ASTM D3402/D3402M-23

(Test Method)Standard Test Method for Tumbler Test for Coke

Standard Test Method for Tumbler Test for Coke

SIGNIFICANCE AND USE

4.1 Coke undergoes various degrees of degradation during removal from coke ovens, transportation, and its decent within a blast furnace to the combustion zone. These processes subject the coke to impact and abrasion. This test method is a relative measure of the resistance of coke to breakage when subjected to these degradation processes.

SCOPE

1.1 This test method describes a procedure for obtaining a relative measure of the resistance to degradation of coke by impact and abrasion.

1.2 Standard Procedure—This procedure uses a coke sample that is sized to 75 mm by 50 mm [ 3.0 in. by 2 in.].

1.3 Alternative Procedure—This procedure uses a composite coke sample that is comprised of coke sized 50 % of 63 mm by 50 mm [2.5 in. by 2 in.] and 50 % of 50 mm by 37.5 mm [2 in. by 1.50 in.].

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3402/D3402M − 23

Standard Test Method for

1

Tumbler Test for Coke

This standard is issued under the fixed designation D3402/D3402M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

3

1. Scope by D 3402 (Withdrawn 1975)

D346/D346M Practice for Collection and Preparation of

1.1 This test method describes a procedure for obtaining a

Coke Samples for Laboratory Analysis

relative measure of the resistance to degradation of coke by

E11 Specification for Woven Wire Test Sieve Cloth and Test

impact and abrasion.

Sieves

1.2 Standard Procedure—This procedure uses a coke

3. Summary of Test Method

sample that is sized to 75 mm by 50 mm [ 3.0 in. by 2 in.].

