ASTM E1086-22

(Test Method)Standard Test Method for Analysis of Austenitic Stainless Steel by Spark Atomic Emission Spectrometry

Standard Test Method for Analysis of Austenitic Stainless Steel by Spark Atomic Emission Spectrometry

SIGNIFICANCE AND USE

5.1 The chemical composition of stainless steels must be determined accurately to ensure the desired metallurgical properties. This test method is suitable for manufacturing control and inspection testing.

SCOPE

1.1 This test method2 covers the analysis of austenitic stainless steel by spark atomic emission spectrometry for the following elements in the ranges shown

Element

Composition Range, %

Chromium

17.0 to 23.0

Nickel

7.5 to 13.0

Molybdenum

0.01 to 3.0

Manganese

0.01 to 2.0

Silicon

0.01 to 0.90

Copper

0.01 to 0.30

Carbon

0.005 to 0.25

Phosphorus

0.003 to 0.15

Sulfur

0.003 to 0.065

1.2 This test method is designed for the analysis of chill-cast disks or inspection testing of stainless steel samples that have a flat surface of at least 13 mm (0.5 in.) in diameter. The samples must be sufficiently massive to prevent overheating during the discharge and of a similar metallurgical condition and composition as the reference materials.

1.3 One or more of the reference materials must closely approximate the composition of the specimen. The technique of analyzing reference materials with unknowns and performing the indicated mathematical corrections (typically referred to as type standardization) may also be used to correct for interference effects and to compensate for errors resulting from instrument drift. A variety of such systems are commonly used. Any of these that will achieve analytical accuracy equivalent to that reported for this test method are acceptable.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E1086 − 22

Standard Test Method for

Analysis of Austenitic Stainless Steel by Spark Atomic

1

Emission Spectrometry

This standard is issued under the fixed designation E1086; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard-

2

1.1 This test method covers the analysis of austenitic

ization established in the Decision on Principles for the

stainless steel by spark atomic emission spectrometry for the

Development of International Standards, Guides and Recom-

following elements in the ranges shown

mendations issued by the World Trade Organization Technical

Element Composition Range, %

Barriers to Trade (TBT) Committee.

Chromium 17.0 to 23.0

Nickel 7.5 to 13.0

Molybdenum 0.01 to 3.0

2. Referenced Documents

Manganese 0.01 to 2.0

3

Silicon 0.01 to 0.90 2.1 ASTM Standards:

Copper 0.01 to 0.30

E29 Practice for Using Significant Digits in Test Data to

Carbon 0.005 to 0.25

Determine Conformance with Specifications

Phosphorus 0.003 to 0.15

Sulfur 0.003 to 0.065 E135 Terminology Relating to Analytical Chemistry for

Metals, Ores, and Related Materials

1.2 Thistestmethodisdesignedfortheanalysisofchill-cast

E305 Practice for Establishing and Controlling Spark

disks or inspection testing of stainless steel samples that have

Atomic Emission Spectrochemical Analytical Curves

a flat surface of at least 13 mm (0.5 in.) in diameter. The

E406 Practice for Using Controlled Atmospheres in Atomic

samples must be sufficiently massive to prevent overheating

Emission Spectrometry

during the discharge and of a similar metallurgical condition

E1060 Practice for Interlaboratory Testing of Spectrochemi-

and composition as the reference materials.

4

cal Methods of Analysis (Withdrawn 1997)

1.3 One or more of the reference materials must closely

E1329 Practice for Verification and Use of Control Charts in

approximate the composition of the specimen. The technique 4

Spectrochemical Analysis (Withdrawn 2019)

of analyzing reference materials with unknowns and perform-

E1806 Practice for Sampling Steel and Iron for Determina-

ing the indicated mathematical corrections (typically referred

tion of Chemical Composition

to as type standardization) may also be used to correct for

2.2 Other ASTM Documents:

interference effects and to compensate for errors resulting from

MNL 7 Manual on Presentation of Data and Control Chart

instrument drift.Avariety of such systems are commonly used.

5

Analysis

Anyofthesethatwillachieveanalyticalaccuracyequivalentto

that reported for this test method are acceptable.

3. Terminology

1.4 This standard does not purport to address all of the

3.1 Definitions—For definitions of terms used in this test

safety concerns, if any, associated with its use. It is the

method, refer to Terminology E135.

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

4. Summary of Test Method

mine the applicability of regulatory limitations prior to use.

4.1 A controlled discharge is produced between the flat

surface of the specimen and the counter electrode. The radiant

1

This test method is under the jurisdiction of ASTM Committee E01 on

Analytical Chemistry for Metals, Ores, and Related Materials and is the direct

3

responsibility of Subcommittee E01.01 on Iron, Steel, and Ferroalloys. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Aug. 15, 2022. Published September 2022. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1985. Last previous edition approved in 2014 as E1086 – 14. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/E1086-22. the ASTM website.

2 4

Supporting data have been filed at ASTM International Headquarters and may The last approved version of this historical standard is referenced on

beobtainedbyrequestingResearchReportRR:E02-1023.ContactASTMCustomer www.astm.org.

