ASTM D7716-11a

(Test Method)Standard Test Method for Determination of Residual Methanol in Glycerin by Gas Chromatography

Standard Test Method for Determination of Residual Methanol in Glycerin by Gas Chromatography

SIGNIFICANCE AND USE

Methanol content reflects the quality of glycerin for use as an engine coolant. The current specification for the maximum methanol content is 0.1 % weight to weight (w/w).

SCOPE

1.1 This test method provides for the quantitative determination of residual methanol in glycerin by gas chromatography. The range of detection for residual methanol is 0.02 to 0.60 mass %.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7716 − 11a

Standard Test Method for

Determination of Residual Methanol in Glycerin by Gas

1

Chromatography

This standard is issued under the fixed designation D7716; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method provides for the quantitative determi- 3.1 Definitions—This test method makes reference to many

nationofresidualmethanolinglycerinbygaschromatography. common gas chromatographic procedures, terms, and relation-

The range of detection for residual methanol is 0.02 to 0.60 ships. Detailed definitions can be found in Practices E355 and

mass %. E594.

1.2 The values stated in SI units are to be regarded as

4. Summary of Test Method

standard. No other units of measurement are included in this

4.1 The sample is analyzed by headspace gas chromatogra-

standard.

phy. Calibration is achieved by the use of external standards of

1.3 This standard does not purport to address all of the

methanol in water.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Significance and Use

priate safety, health, and environmental practices and deter-

5.1 Methanol content reflects the quality of glycerin for use

mine the applicability of regulatory limitations prior to use.

as an engine coolant. The current specification for the maxi-

1.4 This international standard was developed in accor-

mum methanol content is 0.1 % weight to weight (w/w).

dance with internationally recognized principles on standard-

6. Apparatus

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

6.1 Chromatographic System—See Practice E355 for spe-

mendations issued by the World Trade Organization Technical

cificdesignationsanddefinitions.Thegaschromatograph(GC)

Barriers to Trade (TBT) Committee.

system shall be capable of operating at the conditions given in

Table 1.

2. Referenced Documents

6.2 Autosampler system, Gerstel multipurpose sampler

2

2.1 ASTM Standards:

3

MPS-2 or equivalent. This method can also be run manually.

D1193 Specification for Reagent Water

6.3 Column, open tubular column with polyethylene glycol

D7640 Specification for Engine Coolant Grade Glycerin

(PEG) bonded and cross-linked phase internal coating. The

E177 Practice for Use of the Terms Precision and Bias in

column should have an upper temperature limit of 260°C. A

ASTM Test Methods

column 30 m in length, with an internal diameter of 0.32 mm,

E355 Practice for Gas Chromatography Terms and Relation-

and a 1.0-µm film thickness has been found satisfactory. Any

ships

column with equivalent or better chromatographic efficiency

E594 Practice for Testing Flame Ionization Detectors Used

and selectivity can be used.

in Gas or Supercritical Fluid Chromatography

E691 Practice for Conducting an Interlaboratory Study to

6.4 Electronic Data Acquisition System—A computer ca-

Determine the Precision of a Test Method

pable of providing real-time graphic and digital presentation of

the chromatographic data is recommended for use. Peak areas

and retention times shall be measured by computer or elec-

1

This test method is under the jurisdiction ofASTM Committee D15 on Engine

tronic integration (integrator).

Coolants and Related Fluids and is the direct responsibility of Subcommittee

D15.04 on Chemical Properties.

Current edition approved Oct. 1, 2011. Published November 2011. Originally

3

approved in 2011. Last previous edition approved in 2011 as D7716 – 11. DOI: The sole source of supply of the apparatus known to the committee at this time

10.1520/D7716-11A. is GERSTEL GmbH & Co.KG, Eberhard- Gerstel-Platz 1, 45473 Mülheim an der

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Ruhr, Germany. If you are aware of alternative suppliers, please provide this

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM information to ASTM International Headquarters. Your comments will receive

