ASTM E415-99a

(Test Method)Standard Test Method for Optical Emission Vacuum Spectrometric Analysis of Carbon and Low-Alloy Steel

Standard Test Method for Optical Emission Vacuum Spectrometric Analysis of Carbon and Low-Alloy Steel

SCOPE

1.1 This test method covers the simultaneous determination of 18 alloying and residual elements in carbon and low-alloy steels in the concentration ranges shown (Note 1). Concentration Range, % Element Range Tested Applicable Range Aluminum 0.021 to 0.067 0.02 to 0.075 Arsenic 0.014 to 0.041 0.010 to 0.050 Boron 0.0006 to 0.0063 0.0006 to 0.007 Carbon 0.03 to 1.05 0.03 to 1.10 Chromium 0.09 to 2.13 0.03 to 2.25 Cobalt 0.0086 to 0.16 0.008 to 0.18 Copper 0.05 to 0.44 0.01 to 0.50 Manganese 0.32 to 1.89 0.25 to 2.00 Molybdenum 0.15 to 0.56 0.01 to 0.60 Nickel 0.060 to 4.80 0.03 to 5.00 Niobium 0.008 to 0.076 0.008 to 0.085 Phosphorus 0.012 to 0.078 0.005 to 0.085 Silicon 0.18 to 1.06 0.01 to 1.15 Sulfur 0.014 to 0.051 0.005 to 0.055 Tin 0.006 to 0.040 0.003 to 0.045 Titanium 0.002 to 0.190 0.002 to 0.20 Vanadium 0.003 to 0.28 0.002 to 0.30 Zirconium 0.003 to 0.044 0.003 to 0.050

1.2 This test method covers analysis of specimens having a diameter adequate to overlap the bore of the spark stand opening (to effect an argon seal). The specimen thickness should be between 10 and 38 mm.

1.3 This test method covers the routine control analysis of preliminary and ladle tests from either basic oxygen, open-hearth, or electric furnaces and analysis of processed material. It is designed for either chill-cast or rolled and forged specimens. The reference materials and specimens should be of similar metallurgical condition and composition.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E415–99a

Standard Test Method for

Optical Emission Vacuum Spectrometric Analysis of Carbon

and Low-Alloy Steel

This standard is issued under the fixed designation E 415; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope hearth, or electric furnaces and analysis of processed material.

