ASTM F2644-07

(Test Method)Standard Test Method for Performance of Commercial Patio Heaters

Standard Test Method for Performance of Commercial Patio Heaters

SIGNIFICANCE AND USE

The energy input rate test is used to confirm that the patio heater is operating properly prior to further testing.

Preheat energy and time can be useful to food service operators to manage energy demands and to know how quickly the patio heater can be ready for operation.

The temperature distribution of a patio heater can be used by operators and designers to determine the most effective layout for a patio heating system.

The effective heated area can be used by operators to choose a patio heater that meets their heating needs.

SCOPE

1.1 This test method covers the heating performance and energy consumption of commercial radiant patio heaters. The food service operator can use this evaluation to select a commercial patio heater and understand its energy performance and effective heated area.

1.2 This test method is applicable to commercial gas and electric radiant patio heaters.

1.3 The patio heater can be evaluated with respect to the following:

1.3.1 Energy input rate (10.2),

1.3.2 Preheat energy consumption and time (10.3),

1.3.3 Temperature distribution (10.4), and

1.3.4 Effective heated area (10.4).

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2644 − 07 AnAmerican National Standard

Standard Test Method for

Performance of Commercial Patio Heaters

This standard is issued under the fixed designation F2644; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.3 ASHRAE Documents:

ASHRAE 55–1992Thermal Environmental Conditions for

1.1 This test method covers the heating performance and

Human Occupancy

energy consumption of commercial radiant patio heaters. The

food service operator can use this evaluation to select a

3. Terminology

commercial patio heater and understand its energy perfor-

3.1 Definitions:

mance and effective heated area.

3.1.1 boundary,n—theedgeoftheareabeingwarmedunder

1.2 This test method is applicable to commercial gas and

a patio heater that corresponds to 3°F above the design

electric radiant patio heaters.

environment mean radiant temperature.

1.3 The patio heater can be evaluated with respect to the

3.1.2 design environment, n—unheated environment for

following:

which test unit’s performance is to be evaluated. Design

1.3.1 Energy input rate (10.2),

environment is specified as having a mean radiant temperature

1.3.2 Preheat energy consumption and time (10.3),

of 60°F.

1.3.3 Temperature distribution (10.4), and

3.1.3 effectiveheatedarea,n—theamountofsquarefootage

1.3.4 Effective heated area (10.4).

that can be warmed to a specified temperature (3°F above the

design environment mean radiant temperature) under a patio

1.4 Thevaluesstatedininch-poundunitsaretoberegarded

heater.

as the standard. The values given in parentheses are for

information only. 3.1.4 energyinputrate,n—peakrateatwhichapatioheater

consumes energy (kW or Btu/h), typically reflected during

1.5 This standard does not purport to address all of the

preheat.

safety concerns, if any, associated with its use. It is the

3.1.5 heating index, n—the quotient of the effective heated

responsibility of the user of this standard to establish appro-

area and the measured energy input rate.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

3.1.6 mean radiant temperature, n—the uniform surface

temperature of an imaginary black enclosure in which an

2. Referenced Documents occupant would exchange the same amount of radiant heat as

2 in the actual non-uniform space.

2.1 ASTM Standards:

D3588Practice for Calculating Heat Value, Compressibility NOTE 1—Since all environments radiate thermal energy, the mean

radianttemperaturecanbedeterminedforanunheatedaswellasaheated

Factor, and Relative Density of Gaseous Fuels

environment.

2.2 ANSI Documents:

3.1.7 operative temperature, n—the uniform temperature of

ANSI Z83.19Gas-Fired High-Intensity Infrared Heaters

an imaginary black enclosure in which an occupant would

ANSI Z83.20Gas-Fired Low-Intensity Infrared Heaters

exchangethesameamountofheatbyradiationplusconvection

as in the actual non-uniform environment. Operative tempera-

ture is numerically the average of the air temperature (T ) and

a

This test method is under the jurisdiction of ASTM Committee F26 on Food

themeanradianttemperature(T ),weightedbytheirrespective

r

Service Equipment and is the direct responsibility of Subcommittee F26.06 on

heat transfer coefficients (h and h ) (see ASHRAE 55–1992):

c r

Productivity and Energy Protocol.

