ASTM E1823-96(2002)

(Terminology)Standard Terminology Relating to Fatigue and Fracture Testing

Standard Terminology Relating to Fatigue and Fracture Testing

SCOPE

1.1 This terminology contains definitions, definitions of terms specific to certain standards, symbols, and abbreviations approved for use in standards on fatigue and fracture testing. the definitions are preceded by two lists. The first is an alphabetical listing of the symbols used. (Greek symbols are listed in accordance with their spelling in English.) The second is an alphabetical listing of relevant abbreviations.

1.2 This terminology includes Annex A1 on Units and Annex A2 on Designation Codes for Specimen Configuration, applied Loading, and Crack or Notch Orientation.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 1823 – 96 (Reapproved 2002)

Standard Terminology

Relating to Fatigue and Fracture Testing

This standard is issued under the fixed designation E1823; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E740 Practice for Fracture Testing with Surface-Crack

Tension Specimens

1.1 This terminology contains definitions, definitions of

E812 Test Method for Crack Strength of Slow-Bend Pre-

terms specific to certain standards, symbols, and abbreviations

cracked Charpy Specimens of High-Strength Metallic

approved for use in standards on fatigue and fracture testing.

Materials

The definitions are preceded by two lists. The first is an

E813 Test Method for J , a Measure of Fracture Tough-

alphabetical listing of symbols used. (Greek symbols are listed Ic

ness

in accordance with their spelling in English.) The second is an

E992 Practice for Determination of Fracture Toughness of

alphabetical listing of relevant abbreviations.

Steels Using Equivalent Energy Methodology

1.2 This terminology includes Annex A1 on Units and

E1049 Practices for Cycle Counting in Fatigue Analysis

AnnexA2 on Designation Codes for Specimen Configuration,

E1152 Test Method for Determining J-R Curves

Applied Loading, and Crack or Notch Orientation.

E1221 Test Method for Determining Plane-Strain Crack-

2. Referenced Documents

Arrest Fracture Toughness, K , of Ferritic Steels

Ia

E1290 Test Method for Crack-Tip Opening Displacement

2.1 ASTM Standards:

(CTOD) Fracture Toughness Measurement

E6 Terminology Relating to Methods of Mechanical Test-

E 1304 Test Method for Plane-Strain (Chevron-Notch)

ing

Fracture Toughness of Metallic Materials

E338 Test Method for Sharp-Notch Tension Testing of

E1457 Test Method for Measurement of Creep Crack

High-Strength Sheet Materials

Growth Rates in Metals

E399 Test Method for Plane-Strain Fracture Toughness of

E1681 Test Method for Determining a Threshold Stress

Metallic Materials

Intensity Factor for Environment-Assisted Cracking of

E436 Test Method for Drop-Weight Tear Tests of Ferritic

Metallic Materials Under Constant Load

Steels

E1737 TestMethodforJ-IntegralCharacterizationofFrac-

E466 Practice for Conducting Force-Controlled Constant

ture Toughness

Amplitude Axial Fatigue Tests of Metallic Materials

E1820 Test Method for Measurement of Fracture Tough-

E467 Practice for Verification of Constant Amplitude Dy-

ness

namic Forces in an Axial Load Fatigue Testing System

G15 Terminology Relating to Corrosion and Corrosion

E468 Practice for Presentation of Constant Amplitude Fa-

Testing

tigue Test Results for Metallic Materials

E561 Practice for R-Curve Determination

3. Terminology

E602 Test Method for Sharp-Notch Tension Testing with

3.1 AlphabeticalListingofPrincipalSymbolsUsedinThis

Cylindrical Specimens

Terminology:

E604 Test Method for Dynamic Tear Testing of Metallic

Materials

Symbol Term

E606 Practice for Strain-Controlled Fatigue Testing

a crack depth, crack length, crack size, estimated crack

E647 Test Method for Measurement of Fatigue Crack size

a effective crack size

e

Growth Rates

a notch length

n

E739 Practice for Statistical Analysis of Linear or Linear-

a original crack size

o

ized Stress-Life (S-N) and Strain-Life (e-N) Fatigue Data

1 3

ThisterminologyisunderthejurisdictionofASTMCommitteeE08onFatigue Discontinued.ReplacedbyE1737.See1996AnnualBookofASTMStandards,

and Fracture and is the direct responsibility of Subcommittee E08.02 on Standards Vol 03.01.

and Terminology. Discontinued. See 1996 Annual Book of ASTM Standards, Vol 03.01.