It is designed for either chill-cast or rolled and forged speci-

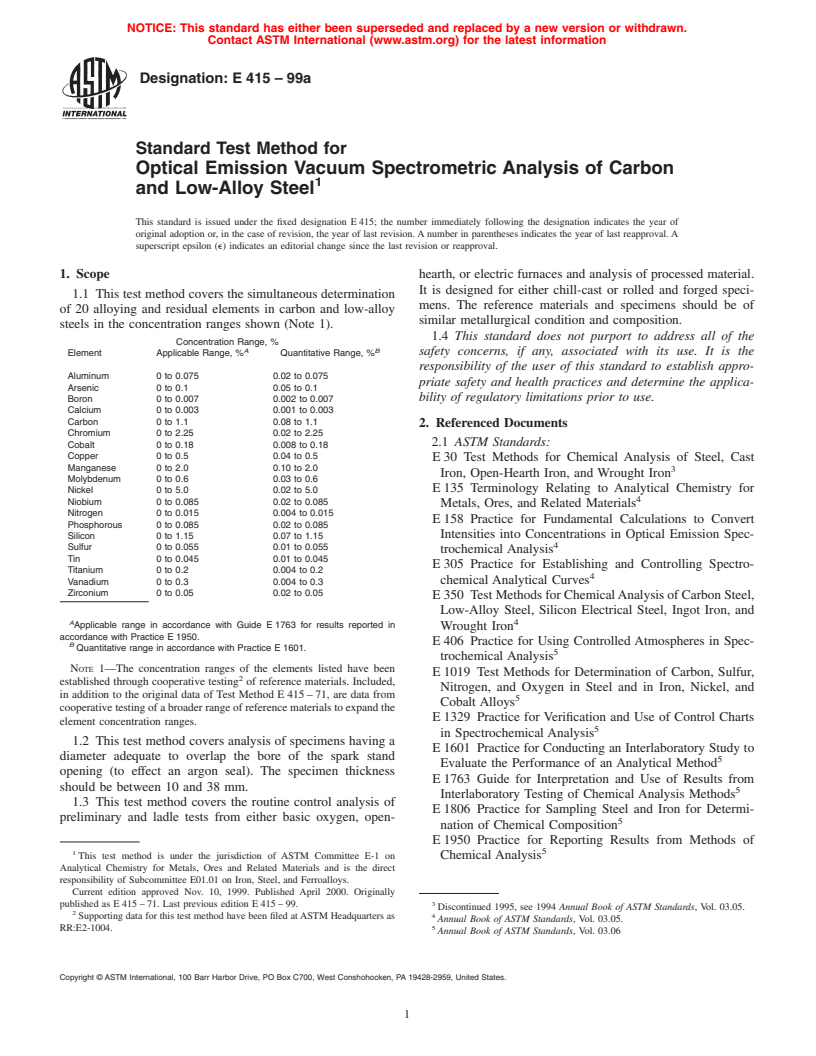

1.1 This test method covers the simultaneous determination

mens. The reference materials and specimens should be of

of 20 alloying and residual elements in carbon and low-alloy

similar metallurgical condition and composition.

steels in the concentration ranges shown (Note 1).

1.4 This standard does not purport to address all of the

Concentration Range, %

A B

safety concerns, if any, associated with its use. It is the

Element Applicable Range, % Quantitative Range, %

responsibility of the user of this standard to establish appro-

Aluminum 0 to 0.075 0.02 to 0.075

priate safety and health practices and determine the applica-

Arsenic 0 to 0.1 0.05 to 0.1

bility of regulatory limitations prior to use.

Boron 0 to 0.007 0.002 to 0.007

Calcium 0 to 0.003 0.001 to 0.003

Carbon 0 to 1.1 0.08 to 1.1

2. Referenced Documents

Chromium 0 to 2.25 0.02 to 2.25

2.1 ASTM Standards:

Cobalt 0 to 0.18 0.008 to 0.18

Copper 0 to 0.5 0.04 to 0.5

E 30 Test Methods for Chemical Analysis of Steel, Cast

Manganese 0 to 2.0 0.10 to 2.0

Iron, Open-Hearth Iron, and Wrought Iron

Molybdenum 0 to 0.6 0.03 to 0.6

E 135 Terminology Relating to Analytical Chemistry for

Nickel 0 to 5.0 0.02 to 5.0

Niobium 0 to 0.085 0.02 to 0.085

Metals, Ores, and Related Materials

Nitrogen 0 to 0.015 0.004 to 0.015

E 158 Practice for Fundamental Calculations to Convert

Phosphorous 0 to 0.085 0.02 to 0.085

Intensities into Concentrations in Optical Emission Spec-

Silicon 0 to 1.15 0.07 to 1.15

Sulfur 0 to 0.055 0.01 to 0.055

trochemical Analysis

Tin 0 to 0.045 0.01 to 0.045

E 305 Practice for Establishing and Controlling Spectro-

Titanium 0 to 0.2 0.004 to 0.2

chemical Analytical Curves

Vanadium 0 to 0.3 0.004 to 0.3

Zirconium 0 to 0.05 0.02 to 0.05

E 350 Test Methods for ChemicalAnalysis of Carbon Steel,

Low-Alloy Steel, Silicon Electrical Steel, Ingot Iron, and

A 4

Applicable range in accordance with Guide E 1763 for results reported in

Wrought Iron

accordance with Practice E 1950.

E 406 Practice for Using Controlled Atmospheres in Spec-

B

Quantitative range in accordance with Practice E 1601.

trochemical Analysis

NOTE 1—The concentration ranges of the elements listed have been

E 1019 Test Methods for Determination of Carbon, Sulfur,

established through cooperative testing of reference materials. Included,

Nitrogen, and Oxygen in Steel and in Iron, Nickel, and

in addition to the original data of Test Method E 415 – 71, are data from

Cobalt Alloys

cooperative testing of a broader range of reference materials to expand the

E 1329 Practice for Verification and Use of Control Charts

element concentration ranges.

in Spectrochemical Analysis

1.2 This test method covers analysis of specimens having a

E 1601 Practice for Conducting an Interlaboratory Study to

diameter adequate to overlap the bore of the spark stand

Evaluate the Performance of an Analytical Method

opening (to effect an argon seal). The specimen thickness

E 1763 Guide for Interpretation and Use of Results from

should be between 10 and 38 mm.

Interlaboratory Testing of Chemical Analysis Methods

1.3 This test method covers the routine control analysis of

E 1806 Practice for Sampling Steel and Iron for Determi-

preliminary and ladle tests from either basic oxygen, open-

nation of Chemical Composition

E 1950 Practice for Reporting Results from Methods of

This test method is under the jurisdiction of ASTM Committee E-1 on Chemical Analysis

Analytical Chemistry for Metals, Ores and Related Materials and is the direct

responsibility of Subcommittee E01.01 on Iron, Steel, and Ferroalloys.