Current edition approved April 1, 2007. Published May 2007. DOI: 10.1520/

~h 3T 1h 3T !

c a r r

F2644-07. T 5

o

h 1h

~ !

2 c r

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Available from American Society of Heating, Refrigerating, and Air-

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St., Conditioning Engineers, Inc. (ASHRAE), 1791 Tullie Circle, NE, Atlanta, GA

4th Floor, New York, NY 10036, http://www.ansi.org. 30329, http://www.ashrae.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2644 − 07

NOTE 2—In the absence of air movement, the operative temperature is

5.3 The temperature distribution of a patio heater can be

equal to the mean radiant temperature.

usedbyoperatorsanddesignerstodeterminethemosteffective

3.1.8 patio heater, n—an appliance that is designed for

layout for a patio heating system.

warming outdoor areas using radiant heat.

5.4 The effective heated area can be used by operators to

3.1.9 preheat energy, n—amount of energy consumed by

choose a patio heater that meets their heating needs.

thepatioheaterwhilepreheatingthepatioheaterfromambient

6. Apparatus

room temperature (75 6 10°F) to its operating temperature.

6.1 Aspirated Thermocouples, for measuring average bulk

3.1.10 preheat rate, n—average rate (°F/min) at which the

air temperature in the test space.

patioheatercomesuptoitsoperatingtemperaturefroma75 6

6.2 Barometer, for measuring absolute atmospheric

10°F ambient temperature.

pressure, to be used for adjustment of measured gas volume to

3.1.11 preheattime,n—timerequiredforthepatioheaterto

standard conditions. Shall have a resolution of 0.2 in. Hg and

preheat from ambient room temperature (75 6 10°F) to its

an uncertainty of 0.2 in. Hg.

operating temperature.

6.3 Data Acquisition System, for measuring energy and

3.1.12 uncertainty, n—measure of systematic and precision

temperatures, capable of multiple channel displays updating at

errors in specified instrumentation or measure of repeatability

least every 2 s.

of a reported test result.

6.4 GasMeter,formeasuringthegasconsumptionofapatio

4. Summary of Test Method

heater, shall be a dry positive displacement type with a

resolution of at least 0.01 ft and a maximum uncertainty no

4.1 Thepatioheaterisconnectedtotheappropriatemetered

greaterthan1%ofthemeasuredvalueforanydemandgreater

energy source, and energy input rate is determined to confirm

than 2.2 ft /h. If the meter is used for measuring the gas

that the appliance is operating within 5% of the nameplate

consumed by the pilot lights, it shall have a resolution of at

energy input rate.

least 0.01 ft and a maximum uncertainty no greater than 2%

4.2 The amount of energy and time required to preheat the

of the measured value.

patio heater to its operating temperature is determined.

