ASTM G46-21

(Guide)Standard Guide for Examination and Evaluation of Pitting Corrosion

Standard Guide for Examination and Evaluation of Pitting Corrosion

SIGNIFICANCE AND USE

4.1 It is important to be able to determine the extent of pitting, either in a service application in which it is necessary to predict the remaining life in a metal structure, or in laboratory test programs that are used to select the most pitting-resistant materials for service. The purpose of the study is crucial in determining the appropriate examination and evaluation steps.

4.2 Some typical purposes of laboratory tests include, but are not limited to, evaluating performance of alloys, determining whether an alloy is resistant to the environment, evaluating how environmental conditions including corrosion inhibitor affect or prevent pitting, and evaluating whether a lot of metal is sufficiently resistant for its use in a particular application or environment.

4.3 Some typical purposes of field studies include, but are not limited to, determining if pits are likely to grow and cause leak or release of process fluid, and assisting a determination of whether to replace or repair damage from pits (remaining life assessment).

SCOPE

1.1 This guide covers the selection of procedures that can be used in the examination and evaluation of pitted metals. These procedures include both nondestructive and destructive approaches.

1.2 The procedures covered in this guide include those that may be used in laboratory evaluations of corroded metal specimens and field examinations and inspections.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.3.1 Exception—In X1.2.1, mils per year (MPY) are regarded as standard for the target corrosion rate.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: G46 − 21

Standard Guide for

1

Examination and Evaluation of Pitting Corrosion

ThisstandardisissuedunderthefixeddesignationG46;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope G16Guide for Applying Statistics to Analysis of Corrosion

Data

1.1 Thisguidecoverstheselectionofproceduresthatcanbe

G61Test Method for Conducting Cyclic Potentiodynamic

used in the examination and evaluation of pitted metals.These

Polarization Measurements for Localized Corrosion Sus-

procedures include both nondestructive and destructive ap-

ceptibility of Iron-, Nickel-, or Cobalt-Based Alloys

proaches.

G193Terminology and Acronyms Relating to Corrosion

1.2 The procedures covered in this guide include those that 3

2.2 ISO Standard:

may be used in laboratory evaluations of corroded metal

ISO 25178-604:2013(E)Geometrical product specifications

specimens and field examinations and inspections.

(GPS) — Surface texture: Areal — Part 604: Nominal

characteristics of non-contact (coherence scanning inter-

1.3 The values stated in SI units are to be regarded as

standard. The values given in parentheses after SI units are ferometry) instruments

4

2.3 NACE Standards:

providedforinformationonlyandarenotconsideredstandard.

1.3.1 Exception—In X1.2.1, mils per year (MPY) are re- NACE RP-01-73Collection and Identification of Corrosion

5

Products

garded as standard for the target corrosion rate.

NACESP0775Preparation,Installation,Analysis,andInter-

1.4 This standard does not purport to address all of the

pretation of Corrosion Coupons in Oilfield Operations

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3. Terminology

priate safety, health, and environmental practices and deter-

3.1 Terms and acronyms used in this guide are defined in

mine the applicability of regulatory limitations prior to use.

Terminology G193.

1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard- 4. Significance and Use

ization established in the Decision on Principles for the

4.1 It is important to be able to determine the extent of

Development of International Standards, Guides and Recom-

pitting, either in a service application in which it is necessary

mendations issued by the World Trade Organization Technical

to predict the remaining life in a metal structure, or in

Barriers to Trade (TBT) Committee.

laboratory test programs that are used to select the most

pitting-resistantmaterialsforservice.Thepurposeofthestudy

2. Referenced Documents

is crucial in determining the appropriate examination and

2

evaluation steps.

2.1 ASTM Standards:

E3Guide for Preparation of Metallographic Specimens

4.2 Some typical purposes of laboratory tests include, but

G1Practice for Preparing, Cleaning, and Evaluating Corro-

are not limited to, evaluating performance of alloys, determin-

sion Test Specimens

ingwhetheranalloyisresistanttotheenvironment,evaluating

how environmental conditions including corrosion inhibitor

affect or prevent pitting, and evaluating whether a lot of metal

1

This guide is under the jurisdiction ofASTM Committee G01 on Corrosion of

is sufficiently resistant for its use in a particular application or

Metals and is the direct responsibility of Subcommittee G01.05 on Laboratory

environment.

Corrosion Tests.

Current edition approved Aug. 1, 2021. Published October 2021. Originally

3

approved in 1976. Last previous edition approved in 2018 as G46-94 (2018). DOI: Available from International Organization for Standardization (ISO), ISO

10.1520/G0046-21. Central Secretariat, Chemin de Blandonnet 8, CP 401, 1214 Vernier, Geneva,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Switzerland, https://www.iso.org.

4

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM AvailablefromAssociationforMaterialsProtectionandPerformance(AMPP),

Standards volume information, refer to the standard’s Document Summary page on 15835 Park Ten Pl., Houston, TX 77084, http://www.ampp.org.

5

the ASTM website.

