ASTM A370-19

(Test Method)Standard Test Methods and Definitions for Mechanical Testing of Steel Products

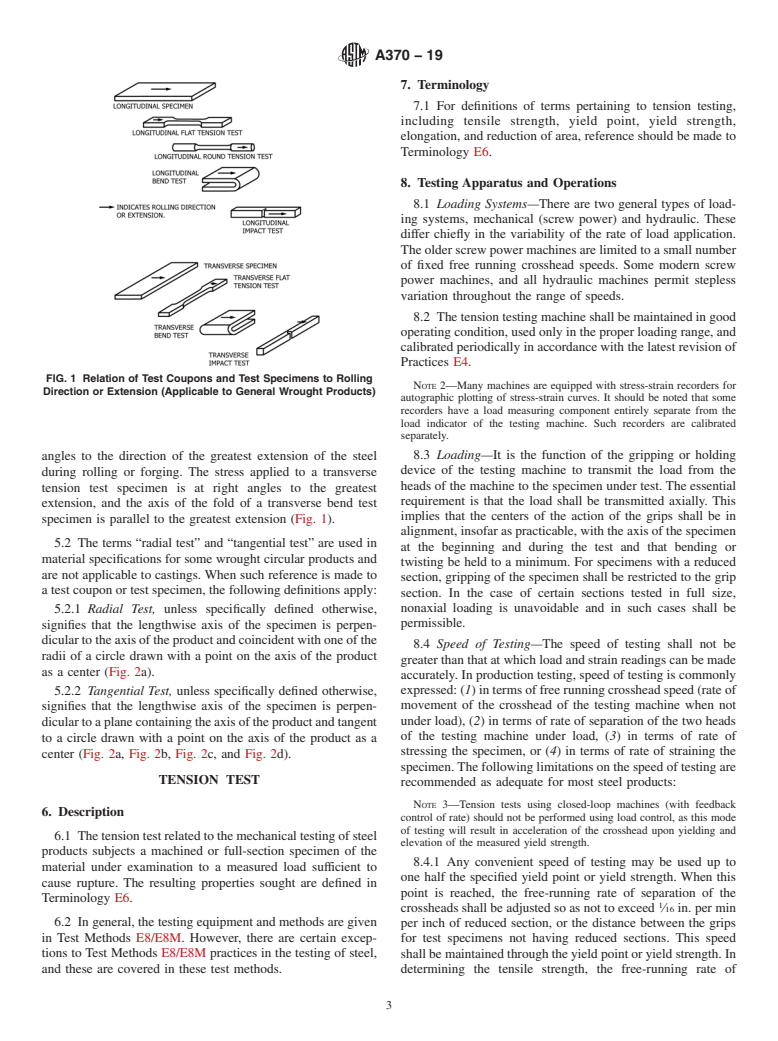

Standard Test Methods and Definitions for Mechanical Testing of Steel Products

SIGNIFICANCE AND USE

3.1 The primary use of these test methods is testing to determine the specified mechanical properties of steel, stainless steel, and related alloy products for the evaluation of conformance of such products to a material specification under the jurisdiction of ASTM Committee A01 and its subcommittees as designated by a purchaser in a purchase order or contract.

3.1.1 These test methods may be and are used by other ASTM Committees and other standards writing bodies for the purpose of conformance testing.

3.1.2 The material condition at the time of testing, sampling frequency, specimen location and orientation, reporting requirements, and other test parameters are contained in the pertinent material specification or in a General Requirement Specification for the particular product form.

3.1.3 Some material specifications require the use of additional test methods not described herein; in such cases, the required test method is described in that material specification or by reference to another appropriate test method standard.

3.2 These test methods are also suitable to be used for testing of steel, stainless steel and related alloy materials for other purposes, such as incoming material acceptance testing by the purchaser or evaluation of components after service exposure.