Current edition approved Nov. 10, 1999. Published April 2000. Originally

published as E 415 – 71. Last previous edition E 415 – 99.

Discontinued 1995, see 1994 Annual Book of ASTM Standards, Vol. 03.05.

Supporting data for this test method have been filed at ASTM Headquarters as

Annual Book of ASTM Standards, Vol. 03.05.

RR:E2-1004.

Annual Book of ASTM Standards, Vol. 03.06

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E415

3. Terminology operated at a vacuum of 25 µm of mercury or below. The

primary slit width is 20 to 50 µm. Secondary slit width is 50 to

3.1 For definitions of terms used in this test method, refer to

200 µm.

Terminology E 135.

6.5 Measuring System, consisting of photomultipliers hav-

4. Summary of Test Method

ing individual voltage adjustments, capacitors in which the

output of each photomultiplier is stored, a voltage measuring

4.1 The most sensitive lines of arsenic, boron, carbon,

system to register the voltages on the capacitors either directly

nitrogen, phosphorus, sulfur, and tin lie in the vacuum ultra-

or indirectly, and the necessary switching arrangements to

violet region. The absorption of the radiation by air in this

provide the desired sequence of operation.

region is overcome by evacuating the spectrometer and flush-

ing the spark chamber with argon. A capacitor discharge is

6.6 Vacuum Pump, capable of maintaining a vacuum of 25

produced between the flat, ground surface of the disk specimen

µm Hg.

and a conically shaped electrode. The discharge is terminated

NOTE 3—A pump with a displacement of at least 0.23 m /min (8

at a predetermined intensity time integral of a selected iron

ft /min) is usually adequate.

line, or at a predetermined time, and the relative radiant

energies or concentrations of the analytical lines are recorded.

6.7 Flushing System, consisting of argon tanks, a pressure

regulator, and a gas flowmeter. Automatic sequencing shall be

5. Significance and Use

provided to actuate the flow of argon at a given flow rate for a

5.1 This test method for the spectrometric analysis of metals

given time interval and to start the excitation at the end of the

and alloys is primarily intended to test such materials for

flush period. Means of changing the flow rate of argon shall be

compliance with compositional specifications. It is assumed

provided. The flushing system shall be in accordance with

that all who use this test method will be analysts capable of

Practice E 406.

performing common laboratory procedures skillfully and

safely. It is expected that work will be performed in a properly

7. Reagents and Materials

equipped laboratory.

7.1 Counter Electrodes—The counter electrodes shall be

6.4-mm ( ⁄4-in.) diameter, hard-drawn, fine, silver rods,

6. Apparatus

1.5-mm ( ⁄16-in.) thoriated, tungsten rods, or other material

6.1 Sample Preparation Equipment:

provided it can be shown experimentally that equivalent

6.1.1 Sample Mold, capable of producing castings that are

precisionandbiasisobtained.Machinetherodstoa90or120°

homogeneous and free from voids and porosity. Refer to

cone.

Practice E 1806 for steel sampling procedures. The following

mold types have been found to produce acceptable samples:

NOTE 4—A black deposit builds up on the tip of the electrode, thus

6.1.1.1 Cast Iron Mold—A mold 70 mm (2 ⁄4 in.) deep, 64

reducing the overall intensity of the spectral radiation. In general this

mm (2 ⁄2 in.) in diameter at the top of the mold, and 57 mm condition will not affect analytical performance for the first 40 or 50

excitations, after which time a freshly prepared counter electrode should

(2 ⁄4in.) in diameter at the bottom of the mold. The wall

1 be installed. The number of acceptable excitations on an electrode varies

thickness of the mold is approximately 32 mm (1 ⁄4 in.).

from one instrument to another, and should be established in each

6.1.1.2 Refractory Mold Ring—Amold that has a minimum

laboratory. With a thoriated tungsten electrode, it has been reported that a

inside diameter of 32 mm (1 ⁄4 in.) and a minimum height of 25

hundred or more excitations can usually be made before replacement.

mm (1 in.).The ring is placed on a flat surface of a copper plate

7.2 Inert Gas, Argon, in accordance with Practice E 406.

approximately 50 mm (2 in.) thick.

6.1.1.3 Book-Type Steel or Copper Mold, to produce a

1 1

8. Reference Materials

chill-cast disk 64 mm (2 ⁄2 in.) in diameter and 13 mm ( ⁄2 in.)

thick.

