ASTM G115-10

(Guide)Standard Guide for Measuring and Reporting Friction Coefficients

Standard Guide for Measuring and Reporting Friction Coefficients

SIGNIFICANCE AND USE

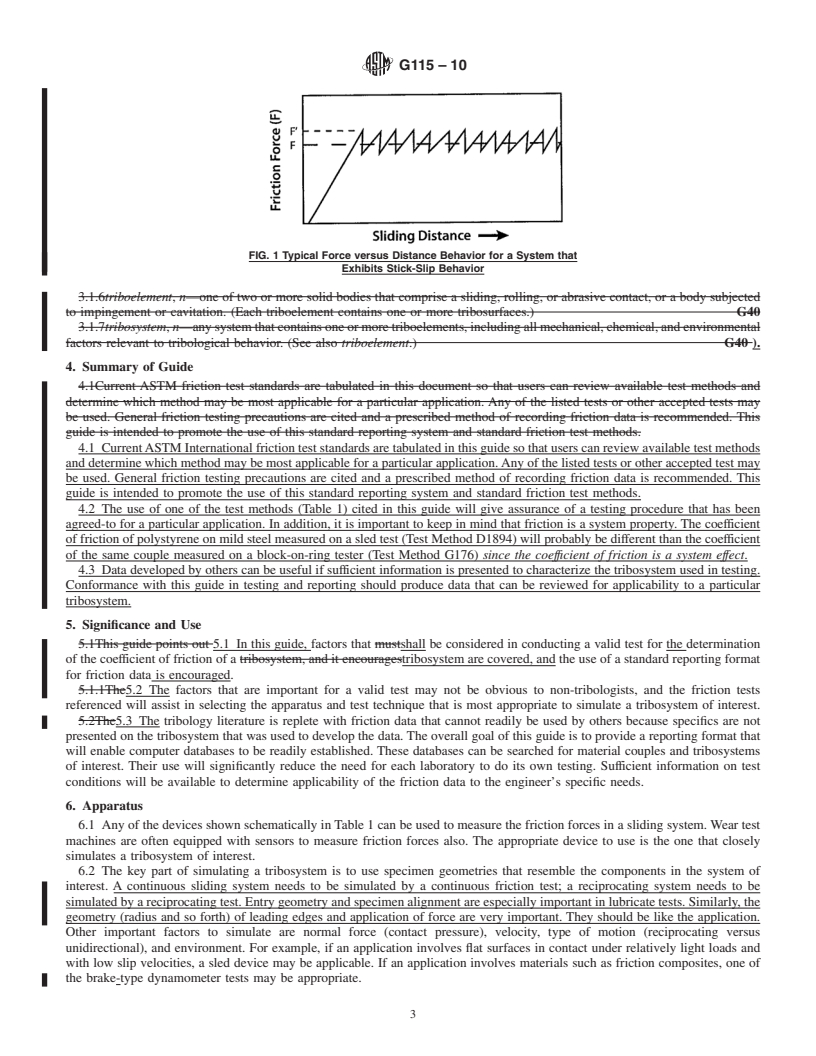

In this guide, factors that shall be considered in conducting a valid test for the determination of the coefficient of friction of a tribosystem are covered, and the use of a standard reporting format for friction data is encouraged.

The factors that are important for a valid test may not be obvious to non-tribologists, and the friction tests referenced will assist in selecting the apparatus and test technique that is most appropriate to simulate a tribosystem of interest.

The tribology literature is replete with friction data that cannot readily be used by others because specifics are not presented on the tribosystem that was used to develop the data. The overall goal of this guide is to provide a reporting format that will enable computer databases to be readily established. These databases can be searched for material couples and tribosystems of interest. Their use will significantly reduce the need for each laboratory to do its own testing. Sufficient information on test conditions will be available to determine applicability of the friction data to the engineer's specific needs.

SCOPE

1.1 This guide covers information to assist in the selection of a method for measuring the frictional properties of materials. Requirements for minimum data and a format for presenting these data are suggested. The use of the suggested reporting form will increase the long-term usefulness of the test results within a given laboratory and will facilitate the exchange of test results between laboratories. It is hoped that the use of a uniform reporting format will provide the basis for the preparation of handbooks and computerized databases.