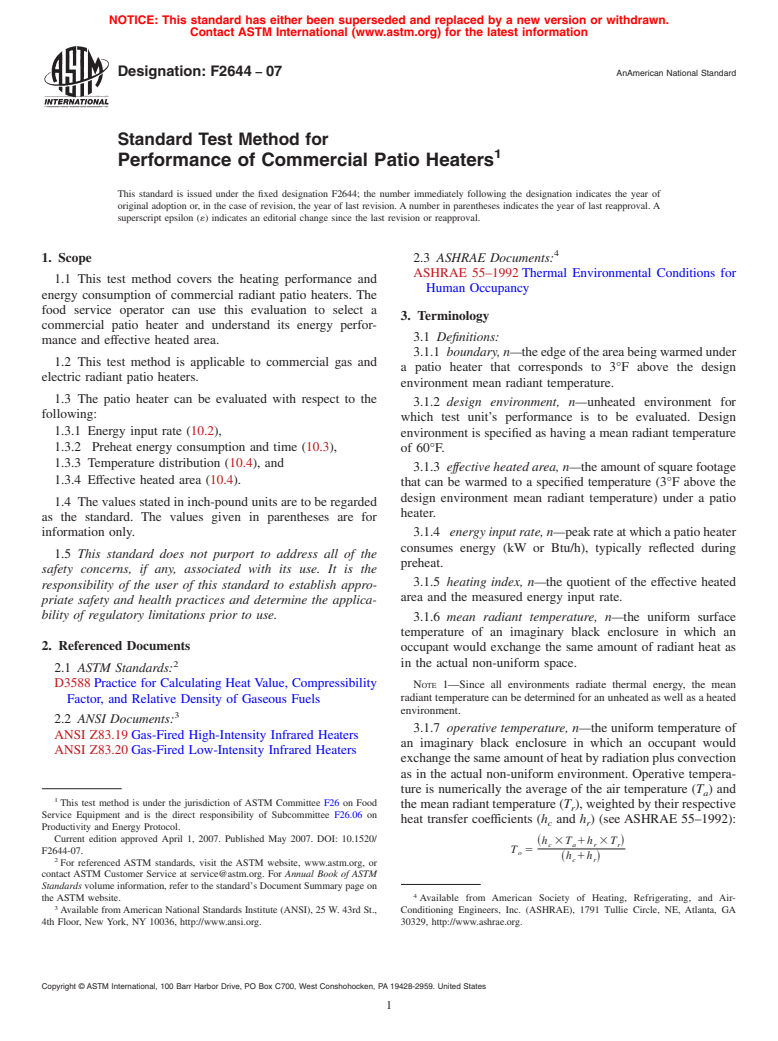

6.5 Globe Thermometer, comprised of a beaded-junction

4.3 The amount of square footage that could be effectively

thermocouple located in the geometric center of a 2-star,

warmed by a heater is determined and characterized.

precise round, ping-pong ball for determining mean radiant

temperature.The globe shall be mounted on a length of ⁄16-in.

5. Significance and Use

plastictubing,whichwillhousethethermocouplewire,andthe

5.1 The energy input rate test is used to confirm that the

entire assembly (globe and tubing) shall be painted flat black.

patio heater is operating properly prior to further testing.

See Fig. 1.

5.2 Preheat energy and time can be useful to food service 6.6 PressureGauge,formonitoringgaspressure.Shallhave

operatorstomanageenergydemandsandtoknowhowquickly a range of zero to 15 in. H O, a resolution of 0.5 in. H O, and

2 2

the patio heater can be ready for operation. a maximum uncertainty of 1% of the measured value.

FIG. 1 Globe Thermometer

F2644 − 07

6.7 Stop Watch,witha1s resolution. 9.2 Connect the patio heater to a calibrated energy test

meter. For gas installations, install a pressure regulator down-

6.8 Temperature Sensor, for measuring gas temperature in

stream from the meter to maintain a constant pressure of gas

the range of 50 to 100°F with an uncertainty of 61°F.

for all tests. Install instrumentation to record both the pressure

6.9 Thermocouple(s), for measuring globe and ambient

and temperature of the gas supplied to the patio heater and the

temperatures, industry standard type T or type K, 24 gauge

barometric pressure during each test so that the measured gas

thermocouplewire,weldedandcalibrated,witharangeof0to

flow can be corrected to standard conditions. For electric

150°F and an uncertainty of 61°F.

installations,avoltageregulatormayberequiredduringtestsif

6.10 Thermocouple Wire, for measuring reflector the voltage supply is not within 62.5% of the manufacturer’s

temperature,shallbetypeKthermocouplewirewitharangeof

nameplate voltage.

0 to 1000°F and an uncertainty of 61°F.

9.3 For a gas patio heater, adjust (during maximum energy

6.11 Watt-Hour Meter, for measuring the electrical energy

input) the gas supply pressure downstream from the appli-

consumptionofapatioheater,shallhavearesolutionofatleast

ance’s pressure regulator to within 62.5% of the operating

10Whandamaximumuncertaintynogreaterthan1.5%ofthe

manifold pressure specified by the manufacturer. Make adjust-

measured value for any demand greater than 100 W. For any

ments to the appliance following the manufacturer’s recom-

demandlessthan100W,themetershallhavearesolutionofat

mendations for optimizing combustion. Proper combustion

least 10Wh and a maximum uncertainty no greater than 10%.

may be verified by measuring air-free CO in accordance with

ANSI Z83.19 and ANSI Z83.20.

