ASTM A1088-13(2019)

(Specification)Standard Specification for Steel, Sheet, Cold-Rolled, Complex Phase (CP), Dual Phase (DP) and Transformation Induced Plasticity (TRIP)

Standard Specification for Steel, Sheet, Cold-Rolled, Complex Phase (CP), Dual Phase (DP) and Transformation Induced Plasticity (TRIP)

ABSTRACT

This specification is intended for cold-rolled, complex phase (CP) grade, dual phase (DP) grade, and transformation induced plasticity (TRIP) grade steel sheet in coils and cut lengths. Cold-rolled steel sheet is supplied for either exposed or unexposed applications, and specified either ”temper rolled” or ”annealed last” in the case of the latter category. The specification covers ordering information necessary to describe the required material, as well as the material's chemical composition, mechanical properties, finish and appearance, and dimensions and permissible variations. Retests and disposition of non-conforming material are also addressed.

SCOPE

1.1 This specification covers cold-rolled, complex phase (CP) grade, dual phase (DP) grade, and transformation induced plasticity (TRIP) grade steel sheet in coils and cut lengths.

1.2 Product furnished under this specification shall conform to the applicable requirements of the latest issue of Specification A568/A568M, unless otherwise provided herein.

1.3 The product is available in a number of designations and grades with mandatory chemical requirements and mandatory mechanical properties that are achieved through thermal or thermal-mechanical treatments, and are designed to be compatible with automotive application requirements.

1.4 The grade designation nomenclature of the product differs from other cold-rolled sheet products having mandatory mechanical properties in that ordering is to tensile, rather than yield strength values.

1.5 The text of this specification references notes and footnotes that provide explanatory material. These notes and footnotes, excluding those in tables and figures, shall not be considered as requirements of this specification.

1.6 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: A1088 −13 (Reapproved 2019)

Standard Specification for

Steel, Sheet, Cold-Rolled, Complex Phase (CP), Dual Phase

(DP) and Transformation Induced Plasticity (TRIP)

This standard is issued under the fixed designation A1088; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This specification covers cold-rolled, complex phase 2.1 ASTM Standards:

(CP) grade, dual phase (DP) grade, and transformation induced A370 Test Methods and Definitions for Mechanical Testing

plasticity (TRIP) grade steel sheet in coils and cut lengths. of Steel Products

A568/A568M Specification for Steel, Sheet, Carbon,

1.2 Product furnished under this specification shall conform

Structural,andHigh-Strength,Low-Alloy,Hot-Rolledand

to the applicable requirements of the latest issue of Specifica-

Cold-Rolled, General Requirements for

tion A568/A568M, unless otherwise provided herein.

A941 TerminologyRelatingtoSteel,StainlessSteel,Related

1.3 Theproductisavailableinanumberofdesignationsand

Alloys, and Ferroalloys

grades with mandatory chemical requirements and mandatory

E646 Test Method for Tensile Strain-Hardening Exponents

mechanical properties that are achieved through thermal or

(n -Values) of Metallic Sheet Materials

thermal-mechanical treatments, and are designed to be com-

patible with automotive application requirements.

3. Terminology

1.4 The grade designation nomenclature of the product

3.1 Definitions—See Terminology A941 for definitions of

differs from other cold-rolled sheet products having mandatory

generalterminologyrelatingtocold-rolledsteelsheetproducts.

mechanical properties in that ordering is to tensile, rather than

3.2 Definitions:

yield strength values.

3.2.1 complex phase (CP) steel, n—steel sheet with a

1.5 The text of this specification references notes and

ferritic/bainitic matrix containing small amounts of retained

footnotes that provide explanatory material. These notes and

austenite or pearlite, or both where significant grain refinement

footnotes, excluding those in tables and figures, shall not be

iscausedbyretardedcrystallizationorprecipitationofmicroal-

considered as requirements of this specification.

loying elements.

1.6 The values stated in SI units are to be regarded as

3.2.2 dual phase (DP) steel, n—steel sheet with a ferritic

standard. No other units of measurement are included in this

matrix containing a martensitic phase present in the form of

standard.

islands.

1.7 This standard does not purport to address all of the

3.2.3 transformation induced plasticity (TRIP) steel,

safety concerns, if any, associated with its use. It is the

n—steel sheet with a mainly ferritic matrix containing retained

responsibility of the user of this standard to establish appro-

austenite where, during the forming process, retained austenite

priate safety, health, and environmental practices and deter-

can transform to martensite.

mine the applicability of regulatory limitations prior to use.

1.8 This international standard was developed in accor- 4. Classification

dance with internationally recognized principles on standard-

4.1 The material is available in several designations and

ization established in the Decision on Principles for the

grades as follows:

Development of International Standards, Guides and Recom-

4.1.1 Complex phase (CP) steel (Grades 600T/350Y, 780T/

mendations issued by the World Trade Organization Technical

500Y, and 980T/700Y),

Barriers to Trade (TBT) Committee.

4.1.2 Dual phase (DP) steel (Grades 440T/250Y, 490T/

290Y, 590T/340Y, 780T/420Y, and 980T/550Y), and

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

A01.19 on Steel Sheet and Strip. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2019. Published November 2019. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2013. Last previous edition approved in 2013 as A1088 – 13. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/A1088-13R19. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A1088 − 13 (2019)

1200 mm by coil, 1520 mm maximum OD, 600 mm ID, 10 000 kg

4.1.3 Transformation induced plasticity (TRIP) steel

maximum, for side reinforcement strut.