3.2.1 As with any mechanical testing, deviations from either specification limits or expected as-manufactured properties can occur for valid reasons besides deficiency of the original as-fabricated product. These reasons include, but are not limited to: subsequent service degradation from environmental exposure (for example, temperature, corrosion); static or cyclic service stress effects, mechanically-induced damage, material inhomogeneity, anisotropic structure, natural aging of select alloys, further processing not included in the specification, sampling limitations, and measuring equipment calibration uncertainty. There is statistical variation in all aspects of mechanical testin...

SCOPE

1.1 These test methods2 cover procedures and definitions for the mechanical testing of steels, stainless steels, and related alloys. The various mechanical tests herein described are used to determine properties required in the product specifications. Variations in testing methods are to be avoided, and standard methods of testing are to be followed to obtain reproducible and comparable results. In those cases in which the testing requirements for certain products are unique or at variance with these general procedures, the product specification testing requirements shall control.

1.2 The following mechanical tests are described:

Sections

Tension

6 to 14

Bend

15

Hardness

16

Brinell

17

Rockwell

18

Portable

19

Impact

20 to 30

Keywords

32

1.3 Annexes covering details peculiar to certain products are appended to these test methods as follows:

Annex

Bar Products

Annex A1

Tubular Products

Annex A2

Fasteners

Annex A3

Round Wire Products

Annex A4

Significance of Notched-Bar Impact Testing

Annex A5

Converting Percentage Elongation of Round Specimens to

Equivalents for Flat Specimens

Annex A6

Testing Multi-Wire Strand

Annex A7

Rounding of Test Data

Annex A8

Methods for Testing Steel Reinforcing Bars

Annex A9

Procedure for Use and Control of Heat-Cycle Simulation

Annex A10

1.4 The values stated in inch-pound units are to be regarded as the standard.

1.5 When this document is referenced in a metric product specification, the yield and tensile values may be determined in inch-pound (ksi) units then converted into SI (MPa) units. The elongation determined in inch-pound gauge lengths of 2 or 8 in. may be reported in SI unit gauge lengths of 50 or 200 mm, respectively, as applicable. Conversely, when this document is referenced in an inch-pound product specific...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A370 −19

Standard Test Methods and Definitions for

1

Mechanical Testing of Steel Products

This standard is issued under the fixed designation A370; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 1.5 When this document is referenced in a metric product

2 specification,theyieldandtensilevaluesmaybedeterminedin

1.1 These test methods cover procedures and definitions

inch-pound (ksi) units then converted into SI (MPa) units.The

forthemechanicaltestingofsteels,stainlesssteels,andrelated

elongation determined in inch-pound gauge lengths of 2 or

alloys. The various mechanical tests herein described are used

8in.maybereportedinSIunitgaugelengthsof50or200mm,

to determine properties required in the product specifications.

respectively, as applicable. Conversely, when this document is

Variations in testing methods are to be avoided, and standard

referenced in an inch-pound product specification, the yield

methods of testing are to be followed to obtain reproducible

and tensile values may be determined in SI units then con-

and comparable results. In those cases in which the testing

verted into inch-pound units. The elongation determined in SI

requirementsforcertainproductsareuniqueoratvariancewith

unit gauge lengths of 50 or 200 mm may be reported in

these general procedures, the product specification testing

inch-pound gauge lengths of 2 or 8in., respectively, as

requirements shall control.

applicable.

1.2 The following mechanical tests are described:

1.5.1 The specimen used to determine the original units

Sections

must conform to the applicable tolerances of the original unit

Tension 6 to 14

system given in the dimension table not that of the converted

Bend 15

Hardness 16 tolerance dimensions.

Brinell 17

Rockwell 18 NOTE 1—This is due to the specimen SI dimensions and tolerances

Portable 19 being hard conversions when this is not a dual standard. The user is

Impact 20 to 30

directed to Test Methods A1058 if the tests are required in SI units.

Keywords 32

1.6 Attention is directed to ISO/IEC 17025 when there may

1.3 Annexes covering details peculiar to certain products

be a need for information on criteria for evaluation of testing

are appended to these test methods as follows:

laboratories.

