ASTM F2913-11

(Test Method)Standard Test Method for Measuring the Coefficient of Friction for Evaluation of Slip Performance of Footwear and Test Surfaces/Flooring Using a Whole Shoe Tester

Standard Test Method for Measuring the Coefficient of Friction for Evaluation of Slip Performance of Footwear and Test Surfaces/Flooring Using a Whole Shoe Tester

SIGNIFICANCE AND USE

This non-proprietary laboratory test method allows preliminarily for the reproducible testing of whole footwear and footwear-related soling materials for evaluating relative slip performance. Other ASTM test methods generally employ a standardized test foot primarily for evaluation of flooring materials.

FIG. 1 Example of Footwear Mounted Using 7° Wedge to Set Proper Contact Angle

SCOPE

1.1 This test method determines the dynamic coefficient of friction between footwear and floorings under reproducible laboratory conditions for evaluating relative slip performance. The method is applicable to all types of footwear, outsole units, heel top-pieces (top-lifts) and sheet soling materials, also to most types of indoor floorings, including matting and stair nosing, and surface contaminants on the flooring surface, including but not limited to liquid water, ice, oil and grease. The method may also be applied to surfaces such as block pavers, turf and gravel.

1.2 Special purpose footwear or fittings containing spikes, metal studs or similar may be tested on appropriate surfaces but the method does not fully take account of the risk of tripping due to footwear/ground interlock.

1.3 The values stated in the ASTM test method in metrics are to be regarded as the standard. The values in parentheses are for information.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2913 − 11

Standard Test Method for

Measuring the Coefficient of Friction for Evaluation of Slip

Performance of Footwear and Test Surfaces/Flooring Using

a Whole Shoe Tester

This standard is issued under the fixed designation F2913; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 Other References:

2 BS EN ISO 4287 Geometrical product specification (GPS).

1.1 This test method determines the dynamic coefficient of

Surface texture: Profile method. Terms, definitions and

friction between footwear and floorings under reproducible

surface texture parameters

laboratory conditions for evaluating relative slip performance.

EN 10088-2 Stainless steels - Part 2: Technical delivery

Themethodisapplicabletoalltypesoffootwear,outsoleunits,

conditions for sheet/plate and strip of corrosion resisting

heel top-pieces (top-lifts) and sheet soling materials, also to

steels for general purposes

most types of indoor floorings, including matting and stair

nosing, and surface contaminants on the flooring surface,

3. Terminology

including but not limited to liquid water, ice, oil and grease.

3.1 For general definitions of terms, refer to the Terminol-

The method may also be applied to surfaces such as block

ogy F1646.

pavers, turf and gravel.

3.2 Definitions:

1.2 Special purpose footwear or fittings containing spikes,

3.2.1 slider—a76 6 1 mm circular test specimen cut from

metalstudsorsimilarmaybetestedonappropriatesurfacesbut

sheet material.

the method does not fully take account of the risk of tripping

3.2.1.1 Discussion—Should a shape and or size of slider

due to footwear/ground interlock.

other than a 76 mm circular shape be used, it shall be

1.3 The values stated in the ASTM test method in metrics

documented within the test report (see 14.1.2.1).

are to be regarded as the standard. The values in parentheses

3.2.2 slider 96—a pre-described rectangular test specimen

are for information.

intended for use in calibration of the test surface (see 10.6.1).

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Summary of Test Method

responsibility of the user of this standard to establish appro-

4.1 The footwear item and underfoot surface are brought

priate safety and health practices and determine the applica-

into contact, subjected to a specified vertical force for a short

bility of regulatory limitations prior to use.

period of static contact then moved horizontally relative to one

another at a constant speed. The horizontal frictional force is

2. Referenced Documents

measured at a given time after movement starts and the

2.1 ASTM Standards:

dynamic coefficient of friction is calculated for the particular

F1646 Terminology Relating to Safety and Traction for

conditions of the test.

