ASTM D4927-20

(Test Method)Standard Test Methods for Elemental Analysis of Lubricant and Additive Components-Barium, Calcium, Phosphorus, Sulfur, and Zinc by Wavelength-Dispersive X-Ray Fluorescence Spectroscopy

Standard Test Methods for Elemental Analysis of Lubricant and Additive Components-Barium, Calcium, Phosphorus, Sulfur, and Zinc by Wavelength-Dispersive X-Ray Fluorescence Spectroscopy

SIGNIFICANCE AND USE

4.1 Some oils are formulated with organo-metallic additives which act as detergents, antioxidants, antiwear agents, and so forth. Some of these additives contain one or more of these elements: barium, calcium, phosphorus, sulfur, and zinc. These test methods provide a means of determining the concentration of these elements which in turn provides an indication of the additive content of these oils.

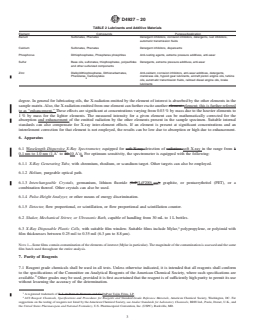

4.2 Several additive elements and their compounds are added to the lubricating oils to give beneficial performance (see Table 2).

SCOPE

1.1 These test methods cover the determination of barium, calcium, phosphorus, sulfur, and zinc in unused lubricating oils at element concentration ranges shown in Table 1. The range can be extended to higher concentrations by dilution of sample specimens. Additives can also be determined after dilution. Two different methods are presented in these test methods.

1.2 Test Method A (Internal Standard Procedure)-Internal standards are used to compensate for interelement effects of X-ray excitation and fluorescence (see Sections 8 through 13).

1.3 Test Method B (Mathematical Correction Procedure)-The measured X-ray fluorescence intensity for a given element is mathematically corrected for potential interference from other elements present in the sample (see Sections 14 through 19).

1.4 The preferred concentration units are mass % barium, calcium, phosphorus, sulfur, or zinc.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Frequently Asked Questions

ASTM D4927-20 is a standard published by ASTM International. Its full title is "Standard Test Methods for Elemental Analysis of Lubricant and Additive Components-Barium, Calcium, Phosphorus, Sulfur, and Zinc by Wavelength-Dispersive X-Ray Fluorescence Spectroscopy". This standard covers: SIGNIFICANCE AND USE 4.1 Some oils are formulated with organo-metallic additives which act as detergents, antioxidants, antiwear agents, and so forth. Some of these additives contain one or more of these elements: barium, calcium, phosphorus, sulfur, and zinc. These test methods provide a means of determining the concentration of these elements which in turn provides an indication of the additive content of these oils. 4.2 Several additive elements and their compounds are added to the lubricating oils to give beneficial performance (see Table 2). SCOPE 1.1 These test methods cover the determination of barium, calcium, phosphorus, sulfur, and zinc in unused lubricating oils at element concentration ranges shown in Table 1. The range can be extended to higher concentrations by dilution of sample specimens. Additives can also be determined after dilution. Two different methods are presented in these test methods. 1.2 Test Method A (Internal Standard Procedure)-Internal standards are used to compensate for interelement effects of X-ray excitation and fluorescence (see Sections 8 through 13). 1.3 Test Method B (Mathematical Correction Procedure)-The measured X-ray fluorescence intensity for a given element is mathematically corrected for potential interference from other elements present in the sample (see Sections 14 through 19). 1.4 The preferred concentration units are mass % barium, calcium, phosphorus, sulfur, or zinc. 1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. 1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

SIGNIFICANCE AND USE 4.1 Some oils are formulated with organo-metallic additives which act as detergents, antioxidants, antiwear agents, and so forth. Some of these additives contain one or more of these elements: barium, calcium, phosphorus, sulfur, and zinc. These test methods provide a means of determining the concentration of these elements which in turn provides an indication of the additive content of these oils. 4.2 Several additive elements and their compounds are added to the lubricating oils to give beneficial performance (see Table 2). SCOPE 1.1 These test methods cover the determination of barium, calcium, phosphorus, sulfur, and zinc in unused lubricating oils at element concentration ranges shown in Table 1. The range can be extended to higher concentrations by dilution of sample specimens. Additives can also be determined after dilution. Two different methods are presented in these test methods. 1.2 Test Method A (Internal Standard Procedure)-Internal standards are used to compensate for interelement effects of X-ray excitation and fluorescence (see Sections 8 through 13). 1.3 Test Method B (Mathematical Correction Procedure)-The measured X-ray fluorescence intensity for a given element is mathematically corrected for potential interference from other elements present in the sample (see Sections 14 through 19). 1.4 The preferred concentration units are mass % barium, calcium, phosphorus, sulfur, or zinc. 1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. 1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

ASTM D4927-20 is classified under the following ICS (International Classification for Standards) categories: 75.100 - Lubricants, industrial oils and related products. The ICS classification helps identify the subject area and facilitates finding related standards.

ASTM D4927-20 has the following relationships with other standards: It is inter standard links to ASTM D6299-23a, ASTM D6299-17b, ASTM D6299-17a, ASTM D6299-17, ASTM D6299-13e1, ASTM D6299-10e2, ASTM D6299-10, ASTM D6299-09, ASTM D6299-08, ASTM D6299-07e1, ASTM D6299-07, ASTM D6299-02e1, ASTM D6299-02, ASTM D6299-00. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase ASTM D4927-20 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ASTM standards.