Standards volume information, refer to the standard’s Document Summary page on careful consideration at a meeting of the responsible technical committee, which

the ASTM website. you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

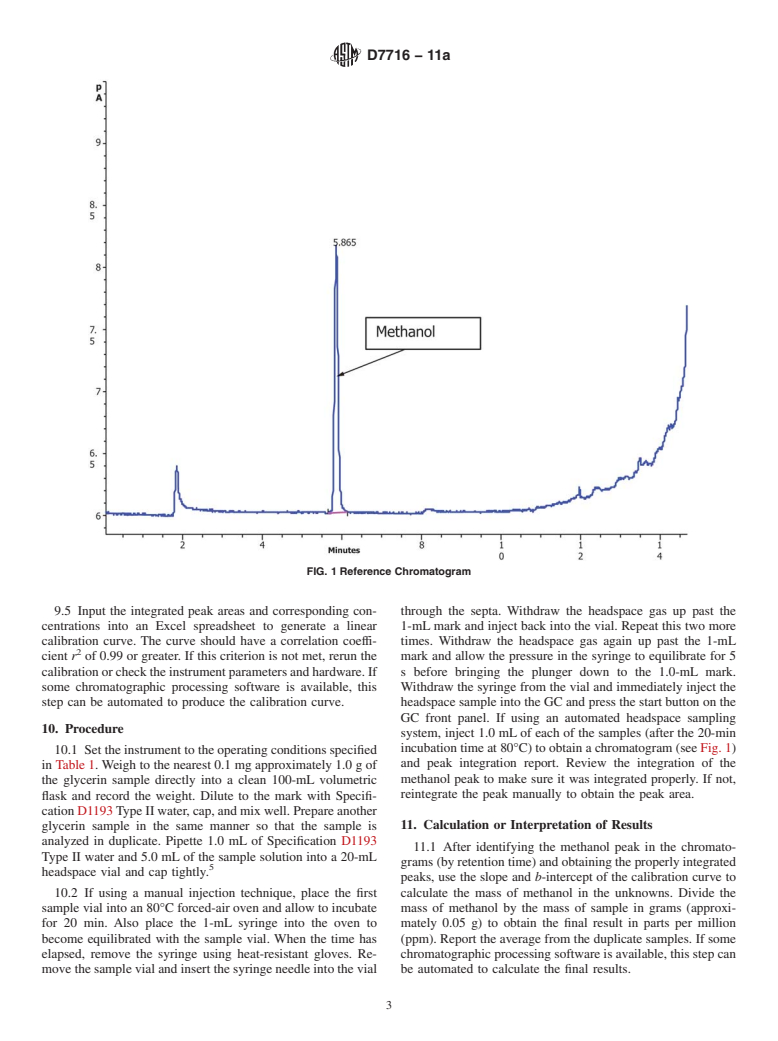

D7716 − 11a

TABLE 1 Operating Conditions

9. Calibration and Standardization

Injector: Hot split/splitless, 240°C, 10:1 split ratio

9.1 Preparation of Calibration Stock Standard—Prepare a

Sample Size: 1.0 mL

stock meth

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D7716–11 Designation:D7716–11a

Standard Test Method for

Determination of Residual Methanol in Glycerin by Gas

1

Chromatography

This standard is issued under the fixed designation D7716; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method provides for the quantitative determination of residual methanol in glycerin by gas chromatography. The

range of detection for residual methanol is 0.02 to 0.60 mass %.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D1193 Specification for Reagent Water

D7640 Specification for Engine Coolant Grade Glycerin

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E355 Practice for Gas Chromatography Terms and Relationships

E594 Practice for Testing Flame Ionization Detectors Used in Gas or Supercritical Fluid Chromatography Practice for Testing

Flame Ionization Detectors Used in Gas or Supercritical Fluid Chromatography

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Definitions—This test method makes reference to many common gas chromatographic procedures, terms, and relationships.

Detailed definitions can be found in Practices E355 and E594.

4. Summary of Test Method

4.1 The sample is analyzed by headspace gas chromatography. Calibration is achieved by the use of external standards of

methanol in water.

5. Significance and Use

5.1 Methanol content reflects the quality of glycerin for use as an engine coolant. The current specification for the maximum

methanol content is 0.1 % weight to weight (w/w).

6. Apparatus

6.1 Chromatographic System—SeePracticeE355forspecificdesignationsanddefinitions.Thegaschromatograph(GC)system

shall be capable of operating at the conditions given in Table 1.

3

6.2 Autosampler system, Gerstel multipurpose sampler MPS-2 or equivalent. This method can also be run manually.

6.3 Column, open tubular column with polyethylene glycol (PEG) bonded and cross-linked phase internal coating. The column

should have an upper temperature limit of 260°C. A column 30 m in length, with an internal diameter of 0.32 mm, and a 1.0-µm

1

This test method is under the jurisdiction ofASTM Committee D15 on Engine Coolants and Related Fluids and is the direct responsibility of Subcommittee D15.93 on

Research and Long Range Planning.