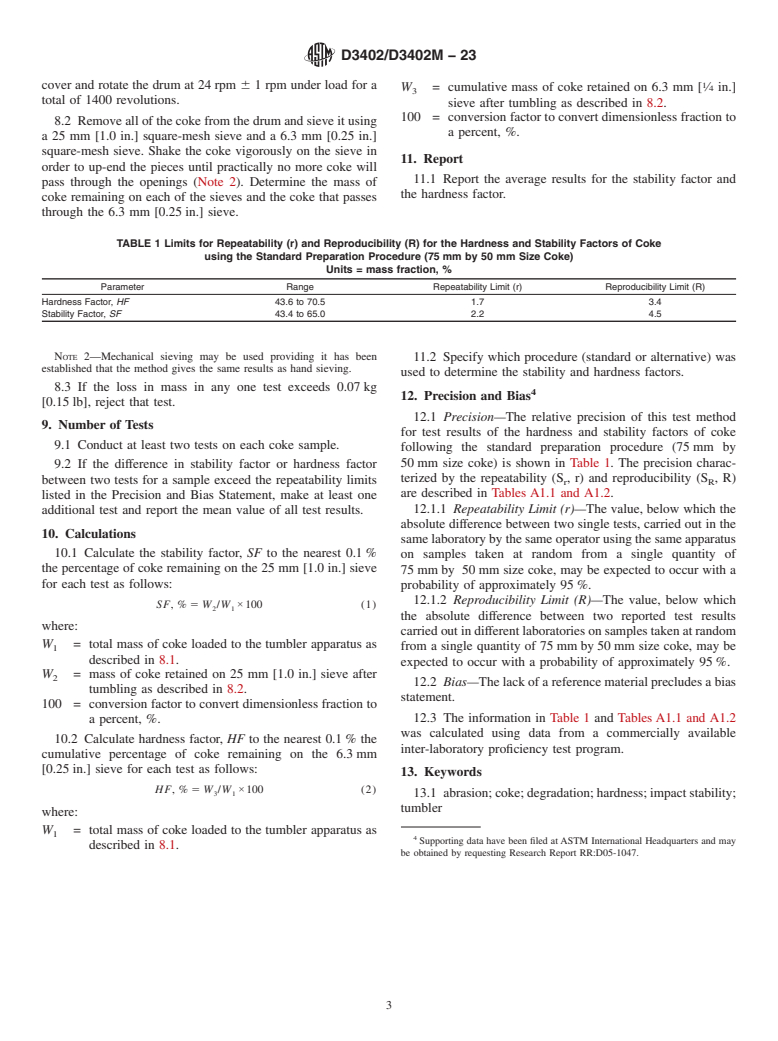

3.1 A sample of dry coke of designated size is tumbled in a

1.3 Alternative Procedure—This procedure uses a compos-

rotating drum at a specified turning rate for a specified number

ite coke sample that is comprised of coke sized 50 % of 63 mm

of revolutions. Two indexes of its strength, the stability factor

by 50 mm [2.5 in. by 2 in.] and 50 % of 50 mm by 37.5 mm

and the hardness factor, are determined by sieve analysis of the

[2 in. by 1.50 in.].

coke after treatment. Studies have indicated that there is no real

1.4 The values stated in either SI units or inch-pound units

difference in the stability factor as determined by the standard

are to be regarded separately as standard. The values stated in

and alternative procedures. The alternative procedure produces

each system may not be exact equivalents; therefore, to ensure

hardness factor results averaging slightly higher than the

conformance with the standard, each system shall be used

standard procedure.

independently of the other, and values from the two systems

4. Significance and Use

shall not be combined.

4.1 Coke undergoes various degrees of degradation during

1.5 This standard does not purport to address all of the

removal from coke ovens, transportation, and its decent within

safety concerns, if any, associated with its use. It is the

a blast furnace to the combustion zone. These processes subject

responsibility of the user of this standard to establish appro-

the coke to impact and abrasion. This test method is a relative

priate safety, health, and environmental practices and deter-

measure of the resistance of coke to breakage when subjected

mine the applicability of regulatory limitations prior to use.

to these degradation processes.

1.6 This international standard was developed in accor-

dance with internationally recognized principles on standard-

5. Apparatus

ization established in the Decision on Principles for the

5.1 Tumbler Machine (see Fig. 1)—The tumbler machine

Development of International Standards, Guides and Recom-

consisting of a cylindrical steel drum 910 mm [36 in.] in inside

mendations issued by the World Trade Organization Technical

diameter and 455 mm [17.9 in.] in inside width and made of

Barriers to Trade (TBT) Committee.

plate at least 6.4 mm [0.25 in.] thick. The machine may be

constructed as a double drum mounted on a common shaft so

2. Referenced Documents

that duplicate coke samples may be tested at the same time.

2

2.1 ASTM Standards:

Two equally spaced 50 mm by 50 mm by 6.4 mm [2 in. by 2 in.

D294 Method of Test for Tumbler Test for Coke; Replaced

by 0.25 in.] steel angles extending across the width of each

drum are solidly fastened inside each drum as shown. These

angles are fastened to the shell so that the attached legs point

1

away from the direction of rotation, thus giving a clear

This test method is under the jurisdiction of ASTM Committee D05 on Coal

and Coke and is the direct responsibility of Subcommittee D05.15 on Metallurgical

unobstructed shelf for lifting the coke. At least one door must

Properties of Coal and Coke.

be provided in each drum for charging and discharging the

Current edition approved Sept. 1, 2023. Published October 2023. Originally

coke sample. This door preferably should extend nearly across

approved in 1975. Last previous edition approved in 2016 as D3402/D3402M – 16.

DOI: 10.1520/D3402_D3402M-23. the width of each drum. As an alternative, a door in the side of

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. w

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D3402/D3402M − 16 D3402/D3402M − 23

Standard Test Method for

1

Tumbler Test for Coke

This standard is issued under the fixed designation D3402/D3402M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

