ASTM G168-17

(Practice)Standard Practice for Making and Using Precracked Double Beam Stress Corrosion Specimens

Standard Practice for Making and Using Precracked Double Beam Stress Corrosion Specimens

SIGNIFICANCE AND USE

5.1 Precracked specimens offer the opportunity to use the principles of linear elastic fracture mechanics (1)4 to evaluate resistance to stress corrosion cracking in the presence of a pre-existing crack. This type of evaluation is not included in conventional bent beam, C-ring, U-bend, and tension specimens. The precracked double beam specimen is particularly useful for evaluation of materials that display a strong dependence on grain orientation. Since the specimen dimension in the direction of applied stress is small for the precracked double beam specimen, it can be successfully used to evaluate short transverse stress corrosion cracking of wrought products, such as rolled plate or extrusions. The research applications and analysis of precracked specimens in general, and the precracked double beam specimen in particular, are discussed in Appendix X1.

5.2 The precracked double beam specimen may be stressed in either constant displacement or constant load. Constant displacement specimens stressed by loading bolts or wedges are compact and self-contained. By comparison, constant load specimens stressed with springs (for example, proof rings, discussed in Test Method G49, 7.2.1.2) or by deadweight loading require additional fixtures that remain with the specimen during exposure.

5.3 The recommendations of this practice are based on the results of interlaboratory programs to evaluate precracked specimen test procedures (2, 3) as well as considerable industrial experience with the precracked double beam specimen and other precracked specimen geometries (4-8).

SCOPE

1.1 This practice covers procedures for fabricating, preparing, and using precracked double beam stress corrosion test specimens. This specimen configuration was formerly designated the double cantilever beam (DCB) specimen. Guidelines are given for methods of exposure and inspection.

1.2 The precracked double beam specimen, as described in this practice, is applicable for evaluation of a wide variety of metals exposed to corrosive environments. It is particularly suited to evaluation of products having a highly directional grain structure, such as rolled plate, forgings, and extrusions, when stressed in the short transverse direction.

1.3 The precracked double beam specimen may be stressed in constant displacement by bolt or wedge loading or in constant load by use of proof rings or dead weight loading. The precracked double beam specimen is amenable to exposure to aqueous or other liquid solutions by specimen immersion or by periodic dropwise addition of solution to the crack tip, or exposure to the atmosphere.

1.4 This practice is concerned only with precracked double beam specimen and not with the detailed environmental aspects of stress corrosion testing, which are covered in Practices G35, G36, G37, G41, G44, and G50.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: G168 − 17

Standard Practice for

Making and Using Precracked Double Beam Stress

1

Corrosion Specimens

This standard is issued under the fixed designation G168; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

1.1 This practice covers procedures for fabricating, 2.1 ASTM Standards:

preparing, and using precracked double beam stress corrosion D1193 Specification for Reagent Water

test specimens. This specimen configuration was formerly E8/E8M Test Methods for Tension Testing of Metallic Ma-

designated the double cantilever beam (DCB) specimen. terials

Guidelines are given for methods of exposure and inspection. E399 Test Method for Linear-Elastic Plane-Strain Fracture

Toughness K of Metallic Materials

Ic

1.2 The precracked double beam specimen, as described in

E1823 TerminologyRelatingtoFatigueandFractureTesting

this practice, is applicable for evaluation of a wide variety of

G15 Terminology Relating to Corrosion and Corrosion Test-

metals exposed to corrosive environments. It is particularly

3

ing (Withdrawn 2010)

suited to evaluation of products having a highly directional

G35 Practice for Determining the Susceptibility of Stainless

grain structure, such as rolled plate, forgings, and extrusions,

Steels and Related Nickel-Chromium-Iron Alloys to

when stressed in the short transverse direction.

