ASTM A370-02e1

(Test Method)Standard Test Methods and Definitions for Mechanical Testing of Steel Products

Standard Test Methods and Definitions for Mechanical Testing of Steel Products

SCOPE

1.1 These test methods cover procedures and definitions for the mechanical testing of wrought and cast steels, stainless steels, and related alloys. The various mechanical tests herein described are used to determine properties required in the product specifications. Variations in testing methods are to be avoided, and standard methods of testing are to be followed to obtain reproducible and comparable results. In those cases in which the testing requirements for certain products are unique or at variance with these general procedures, the product specification testing requirements shall control.

1.2 The following mechanical tests are described: SectionsTension 5 to 13Bend14Hardness15Brinell16Rockwell17Portable18Impact19 to 28Keywords29

1.3 Annexes covering details peculiar to certain products are appended to these test methods as follows: AnnexBar ProductsA1.1Tubular ProductsAnnex A2FastenersAnnex A3Round Wire ProductsAnnex A4Significance of Notched-Bar Impact TestingAnnex A5Converting Percentage Elongation of Round Specimens to Equivalents for Flat SpecimensAnnex A6Testing Multi-Wire StrandAnnex A7Rounding of Test DataAnnex A8Methods for Testing Steel Reinforcing BarsAnnex A9Procedure for Use and Control of Heat-Cycle SimulationAnnex A10

1.4 The values stated in inch-pound units are to be regarded as the standard.

1.5 When this document is referenced in a metric product specification, the yield and tensile values may be determined in inch-pound (ksi) units then converted into SI (MPa) units. The elongation determined in inch-pound gage lengths of 2 or 8 in. may be reported in SI unit gage lengths of 50 or 200 mm, respectively, as applicable. Conversely, when this document is referenced in an inch-pound product specification, the yield and tensile values may be determined in SI units then converted into inch-pound units. The elongation determined in SI unit gage lengths of 50 or 200 mm may be reported in inch-pound gage lengths of 2 or 8 in., respectively, as applicable.

1.6 Attention is directed to Practices A 880 and E 1595 when there may be a need for information on criteria for evaluation of testing laboratories.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: A 370 – 02

Standard Test Methods and Definitions for

1

Mechanical Testing of Steel Products

This standard is issued under the fixed designation A 370; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