Current edition approved June 1, 2011. Published August 2011. DOI: 10.1520/D7716-11.

Current edition approved Oct. 1, 2011. Published November 2011. Originally approved in 2011. Last previous edition approved in 2011 as D7716 – 11. DOI:

10.1520/D7716-11A.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The sole source of supply of the apparatus known to the committee at this time is GERSTEL GmbH & Co.KG, Eberhard- Gerstel-Platz 1, 45473 Mülheim an der Ruhr,

Germany. If you are aware of alternative suppliers, please provide this information to ASTM International Headquarters. Your comments will receive careful consideration

at a meeting of the responsible technical committee, which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

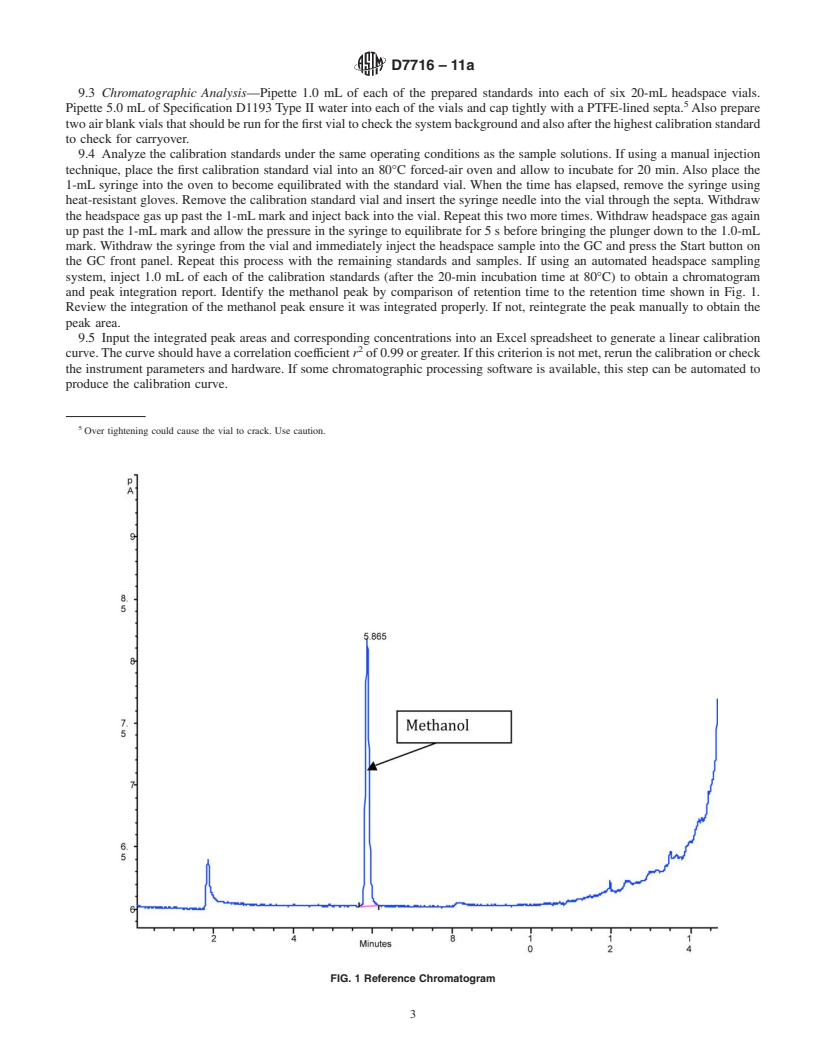

D7716–11a

TABLE 1 Operating Conditions

Injector: Hot split/splitless, 240°C, 10:1 split ratio

Sample Size: 1.0 mL

Column Temperature Program: Initial temperature: 50°C hold 8 min,

ramp at 20°C/min to 200°C, hold for 0 min

Detector: Flame ionization at 250°C

Carrier gas: helium or hydrogen, 1.5 mL/min

Vial incubation time: 20 min

Vial incubation temperature: 80°C

Agitator speed: 600 rpm

Injection speed: 200 µL/s

Pull-up delay: 5 s

film thickness has been found satisfactory. Any column wit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.