Stress-Corrosion Cracking in Polythionic Acids

1.3 The precracked double beam specimen may be stressed

G36 Practice for Evaluating Stress-Corrosion-Cracking Re-

in constant displacement by bolt or wedge loading or in

sistance of Metals and Alloys in a Boiling Magnesium

constantloadbyuseofproofringsordeadweightloading.The

Chloride Solution

precracked double beam specimen is amenable to exposure to

G37 Practice for Use of Mattsson’s Solution of pH 7.2 to

aqueous or other liquid solutions by specimen immersion or by

Evaluate the Stress-Corrosion Cracking Susceptibility of

periodic dropwise addition of solution to the crack tip, or

Copper-Zinc Alloys

exposure to the atmosphere.

G41 Practice for Determining Cracking Susceptibility of

Metals Exposed Under Stress to a Hot Salt Environment

1.4 This practice is concerned only with precracked double

beam specimen and not with the detailed environmental G44 PracticeforExposureofMetalsandAlloysbyAlternate

Immersion in Neutral 3.5 % Sodium Chloride Solution

aspects of stress corrosion testing, which are covered in

Practices G35, G36, G37, G41, G44, and G50. G49 Practice for Preparation and Use of Direct Tension

Stress-Corrosion Test Specimens

1.5 This standard does not purport to address all of the

G50 Practice for Conducting Atmospheric Corrosion Tests

safety concerns, if any, associated with its use. It is the

on Metals

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

3. Terminology

mine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accor-

3.1 Definitions of Terms Specific to This Standard:

dance with internationally recognized principles on standard- 3.1.1 stress corrosion cracking (SCC) threshold stress

ization established in the Decision on Principles for the

intensity, K —the stress intensity level below which stress

Iscc

Development of International Standards, Guides and Recom- corrosioncrackingdoesnotoccurforaspecificcombinationof

mendations issued by the World Trade Organization Technical

material and environment when plane strain conditions are

Barriers to Trade (TBT) Committee. satisfied.

1 2

This practice is under the jurisdiction of ASTM Committee G01 on Corrosion For referenced ASTM standards, visit the ASTM website, www.astm.org, or

of Metals and is the direct responsibility of Subcommittee G01.06 on Environmen- contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

tally Assisted Cracking. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Nov. 1, 2017. Published December 2017. Originally the ASTM website.

3

approved in 2000. Last previous edition approved in 2013 as G168 – 00 (2013). The last approved version of this historical standard is referenced on

DOI: 10.1520/G0168-17. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959.

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: G168 − 00 (Reapproved 2013) G168 − 17

Standard Practice for

Making and Using Precracked Double Beam Stress

1

Corrosion Specimens

This standard is issued under the fixed designation G168; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

