ASTM D7716-11

(Test Method)Standard Test Method for Determination of Residual Methanol in Glycerin by Gas Chromatography

Standard Test Method for Determination of Residual Methanol in Glycerin by Gas Chromatography

SIGNIFICANCE AND USE

Methanol content reflects the quality of glycerin for use as an engine coolant. The current specification for the maximum methanol content is 0.1 % weight to weight (w/w).

SCOPE

1.1 This test method provides for the quantitative determination of residual methanol in glycerin by gas chromatography. The range of detection for residual methanol is 0.02 to 0.60 mass %.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7716–11

Standard Test Method for

Determination of Residual Methanol in Glycerin by Gas

Chromatography

This standard is issued under the fixed designation D7716; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 5. Significance and Use

1.1 This test method provides for the quantitative determi- 5.1 Methanol content reflects the quality of glycerin for use

nationofresidualmethanolinglycerinbygaschromatography. as an engine coolant. The current specification for the maxi-

The range of detection for residual methanol is 0.02 to 0.60 mum methanol content is 0.1 % weight to weight (w/w).

mass %.

6. Apparatus

1.2 The values stated in SI units are to be regarded as

6.1 Chromatographic System—See Practice E355 for spe-

standard. No other units of measurement are included in this

standard. cificdesignationsanddefinitions.Thegaschromatograph(GC)

system shall be capable of operating at the conditions given in

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the Table 1.

6.2 Autosampler system, Gerstel multipurpose sampler

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- MPS-2 or equivalent. This method can also be run manually.

6.3 Column, open tubular column with polyethylene glycol

bility of regulatory limitations prior to use.

(PEG) bonded and cross-linked phase internal coating. The

2. Referenced Documents

column should have an upper temperature limit of 260°C. A

2.1 ASTM Standards: column 30 m in length, with an internal diameter of 0.32 mm,

D1193 Specification for Reagent Water and a 1.0-µm film thickness has been found satisfactory. Any

D7640 Specification for Engine Coolant Grade Glycerin column with equivalent or better chromatographic efficiency

E355 Practice for Gas Chromatography Terms and Rela- and selectivity can be used.

tionships 6.4 Electronic Data Acquisition System—A computer ca-

E594 Practice for Testing Flame Ionization Detectors Used pable of providing real-time graphic and digital presentation of

in Gas or Supercritical Fluid Chromatography the chromatographic data is recommended for use. Peak areas

and retention times shall be measured by computer or elec-

3. Terminology

tronic integration (integrator).

3.1 Definitions—This test method makes reference to many

7. Reagents and Materials

common gas chromatographic procedures, terms, and relation-

ships. Detailed definitions can be found in Practices E355 and 7.1 Purity of Reagents—Reagent-grade chemicals shall be