Annex

1.7 This standard does not purport to address all of the

Bar Products Annex A1

Tubular Products Annex A2

safety concerns, if any, associated with its use. It is the

Fasteners Annex A3

responsibility of the user of this standard to establish appro-

Round Wire Products Annex A4

priate safety, health, and environmental practices and deter-

Significance of Notched-Bar Impact Testing Annex A5

Converting Percentage Elongation of Round Specimens to Annex A6

mine the applicability of regulatory limitations prior to use.

Equivalents for Flat Specimens

1.8 This international standard was developed in accor-

Testing Multi-Wire Strand Annex A7

dance with internationally recognized principles on standard-

Rounding of Test Data Annex A8

Methods for Testing Steel Reinforcing Bars Annex A9

ization established in the Decision on Principles for the

Procedure for Use and Control of Heat-Cycle Simulation Annex A10

Development of International Standards, Guides and Recom-

1.4 The values stated in inch-pound units are to be regarded

mendations issued by the World Trade Organization Technical

as the standard.

Barriers to Trade (TBT) Committee.

2. Referenced Documents

3

1 2.1 ASTM Standards:

These test methods and definitions are under the jurisdiction of ASTM

Committee A01 on Steel, Stainless Steel and Related Alloys and are the direct A623Specification for Tin Mill Products, General Require-

responsibility of Subcommittee A01.13 on Mechanical and Chemical Testing and

ments

Processing Methods of Steel Products and Processes.

CurrenteditionapprovedJuly1,2019.PublishedJuly2019.Originallyapproved

3

in 1953. Last previous edition approved in 2018 as A370–18. DOI: 10.1520/ For referenced ASTM standards, visit the ASTM website, www.astm.org, or

A0370-19. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

For ASME Boiler and Pressure Vessel Code applications see related Specifi- Standards volume information, refer to the standard’s Document Summary page on

cation SA-370 in Section II of that Code. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Pa

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A370 − 18 A370 − 19

Standard Test Methods and Definitions for

1

Mechanical Testing of Steel Products

This standard is issued under the fixed designation A370; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

2

1.1 These test methods cover procedures and definitions for the mechanical testing of steels, stainless steels, and related alloys.

The various mechanical tests herein described are used to determine properties required in the product specifications. Variations

in testing methods are to be avoided, and standard methods of testing are to be followed to obtain reproducible and comparable

results. In those cases in which the testing requirements for certain products are unique or at variance with these general

procedures, the product specification testing requirements shall control.

1.2 The following mechanical tests are described:

Sections

Tension 6 to 14

Bend 15

Hardness 16

Brinell 17

Rockwell 18

Portable 19

Impact 20 to 30

Keywords 32

1.3 Annexes covering details peculiar to certain products are appended to these test methods as follows:

Annex

Bar Products Annex A1

Tubular Products Annex A2

Fasteners Annex A3

Round Wire Products Annex A4

Significance of Notched-Bar Impact Testing Annex A5

Converting Percentage Elongation of Round Specimens to Annex A6

Equivalents for Flat Specimens

Testing Multi-Wire Strand Annex A7

Rounding of Test Data Annex A8

Methods for Testing Steel Reinforcing Bars Annex A9

Procedure for Use and Control of Heat-Cycle Simulation Annex A10

1.4 The values stated in inch-pound units are to be regarded as the standard.

1.5 When this document is referenced in a metric product specification, the yield and tensile values may be determined in

inch-pound (ksi) units then converted into SI (MPa) units. The elongation determined in inch-pound gauge lengths of 2 or 8 in.

may be reported in SI unit gauge lengths of 50 or 200 mm, respectively, as applicable. Conversely, when this document is

referenced in an inch-pound product specification, the yield and tensile values may be determined in SI units then converted into

inch-pound units. The elongation determined in SI unit gauge lengths of 50 or 200 mm may be reported in inch-pound gauge

lengths of 2 or 8 in., respectively, as applicable.