Current edition approved Oct. 10, 2002. Published April 2003. Originally Discontinued.ReplacedbyE1820.See1997AnnualBookofASTMStandards,

approved in 1996. Last previous edition approved in 1996 as E1823–96. Vol 03.01.

2 6

Annual Book of ASTM Standards, Vol 03.01. Annual Book of ASTM Standards, Vol 03.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 1823 – 96 (2002)

Symbol Term Symbol Term

a physical crack size T specimen temperature

p

a/W normalized crack size t transition time

T

A load ratio (P /P ) t total cycle period

a m t

A net-section area t ,t , t shear stresses (refer to Fig. 1)

N xy yz zx

b remaining ligament u displacement in x direction

b original uncracked ligament v displacement in y direction

o

B specimen thickness 2v crack-mouth opening displacement

m

B effective thickness V load-line displacement due to creep

e c

B net thickness w displacement in z direction

N

2c surface-crack length W specimen width

C normalized K-gradient Y* stress-intensity factor coefficient

D cycle ratio (n/N ) Y* minimum stress-intensity factor coefficient

f m

C*(t) C*(t) − Integral

3.2 Alphabetical Listing of Abbreviations Used:

da/dN fatigue-crack-growth rate

d crack-tip opening displacement (CTOD)

CMOD crack-mouth opening displacement

dd speciment gage length

COD see CTOD

Da crack extension, estimated crack extension

CTOD crack-tip opening displacement

DK stress-intensity-factor range

DT dynamic tear

DK fatigue-crack-growth threshold

th

DWTT drop-weight tear test

DP load range

EAC environment-assisted cracking

e strain amplitude

a

K-EE equivalent-energy fracture toughness

e inelastic strain

in NTS notch tensile strength

e mean load

m

PS part-through surface

G crack-extension force

SCC stress corrosion cracking

G crack-extension resistance

R

SZW stretch zone width

H* specimen center of pin hole distance

G the path of the J-integral

3.3 Definitions—Each definition is followed by the desig-

JJ-integral

nation(s) of the standard(s) of origin. The listing of definitions

J plane-strain fracture toughness

Ic

is alphabetical.

J crack-extension resistance

R

k fatigue notch factor

f

alternating load—See loading amplitude.

k theoretical stress concentration factor (sometimes ab-

t

breviated stress concentration factor)

block—in fatigue loading, a specified number of constant

K, K , K , K , stress-intensity factor (see mode)

1 2 3

amplitude loading cycles applied consecutively, or a spec-

K , K , K

I II III

trum loading sequence of finite length that is repeated

K crack-arrest fracture toughness

a

K plane-stress fracture toughness

c identically. E 1823

K stress intensity factor threshold for environment-

EAC

blunting line—in fracture testing, a line that approximates

assisted cracking

apparent crack advance due to crack-tip blunting in the

K plane-strain crack-arrest fracture toughness

Ia

K stress intensity factor threshold for plane strain

IEAC absence of slow stable crack tearing. The line is defined

environment-assisted cracking

based on the assumption that the crack advance is equal to

K plane-strain fracture toughness

Ic

onehalfofthecrack-tipopeningdisplacement.Thisestimate

K , K , K plane-strain (chevron-notch) fracture toughness

IvM Iv Ivj

K maximum stress-intensity factor

max

of pseudo-crack advance, Da , is based on the effective

B

K minimum stress-intensity factor

min

yield strength of the material tested. E 813

K stress-intensity factor at crack initiation

o

K crack-extension resistance

R

Da 5 J/2 s (1)