E594. used in all tests. Unless otherwise indicated, it is intended that

all reagents conform to the specifications of the Committee on

4. Summary of Test Method

Analytical Reagents of the American Chemical Society where

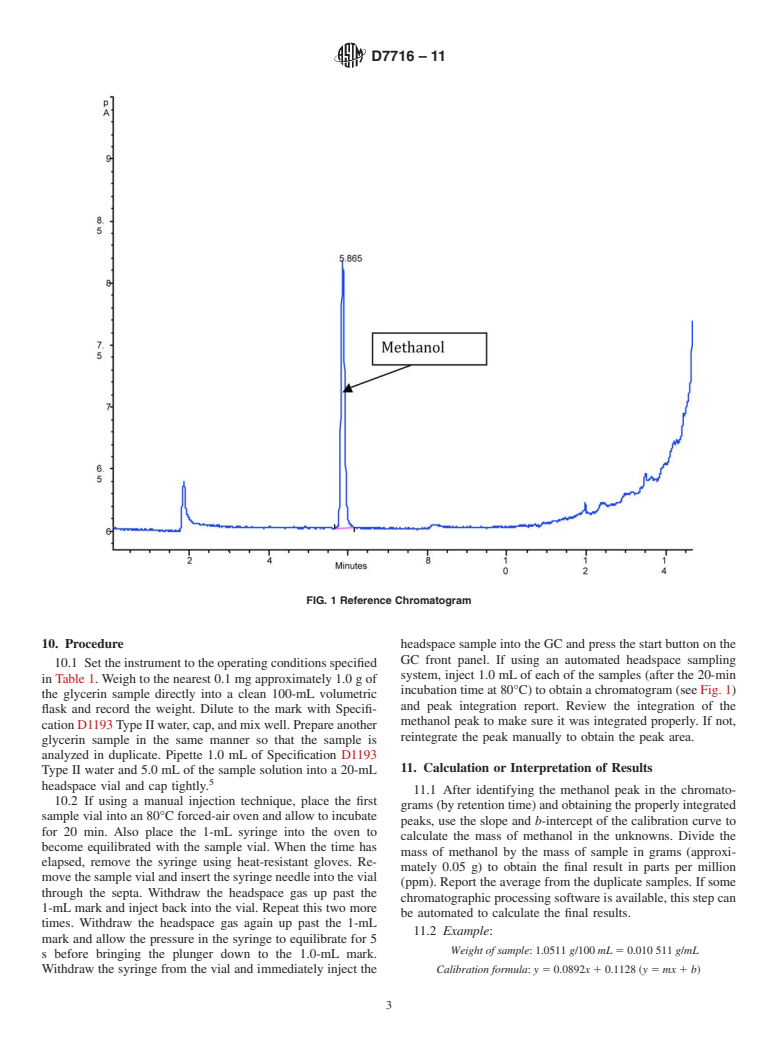

4.1 The sample is analyzed by headspace gas chromatogra-

phy. Calibration is achieved by the use of external standards of

methanol in water.

This test method is under the jurisdiction ofASTM Committee D15 on Engine

Coolants and is the direct responsibility of Subcommittee D15.93 on Research and

Long Range Planning.

Current edition approved June 1, 2011. Published August 2011. DOI: 10.1520/ The sole source of supply of the apparatus known to the committee at this time

D7716-11. is GERSTEL GmbH & Co.KG, Eberhard- Gerstel-Platz 1, 45473 Mülheim an der

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Ruhr, Germany. If you are aware of alternative suppliers, please provide this

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM information to ASTM International Headquarters. Your comments will receive

Standards volume information, refer to the standard’s Document Summary page on careful consideration at a meeting of the responsible technical committee, which

the ASTM website. you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7716–11

TABLE 1 Operating Conditions

9.2 Standard Solutions—Prepare six calibration standards

Injector: Hot split/splitless, 240°C, 10:1 split ratio by first pipeting 2.0 mL of the stock standard into a 100-mL

Sample Size: 1.0 mL

volumetric flask, dilute with Specification D1193Type II water

Column Temperature Program: Initial temperature: 50°C hold 8 min,

to the mark and mix well. This standard contains approxi-

ramp at 20°C/min to 200°C, hold for 0 min

Detector: Flame ionization at 250°C

mately300ppmofmethanol.Pipette5mLofthisstandardinto

Carrier gas: helium or hydrogen, 1.5 mL/min

a 10-mL volumetric flask, dilute with Specification D1193

Vial incubation time: 20 min

Type II water to the mark and mix well. This standard contains

Vial incubation temperature: 80°C

Agitator speed: 600 rpm

approximately 150 ppm of methanol. Pipette 5 mL of this

Injection speed: 200 µL/s

standard into a 10-mL volumetric flask, dilute with Specifica-

Pull-up delay: 5 s

tion D1193 Type II water to the mark and mix well. This

standard contains approximately 75 ppm of methanol. Make

three more dilutions in the same manner to give solutions with

such specifications are available. Other grades may be used

methanol concentrations of approximately 37.5, 18.8, and 9.4

provided it is first ascertained that the reagent is of sufficient

ppm. There will be six calibration standards with approximate

purity to permit its use without lessening the accuracy of the

concentrations of 9.4, 18.8, 37.5, 75, 150, and 300 ppm of

determination.

methanol.

7.2 Purity of Water—Unless otherwise indicated, references

9.3 Chromatographic Analysis—Pipette 1.0 mL of each of

to water shall be understood to mean reagent water as defined

the prepared standards into each of six 20-mLheadspace vials.

by Type II of Specification D1193.

Pipette 5.0 mL of Specification D1193 Type II water into each

7.3 Methanol, reagent grade.

of the vials and cap tightly with a PTFE-lined septa. Also

7.4 Glycerin, meeting Specification D7640.

prepare two air blank vials that should be run for the first vial

7.5 Carrier gas, hydrogen or helium of high purity. Addi-

to check the system background and also after the highest

tional purification is recommended by the use of molecular

calibration standard to check for carryover.

sieves or other suitable agents to remove water, oxygen, and

hydrocarbons.Available pressure shall be sufficient to ensure a 9.4 Analyze the calibration standards under the same oper-

ating conditions as the sample solutions. If using a manual

constant carrier gas flow rate.

7.6 Microlitre syringe on auto sampler, 2500-µL capacity. injection technique, place the first calibration standard vial into

7.7 Microlitre syringe, gastight, 1000-µL capacity (needed an 80°C forced-air oven and allow to incubate for 20 min.Also

for manual injections). place the 1-mL syringe into the oven to become equilibrated

7.8 Screw-cap vials, with polytetrafluoroethylene (PTFE)- with the standard vial. When the time has elapsed, remove the

faced septa, 20-mL capacity.

syringe using heat-resistant gloves. Remove the calibration

7.9 Volumetric pipets, various capacities.

standard vial and insert the sy

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.