Footwear

5. Significance and Use

5.1 This non-proprietary laboratory test method allows pre-

liminarily for the reproducible testing of whole footwear and

This test method is under the jurisdiction of ASTM Committee F13 on

Pedestrian/Walkway Safety and Footwear and is the direct responsibility of

footwear-related soling materials for evaluating relative slip

Subcommittee F13.30 on Footwear.

performance. Other ASTM test methods generally employ a

Current edition approved Nov. 1, 2011. Published December 2011. DOI:

standardized test foot primarily for evaluation of flooring

10.1520/F2913-11.

This standard is derived from SATRA TM144, Friction {Slip Resistance} of materials.

Footwear and Floorings, copyright SATRA Technology Centre, Kettering

Northamptonshire, NN16 8SD, United Kingdom.

3 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from British Standards Institution (BSI), 389 Chiswick High Rd.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM London W4 4AL, U.K., http://www.bsigroup.com.

Standards volume information, refer to the standard’s Document Summary page on Available from European Committee for Standardization (CEN), Avenue

the ASTM website. Marnix 17, B-1000, Brussels, Belgium, http://www.cen.eu.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2913 − 11

TABLE 1 Vertical Load to be Applied in Slip Test Run

Full Load

to be

Footwear Item

Applied

(N)

Footwear and finished soles of size US size 7.5 men’s and 8.5 500±25

women’s, (Paris Points 40) (UK size 6.5) and above

Footwear and finished soles of sizes below US size 7.5 men’s 400±20

and 8,5 women’s (Paris Points 40) (UK size 6.5)

Top-pieces and sole materials intended for men’s footwear 500 ± 25

Top-pieces and sole materials intended for women’s, children’s 400±20

and infant’s footwear

FIG. 1 Example of Footwear Mounted Using 7° Wedge to Set

Proper Contact Angle

6.9 A means of sliding the test surface relative to the

footwear, sole unit or slider at a speed of 0.3 6 0.03 m/s

6. Apparatus

commencing within 0.2 s after a vertical load of 50 N is

6,7

6.1 Slip tester capable of performing the required test.

achieved. Sliding shall not start until full vertical force is

achieved, see Fig. 2. The footwear test specimen may be

6.2 Ameansofconditioningthetestspecimensandstandard

constrained while the test floor is moved relative to it, or vice

reference materials, prior to the test, against which the speci-

versa.

mens are to be tested, at 23 6 2°C and 50 6 5% RH relative

humidity and carrying out the test at 23 6 2°C.

6.10 Ameans of measuring time with a resolution of 0.01 s

(graph should have tick marks every 0.01 s) or better.

6.3 Ameans of securely mounting the footwear, outsoles or

slider.

6.11 A means of measuring:

6.11.1 The continuous vertical force exerted on the test

6.4 Aflat rigid horizontal surface mount of minimum width

specimen, with an accuracy of2%or better.

150 mm and minimum length 450 mm, to which the test

6.11.2 The continuous horizontal frictional force, with an

underfoot surface, hereafter termed the test surface, shall be

accuracy of2%or better, exerted on the test specimen

securely mounted.

measured in the plane of the surface of the test surface.

NOTE 1—A device may be used to entrap lubricant within the

footwear/surfacecontactareatoensurethattherequireddepthoflubricant

6.11.3 The displacement of the moving item, test surface or

is maintained.

footwear, sole unit or slider, to the nearest 1 mm.

6.5 Ameansofholdingthefootwear,soleunitorsliderclear

6.12 The apparatus comprising elements 6.2 – 6.10 shall be

of the test surface between test measurements without contact

sufficiently rugged to prevent vibration.

with any other surfaces.

6.6 A means of adjusting the angle between the footwear, 7. Hazards

sole unit or slider and the test surface so that the required

7.1 Care should be used when working with mechanical

contact angle can be achieved, and a means of adjusting the

equipment. Attention to be given to preventing a pinch hazard

contact point horizontally with respect to the line of action of

while in operation.

the vertical force when required.