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4927 − 20

Standard Test Methods for

Elemental Analysis of Lubricant and Additive Components—

Barium, Calcium, Phosphorus, Sulfur, and Zinc by

Wavelength-Dispersive X-Ray Fluorescence Spectroscopy

This standard is issued under the fixed designation D4927; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 2. Referenced Documents

2.1 ASTM Standards:

1.1 These test methods cover the determination of barium,

D6299 Practice for Applying Statistical Quality Assurance

calcium,phosphorus,sulfur,andzincinunusedlubricatingoils

and Control Charting Techniques to Evaluate Analytical

at element concentration ranges shown in Table 1. The range

Measurement System Performance

can be extended to higher concentrations by dilution of sample

specimens. Additives can also be determined after dilution.

3. Summary of the Test Methods

Two different methods are presented in these test methods.

3.1 Asample specimen is placed in the X-ray beam and the

1.2 Test Method A (Internal Standard Procedure)—Internal

intensity of the appropriate fluorescence lines of barium,

standards are used to compensate for interelement effects of

calcium,phosphorus,sulfur,andzincaremeasured.Instrument

X-ray excitation and fluorescence (see Sections 8 through 13).

response factors related to the concentration of standards

1.3 Test Method B (Mathematical Correction Procedure)—

enable the determination of the concentration of elements in

The measured X-ray fluorescence intensity for a given element

thetestedsamplespecimens.Enhancementorabsorptionofthe

is mathematically corrected for potential interference from

X-ray fluorescence of a given element by an interfering

other elements present in the sample (see Sections 14 through

element in the sample may occur. Two test methods (A and B)

19).

are described for compensating any interference effect.

1.4 The preferred concentration units are mass % barium,

3.2 Test Method A (Internal Standard Procedure)—Internal

calcium, phosphorus, sulfur, or zinc.

standards are used with the standards and sample specimens to

compensate for the potential interelement effects.

1.5 This standard does not purport to address all of the

3.2.1 Barium, Calcium, Phosphorus, and Zinc—A sample

safety concerns, if any, associated with its use. It is the

that has been blended with a single internal standard solution

responsibility of the user of this standard to establish appro-

(containing tin or titanium for barium and calcium, zirconium

priate safety, health, and environmental practices and deter-

for phosphorus, and nickel for zinc) is poured into an X-ray

mine the applicability of regulatory limitations prior to use.

cell. Total net counts (peak intensity – background) for each

1.6 This international standard was developed in accor-

element and its respective internal standard are collected at

dance with internationally recognized principles on standard-

their appropriate wavelengths. The ratios between elemental

ization established in the Decision on Principles for the

and internal standard counts are calculated and converted into

Development of International Standards, Guides and Recom-

barium, calcium, phosphorus, or zinc concentrations, or a

mendations issued by the World Trade Organization Technical

combination thereof, from calibration curves.

Barriers to Trade (TBT) Committee.

3.2.2 Sulfur—A sample is mixed with a lead internal stan-

dard solution and analyzed as described in 3.2.1.

These test methods are under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and are the direct responsibility

of Subcommittee D02.03 on Elemental Analysis. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Dec. 1, 2020. Published January 2021. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1989. Last previous edition approved in 2020 as D4927 – 15 (2020). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D4927-20. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4927 − 20

TABLE 1 Range of Applicability

4.2 Several additive elements and their compounds are

Element Range, Mass % addedtothelubricatingoilstogivebeneficialperformance(see

Barium 0.04-8.5

Table 2).

Calcium 0.01-1.0

Phosphorus 0.01-0.5

Sulfur 0.1-4.0

5. Interferences

Zinc 0.01-0.6

5.1 The additive elements found in lubricating oils will

affect the measured intensities from the elements of interest to

avaryingdegree.Ingeneralforlubricatingoils,theX-radiation

3.3 Test Method B (Mathematical Correction Procedure)— emitted by the element of interest is absorbed by the other

elements in the sample matrix. Also, the X-radiation emitted

The measured intensity for a given element is mathematically

corrected for the interference from other elements in the from one element can further excite another element; this is

sample specimen. This requires that intensities from all ele- further referred to as “enhancement.” These effects are signifi-

ments in the specimen be obtained.

cant at concentrations varying from 0.03 % by mass due to the

3.3.1 The test specimen is placed in the X-ray beam. Total

heavier elements to 1 % by mass for the lighter elements. The

net counts or intensities (peak intensity – background) for

measured intensity for a given element can be mathematically

barium, calcium, phosphorus, sulfur, and zinc are measured at

corrected for the absorption and enhancement of the emitted

their appropriate wavelengths. Concentrations of the elements

radiationbytheotherelementspresentinthesamplespecimen.

of interest are determined by comparison of net signals against

Suitable internal standards can also compensate for X-ray

calibration curves developed from responses of calibration

inter-element effects. If an element is present at significant

standards. The calibration procedure includes interelement

concentrations and an interelement correction for that element

corrections.

is not employed, the results can be low due to absorption or

3.3.2 The X-ray fluorescence spectrometer is initially cali-

high due to enhancement.

brated with a suite of standards in order to determine by

regression analysis, interelement correction factors and instru-

6. Apparatus

ment response factors.