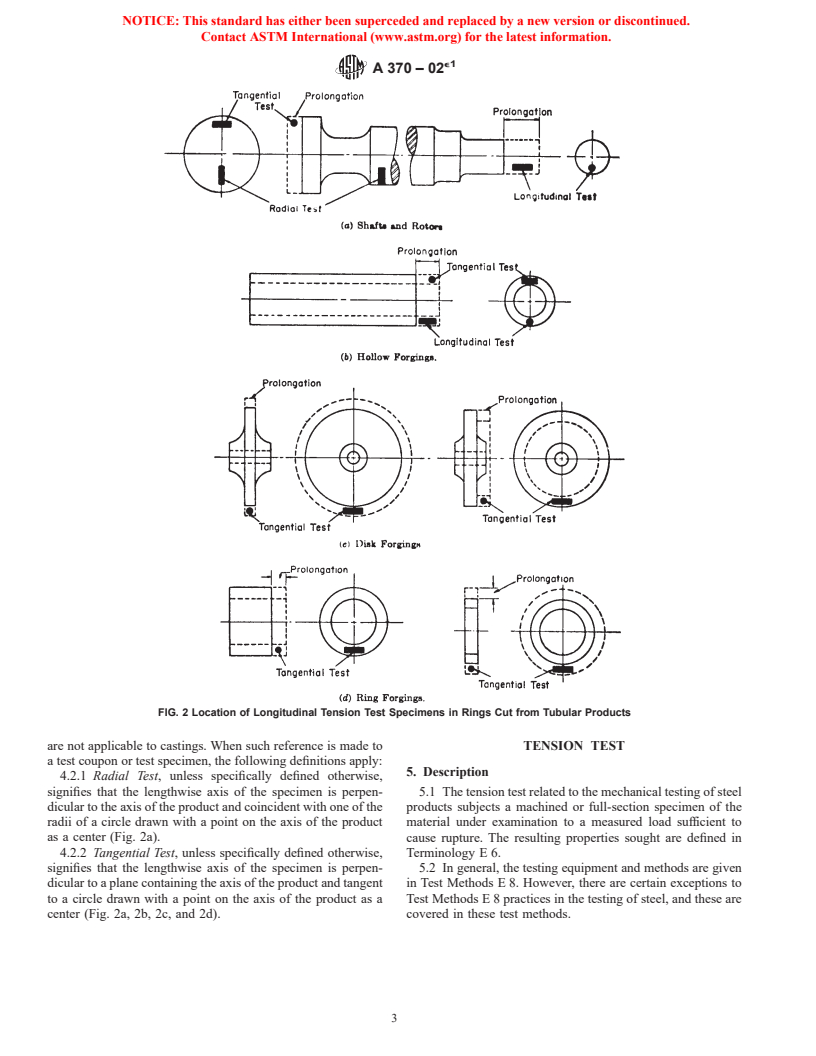

e NOTE—The title of Figure 3 was corrected editorially in August 2002.

1. Scope 1.5 When this document is referenced in a metric product

2

specification, the yield and tensile values may be determined in

1.1 These test methods cover procedures and definitions

inch-pound (ksi) units then converted into SI (MPa) units. The

for the mechanical testing of wrought and cast steels, stainless

elongation determined in inch-pound gage lengths of 2 or 8 in.

steels, and related alloys. The various mechanical tests herein

may be reported in SI unit gage lengths of 50 or 200 mm,

described are used to determine properties required in the

respectively, as applicable. Conversely, when this document is

product specifications. Variations in testing methods are to be

referenced in an inch-pound product specification, the yield

avoided, and standard methods of testing are to be followed to

and tensile values may be determined in SI units then con-

obtain reproducible and comparable results. In those cases in

verted into inch-pound units. The elongation determined in SI

which the testing requirements for certain products are unique

unit gage lengths of 50 or 200 mm may be reported in

or at variance with these general procedures, the product

inch-pound gage lengths of 2 or 8 in., respectively, as appli-

specification testing requirements shall control.

cable.

1.2 The following mechanical tests are described:

1.6 Attention is directed to Practices A 880 and E 1595

Sections

when there may be a need for information on criteria for

Tension 5 to 13

Bend 14

evaluation of testing laboratories.

Hardness 15

1.7 This standard does not purport to address all of the

Brinell 16

safety concerns, if any, associated with its use. It is the

Rockwell 17

Portable 18

responsibility of the user of this standard to establish appro-

Impact 19 to 28

priate safety and health practices and determine the applica-

Keywords 29

bility of regulatory limitations prior to use.

1.3 Annexes covering details peculiar to certain products

are appended to these test methods as follows: 2. Referenced Documents

Annex

2.1 ASTM Standards:

Bar Products A1.1

A 703/A 703M Specification for Steel Castings, General

Tubular Products Annex A2

3

Fasteners Annex A3 Requirements, for Pressure-Containing Parts

Round Wire Products Annex A4

A 781/A 781M Specification for Castings, Steel and Alloy,

Significance of Notched-Bar Impact Testing Annex A5

3

Common Requirements, for General Industrial Use

Converting Percentage Elongation of Round Specimens to Annex A6

Equivalents for Flat Specimens A 833 Practice for Indentation Hardness of Metallic Mate-

4

Testing Multi-Wire Strand Annex A7

rials by Comparison Hardness Testers

Rounding of Test Data Annex A8

A 880 Practice for Criteria for Use in Evaluation of Testing

Methods for Testing Steel Reinforcing Bars Annex A9

Laboratories and Organizations for Examination and In-

Procedure for Use and Control of Heat-Cycle Simulation Annex A10

5

spection of Steel, Stainless Steel, and Related Alloys

1.4 The values stated in inch-pound units are to be regarded

6

E 4 Practices for Force Verification of Testing Machines

as the standard.

E 6 Terminology Relating to Methods of Mechanical Test-

6

ing

6

E 8 Test Methods for Tension Testing of Metallic Materials

1

These test methods and definitions are under the jurisdiction of ASTM

Committee A01 on Steel, Stainless Steel and Related Alloys and are the direct

responsibility of Subcommittee A01.13 on Mechanical and Chemical Testing and

Processing Methods of Steel Products and Processes.

3

Current edition approved Jan. 10, 2002. Published March 2002. Originally Annual Book of ASTM Standards, Vol 01.02.

4

published as A 370 – 53 T. Last previous edition A 370 – 01. Annual Book of ASTM Standards, Vol 01.05.

2 5

For ASME Boiler and Pressure Vessel Code applications see related Specifi- Annual Book of ASTM Standards, Vol 01.03.

6

cation SA-370 in Section II of that Code. Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.