1.5.1 The specimen used to determine the original units must conform to the applicable tolerances of the original unit system

given in the dimension table not that of the converted tolerance dimensions.

NOTE 1—This is due to the specimen SI dimensions and tolerances being hard conversions when this is not a dual standard. The user is directed to

Test Methods A1058 if the tests are required in SI units.

1

These test methods and definitions are under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and are the direct responsibility of

Subcommittee A01.13 on Mechanical and Chemical Testing and Processing Methods of Steel Products and Processes.

Current edition approved Dec. 1, 2018July 1, 2019. Published January 2019July 2019. Originally approved in 1953. Last previous edition approved in 20172018 as

A370 – 17a.A370 – 18. DOI: 10.1520/A0370-18.10.1520/A0370-19.

2

For ASME Boiler and Pressure Vessel Code applications see related Specification SA-370 in Section II of that Code.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

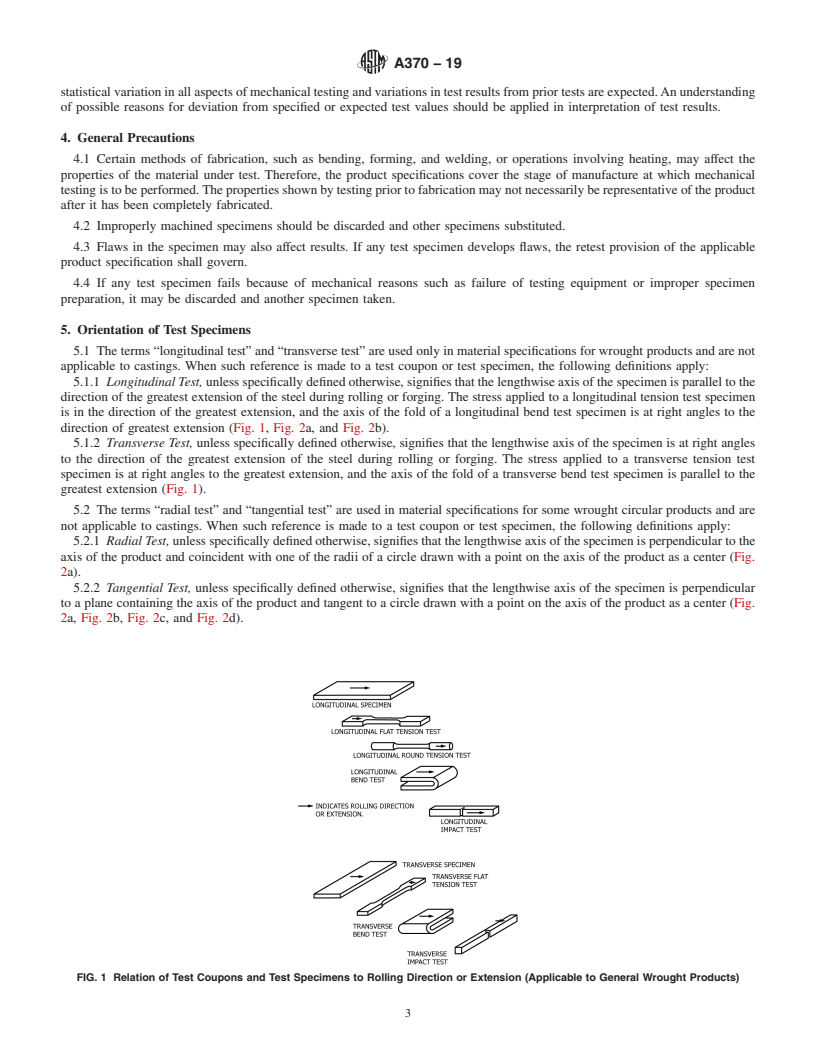

A370 − 19

1.6 Attention is directed to ISO/IEC 17025 when there may be a need for information on criteria for evaluation of testing

laboratories.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.