8. Sampling and Test Specimens

6.7 Arigid wedge of minimum dimensions 80 mm wide by

120 mm long shall be used to set the contact angle of 7.0 6

8.1 For footwear items (footwear, sole units or slider), see

0.5°betweenfootwear,soleunitorsliderandtestsurfacewhen

10.10.

required.Fig. 1

NOTE 2—The term slider refers to sample of soling material generally

cut from a larger sample so to fit the apparatus. Such as a piece of soling

6.8 A mechanism for lowering the footwear, sole unit or

material or heel toplift, which is sold in sheets and cut to size as needed

slider onto the test surface and applying a steadily increasing

for use in footwear.

downward force, including the weight of the test specimen and

8.2 For test surfaces, see 10.3 and 10.4; for contaminants/

its mounting, at a rate that enables the required full force—

lubricants, see 10.5.

either 400 6 20 N or 500 6 25 N (see Table 1) to be achieved

NOTE 3—Either the footwear item or the test surface may be the subject

within 0.2 s of reaching 50 N.

of the test.Appropriate flooring items and footwear items respectively are

selected as the reference materials against which the test item is to be

tested.

The sole source of supply of the slip tester (STM603) known to the committee

9. Preparation of Apparatus, Test Specimens and Test

atthistimeisSATRATechnologyCentre,Kettering,Northamptonshire,NN168SD,

United Kingdom. Surfaces

If you are aware of alternative suppliers, please provide this information to

9.1 Prepare and condition standard reference materials (test

ASTM International Headquarters. Your comments will receive careful consider-

ation at a meeting of the responsible technical committee, which you may attend. surfaces and/or test sliders) according to 10.7.

F2913 − 11

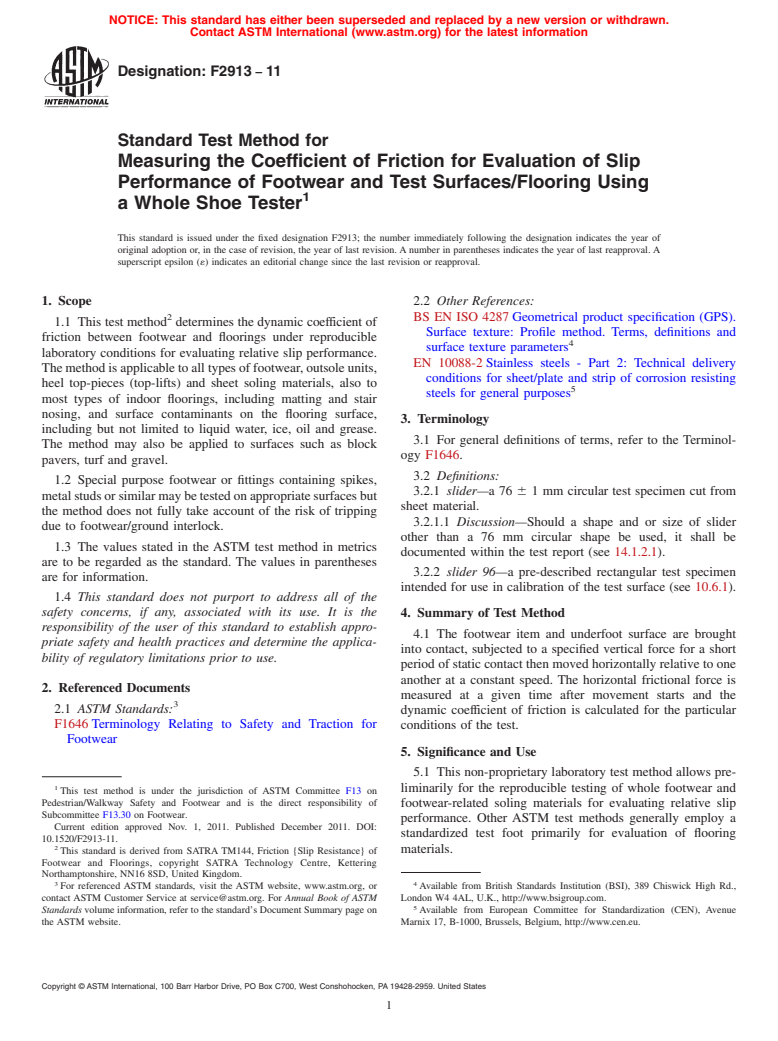

Key:

A – 50 N reached

B – Full force achieved and relative movement started within 0.2 s after ‘A’

C – Snapshot value of horizontal force taken at (0.1 6 0.01) s after the start of sliding movement

D – Snapshot value of vertical force taken at (0.1 6 0.01) s after the start of sliding movement

FIG. 2 Test Chart Showing Sequence of Events in a Typical Test Run

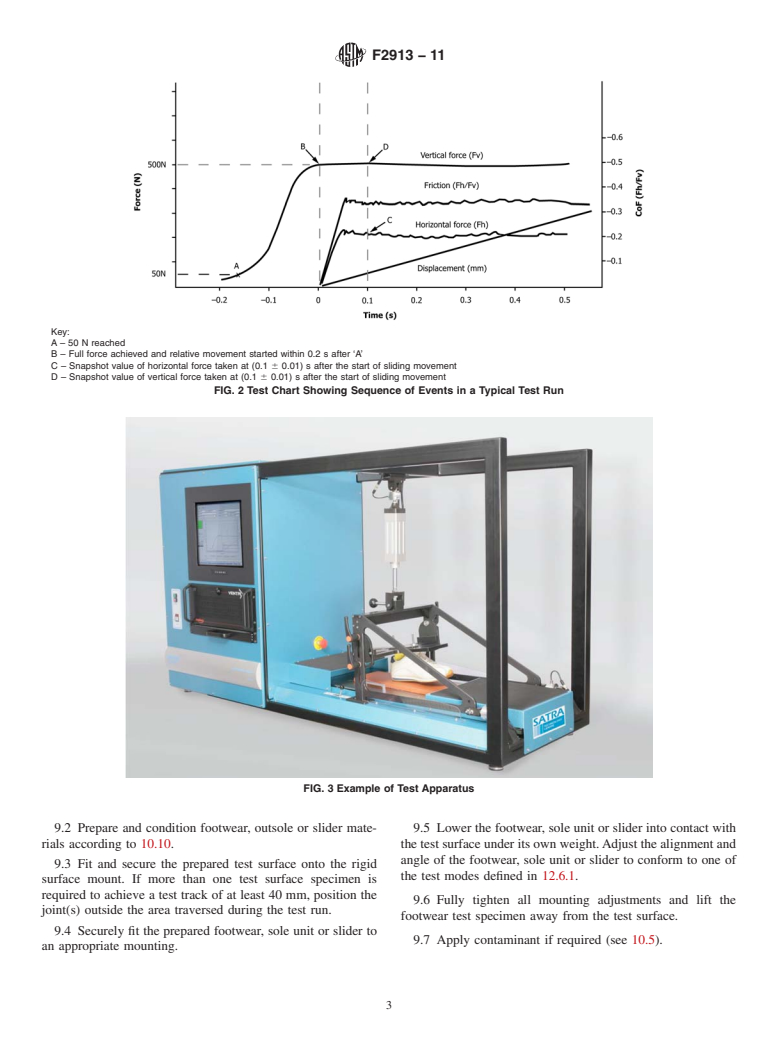

FIG. 3 Example of Test Apparatus

9.2 Prepare and condition footwear, outsole or slider mate- 9.5 Lower the footwear, sole unit or slider into contact with

rials according to 10.10. the test surface under its own weight.Adjust the alignment and

angle of the footwear, sole unit or slider to conform to one of

9.3 Fit and secure the prepared test surface onto the rigid

the test modes defined in 12.6.1.

surface mount. If more than one test surface specimen is

required to achieve a test track of at least 40 mm, position the

9.6 Fully tighten all mounting adjustments and lift the

joint(s) outside the area traversed during the test run.

footwear test specimen away from the test surface.

9.4 Securely fit the prepared footwear, sole unit or slider to

9.7 Apply contaminant if required (see 10.5).

an appropriate mounting.

F2913 − 11

TABLE 2 Coefficient of Friction Range for Calibrated

10.1.9 Cleaning procedures for test materials are given in

Quarry Tiles

10.11.