8.1 Certified Reference Materials (CRMs) are available

6.2 Excitation Source, capable of providing a triggered

from the National Institute of Standards and Technology and

capacitor discharge having source parameters meeting the

other sources. These cover all or part of the concentration

requirements of 11.1.

ranges listed in 1.1. They are valuable in establishing prelimi-

6.3 Spark Chamber, automatically flushed with argon. The

nary working curves and determining the precision of the

spark chamber shall be mounted directly on the spectrometer,

instrument. However, because of differences between these

and shall be provided with a spark stand to hold a flat specimen

CRMs and the production specimens prepared by the sampling

and a lower electrode of rod form.

procedures recommended for this test method, curves based on

CRMs may (in very unusual circumstances) need to be

NOTE 2—Clean the excitation chamber when the counter electrode is

replaced. Clean the lens or protective window after approximately 200 to correctedwithvaluesfromreferencematerialsmadebynormal

300 excitations to minimize transmission losses.

production sampling techniques and analyzed in accordance

with Test Methods E 30, E 350, and E 1019.

6.4 Spectrometer, having a reciprocal linear dispersion of

0.60 nm/mm, or better, in the first order and a focal length of 8.2 Reference Materials—Periodically check the instrument

0.75 to 3 m. Its approximate range shall be from 120.0 to 400.0 for drift. For this purpose, verifiers and standardants are

nm. Masks shall be provided in the spectrometer to eliminate employed. These reference materials shall be homogeneous

scattered radiation. The spectrometer shall be provided with an and contain appropriate amounts of each element, covering the

air inlet and a vacuum outlet. The spectrometer shall be concentration range of elements contained in the specimens.