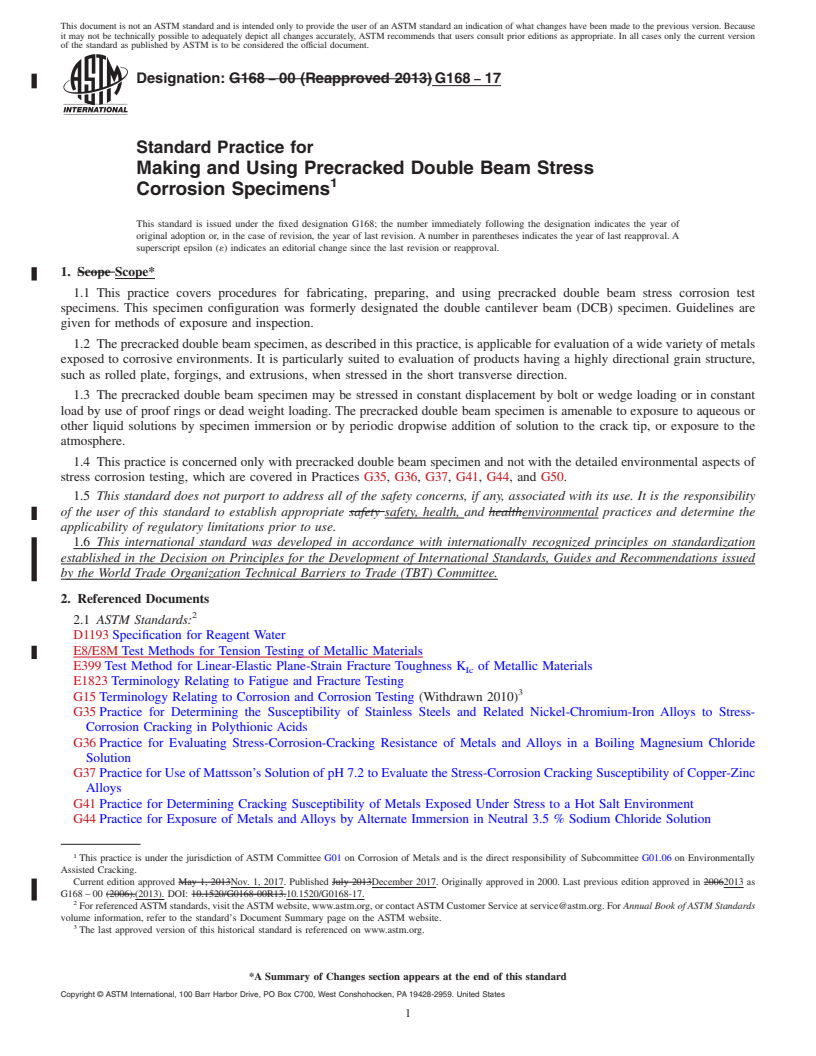

1. Scope Scope*

1.1 This practice covers procedures for fabricating, preparing, and using precracked double beam stress corrosion test

specimens. This specimen configuration was formerly designated the double cantilever beam (DCB) specimen. Guidelines are

given for methods of exposure and inspection.

1.2 The precracked double beam specimen, as described in this practice, is applicable for evaluation of a wide variety of metals

exposed to corrosive environments. It is particularly suited to evaluation of products having a highly directional grain structure,

such as rolled plate, forgings, and extrusions, when stressed in the short transverse direction.

1.3 The precracked double beam specimen may be stressed in constant displacement by bolt or wedge loading or in constant

load by use of proof rings or dead weight loading. The precracked double beam specimen is amenable to exposure to aqueous or

other liquid solutions by specimen immersion or by periodic dropwise addition of solution to the crack tip, or exposure to the

atmosphere.

1.4 This practice is concerned only with precracked double beam specimen and not with the detailed environmental aspects of

stress corrosion testing, which are covered in Practices G35, G36, G37, G41, G44, and G50.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D1193 Specification for Reagent Water

E8/E8M Test Methods for Tension Testing of Metallic Materials

E399 Test Method for Linear-Elastic Plane-Strain Fracture Toughness K of Metallic Materials

Ic

E1823 Terminology Relating to Fatigue and Fracture Testing

3

G15 Terminology Relating to Corrosion and Corrosion Testing (Withdrawn 2010)

G35 Practice for Determining the Susceptibility of Stainless Steels and Related Nickel-Chromium-Iron Alloys to Stress-

Corrosion Cracking in Polythionic Acids

G36 Practice for Evaluating Stress-Corrosion-Cracking Resistance of Metals and Alloys in a Boiling Magnesium Chloride

Solution

G37 Practice for Use of Mattsson’s Solution of pH 7.2 to Evaluate the Stress-Corrosion Cracking Susceptibility of Copper-Zinc

Alloys

G41 Practice for Determining Cracking Susceptibility of Metals Exposed Under Stress to a Hot Salt Environment

G44 Practice for Exposure of Metals and Alloys by Alternate Immersion in Neutral 3.5 % Sodium Chloride Solution

1

This practice is under the jurisdiction of ASTM Committee G01 on Corrosion of Metals and is the direct responsibility of Subcommittee G01.06 on Environmentally

Assisted Cracking.

Current edition approved May 1, 2013Nov. 1, 2017. Published July 2013December 2017. Originally approved in 2000. Last previous edition approved in 20062013 as

G168 – 00 (2006).(2013). DOI: 10.1520/G0168-00R13.10.1520/G0168-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G168 − 17

G49 Practice for Preparation and Use of Direct Tension Stress-Corrosion Test Specimens

G50 Practice for Conducting Atmospheric Corrosion Tests on M

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.