6.1 Wavelength Dispersive X-Ray Spectrometer, equipped

3.3.3 Subsequent calibration is achieved using a smaller

for detection of soft X-ray in the range from 0.1 nm to 1.0 nm

number of standards since only the instrument response factors

˚ ˚

needtoberedetermined.Oneofthesestandards(oranoptional (1 A to 10 A). For optimum sensitivity, the spectrometer is

equipped with the following:

syntheticpellet)canbeusedtomonitorinstrumentaldriftwhen

performing a high volume of analyses.

6.1.1 X-Ray Generating Tube, with chromium, rhodium, or

scandium target. Other targets can also be employed.

3.4 Additivesandadditivepackagescanbedeterminedafter

dilution with base oil to place the elemental concentrations in

6.1.2 Helium, purgeable optical path.

the range described in 1.1.

6.1.3 Interchangeable Crystals, germanium, lithium fluo-

ride (LiF200), graphite, or pentaerythritol (PET), or a combi-

4. Significance and Use

nation thereof. Other crystals can also be used.

4.1 Some oils are formulated with organo-metallic additives

6.1.4 Pulse-Height Analyzer, or other means of energy

which act as detergents, antioxidants, antiwear agents, and so

discrimination.

forth. Some of these additives contain one or more of these

6.1.5 Detector, flow proportional, or scintillation, or flow

elements: barium, calcium, phosphorus, sulfur, and zinc.These

proportional and scintillation counter.

test methods provide a means of determining the concentration

of these elements which in turn provides an indication of the 6.2 Shaker, Mechanical Stirrer, or Ultrasonic Bath, capable

additive content of these oils. of handling from 30 mL to 1 L bottles.

TABLE 2 Lubricants and Additive Materials

Element Compounds Purpose/Application

Barium Sulfonates, Phenates Detergent inhibitors, corrosion inhibitors, detergents, rust inhibitors,

automatic transmission fluids

Calcium Sulfonates, Phenates Detergent inhibitors, dispersants

Phosphorus Dithiophosphates, Phosphates phosphites Anti-rusting agents, extreme pressure additives, anti-wear

Sulfur Base oils, sulfonates, thiophosphates, polysulfides Detergents, extreme pressure additives, anti-wear

and other sulfurized components

Zinc Dialkyldithiophosphates, Dithiocarbamates, Anti-oxidant, corrosion inhibitors, anti-wear additives, detergents,

Phenolates, Carboxylates crankcase oils, hypoid gear lubricants, aircraft piston engine oils, turbine

oils, automatic transmission fluids, railroad diesel engine oils, brake

lubricants

D4927 − 20

6.3 X-Ray Disposable Plastic Cells, with suitable film concentration that can be used is 4.0 % by mass 6 0.1 % by

window. Suitable films include Mylar, polypropylene, or masstitaniumortin),thelaboratoryneedstoadjusttheamount

polyimid with film thicknesses between 0.25 mil to 0.35 mil of sample taken in 9.1 to yield an equivalent titanium or tin

(6.3 µm to 8.8 µm). concentration level in the internal standard. Other titanium or

tin containing organic matrices (free of other metals, sulfur,

NOTE 1—Some films contain contamination of the elements of interest

and phosphorus) may be substituted, provided the titanium or

(Mylar in particular). The magnitude of the contamination is assessed and

the same film batch used throughout the entire analysis. tin is stable in solution, the concentration is known (≥4.0 % by

mass 6 0.1 % by mass titanium or tin), and the laboratory can

7. Purity of Reagents

adjust the amount of sample taken in 9.1 to yield an equivalent

7.1 Reagent grade chemicals shall be used in all tests. titaniumortinconcentrationlevelintheinternalstandardifthe

Unless otherwise indicated, it is intended that all reagents shall titaniumortinconcentrationdoesnotinitiallycontain8.0 %by

conform to the specifications of the Committee on Analytical mass 6 0.1 % by mass titanium or tin.

Reagents of the American Chemical Society, where such

8.4.3 Zirconium Octoate, preferably containing 12.0 % by

specifications are available. Other grades may be used, pro-

mass 6 0.1 % by mass zirconium. If the laboratory uses

vided it is first ascertained that the reagent is of sufficiently

zirconium octoate with a lower mass % zirconium concentra-

high purity to permit its use without lessening the accuracy of

tion level, the laboratory needs to evaporate away the petro-

the determination.

leum solvent to yield a solution that contains 12.0 % by mass

6 0.1 % by mass zirconium. Other zirconium containing

TEST METHOD A (INTERNAL STANDARD

organic matrices (free of other metals, sulfur, and phosphorus)

PROCEDURE)

maybesubstituted,providedthezirconiumisstableinsolution

and the concentration is known and does not exceed 12.0 % by

8. Reagents and Materials

mass 6 0.1 % by mass zirconium. If the zirconium concentra-

8.1 Helium, for optical path of spectrometer.

tionis<12.0 %bymass 60.1 %bymass,thelaboratoryneeds

8.2 P-10 Ionization Gas, 90 % by volume argon and 10 %

toevaporateawaythepetroleumsolventtoyieldasolutionthat

by volume methane for the flow proportional counter. contains 12.0 % by mass 6 0.1 % by mass zirconium.

8.4.4 Lead Naphthenate, containing 24.0 % by mass 6

8.3 Diluent Solvent, a suitable solvent free of metals, sulfur,

0.1 % by mass lead.

and phosphorus (for example, kerosene, white oil, or xylenes).