7. Reagents and Materials

9.4 Confirm (while the elements are energized) that the

7.1 Ping-Pong Balls, two-star, precise round, weighing 2.5

supply voltage is within 62.5% of the operating voltage

6 0.5 g for constructing globe thermometers.

specified by the manufacturer. Record the test voltage for each

7.2 Model Airplane Control Rods, for supporting the globe

test.

thermometers, shall be a minimum of 12 in. long with a

NOTE 4—It is the intent of the testing procedure herein to evaluate the

nominal outside diameter of ⁄16 in.

performanceofapatioheateratitsratedelectricvoltage.Ifanelectricunit

is rated dual voltage (that is, designed to operate at either 208 or 240 V

with no change in components), the voltage selected by the manufacturer

8. Sampling, Test Units

and/or tester shall be reported. If a patio heater is designed to operate at

8.1 Patio Heater—Select a representative production model

two voltages without a change in the resistance of the heating elements,

for performance testing. the performance of the unit (for example, preheat time) may differ at the

two voltages.

9. Preparation of Apparatus

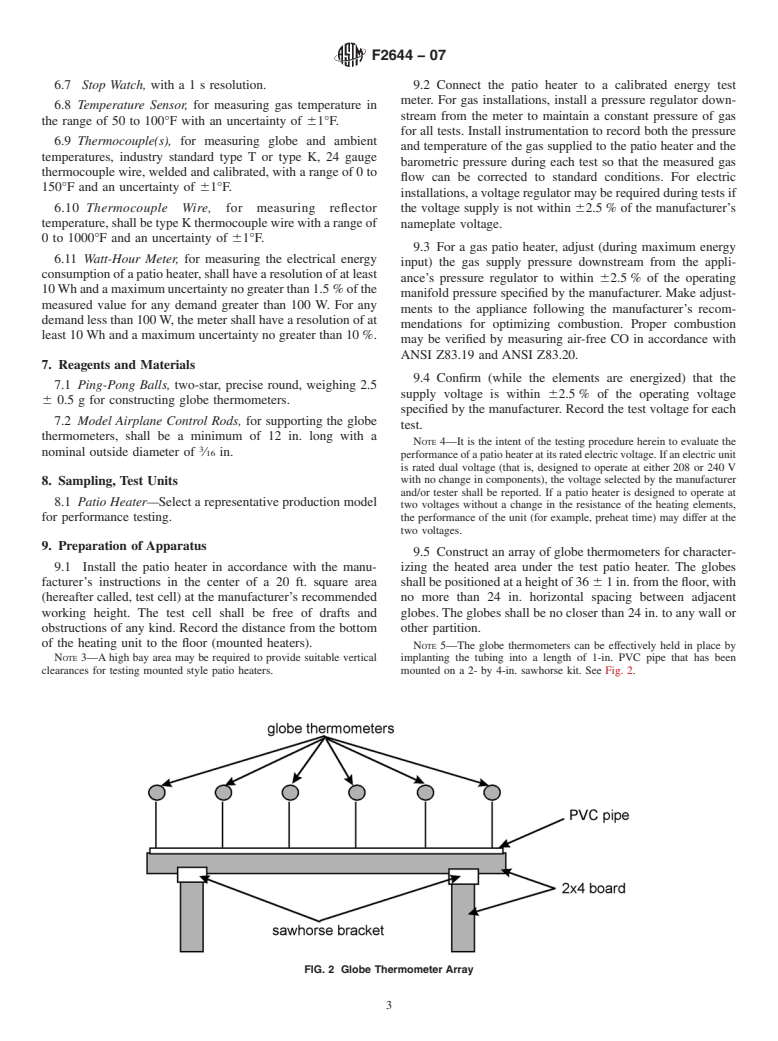

9.5 Construct an array of globe thermometers for character-

9.1 Install the patio heater in accordance with the manu- izing the heated area under the test patio heater. The globes

facturer’s instructions in the center of a 20 ft. square area shallbepositionedataheightof36 61in.fromthefloor,with

(hereafter called, test cell) at the manufacturer’s recommended no more than 24 in. horizontal spacing between adjacent

working height. The test cell shall be free of drafts and globes.The globes shall be no closer than 24 in. to any wall or

obstructions of any kind. Record the distance from the bottom other partition.

of the heating unit to the floor (mounted heaters).