B Y

n cycles endured 3 −1

circulation rate [L T ]—in fatigue testing, the volume rate

N fatigue life

f

of change of the environment chamber volume. E 1823

P load

P load amplitude

a

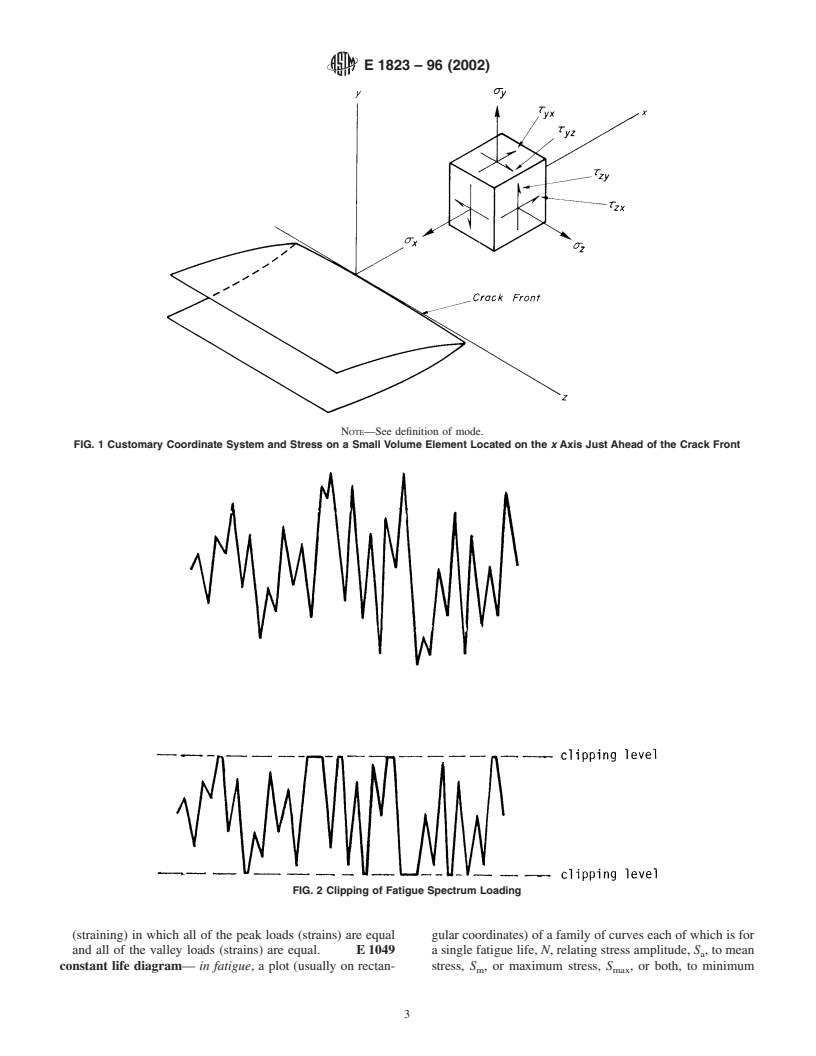

clipping—in fatigue spectrum loading, the process of decreas-

P mean load

m

ingorincreasingthemagnitudeofallloads(strains)thatare,

P precrack load

M

P maximum load respectively, above or below a specified level, referred to as

max

P minimum load

min

clipping level; the loads (strains) are decreased or increased

q fatigue notch sensitivity

to the clipping level (see Fig. 2). E 1823

r effective unloading slope ratio

−1

compliance (LF ],n—theratioofdisplacementincrementto

r critical slope ratio

c

r plastic-zone adjustment

y

load increment. E 1820

R load ratio (P /P )

min max

confidence interval—an interval estimate of a population

s sample standard deviation

parameter computed so that the statement 88the population

s sample variance

S specimen span

parameter included in this interval” will be true, on the

S load amplitude

a

average, in a stated proportion of the times such computa-

S fatigue limit

f

S mean load tions are made based on different samples from the popula-

m

S fatigue strength at N cycles

N

tion. E 1823

s crack strength

c

confidence level (or coefficient)—the stated proportion of the

s nominal (net-section) stress

N

s residual strength times the confidence interval is expected to include the

r

s sharp-notch strength

s

population parameter. E 1823

s tensile strength

TS

confidence limits—the two statistics that define a confidence

s , s , s normal stresses (refer to )

x y z

s effective yield strength interval. E 1823

Y

s yield strength

YS

constant amplitude loading— in fatigue loading, a loading

E 1823 – 96 (2002)

NOTE—See definition of mode.

FIG. 1 Customary Coordinate System and Stress on a Small Volume Element Located on the x Axis Just Ahead of the Crack Front

FIG. 2 Clipping of Fatigue Spectrum Loading

(straining) in which all of the peak loads (strains) are equal gular coordinates) of a family of curves each of which is for

and all of the valley loads (strains) are equal. E 1049 a single fatigue life, N, relating stress amplitude, S , to mean

a

constant life diagram— in fatigue, a plot (usually on rectan- stress, S , or maximum stress, S , or both, to minimum

m max

E 1823 – 96 (2002)

is measured on the specimen surface at the midpoint of the crack

stress, S . The constant life fatigue diagram is usually

min

length. E 740

derived from a family of S-N curves each of which repre-

sents a different stress ratio (A or R) for a 50% probability

crack-plane orientation—an identification of the plane and

of survival. E 1823

direction of a fracture in relation to product configuration.