8.4 Internal Standard Materials: 8.5 Calibration Standard Materials:

8.4.1 Nickel Octoate, preferably containing 5.0 % by mass

NOTE 3—In addition to calibration standards identified in 8.5.1 – 8.5.5,

60.1 %bymassnickel.Ifthenickelconcentrationishigheror

single-elementormultielementcalibrationstandardsmayalsobeprepared

lower (minimum concentration that can be used is 2.5 % by

from materials similar to the samples being analyzed, provided the

mass 6 0.1 % by mass nickel), the laboratory needs to adjust

calibration standards to be used have previously been characterized by

the amount of sample taken in 9.1 to yield an equivalent nickel independent primary (for example, gravimetric or volumetric) analytical

techniques to establish the elemental concentration mass percent levels.

concentration level in the internal standard. Other nickel-

containing organic matrices (free of other metals, sulfur, and

8.5.1 Barium 2-Ethylhexoide or Sulfonate, with concentra-

phosphorus) may be substituted provided the nickel is stable in

tions ≥4 % by mass barium and certified to better than 60.1 %

solution, the concentration is known (≥2.5 % by mass 6 0.1 %

absolute (95 % confidence limit), so that calibration standards

by mass nickel), and the laboratory can adjust the amount of

can be prepared as stated in 10.1.1 and 10.1.2.

sample taken in 9.1 to yield an equivalent nickel concentration

8.5.2 Calcium Octoate or Sulfonate, with concentrations

level in the internal standard if the nickel concentration does

≥4 % by mass calcium and certified to better than 60.1 %

not initially contain 5.0 % by mass 6 0.1 % by mass nickel.

absolute (95 % confidence limit), so that calibration standards

can be prepared as stated in 10.1.1 and 10.1.2.

NOTE 2—Many X-ray tubes emit copper X rays which increase in

intensity with age. This does not present a problem when using copper as

8.5.3 Bis(2-Ethylhexyl)Hydrogen Phosphate, 97 % purity

an internal standard for zinc providing that frequent calibrations are

(9.62 % by mass phosphorus). Other phosphorus containing

performed. No problem exists when using nickel as internal for zinc and

organic matrices (free of other metals) may be substituted

nickel is the preferred internal standard material. The use of a primary

beam filter (such as, for example, 100 micron Al) when measuring Cu is provided the phosphorus is stable in solution and the concen-

recommended to fully avoid problems with the tube contamination.

tration is ≥4 % by mass phosphorus and certified to better than

60.1 % absolute (95 % confidence limit), so that calibration

8.4.2 Titanium 2-Ethylhexoide or Tin Octoate, preferably

standards can be prepared as stated in 10.1.1 and 10.1.2.

containing 8.0 % by mass 6 0.1 % by mass titanium or tin. If

the titanium or tin concentration is higher or lower (minimum

8.5.4 Zinc Sulfonate or Octoate,withconcentration≥4%by

mass zinc and certified to better than 60.1 % absolute (95 %

confidence limit), so that calibration standards can be prepared

A registered trademark of DuPont Teijin Films, LP.

4 as stated in 10.1.1 and 10.1.2.

ACS Reagent Chemicals, Specifications and Procedures for Reagents and

Standard-Grade Reference Materials, American Chemical Society, Washington,

8.5.5 Di-n-Butyl Sulfide, 97 % purity, (21.9 % by mass

DC. For suggestions on the testing of reagents not listed by theAmerican Chemical

sulfur). Other sulfur containing organic matrices (free of

Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset,

metals) may be substituted, provided the sulfur is stable in

U.K., and the United States Pharmacopeia and National Formulary, U.S. Pharma-

copeial Convention, Inc. (USPC), Rockville, MD. solution and the concentration is ≥2 % by mass sulfur and

D4927 − 20

certified to better than 60.1 % absolute (95 % confidence 10.1.5 Add 8.00 g 6 0.001 g of each standard to a respec-

limit), so that calibration standards can be prepared as stated in tive bottle containing the internal standards and shake or stir

10.1.2.

well (minimum of 10 min) to mix the constituents.

8.6 Quality Control (QC) Samples, preferably are portions

10.2 Sulfur:

of one or more lubricating oils or additives that are stable and

10.2.1 Prepare five standards covering the range from

representative of the samples of interest. These QC samples

0.00 %bymassto2.00 %bymasssulfurinthediluentsolvent.

can be used to check the validity of the testing process and

10.2.2 Dispense 1.000 g 6 0.001 g of lead internal standard

performance of the instrument as described in Section 12.

into 30 mL bottles (one bottle for each standard).

9. Preparation of Internal Standards

10.2.3 Add 9.000 g 6 0.001 g of each standard to each

9.1 Barium, Calcium, Phosphorus, and Zinc—Dispense

respective bottle containing internal standard. Shake or stir

240 g 6 0.5 g of nickel octoate (5.0 % 6 0.1 % by mass

contents for a minimum of 10 min using apparatus defined in

nickel), 30 g 6 0.1 g of titanium 2-ethylhexoide (8.0 % 6

6.2.

0.1 % by mass titanium) or 30 g 6 0.1 g of tin octoate (8.0 %

6 0.1 % by mass tin), and 450 g 6 1 g of diluent solvent into

11. Instrument Calibration for Barium, Calcium,

a 1 L bottle. Shake or stir the bottle for a minimum of 10 min.