5

Service at service@astm.org. ASTM Manual Series, ASTM International, 9th edition, 2018.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1086 − 22

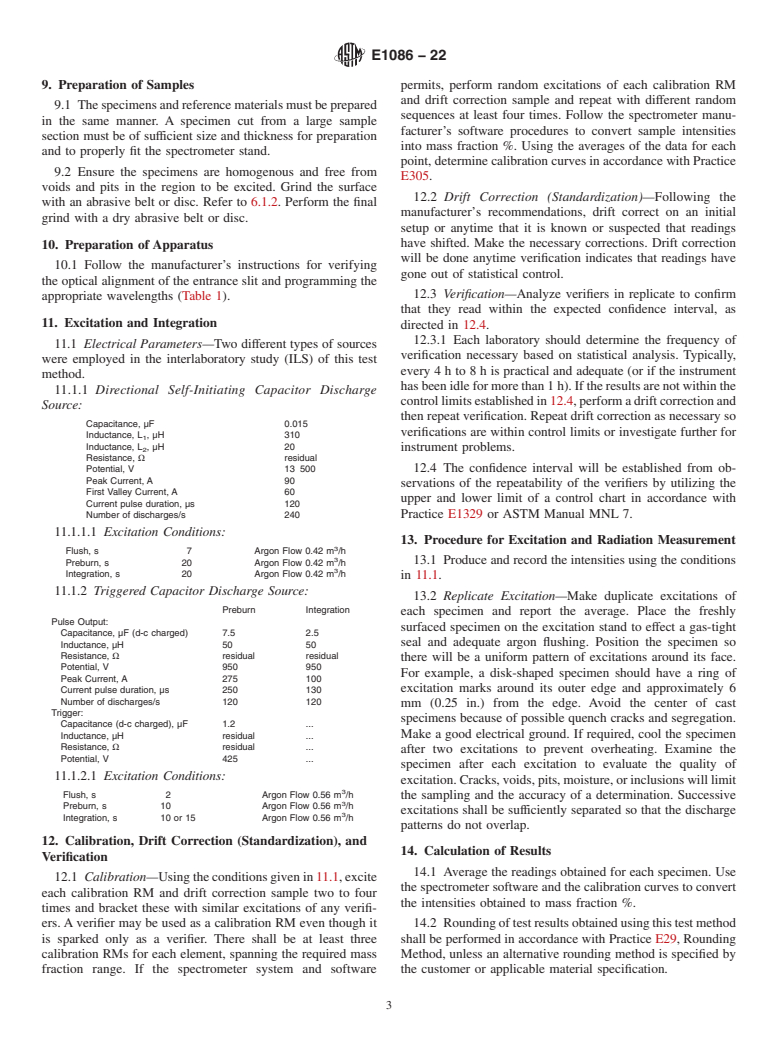

TABLE 1 Analytical and Internal Standard Lines

energies of selected analytical lines are c

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E1086 − 14 E1086 − 22

Standard Test Method for

Analysis of Austenitic Stainless Steel by Spark Atomic

1

Emission Spectrometry

This standard is issued under the fixed designation E1086; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

2

1.1 This test method covers the analysis of austenitic stainless steel by spark atomic emission vacuum spectrometry for the

following elements in the ranges shown

Element Composition Range, %

Chromium 17.0 to 23.0

Nickel 7.5 to 13.0

Molybdenum 0.01 to 3.0

Manganese 0.01 to 2.0

Silicon 0.01 to 0.90

Copper 0.01 to 0.30

Carbon 0.005 to 0.25

Phosphorus 0.003 to 0.15

Sulfur 0.003 to 0.065

1.2 This test method is designed for the routine analysis of chill-cast disks or inspection testing of stainless steel samples that have

a flat surface of at least 13 mm (0.5 in.) in diameter. The samples must be sufficiently massive to prevent overheating during the

discharge and of a similar metallurgical condition and composition as the reference materials.

1.3 One or more of the reference materials must closely approximate the composition of the specimen. The technique of analyzing

reference materials with unknowns and performing the indicated mathematical corrections (typically referred to as type

standardization) may also be used to correct for interference effects and to compensate for errors resulting from instrument drift.

A variety of such systems are commonly used. Any of these that will achieve analytical accuracy equivalent to that reported for

this test method are acceptable.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

This test method is under the jurisdiction of ASTM Committee E01 on Analytical Chemistry for Metals, Ores, and Related Materials and is the direct responsibility of

Subcommittee E01.01 on Iron, Steel, and Ferroalloys.

Current edition approved March 1, 2014Aug. 15, 2022. Published April 2014September 2022. Originally approved in 1985. Last previous edition approved in 20082014

as E1086 – 08.E1086 – 14. DOI: 10.1520/E1086-14.10.1520/E1086-22.

2

Supporting data have been filed at ASTM International Headquarters and may be obtained by requesting Research Report RR:E02-1023. Contact ASTM Customer

Service at service@astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1086 − 22

2. Referenced Documents

3

2.1 ASTM Standards:

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E135 Terminology Relating to Analytical Chemistry for Metals, Ores, and Related Materials

E305 Practice for Establishing and Controlling Spark Atomic Emission Spectrochemical Analytical Curves

E406 Practice for Using Controlled Atmospheres in Atomic Emission Spectrometry

4

E1060 Practice for Interlaboratory Testing of Spectrochemical Methods of Analysis (Withdrawn 1997)

4

E1329 Practice for Verification and Use of Control Charts in Spectrochemical Analysis (Withdrawn 2019)

E1806 Practice for Sampling Steel and Iron for Determination of Chemical Composition

2.2 Other ASTM Documents:

5

ASTM MNL 7 Manual on Presentation of Data and Control Chart Analysis

3. Terminology

3.1 Definitions—For definitions of terms used in this test method, refer to Terminology E135.

4. Summary of Test Method

4.1 A controlled discharge is produced between the flat surface of the specimen and the counter electrode. The radiant

energyenergies of selected analytical lines are converted into electrical energies by photomultiplier tubes and stored on capacitors.

The discharge is terminated at a predetermined level of accumulated radiant energy from the internal standard iron l

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.