ASTM D4628-05

(Test Method)Standard Test Method for Analysis of Barium, Calcium, Magnesium, and Zinc In Unused Lubricating Oils By Atomic Absorption Spectrometry

Standard Test Method for Analysis of Barium, Calcium, Magnesium, and Zinc In Unused Lubricating Oils By Atomic Absorption Spectrometry

SIGNIFICANCE AND USE

Some oils are formulated with metal-containing additives that act as detergents, antioxidants, antiwear agents, etc. Some of these additives contain one or more of these metals: barium, calcium, zinc, and magnesium. This test method provides a means of determining the concentration of these metals that gives an indication of the additive content in these oils.

SCOPE

1.1 This test method is applicable for the determination of mass percent barium from 0.005 to 1.0 %, calcium and magnesium from 0.002 to 0.3 %, and zinc from 0.002 to 0.2 % in lubricating oils.

1.2 Higher concentrations can be determined by appropriate dilution. Lower concentrations of metals such as barium, calcium, magnesium, and zinc at about 10 ppm level can also be determined by this test method. Use of this test method for the determination at these lower concentrations should be by agreement between the buyer and the seller.

1.3 Lubricating oils that contain viscosity index improvers may give low results when calibrations are performed using standards that do not contain viscosity index improvers.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific warning statements are given in , , and .

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4628–05

Standard Test Method for

Analysis of Barium, Calcium, Magnesium, and Zinc in

Unused Lubricating Oils by Atomic Absorption

1

Spectrometry

This standard is issued under the fixed designation D4628; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 2. Referenced Documents

2

1.1 This test method is applicable for the determination of 2.1 ASTM Standards:

mass percent barium from 0.005 to 1.0 %, calcium and D6299 Practice for Applying Statistical Quality Assurance

magnesium from 0.002 to 0.3 %, and zinc from 0.002 to 0.2 % and Control Charting Techniques to Evaluate Analytical

in lubricating oils. Measurement System Performance

1.2 Higher concentrations can be determined by appropriate

3. Summary of Test Method

dilution. Lower concentrations of metals such as barium,

calcium, magnesium, and zinc at about 10 ppm level can also 3.1 A sample is weighed and base oil is added to 0.25 6

0.01-g total mass. Fifty millilitres of a kerosine solution,

be determined by this test method. Use of this test method for

the determination at these lower concentrations should be by containing potassium as an ionization suppressant, are added,

and the sample and oil are dissolved. (Warning—Hazardous.

agreement between the buyer and the seller.

1.3 Lubricating oils that contain viscosity index improvers Potentially toxic and explosive.) Standards are similarly pre-

pared, always adding oil if necessary to yield a total mass of

may give low results when calibrations are performed using

standards that do not contain viscosity index improvers. 0.25 g. These solutions are burned in the flame of an atomic

absorption spectrophotometer. An acetylene/nitrous oxide

1.4 The values stated in SI units are to be regarded as

standard. The values given in parentheses are for information flame is used. (Warning—Combustible. Vapor harmful.)

only.

4. Significance and Use

1.5 This standard does not purport to address all of the

4.1 Some oils are formulated with metal-containing addi-

safety concerns, if any, associated with its use. It is the

tives that act as detergents, antioxidants, antiwear agents, etc.

responsibility of the user of this standard to establish appro-

Some of these additives contain one or more of these metals:

priate safety and health practices and determine the applica-

barium, calcium, zinc, and magnesium. This test method

bility of regulatory limitations prior to use. Specific warning

provides a means of determining the concentration of these

statements are given in 3.1, 6.3, and 8.1.

metals that gives an indication of the additive content in these

oils.

1

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

2

D02.03 on Elemental Analysis. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2005. Published November 2005. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1986. Last previous edition approved in 2002 as D4628–02. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D4628-05. the ASTM website.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D4628–05

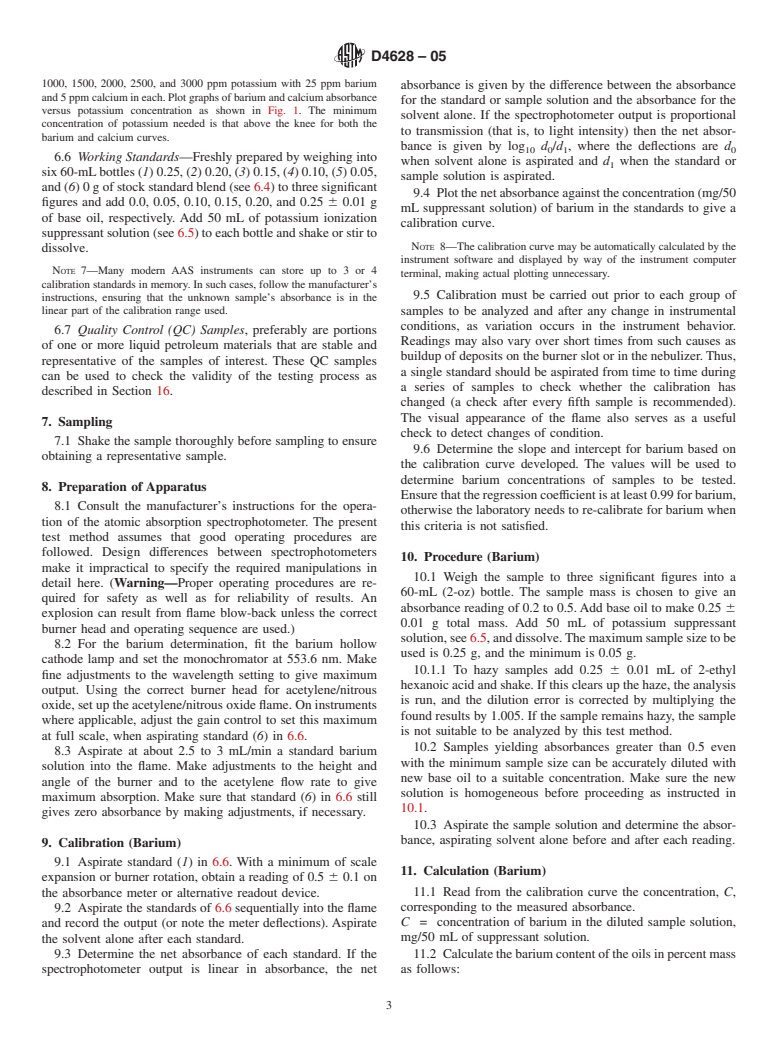

FIG. 1 Plot Graphs for Barium and Calcium

of 3.2 volume % aromatics. If the kerosine used by an operator deviates

5. Apparatus

appreciably from this composition, there may be significant error.

5.1 Atomic Absorption Spectrophotometer.

3

6.4 Oil-SolubleMetalCompounds, stockstandardblendin

5.2 Analytical Balance.

base oil. A 0.25 6 0.01-g portion of this stock standard blend

5.3 AutomaticMeasuringPipetorVolumetricClassAPipet,

diluted with 50 mL of the potassium ionization suppressant

50-mL capacity.

solution (see 6.5) shall yield a reading of 0.5 6 0.1 absorbance

5.4 Bottles with Screw Caps, 60 mL (2 oz).

units for each of the elements barium, calcium, magnesium,

NOTE 1—Suitable volumetric flasks or plastic bottles may be substi-

and zinc using a minimum of scale expansion or burner

tuted.

rotation. The concentrations of the metal should be blended

5.5 Shaker, Mechanical Stirrer, or Ultrasonic Bath, capable

accurately to three significant figures. The actual concentra-

of handling 60-mL bottles.

tions should be chosen to conform to the opt

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.