Phosphorus, Sulfur, and Zinc

If the laboratory uses internal materials that have different

11.1 Fill respective X-ray cups at least half full with the

elemental concentrations than those explicitly stated in 8.4.1

and 8.4.2, it will be necessary for the laboratory to adjust the calibration standard solutions. Make sure that no wrinkles or

amount of sample taken in order to obtain an equivalent

bulges are present in the film. The film must be flat.

elemental concentration in the internal standard blend that is

11.2 Place the sample cups in the X-ray beam in order to

prepared according to the following equations:

measure and record the net intensity (peak intensity minus

A 5 240 3 ~5/x! (1)

background intensity) for both the analyte signal and the

B 5 30 3 8/y (2)

~ !

internal standard signal. Table 3 provides suggested crystal

parameters. Up to 60 s counting periods may be used at each

C 5 720 2 A1B (3)

@ #

wavelength position. Do this for each of the calibration

where:

standards for each of the elements.

A = nickel containing material in blend, g,

B = titanium or tin containing material in blend, g, NOTE 4—The parameters indicated in Table 3 are presented for

guidance only and they will vary according to the instrument used.

C = diluent to add to blend, g,

x = nickel in material chosen as an internal standard,

11.3 Calculate the ratio, R, of the net element counts to their

mass %, and

corresponding net internal standard counts for all of the net

y = titanium or tin in material chosen as an internal

elements and standards as follows:

standard, mass %.

R 5 E/I (4)

9.2 Sulfur—Lead naphthenate, 24 % by mass lead, serves as

a suitable internal standard. (Warning—Hazardous. Lead

where:

naphthenate is toxic and precautions should be taken to avoid

E = net element counts, and

inhalation of vapors, ingestion, or skin contact.) No further

I = net internal standard counts.

treatment of this compound is necessary.

NOTE 5—Many modern X-ray spectrometer instruments will calculate

this ratio automatically and store the information in the instrument

10. Preparation of Calibration Standards

computer system.

10.1 Barium, Calcium, Phosphorus, and Zinc:

NOTE 6—Many modern X-ray spectrometer instruments use count rate

10.1.1 For concentrations less than 0.1 % by mass, prepare

(intensity, expressed in kcps) instead of counts collected in a given

measuring time.

standards containing 0.00 % by mass, 0.01 % by mass,

0.025 % by mass, 0.050 % by mass, 0.075 % by mass, and

11.4 Perform regression analyses for each calibration ele-

0.10 % by mass of each respective element in the diluent

ment by ratioing the net element counts to the net internal

solvent.

standard counts versus the element concentration (mass %) on

10.1.2 For concentrations greater than 0.1 % by mass,

linear graph paper or by way of the instrument computer

prepare standards containing 0.00 % by mass, 0.10 % by mass,

system. Following apparatus supplier guidance, the measure-

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4927 − 15 (Reapproved 2020) D4927 − 20

Standard Test Methods for

Elemental Analysis of Lubricant and Additive Components—

Barium, Calcium, Phosphorus, Sulfur, and Zinc by

Wavelength-Dispersive X-Ray Fluorescence Spectroscopy

This standard is issued under the fixed designation D4927; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope Scope*

1.1 These test methods cover the determination of barium, calcium, phosphorus, sulfur, and zinc in unused lubricating oils at

element concentration ranges shown in Table 1. The range can be extended to higher concentrations by dilution of sample

specimens. Additives can also be determined after dilution. Two different methods are presented in these test methods.

1.2 Test Method A (Internal Standard Procedure)—Internal standards are used to compensate for interelement effects of X-ray

excitation and fluorescence (see Sections 8 through 13).

1.3 Test Method B (Mathematical Correction Procedure)—The measured X-ray fluorescence intensity for a given element is

mathematically corrected for potential interference from other elements present in the sample (see Sections 14 through 19).

1.4 The preferred concentration units are mass % barium, calcium, phosphorus, sulfur, or zinc.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D6299 Practice for Applying Statistical Quality Assurance and Control Charting Techniques to Evaluate Analytical Measure-

ment System Performance

3. Summary of the Test Methods

3.1 A sample specimen is placed in the X-ray beam and the intensity of the appropriate fluorescence lines of barium, calcium,

These test methods are under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and are the direct responsibility of

Subcommittee D02.03 on Elemental Analysis.

Current edition approved May 1, 2020Dec. 1, 2020. Published June 2020January 2021. Originally approved in 1989. Last previous edition approved in 20152020 as

D4927 – 15.D4927 – 15 (2020). DOI: 10.1520/D4927-15R20.10.1520/D4927-20.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4927 − 20

TABLE 1 Range of Applicability

Element Range, Mass %

Barium 0.04-8.5

Calcium 0.01-1.0

Phosphorus 0.01-0.5

Sulfur 0.1-4.0

Zinc 0.01-0.6

phosphorus, sulfur, and zinc are measured. Instrument response factors related to the concentration of standards enable the

determination of the concentration of elements in the tested sample specimens. Enhancement or depressionabsorption of the X-ray

fluorescence of a given element by an interfering element in the sample may occur. Two test methods (A and B) are described for

compensating any interference effect.

3.2 Test Method A (Internal Standard Procedure)—Internal standards are used with the standards and sample specimens to

compensate for the potential interelement effects.

3.2.1 Barium, Calcium, Phosphorus, and Zinc—A sample specimen that has been blended with a single internal standard solution

(containing tin or titanium for barium and calcium, zirconium for phosphorus, and nickel for zinc) is poured into an X-ray cell.