(Grades 690T/410Y and 780T/440Y).

4.2 Cold-rolled steel sheet is supplied for either exposed or

6. Chemical Composition

unexposed applications. Within the latter category, cold-rolled

6.1 The heat analysis of the steel shall conform to the

sheet is specified either “temper rolled” or “annealed last.” For

requirements shown in Table 1.

details on processing, attributes and limitations, and inspection

6.2 Each of the elements listed in Table 1 shall be included

standards, refer to Specification A568/A568M.

in the report of heat analysis, including each element in

5. Ordering Information

columns with grouped elements. When the amount of copper,

nickel, chromium, or molybdenum is less than 0.02 %, report

5.1 It is the purchaser’s responsibility to specify in the

the analysis as either <0.02 % or the actual determined value.

purchase order all ordering information necessary to describe

When the amount of vanadium, titanium, or niobium is less

the required material. Examples of such information include,

than 0.008 %, report the analysis as either <0.008 % or the

but are not limited to, the following:

actual determined value.

5.1.1 ASTM specification number and year of issue;

5.1.2 Name of product (steel sheet, cold-rolled);

NOTE 3—Niobium is also known as Columbium.

5.1.3 Designation of sheet [CP (Grades 600T/350Y, 780T/

6.2.1 See Specification A568/A568M for chemical analy-

500Y, or 980T/700Y), DP (Grades 440T/250Y, 490T/290Y,

sis procedures and product analysis tolerances.

590T/340Y, 780T/420Y, or 980T/550Y), or TRIP (Grades

690T/410Y or 780T/440Y)];

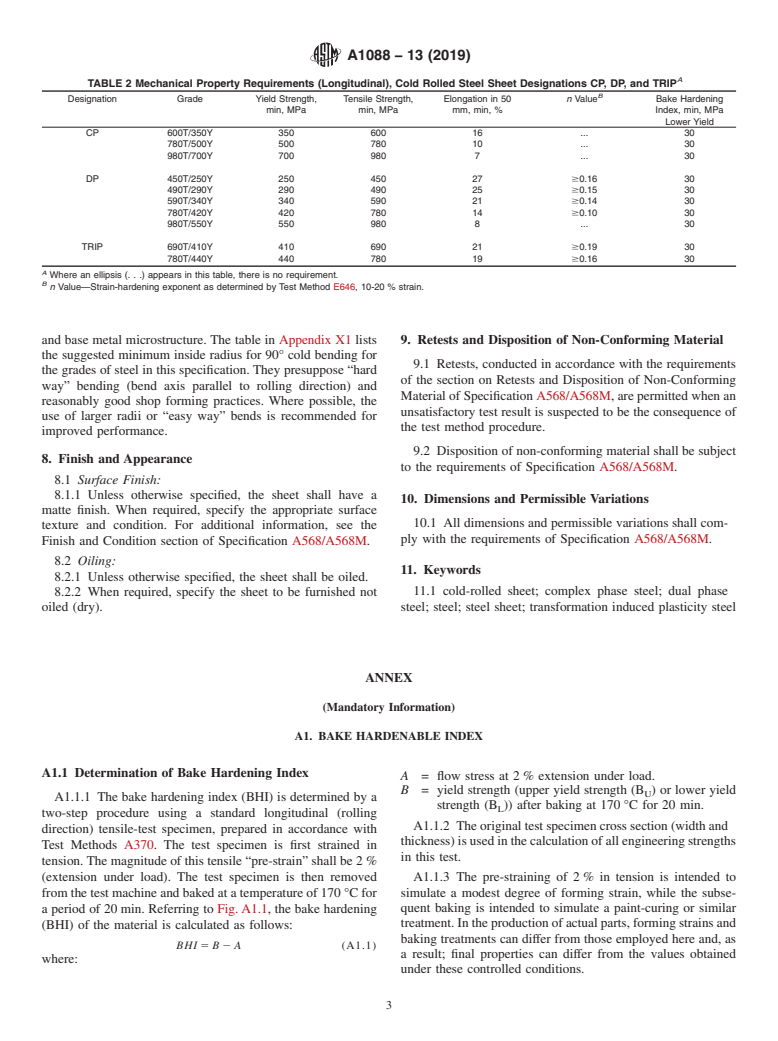

7. Mechanical Properties

5.1.4 Finish (see 8.1);

7.1 All designations and grades shall conform to the

5.1.5 Oiled or not oiled (see 8.2);

mechanical property requirements in Table 2.

5.1.6 Dimensions (show thickness, minimum or nominal,

7.1.1 All designations and grades shall conform to bake

width, flatness requirements, and length, (if cut lengths));

hardening index requirements included in Table 2. The mini-

NOTE 1—Not all producers are capable of meeting all the limitations of

mum increase in yield strength is based on the lower yield

the thickness tolerance tables in Specification A568/A568M. The pur-

stress, after a prestrained specimen has been exposed to a

chaser should contact the producer regarding possible limitations prior to

standard bake cycle of 170 °C for 20 min. The method for

placing an order.

measuring the bake hardening index is described in the Annex

5.1.7 Coil size requirements (specify maximum outside

A1.

diameter (OD), acceptable inside diameter (ID), and maximum

7.2 Mechanical property tests shall be conducted in accor-

mass);

dance with the methods specified in Specification A568/

5.1.8 Quantity;

A568M, or those prescribed by the purchaser.

5.1.9 Packaging;

5.1.10 Certification, if required, heat analysis and mechani-

7.3 Bending Properties Minimum Cold Bending Radi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.