Insert in Materials Protection and Performance,Vol 12, June 1973, p. 65.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G46−21

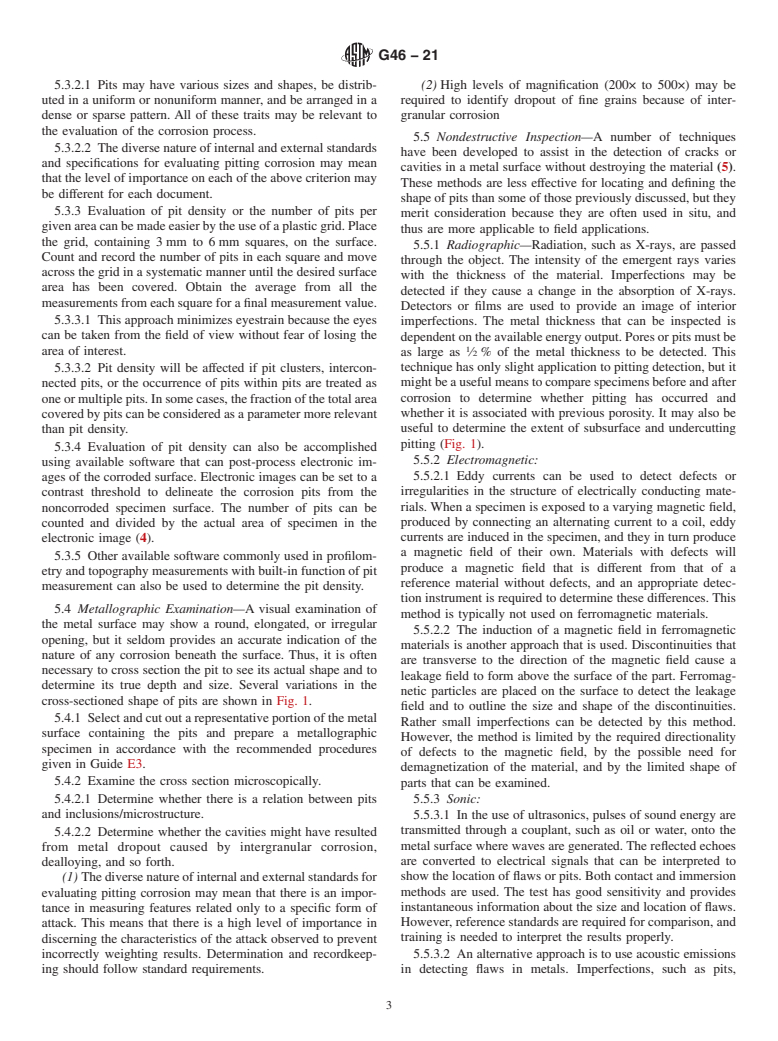

FIG. 1 Variations in Cross-Sectional Shape of Pits

4.3 Some typical purposes of field studies include, but are (20×) t

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: G46 − 94 (Reapproved 2018) G46 − 21

Standard Guide for

1

Examination and Evaluation of Pitting Corrosion

This standard is issued under the fixed designation G46; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide covers the selection of procedures that can be used in the identification and examination of pits and in the evaluation

of pitting (See Terminologyexamination and evaluation of pitted metals. These G15) corrosion to determine the extent of its

effect.procedures include both nondestructive and destructive approaches.

1.2 The procedures covered in this guide include those that may be used in laboratory evaluations of corroded metal specimens

and field examinations and inspections.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for

information only and are not considered standard.

1.3.1 Exception—In X1.2.1, mils per year (MPY) are regarded as standard for the target corrosion rate.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E3 Guide for Preparation of Metallographic Specimens

G1 Practice for Preparing, Cleaning, and Evaluating Corrosion Test Specimens

3

G15 Terminology Relating to Corrosion and Corrosion Testing (Withdrawn 2010)

G16 Guide for Applying Statistics to Analysis of Corrosion Data

G61 Test Method for Conducting Cyclic Potentiodynamic Polarization Measurements for Localized Corrosion Susceptibility of

Iron-, Nickel-, or Cobalt-Based Alloys

G193 Terminology and Acronyms Relating to Corrosion

1

This guide is under the jurisdiction of ASTM Committee G01 on Corrosion of Metals and is the direct responsibility of Subcommittee G01.05 on Laboratory Corrosion

Tests.

Current edition approved Oct. 1, 2018Aug. 1, 2021. Published November 2018October 2021. Originally approved in 1976. Last previous edition approved in 20132018

as G46 – 94 (2013).G46-94 (2018). DOI: 10.1520/G0046-94R18.10.1520/G0046-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G46 − 21

3

2.2 ISO Standard:

ISO 25178-604:2013(E) Geometrical product specifications (GPS) — Surface texture: Areal — Part 604: Nominal character-

istics of non-contact (coherence scanning interferometry) instruments

4

2.3 National Association of Corrosion Engineers Standard:NACE Standards:

5

NACE RP-01-73 Collection and Identification of Corrosion Products

NACE SP0775 Preparation, Installation, Analysis, and Interpretation of Corrosion Coupons in Oilfield Operations

3. Terminology

3.1 Terms and acronyms used in this guide are defined in Terminology G193.

4. Significance and Use

4.1 It is important to be able to determine the extent of pitting, either in a service application where in which it is necessary to

predict the remaining life in a metal structure, or in laboratory test programs that are used to select the most pitting-resistant

materials for service. The purpose of the study is crucial in determining the appropriate examination and evaluation steps.

4.2 Some typical purposes of laboratory tests include, but are not limited to, evaluating performance of alloys, determining

whether an alloy is resistant to the environment, evaluating how environmental conditions including corrosion inhibitor affect or

prevent pitting, and evaluating whether a lot of metal is sufficiently

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.