Total net counts (peak intensity—background) intensity – background) for each element and its respective internal standard are

collected at their appropriate wavelengths. The ratios between elemental and internal standard counts are calculated and converted

into barium, calcium, phosphorus, or zinc concentrations, or a combination thereof, from calibration curves.

3.2.2 Sulfur—A sample specimen is mixed with a lead internal standard solution and analyzed as described in 3.2.1.

3.3 Test Method B (Mathematical Correction Procedure)—The measured intensity for a given element is mathematically corrected

for the interference from other elements in the sample specimen. This requires that intensities from all elements in the specimen

be obtained.

3.3.1 The sampletest specimen is placed in the X-ray beam and the intensities of the fluorescence lines ofbeam. Total net counts

or intensities (peak intensity – background) for barium, calcium, phosphorus, sulfur, and zinc are measured. A similar measurement

is made away from the fluorescence lines in order to obtain a background correction. measured at their appropriate wavelengths.

Concentrations of the elements of interest are determined by comparison of net signals against appropriate interelement correction

factors calibration curves developed from responses of calibration standards. The calibration procedure includes interelement

corrections.

3.3.2 The X-ray fluorescence spectrometer is initially calibrated with a suite of standards in order to determine by regression

analysis, interelement correction factors and instrument response factors.

3.3.3 Subsequent calibration is achieved using a smaller number of standards since only the instrument response factors need to

be redetermined. One of these standards (or an optional synthetic pellet) can be used to monitor instrumental drift when performing

a high volume of analyses.

3.4 Additives and additive packages can be determined after dilution with base oil to place the elemental concentrations in the

range described in 1.1.

4. Significance and Use

4.1 Some oils are formulated with organo-metallic additives which act as detergents, antioxidants, antiwear agents, and so forth.

Some of these additives contain one or more of these elements: barium, calcium, phosphorus, sulfur, and zinc. These test methods

provide a means of determining the concentration of these elements which in turn provides an indication of the additive content

of these oils.

4.2 Several additive elements and their compounds are added to the lubricating oils to give beneficial performance (see Table 2).

5. Interferences

5.1 The additive elements found in lubricating oils will affect the measured intensities from the elements of interest to a varying

D4927 − 20

TABLE 2 Lubricants and Additive Materials

Element Compounds Purpose/Application

Barium Sulfonates, Phenates Detergent inhibitors, corrosion inhibitors, detergents, rust inhibitors,

automatic transmission fluids

Calcium Sulfonates, Phenates Detergent inhibitors, dispersants

Phosphorus Dithiophosphates, Phosphates phosphites Anti-rusting agents, extreme pressure additives, anti-wear

Sulfur Base oils, sulfonates, thiophosphates, polysulfides Detergents, extreme pressure additives, anti-wear

and other sulfurized components

Zinc Dialkyldithiophosphates, Dithiocarbamates, Anti-oxidant, corrosion inhibitors, anti-wear additives, detergents,

Phenolates, Carboxylates crankcase oils, hypoid gear lubricants, aircraft piston engine oils, turbine

oils, automatic transmission fluids, railroad diesel engine oils, brake

lubricants

degree. In general for lubricating oils, the X-radiation emitted by the element of interest is absorbed by the other elements in the

sample matrix. Also, the X-radiation emitted from one element can further excite another element. element; this is further referred

to as “enhancement.” These effects are significant at concentrations varying from 0.03 % by mass due to the heavier elements to

1 % by mass for the lighter elements. The measured intensity for a given element can be mathematically corrected for the

absorption and enhancement of the emitted radiation by the other elements present in the sample specimen. Suitable internal

standards can also compensate for X-ray inter-element effects. If an element is present at significant concentrations and an

interelement correction for that element is not employed, the results can be low due to absorption or high due to enhancement.

6. Apparatus

6.1 Wavelength Dispersive X-Ray Spectrometer, equipped for soft X-ray detection of radiation soft X-ray in the range from 1

0.1 nm to 1.0 nm (1 A˚ to 10 10 A˚.). For optimum sensitivity, the spectrometer is equipped with the following:

6.1.1 X-Ray Generating Tube, with chromium, rhodium, or scandium target. Other targets can also be employed.

6.1.2 Helium, purgeable optical path.

6.1.3 Interchangeable Crystals, germanium, lithium fluoride (LiF(LiF200), ), graphite, or pentaerythritol (PET), or a

combination thereof. Other crystals can also be used.

6.1.4 Pulse-Height Analyzer, or other means of energy discrimination.

6.1.5 Detector, flow proportional, or scintillation, or flow proportional and scintillation counter.

6.2 Shaker, Mechanical Stirrer, or Ultrasonic Bath, capable of handling from 30 mL to 1 L bottles.

6.3 X-Ray Disposable Plastic Cells, with suitable film window. Suitable films include Mylar, polypropylene, or polyimid with

film thicknesses between 0.25 mil to 0.35 mil (6.3 μm to 8.8 μm).

NOTE 1—Some films contain contamination of the elements of interest (Mylar in particular). The magnitude of the contamination is assessed and the same

film batch used throughout the entire analysis.

7. Purity of Reagents

7.1 Reagent grade chemicals shall be used in all tests. Unless otherwise indicated, it is intended that all reagents shall conform

to the specifications of the Committee on Analytical Reagents of the American Chemical Society, where such specifications are

available. Other grades may be used, provided it is first ascertained that the reagent is of sufficiently high purity to permit its use

without lessening the accuracy of the determination.