corrosion fatigue—the process by which fracture occurs

This identification is designated by a hyphenated code with

prematurely under conditions of simultaneous corrosion and

the first letter(s) representing the direction normal to the

repeatedcyclicloadingatlowerstresslevelsorfewercycles

crackplaneandthesecondletter(s)designatingtheexpected

than would be required in the absence of the corrosive

direction of crack propagation.

environment. G15

DISCUSSION—See also Annex A2, (A2.4 on crack or notch orienta-

counting method—in fatigue spectrum loading, a method of

tion). E 399

counting the occurrences and defining the magnitude of

various loading parameters from a load-time history; (some

crack size, a [L]—a lineal measure of a principal planar

of the counting methods are: level crossing count, peak

dimensionofacrack.Thismeasureiscommonlyusedinthe

count, mean crossing peak count, range count, range-pair

calculation of quantities descriptive of the stress and dis-

count, rain-flow count, racetrack count). E 1049

placement fields and is often also termed crack length or

crack displacement [L]—the load-induced separation vector

depth.

between two points (on the facing surfaces of a crack) that

DISCUSSION—In practice, the value of a is obtained from procedures

were initially coincident.

for measurement of physical crack size, a , original crack size, a , and

p o

DISCUSSION—In Practice E561, displacement is the distance that a

effectivecracksize,a ,asappropriatetothesituationbeingconsidered.

e

chosen measurement point on the specimen displaces normal to the

E 647

crack plane. Measurement points on the C(W) and C(T) specimen

−2

crack strength, s [FL ]—the maximum value of the nomi-

configurations are identified as locations V0, V1, and V2. E 561 c

nal stress that a cracked structure is capable of sustaining.

crack extension, Da [L]—an increase in crack size.

DISCUSSION—1 Crack strength is calculated on the basis of the

DISCUSSION—For example, in Practice E561, Da or Da is the

p e maximum load and the original minimum cross-sectional area (net

difference between the crack size, either a (physical crack size) or a

p e cross section or ligament). Thus, it takes into account the original size

of the crack but ignores any crack extension that may occur during the

(effective crack size), and a (original crack size). E 561

o

test.

−1 −2

crack-extension force, G [FL or FLL ]—the elastic en-

DISCUSSION—2 Crack strength is analogous to the ultimate tensile

ergyperunitofnewseparationareathatismadeavailableat strength, as it is based on the ratio of the maximum load to the

the front of an ideal crack in an elastic solid during a virtual

minimum cross-sectional area at the start of the test. E 338, E 602

increment of forward crack extension.

crack-tip opening displacement (CTOD), d, [L]—the crack

DISCUSSION—This force concept implies an analytical model for

displacement resulting from the total deformation (elastic

which the stress-strain relations are regarded as elastic. The preceding

plus plastic) at variously defined locations near the original

definition of G applies to either static cracks or running cracks. From

(prior to load application) crack tip.

past usage, G is commonly associated with linear-elastic methods of

analysis, although the J (see J-integral) also may be used for such

DISCUSSION—In common practice, d is estimated for Mode 1 by

inference from observations of crack displacement nearby or away, or

analyses. E 1823

both, from the crack tip. E 1290

−3/2 −1

crack-extension resistance, K [FL ], G [FL ]or J

R R R

−1

crack-tip plane strain—a stress-strain field (near the crack

[FL ]—a measure of the resistance of a material to crack

tip)thatapproachesplanestraintothedegreerequiredbyan

extensionexpressedintermsofthestress-intensityfactor,K;

empirical criterion.

crack-extension force, G; or values of J derived using the

J-integral concept.

DISCUSSION—For example, in Mode 1, the criterion for crack-tip

plane strain given by Test Method E399 requires that plate thickness,

DISCUSSION—See definition of R-curve. E 561

B, must be equal to or greater than 2.5 (K/s ) . E 399

YS

crack length, a [L]—See crack size and surface crack length.

crack-tip plane stress—astress-strainfield(nearthecracktip)

Also see crack length in the Description of Terms. For

that is not in plane strain.

example, in the C(T) specimen, a is measured from the line

DISCUSSION—In such situations, a significant degree of plane strain

connecting the bearing points of load application; in the

may be present. E 1823

M(T) specimen, a is measured from the perpendicular

bisector

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.