Dry COF Wet COF

10.2 Additional Apparatus:

Minimum 0.57 0.43

10.2.1 For retaining friable, weak or loose surfaces such as

Maximum 0.63 0.49

natural grass or gravel, a walled tray that will locate on the

horizontal surface of the friction test apparatus and is suffi-

ciently large that no part of the footwear or footwear materials

9.8 Activate the data recording system.

beingtestedwillcomeintocontactwiththetrayduringthetest.

9.9 Bring the footwear test specimen into contact with the

Aflat rigid plate 5 mm less in length and in width than the tray

test surface and apply the required vertical force as specified in

that is used for consolidating friable, weak or loose surfaces

Table 1.

such as natural grass or gravel.

10.2.1.1 Ameans of applying a vertical load to the center of

10. Calibration and Standardization—Test Surfaces

the plate shall be laid on the surface, which should be evenly

(Floorings) and Lubricants

distributed in the tray, and a vertical load applied through the

10.1 General Information: center of the plate. The area of the plate and the total load

applied should be recorded.

10.1.1 Any type of test surface and lubricant may be used

provided it can be securely mounted without interfering with

10.3 Test Surface Specifications—Calibrated Clay Quarry

the action of the test.

Tile:

10.1.2 Test specimens shall be of uniform mean thickness, 9,7

10.3.1 Flat unglazed clay quarry tile that is wider than the

allowing for any surface pattern, and have minimum dimen-

test specimen and long enough to allow a sliding distance of at

sions of 220 by 120 mm.

least 75 mm without crossing a joint.

10.1.3 When evaluating an extruded or rolled product,

10.3.1.1 Sufficiently flat to allow it to be secured on the

where possible, cut specimens either:

mounting table such that no movement occurs between the tile

10.1.3.1 Parallel to the process direction,

and mounting table during the test.

10.1.3.2 Perpendicular to the process direction, or

10.3.1.2 Has a ribbed profile or directional marking on the

10.1.3.3 At 45° to the process direction.

underside to identify the direction in which the tile should be

aligned (with the ribs parallel to the sliding direction).

NOTE 4—Where the process direction is not known, the directions

should be referenced in relation to some other distinguishing feature on

10.3.1.3 Conforms to the values specified in Table 2 when

the flooring.

calibrated by the Slider 96 method (see 10.6).

10.1.4 Whenevaluatingwornsurfacesitmaybeappropriate

NOTE5—Calibrationfigurescoulddifferassuppliedbythetileprovider

to measure these items in directions aligned with any patterns

and should be reported within the test document.

of wear in addition to the normal modes of testing.

10.3.1.4 Calibration of the tiles should be checked after

10.1.5 When preparing specimens to be used as reference

every 10 tests or prior to each day of testing whichever is the

materials for testing footwear or footwear materials, the

less frequent, to ensure that they are not being worn smooth or

specimens shall be calibrated in the direction in which they are

otherwise damaged. However, if experience shows that the

to be used by either:

friction properties of the test floor are not strongly influenced

10.1.5.1 Determination of standard COF test values against

by repeated testing then calibration intervals may be extended.

a Slider 96 slider in 10.6,or

10.4 Test Surface Specifications—Stainless Steel:

10.1.5.2 Specification of surface roughness in 10.9.2.

10.4.1 A Stainless Steel Plate:

10.1.6 Other floors used for comparing performance of

10.4.1.1 Such as steel Number 1.4301, Type 2G (cold

footwear or footwear materials should be characterized by

rolled, ground) conforming to EN 10088-2 or AISA Type

testing against Slider 96 rubber to establish the nominal

10,7

8,7

304.

performance level of the flooring for future reference.

10.4.1.2 That when calibrated by the roughness method

10.1.7 Transient surfaces such as natural grass and ice

which gives an overall mean value of R from all 10 locations

shouldbecharacterizedbyothermeansasappropriate,describ-

z

of between 1.6 µm and 2.5 µm, as described in 10.9.

ing in full detail how they were made. In general such surfaces

10.4.2 Other Test Surfaces—These test surfaces may in-

will be damaged or changed by the action

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.