A registered trademark of E. I. du Pont de Nemours and Co.DuPont Teijin Films, LP.

ACS Reagent Chemicals, Specifications and Procedures for Reagents and Standard-Grade Reference Materials, American Chemical Society, Washington, DC. For

suggestions on the testing of reagents not listed by the American Chemical Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset, U.K., and

the United States Pharmacopeia and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, MD.

D4927 − 20

TEST METHOD A (INTERNAL STANDARD PROCEDURE)

8. Reagents and Materials

8.1 Helium, for optical path of spectrometer.

8.2 P-10 Ionization Gas, 90 % by volume argon and 10 % by volume methane for the flow proportional counter.

8.3 Diluent Solvent, a suitable solvent free of metals, sulfur, and phosphorus (for example, kerosene, white oil, or xylenes).

8.4 Internal Standard Materials:

8.4.1 Nickel Octoate, preferably containing 5.0 % by mass 6 0.1 % by mass nickel. If the nickel concentration is higher or lower

(minimum concentration that can be used is 2.5 % by mass 6 0.1 % by mass nickel), the laboratory needs to adjust the amount

of sample taken in 9.1 to yield an equivalent nickel concentration level in the internal standard. Other nickel-containing organic

matrices (free of other metals, sulfur, and phosphorus) may be substituted provided the nickel is stable in solution, the

concentration is known (≥2.5 % by mass 6 0.1 % by mass nickel), and the laboratory can adjust the amount of sample taken in

9.1 to yield an equivalent nickel concentration level in the internal standard if the nickel concentration does not initially contain

5.0 % by mass 6 0.1 % by mass nickel.

NOTE 2—Many X-ray tubes emit copper X rays which increase in intensity with age. This does not present a problem when using copper as an internal

standard for zinc providing that frequent calibrations are performed. No problem exists when using nickel as internal for zinc and nickel is the preferred

internal standard material. The use of a primary beam filter (such as, for example, 100 micron Al) when measuring Cu is recommended to fully avoid

problems with the tube contamination.

8.4.2 Titanium 2-Ethylhexoide or Tin Octoate, preferably containing 8.0 % by mass 6 0.1 % by mass titanium or tin. If the

titanium or tin concentration is higher or lower (minimum concentration that can be used is 4.0 % by mass 6 0.1 % by mass

titanium or tin), the laboratory needs to adjust the amount of sample taken in 9.1 to yield an equivalent titanium or tin concentration

level in the internal standard. Other titanium or tin containing organic matrices (free of other metals, sulfur, and phosphorus) may

be substituted, provided the titanium or tin is stable in solution, the concentration is known (≥4.0 % by mass 6 0.1 % by mass

titanium or tin), and the laboratory can adjust the amount of sample taken in 9.1 to yield an equivalent titanium or tin concentration

level in the internal standard if the titanium or tin concentration does not initially contain 8.0 % by mass 6 0.1 % by mass titanium

or tin.

8.4.3 Zirconium Octoate, preferably containing 12.0 % by mass 6 0.1 % by mass zirconium. If the laboratory uses zirconium

octoate with a lower mass % zirconium concentration level, the laboratory needs to evaporate away the petroleum solvent to yield

a solution that contains 12.0 % by mass 6 0.1 % by mass zirconium. Other zirconium containing organic matrices (free of other

metals, sulfur, and phosphorus) may be substituted, provided the zirconium is stable in solution and the concentration is known

and does not exceed 12.0 % by mass 6 0.1 % by mass zirconium. If the zirconium concentration is <12.0 % by mass 6 0.1 %

by mass , mass, the laboratory needs to evaporate away the petroleum solvent to yield a solution that contains 12.0 % by mass 6

0.1 % by mass zirconium.

8.4.4 Lead Naphthenate, containing 24.0 % by mass 6 0.1 % by mass lead.

8.5 Calibration Standard Materials:

NOTE 3—In addition to calibration standards identified in 8.5.1 – 8.5.5, single-element or multielement calibration standards may also be prepared from

materials similar to the samples being analyzed, provided the calibration standards to be used have previously been characterized by independent primary

(for example, gravimetric or volumetric) analytical techniques to establish the elemental concentration mass percent levels.

8.5.1 Barium 2-Ethylhexoide or Sulfonate, with concentrations ≥4 mass % ≥4 % by mass barium and certified to better than

60.1 % absolute (95 % confidence limit), so that calibration standards can be prepared as stated in 10.1.1 and 10.1.2.

8.5.2 Calcium Octoate or Sulfonate, with concentrations ≥ 4 mass % ≥4 % by mass calcium and certified to better than 60.1 %

absolute (95 % confidence limit), so that calibration standards can be prepared as stated in 10.1.1 and 10.1.2.

D4927 − 20

8.5.3 Bis(2-Ethylhexyl)Hydrogen Phosphate, 97 % purity (9.62 % by mass phosphorus). Other phosphorus containing organic

matrices (free of other metals) may be substituted provided the phosphorus is stable in solution and the concentration is ≥4 mass %

≥4 % by mass phosphorus and certified to better than 60.1 % absolute (95 % confidence limit), so that calibration standards can

be prepared as stated in 10.1.1 and 10.1.2.