E415

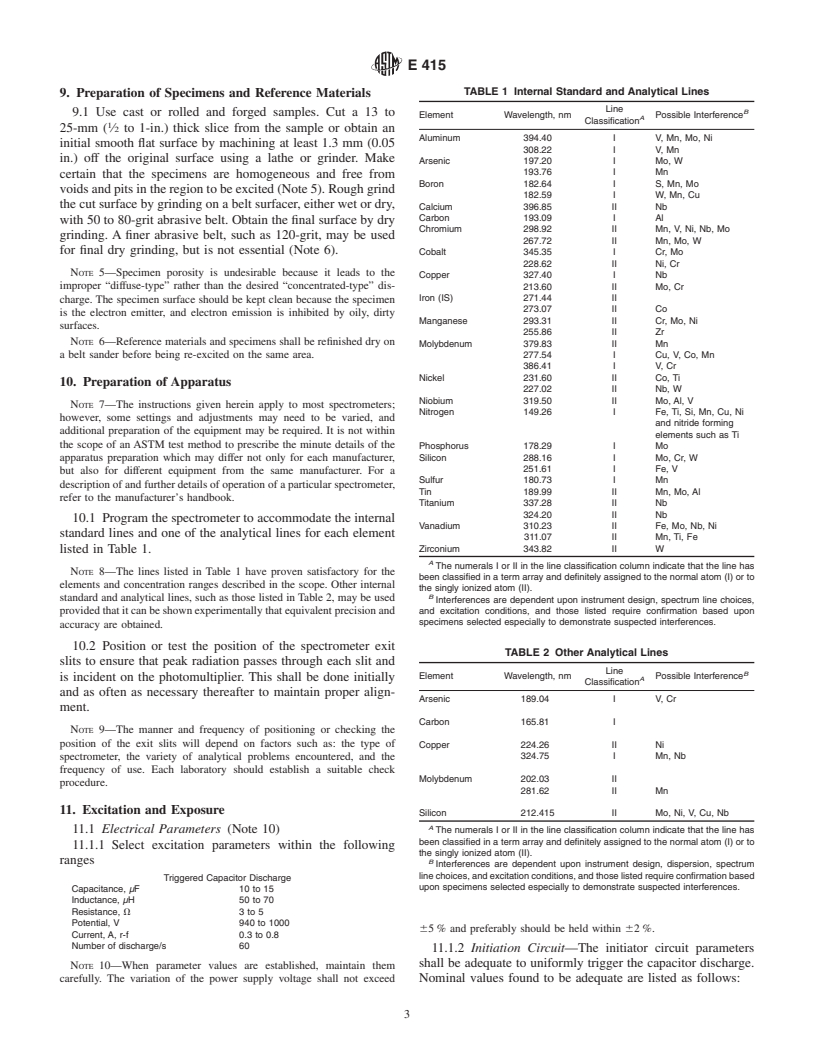

TABLE 1 Internal Standard and Analytical Lines

9. Preparation of Specimens and Reference Materials

Line

B

9.1 Use cast or rolled and forged samples. Cut a 13 to

Element Wavelength, nm Possible Interference

A

Classification

25-mm ( ⁄2 to 1-in.) thick slice from the sample or obtain an

Aluminum 394.40 I V, Mn, Mo, Ni

initial smooth flat surface by machining at least 1.3 mm (0.05

308.22 I V, Mn

in.) off the original surface using a lathe or grinder. Make

Arsenic 197.20 I Mo, W

193.76 I Mn

certain that the specimens are homogeneous and free from

Boron 182.64 I S, Mn, Mo

voids and pits in the region to be excited (Note 5). Rough grind

182.59 I W, Mn, Cu

the cut surface by grinding on a belt surfacer, either wet or dry,

Calcium 396.85 II Nb

Carbon 193.09 I Al

with 50 to 80-grit abrasive belt. Obtain the final surface by dry

Chromium 298.92 II Mn, V, Ni, Nb, Mo

grinding. A finer abrasive belt, such as 120-grit, may be used

267.72 II Mn, Mo, W

for final dry grinding, but is not essential (Note 6).

Cobalt 345.35 I Cr, Mo

228.62 II Ni, Cr

NOTE 5—Specimen porosity is undesirable because it leads to the

Copper 327.40 I Nb

improper “diffuse-type” rather than the desired “concentrated-type” dis- 213.60 II Mo, Cr

Iron (IS) 271.44 II

charge. The specimen surface should be kept clean because the specimen

273.07 II Co

is the electron emitter, and electron emission is inhibited by oily, dirty

Manganese 293.31 II Cr, Mo, Ni

surfaces.

255.86 II Zr

NOTE 6—Reference materials and specimens shall be refinished dry on

Molybdenum 379.83 II Mn

a belt sander before being re-excited on the same area. 277.54 I Cu, V, Co, Mn

386.41 I V, Cr

Nickel 231.60 II Co, Ti

10. Preparation of Apparatus

227.02 II Nb, W

Niobium 319.50 II Mo, Al, V

NOTE 7—The instructions given herein apply to most spectrometers;

Nitrogen 149.26 I Fe, Ti, Si, Mn, Cu, Ni

however, some settings and adjustments may need to be varied, and

and nitride forming

additional preparation of the equipment may be required. It is not within

elements such as Ti

the scope of an ASTM test method to prescribe the minute details of the

Phosphorus 178.29 I Mo

apparatus preparation which may differ not only for each manufacturer, Silicon 288.16 I Mo, Cr, W

251.61 I Fe, V

but also for different equipment from the same manufacturer. For a

Sulfur 180.73 I Mn

description of and further details of operation of a particular spectrometer,

Tin 189.99 II Mn, Mo, Al

refer to the manufacturer’s handbook.

Titanium 337.28 II Nb

324.20 II Nb

10.1 Program the spectrometer to accommodate the internal

Vanadium 310.23 II Fe, Mo, Nb, Ni

standard lines and one of the analytical lines for each element

311.07 II Mn, Ti, Fe

Zirconium 343.82 II W

listed in Table 1.

A

The numerals I or II in the line classification column indicate that the line has

NOTE 8—The lines listed in Table 1 have proven satisfactory for the

been classified in a term array and definitely assigned to the normal atom (I) or to

elements and concentration ranges described in the scope. Other internal

the singly ionized atom (II).

B

standard and analytical lines, such as those listed in Table 2, may be used

Interferences are dependent upon instrument design, spectrum line choices,

provided that it can be shown experimentally that equivalent precision and and excitation conditions, and those listed require confirmation based upon

specimens selected especially to demonstrate suspected interferences.

accuracy are obtained.

10.2 Position or test the position of the spectrometer exit

TABLE 2 Other Analytical Lines

slits to ensure that peak radiation passes through each slit and

Line

B

Element Wavelength, nm Possible Interference

is incident on the photomultiplier. This shall be done initially A

Classification

and as often as necessary thereafter to maintain proper align-

Arsenic 189.04 I V, Cr

ment.

Carbon 165.81 I

NOTE 9—The manner and frequency of positioning or checking the

position of the exit slits will depend on factors such as: the type of

Copper 224.26 II Ni

spectrometer, the variety of analytical problems encountered, and the 324.75 I Mn, Nb

frequency of use. Each laboratory should establish a s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.