1.2 This guide applies to most solid materials and to most friction measuring techniques and test equipment.

1.3 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G115 − 10

StandardGuide for

1

Measuring and Reporting Friction Coefficients

This standard is issued under the fixed designation G115; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D2394 Test Methods for Simulated ServiceTesting ofWood

and Wood-Base Finish Flooring

1.1 This guide covers information to assist in the selection

D2534 Test Method for Coefficient of Kinetic Friction for

of a method for measuring the frictional properties of materi-

Wax Coatings

als. Requirements for minimum data and a format for present-

D2714 Test Method for Calibration and Operation of the

ingthesedataaresuggested.Theuseofthesuggestedreporting

Falex Block-on-Ring Friction and Wear Testing Machine

form will increase the long-term usefulness of the test results

D3108 Test Method for Coefficient of Friction,Yarn to Solid

within a given laboratory and will facilitate the exchange of

Material

test results between laboratories. It is hoped that the use of a

D3412 Test Method for Coefficient of Friction,Yarn toYarn

uniform reporting format will provide the basis for the prepa-

D3702 Test Method for Wear Rate and Coefficient of Fric-

ration of handbooks and computerized databases.

tion of Materials in Self-Lubricated Rubbing Contact

1.2 This guide applies to most solid materials and to most

Using a Thrust Washer Testing Machine

friction measuring techniques and test equipment.

D4103 Practice for Preparation of Substrate Surfaces for

1.3 Units—The values stated in SI units are to be regarded

Coefficient of Friction Testing

as standard. No other units of measurement are included in this

D4917 Test Method for Coefficient of Static and Kinetic

standard.

FrictionofUncoatedWritingandPrintingPaperbyUseof

3

the Horizontal Plane Method (Withdrawn 2010)

1.4 This standard does not purport to address all of the

D4918 Test Method for Coefficient of Static Friction of

safety concerns, if any, associated with its use. It is the

Uncoated Writing and Printing Paper by Use of the

responsibility of the user of this standard to establish appro-

3

Inclined Plane Method (Withdrawn 2010)

priate safety and health practices and determine the applica-

D5183 Test Method for Determination of the Coefficient of

bility of regulatory limitations prior to use.

Friction of Lubricants Using the Four-Ball Wear Test

2. Referenced Documents

Machine

2

D6425 Test Method for Measuring Friction and Wear Prop-

2.1 ASTM Standards:

erties of Extreme Pressure (EP) Lubricating Oils Using

C808 Guide for Reporting Friction and Wear Test Results of

SRV Test Machine

Manufactured Carbon and Graphite Bearing and Seal

E122 Practice for Calculating Sample Size to Estimate,With

Materials

Specified Precision, the Average for a Characteristic of a

C1028 TestMethodforDeterminingtheStaticCoefficientof

Lot or Process

Friction of Ceramic Tile and Other Like Surfaces by the

E303 Test Method for Measuring Surface Frictional Proper-

Horizontal Dynamometer Pull-Meter Method

ties Using the British Pendulum Tester

D1894 Test Method for Static and Kinetic Coefficients of

E670 Test Method for Testing Side Force Friction on Paved

Friction of Plastic Film and Sheeting

Surfaces Using the Mu-Meter

D2047 Test Method for Static Coefficient of Friction of

E1911 Test Method for Measuring Paved Surface Frictional

Polish-Coated Flooring Surfaces as Measured by the

Properties Using the Dynamic Friction Tester

James Machine

E2100 Practice for Calculating the International Runway

Friction Index

1

This guide is under the jurisdiction of ASTM Committee G02 on Wear and

E2101 Test Method for Measuring the Frictional Properties

Erosion and is the direct responsibility of Subcommittee G02.50 on Friction.

of Winter Contaminated Pavement Surfaces Using an

Current edition approved June 15, 2010. Published October 2010. Originally

Averaging-Type Spot Measuring Decelerometer

approved in 1993. Last previous edition was approved in 2004 as G115–04. DOI:

10.1520/G0115-10.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G115 − 10

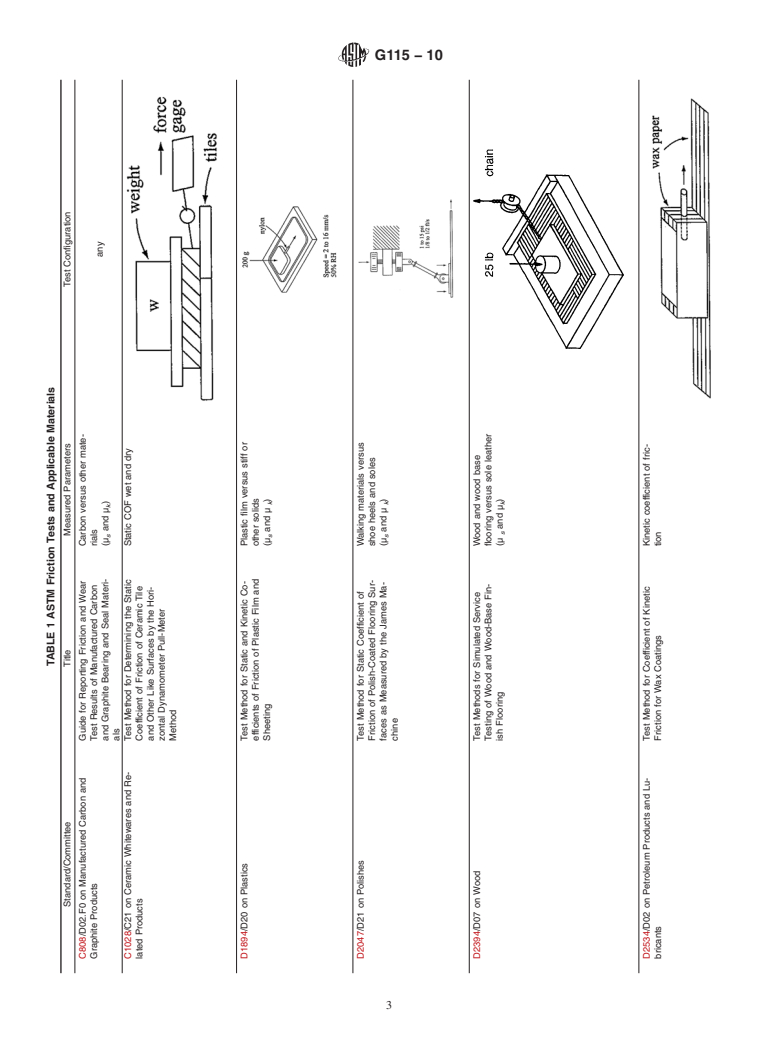

4. Summary of Guide

4.1 Current ASTM International friction test standards are

tabulated in this guide so that users ca

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:G115–04 Designation: G115 – 10

Standard Guide for

1

Measuring and Reporting Friction Coefficients

This standard is issued under the fixed designation G115; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide covers information to assist in the selection of a method for measuring the frictional properties of materials.

Requirements for minimum data and a format for presenting these data are suggested.The use of the suggested reporting form will

increasethelong-termusefulnessofthetestresultswithinagivenlaboratoryandwillfacilitatetheexchangeoftestresultsbetween

laboratories. It is hoped that the use of a uniform reporting format will provide the basis for the preparation of handbooks and

computerized databases.

1.2 This guide applies to most solid materials and to most friction measuring techniques and test equipment.

1.3 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this

standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

3

B460Test Method for Dynamic Coefficient of Friction and Wear of Sintered Metal Friction Materials Under Dry Conditions

3

B461Test Method for Frictional Characteristics of Sintered Metal Friction Materials Run in Lubricants

3

B526Test Method for Coefficient of Friction and Wear of Sintered Metal Friction Materials Under Dry-Clutch Conditions

C808 Guide for Reporting Friction and Wear Test Results of Manufactured Carbon and Graphite Bearing and Seal Materials

C1028 Test Method for Determining the Static Coefficient of Friction of Ceramic Tile and Other Like Surfaces by the

Horizontal Dynamometer Pull-Meter Method

D1894 Test Method for Static and Kinetic Coefficients of Friction of Plastic Film and Sheeting

D2047 Test Method for Static Coefficient of Friction of Polish-Coated Flooring Surfaces as Measured by the James Machine

D2394 Test Methods for Simulated Service Testing of Wood and Wood-Base Finish Flooring

D2534 Test Method for Coefficient of Kinetic Friction for Wax Coatings

D2714 Test Method for Calibration and Operation of the Falex Block-on-Ring Friction and Wear Testing Machine D3028Test

Method

for Ki-

netic

Coeffi-

cient of

Fric-

tion of

Plastic

Solids

D3108 Test Method for Coefficient of Friction, Yarn to Solid Material

3

D3247Test Method for Coefficient of Static Friction of Corrugated and Solid Fiberboard (Horizontal Plane Method)

3

D3248Test Method for Coefficient of Static Friction of Corrugated and Solid Fiberboard (Inclined Plane Method)

3

D3334Methods of Testing Fabrics Woven from Polyolefin Monofilaments

1

This guide is under the jurisdiction of ASTM Committee G02 on Wear and Erosion and is the direct responsibility of Subcommittee G02.50 on Friction.

´1

Current edition approved May 1, 2004. Published June 2004. Originally approved in 1993. Last previous edition was approved in 2004 as G115-98 (2004) . DOI:

10.1520/G0115-04.

Current edition approved June 15, 2010. Published October 2010. Originally approved in 1993. Last previous edition was approved in 2004 as G115–04. DOI:

10.1520/G0115-10.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

G115 – 10

D3412 Test Method for Coefficient of Friction, Yarn to Yarn

D3702 Test Method for Wear Rate and Coefficient of Friction of Materials in Self-Lubricated Rubbing Contact Using a Thrust

Washer Testing Machine

D4103 Practice for Preparation of Substrate Surfaces for Coefficient of Friction Testing

D4917 Test Method for Coefficient of Static and Kinetic Friction of Uncoated Writing and Printing Paper by Use of the

Horizontal Plane Method

D4918 Test Method for Coefficient of Static Friction of Uncoated Writi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.