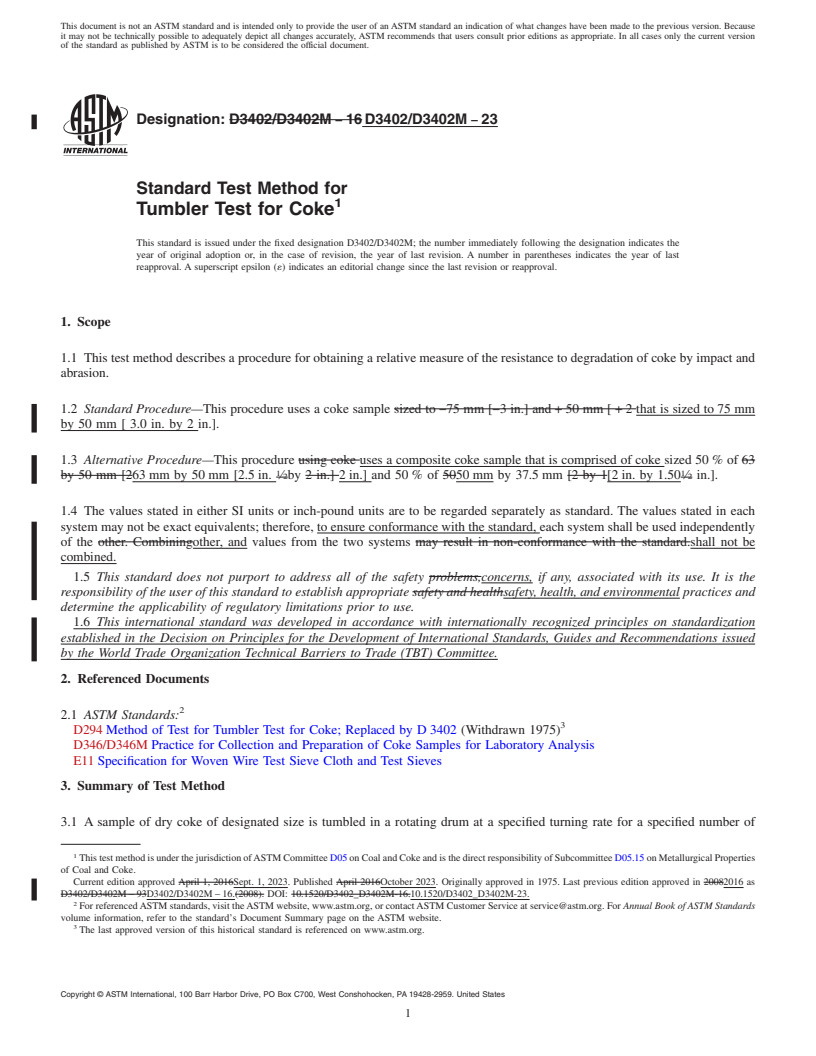

1. Scope

1.1 This test method describes a procedure for obtaining a relative measure of the resistance to degradation of coke by impact and

abrasion.

1.2 Standard Procedure—This procedure uses a coke sample sized to −75 mm [−3 in.] and + 50 mm [ + 2 that is sized to 75 mm

by 50 mm [ 3.0 in. by 2 in.].

1.3 Alternative Procedure—This procedure using coke uses a composite coke sample that is comprised of coke sized 50 % of 63

1 1

by 50 mm [263 mm by 50 mm [2.5 in. ⁄2by 2 in.] 2 in.] and 50 % of 5050 mm by 37.5 mm [2 by 1[2 in. by 1.50 ⁄2 in.].

1.4 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently

of the other. Combiningother, and values from the two systems may result in non-conformance with the standard.shall not be

combined.

1.5 This standard does not purport to address all of the safety problems,concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appropriate safety and healthsafety, health, and environmental practices and

determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

3

D294 Method of Test for Tumbler Test for Coke; Replaced by D 3402 (Withdrawn 1975)

D346/D346M Practice for Collection and Preparation of Coke Samples for Laboratory Analysis

E11 Specification for Woven Wire Test Sieve Cloth and Test Sieves

3. Summary of Test Method

3.1 A sample of dry coke of designated size is tumbled in a rotating drum at a specified turning rate for a specified number of

1

This test method is under the jurisdiction of ASTM Committee D05 on Coal and Coke and is the direct responsibility of Subcommittee D05.15 on Metallurgical Properties

of Coal and Coke.