8.5.4 Zinc Sulfonate or Octoate, with concentration ≥4 mass % ≥4 % by mass zinc and certified to better than 60.1 % absolute

(95 % confidence limit), so that calibration standards can be prepared as stated in 10.1.1 and 10.1.2.

8.5.5 Di-n-Butyl Sulfide, 97 % purity, (21.9 % by mass sulfur). Other sulfur containing organic matrices (free of metals) may be

substituted, provided the sulfur is stable in solution and the concentration is ≥2 % by mass sulfur and certified to better than

60.1 % absolute (95 % confidence limit), so that calibration standards can be prepared as stated in 10.1.2.

8.6 Quality Control (QC) Samples, preferably are portions of one or more lubricating oils or additives that are stable and

representative of the samples of interest. These QC samples can be used to check the validity of the testing process and

performance of the instrument as described in Section 12.

9. Preparation of Internal Standards

9.1 Barium, Calcium, Phosphorus, and Zinc—Dispense 240 g 6 0.5 g of nickel octoate (5.0 % 6 0.1 % by mass nickel), 30 g 6

0.1 g of titanium 2-ethylhexoide (8.0 % 6 0.1 % by mass titanium) or 30 g 6 0.1 g of tin octoate (8.0 % 6 0.1 % by mass tin),

and 450 g 6 1 g of diluent solvent into a 1 L bottle. Shake or stir the bottle for a minimum of 10 min. If the laboratory uses internal

materials that have different elemental concentrations than those explicitly stated in 8.4.1 and 8.4.2, it will be necessary for the

laboratory to adjust the amount of sample taken in order to obtain an equivalent elemental concentration in the internal standard

blend that is prepared according to the following equations:

A 5 240 3 5/x (1)

~ !

B 5 30 3 8/y (2)

~ !

C 5 720 2 @A1B# (3)

where:

A = nickel containing material in blend, g,

B = titanium or tin containing material in blend, g,

C = diluent to add to blend, g,

x = nickel in material chosen as an internal standard, mass %, and

y = titanium or tin in material chosen as an internal standard, mass %.

9.2 Sulfur—Lead naphthenate, 24 % by mass lead, serves as a suitable internal standard. (Warning—Hazardous. Lead

naphthenate is toxic and precautions should be taken to avoid inhalation of vapors, ingestion, or skin contact.) No further treatment

of this compound is necessary.

10. Preparation of Calibration Standards

10.1 Barium, Calcium, Phosphorus, and Zinc:

10.1.1 For concentrations less than 0.1 % by mass, prepare standards containing 0.00 % by mass, 0.01 % by mass, 0.025 % by

mass, 0.050 % by mass, 0.075 % by mass, and 0.10 % by mass of each respective element in the diluent solvent.

10.1.2 For concentrations greater than 0.1 % by mass, prepare standards containing 0.00 % by mass, 0.10 % by mass, 0.25 % by

mass, 0.50 % by mass, 0.75 % by mass, and 1.00 % by mass of each respective element in the diluent solvent.

10.1.3 Dispense 1.000 g 6 0.001 g of the zirconium internal standard solution described in 8.4.3 into a 30 mL bottle. Prepare an

individual bottle for each of the calibration standards.

10.1.4 Dispense 1.000 g 6 0.001 g of the internal standard solution described in 9.1 into a 30 mL bottle. Repeat for all of the

calibration-standard bottles.

D4927 − 20

10.1.5 Add 8.00 g 6 0.001 g of each standard to a respective bottle containing the internal standards and shake or stir well

(minimum of 10 min) to mix the constituents.

10.2 Sulfur:

10.2.1 Prepare five standards covering the range from 0.00 % by mass to 2.00 % by mass sulfur in the diluent solvent.

10.2.2 Dispense 1.000 g 6 0.001 g of lead internal standard into 30 mL bottles (one bottle for each standard).

10.2.3 Add 9.000 g 6 0.001 g of each standard to each respective bottle containing internal standard. Shake or stir contents for

a minimum of 10 min using apparatus defined in 6.2.

11. Instrument Calibration for Barium, Calcium, Phosphorus, Sulfur, and Zinc

11.1 Fill respective X-ray cups at least half full with the calibration standard solutions. Make sure that no wrinkles or bulges are

present in the film. The film must be flat.

11.2 Place the sample cups in the X-ray beam in order to measure and record the net intensity (peak intensity—background

intensity minus background intensity) for both the analyte signal and the internal standard signal accordingsignal. Table 3 to the

wavelengths and conditions suggested in provides suggested crystal parameters. Table 3. Up to 60 s counting periods may be used

at each wavelength position. Do this for each of the calibration standards for each of the elements.

NOTE 4—The parameters indicated in Table 3 are presented for guidance only and they will vary according to the instrument used.

11.3 Calculate the ratio, R, of the net element counts to their corresponding net internal standard counts for all of the net elements

and standards as follows:

R 5 E/I (4)

where:

E = net element counts, and

I = net internal standard counts.

NOTE 5—Many modern X-ray spectrometer instruments will calculate this ratio automatically and store the information in the instrument computer

system.

NOTE 6—Many modern X-ray spectrometer instruments use count rate (intensity, expressed in kcps) instead of counts collected in a given measuring time.

11.4 Perform regression analyses for each calibration element by ratioing the net element counts to the net internal standard counts

versus the element concentration (mass %) on linear graph paper or by way of the instrument computer system. It is r

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...