NOTE 5—The globe thermometers can be effectively held in place by

NOTE 3—A high bay area may be required to provide suitable vertical implanting the tubing into a length of 1-in. PVC pipe that has been

clearances for testing mounted style patio heaters. Fig. 2.

mounted on a 2- by 4-in. sawhorse kit. See

FIG. 2 Globe Thermometer Array

F2644 − 07

9.6 Divide the test area into four equal-sized quadrants. 10.3 Preheat Energy Consumption and Time:

Position four aspirated thermocouples, one in the center of

NOTE 7—The preheat test should be conducted as the first appliance

eachquadrantataheightof36-in.Thesefourtemperatureswill

operation on the day of the test, starting at a 75 6 10°F ambient

be used to determine the average ambient temperature.

temperature.

9.7 In preparation for the preheat test, tack-weld a thermo-

10.3.1 Confirmthatthepatioheater’sreflectorisatambient

couple to the heater’s reflector, centered as closely as possible.

temperature (75 6 10°F). Turn the unit on with control(s) set

to their maximum setting.

10. Procedure

10.3.2 Commence monitoring globe and ambient tempera-

tures.Theambientshallbe75 610°Fduringthecourseofthe

10.1 General:

test. If the ambient temperature is outside the specified range,

10.1.1 For gas patio heaters, record the following for each

the test is invalid and must be repeated.

test run:

10.3.3 Record the globe temperatures over a minimum of

10.1.1.1 Higher heating value,

10-s intervals during the course of preheat.

10.1.1.2 Standard gas pressure and temperature used to

10.3.4 Record the energy and time to preheat the patio

correct measured gas volume to standard conditions,

heater. Preheat is judged complete when the reflector reaches

10.1.1.3 Measured gas temperature,

95% of its maximum temperature.

10.1.1.4 Measured gas pressure,

10.1.1.5 Barometric pressure,

10.4 Temperature Distribution and Effective Heated Area:

10.1.1.6 Average ambient temperature, and

10.4.1 The temperature distribution and effective heated

10.1.1.7 Energy input rate during or immediately prior to

area test shall be repeated a minimum of three times. Conduct

test.

each replicate on different days.

10.4.2 Record globe and ambient temperatures at 30-s

NOTE6—Usingacalorimeterorgaschromatographinaccordancewith

accepted laboratory procedures is the preferred method for determining

intervals for a period of 5 min before the test unit is turned on.

the higher heating value of gas supplied to the patio heater under test. It

Both temperatures shall not vary more than 60.5°F over the

is recommended that all testing be performed with natural gas having a

3 5-min period. The ambient temperature shall be 75 6 10°F at

higher heating value of 1000 to 1075 Btu/ft .

the start of the test.

10.1.2 For gas patio heaters, record any electric energy

10.4.3 Preheat the patio heater for a period of 15 6 1 min.

consumption, in addition to gas energy for all tests.

10.4.4 Commence monitoring globe and ambient tempera-

10.1.3 For electric patio heaters, record the following for

tures.Theambientshallbe75 610°Fduringthecourseofthe

each test run:

test. If the ambient temperature is outside the specified range,

10.1.3.1 Voltage while elements are energized,

the test is invalid and must be repeated.

10.1.3.2 Average ambient temperature, and

10.4.5 With the heater on and stabilized, record globe and

10.1.3.3 Energy input rate during or immediately prior to

ambient temperatures at 30-s intervals for a period of 5 min.

tes

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.