Current edition approved April 1, 2016Sept. 1, 2023. Published April 2016October 2023. Originally approved in 1975. Last previous edition approved in 20082016 as

D3402/D3402M – 93D3402/D3402M – 16.(2008). DOI: 10.1520/D3402_D3402M-16.10.1520/D3402_D3402M-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

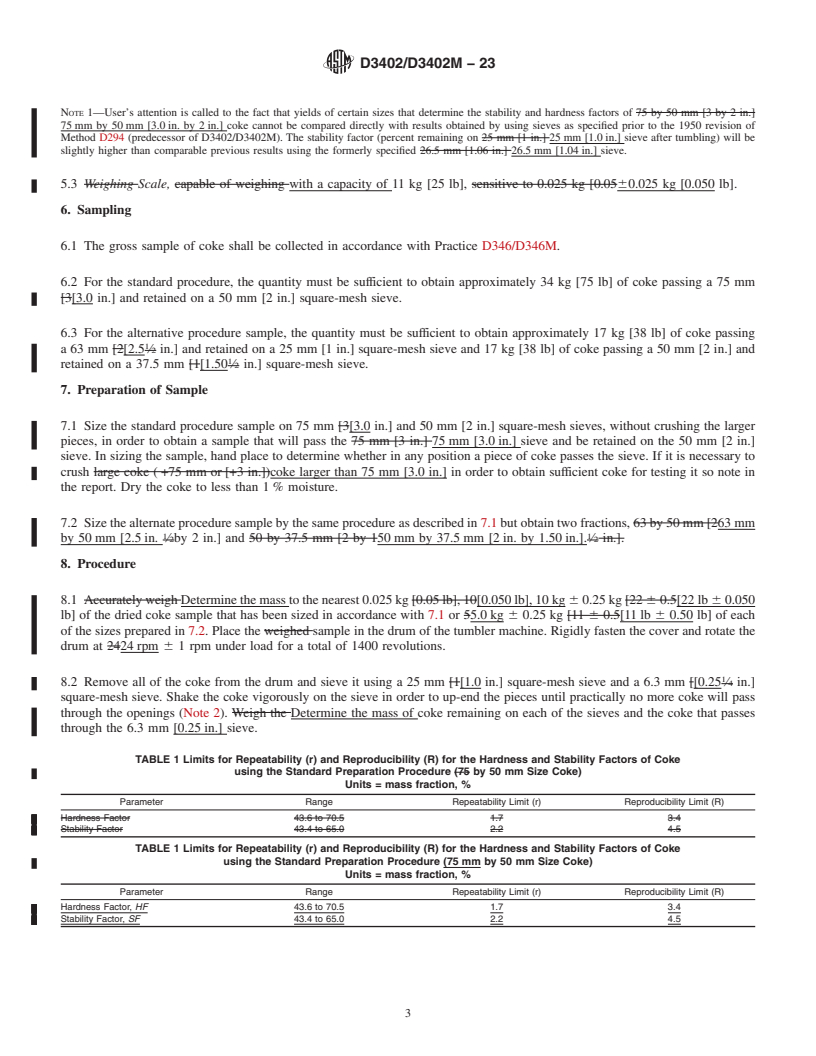

D3402/D3402M − 23

revolutions. Two indexes of its strength, the stability factor and the hardness factor, are determined by sieve analysis of the coke

after treatment. Studies have indicated that there is no real difference in the stability factor as determined by the standard and

alternative procedures. The alternative procedure produces hardness factor results averaging slightly higher than the standard

procedure.

4. Significance and Use

4.1 Coke undergoes various degrees of degradation during removal from coke ovens, transportation, and its decent within a blast

furnace to the combustion zone. These processes subject the coke to impact and abrasion. This test method is a relative measure

of the resistance of coke to breakage when subjected to these degradation processes.

5. Apparatus

5.1 Tumbler Machine (see Fig. 1)—The tumbler machine consisting of a cylindrical steel drum 910 mm [36 in.] in inside diameter

1

and 455 mm [18[17.9 in.] in inside width and made of plate at least 6 mm [6.4 mm [0.25 ⁄4 in.] thick. The machine may be

constructed as a double drum mounted on a common shaft so that

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.