182 (400) 45 (100)

Drop shatter test 182 (400) 159 (350) 136 (300) 91 (200) .

Tumbler test 68 (150) 45 (100) 57 (125) 57 (125) .

Apparent specific gravity 46 (100) 46 (100) 46 (100) 46 (100) 23 (50)

Coke moisture 46 (100) 46 (100) 46 (100) 46 (100) 23 (50)

Chemical analysis 113 (250) 113 (250) 57 (125) 57 (125) 34 (75)

A

Coke passing a ⁄4-in. (19-mm) square hole sieve or smaller top size.

retained on 75-mm (3-in.) square mesh sieve if foundry coke is 6.1.2 Condition B (Full-Stream Cut), in which a full cross

being processed, is required. The quantities given in Table 1 section is removed from a moving stream of coke.

represent the minimum amounts required of sized coke. 6.1.3 Condition C (Part-Stream Cut), in which a portion,

5.1.1.3 The tumbler test requires a minimum of 35 kg (75

not a full cross section, is removed from a moving stream of

lb) of coke that will pass a 75-mm (3-in.) square mesh sieve coke.

and can be retained on a 50-mm (2-in.) square mesh sieve, or

6.1.4 Condition D (Stationary Sampling), in which a portion

that which will pass a 64-mm (2 ⁄2-in.) square mesh sieve and

of coke is collected from a pile, a railroad car, a barge, or a

can be retained on a 38-mm (1 ⁄2-in.) square mesh sieve. The

shiphold.

quantities given in Table 1 represent the minimum amount of

NOTE 2—See Section 6 of Practice D 2234.

the required sized coke.

5.1.1.4 The apparent specific gravity test required a mini-

7. Size of Increments

mum of 23 kg (50 lb) of representative coke pieces. The

7.1 To collect increments, use a shovel or specially designed

quantities given in Table 1 represent the minimum amounts of

tool or mechanical means for taking equal increments. When

the required coke pieces.

increments are collected from the surface of a loaded rail car or

5.1.1.5 The determination of total moisture of the coke

truck shipment, the gross sample shall consist of nine incre-

requires approximately 45 kg (100 lb) of coke. The quantities

ments of approximately equal quantity. When increments are

given in Table 1 represent the minimum amount to be col-

taken from piles, conveyor belts, barges, and so forth, the gross

lected.

sample shall consist of not less than 25, nor more than 50

5.1.1.6 The quantities given for samples for chemical analy-

increments, of approximately equal quantity.

sis represent the minimum amounts to be collected.

NOTE 3—When large-size coke, such as foundry coke, is being

NOTE 1—Samples collected from the surface of coke in piles, bins, cars,

sampled, it is likely that quantities larger than those given in Table 1 will

ships, or barges are, in general, unreliable because of size segregation and

be collected. However, the minimum number of increments collected

should not be used for determining conformance to specifications unless

should not be decreased unless such is agreed upon between the purchaser

the purchaser and the seller so agree. If necessary to collect a sample of

and the seller.

coke from the surface of a loaded railroad car, take nine equal increments

NOTE 4—If the sample for chemical analysis is obtained from the sieve

about 305 mm (1 ft) below the surface. Locate the nine points as shown

analysis sample, a sample not smaller than that shown in Table 1 should

in Fig. 1. The diameter of the hole must be at least 3 times that of the

be reconstituted from the size fractions obtained when the sieve analysis

largest piece in the shipment.

sample was processed.

6. Condition of Increment Collection

8. Quantities Represented

6.1 Four conditions of increment collection are recognized:

6.1.1 Condition A (Stopped-Belt Cut), in which a loaded 8.1 Take a gross sample for each 454 Mg (500 tons) or

conveyor belt is stopped and a full cross-section cut with fraction thereof, or in case of larger tonnages, for such

parallel sides is removed from the coke stream. The distance quantities as may be agreed upon. Sample separately each lot

between the parallel faces shall not be less than three times the of coke arising f

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.