ASTM D2549-91(1995)

(Test Method)Standard Test Method for Separation of Representative Aromatics and Nonaromatics Fractions of High-Boiling Oils by Elution Chromatography

Standard Test Method for Separation of Representative Aromatics and Nonaromatics Fractions of High-Boiling Oils by Elution Chromatography

SCOPE

1.1 This test method covers the separation and determination of representative aromatics and nonaromatics fractions from hydrocarbon mixtures that boil between 232 and 538°C (450 and 1000°F). Alternative procedures are provided for the separation of 2 g or 10 g of hydrocarbon mixture. Note 1-Some components may not be eluted from the chromatographic column for some types of samples under the conditions used in this method. Note 2-Test Method D2007 is an alternative method of separating high-boiling oils into polar compounds, aromatics, and saturates fractions.

1.2 An alternative procedure is provided to handle samples boiling below 232°C (450°F), but whose 5% point is above 178°C (350°F) as determined by Test Method D2887. This procedure is given in Annex A1.

1.3 The values stated in acceptable SI units are to be regarded as the standard. The values given in parentheses are provided for information purposes only.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: D 2549 – 91 (Reapproved 1995)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Separation of Representative Aromatics and Nonaromatics

Fractions of High-Boiling Oils by Elution Chromatography

This standard is issued under the fixed designation D 2549; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 3239 Test Method for Aromatic Types Analysis of Gas-

Oil Aromatic Fractions by High Ionizing Voltage Mass

1.1 This test method covers the separation and determina-

Spectrometry

tion of representative aromatics and nonaromatics fractions

from hydrocarbon mixtures that boil between 232 and 538°C

3. Terminology

(450 and 1000°F). Alternative procedures are provided for the

separation of2gor10gof hydrocarbon mixture.

3.1 Definitions of Terms Specific to This Standard:

NOTE 1—Some components may not be eluted from the chromato-

3.1.1 aromatics fraction—the portion of the sample des-

graphic column for some types of samples under the conditions used in

orbed with the polar eluants. The aromatics fraction may

this method.

contain aromatics, condensed naphthenic-aromatics, aromatic

NOTE 2—Test Method D 2007 is an alternative method of separating

olefins, and compounds containing sulfur, nitrogen, and oxy-

high-boiling oils into polar compounds, aromatics, and saturates fractions.

gen atoms.

1.2 An alternative procedure is provided to handle samples

3.1.2 nonaromatics fraction—the portion of the sample

boiling below 232°C (450°F), but whose 5 % point is above

eluted with n-pentane. The nonaromatics fraction is a mixture

178°C (350°F) as determined by Test Method D 2887. This

of paraffinic and naphthenic hydrocarbons if the sample is a

procedure is given in Annex A1.

straight-run material. If the sample is a cracked stock, the

1.3 The values stated in acceptable SI units are to be

nonaromatics fraction will also contain aliphatic and cyclic

regarded as the standard. The values given in parentheses are

olefins.

provided for information purposes only.

1.4 This standard does not purport to address all of the

4. Summary of Test Method

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4.1 A weighed amount of sample is charged to the top of a

priate safety and health practices and determine the applica-

glass chromatographic column packed with activated bauxite

bility of regulatory limitations prior to use.

and silica gel. n-Pentane is added to the column to elute the

nonaromatics. When all of the nonaromatics are eluted, the

2. Referenced Documents

aromatics fraction is eluted by additions of diethyl ether,

2.1 ASTM Standards:

chloroform, and ethyl alcohol.

D 2007 Test Method for Characteristic Groups in Rubber

4.2 The solvents are completely removed by evaporation,

Extender and Processing Oils and Other PetroleumDerived

and the residues are weighed and calculated as the aromatics

Oils by the Clay-Gel Adsorption Chromatographic

and nonaromatics fractions of the sample.

Method

D 2425 Test Method for Hydrocarbon Types in Middle

Distillates by Mass Spectrometry 5. Significance and Use

D 2786 Test Method for Hydrocarbon Types Analysis of

5.1 The determination of compound types by mass spec-

Gas-Oil Saturate Fractions by High Ionizing Voltage Mass

trometry requires, in some instances, a preliminary separation

Spectrometry

of the petroleum sample into representative aromatics and

D 2887 Test Method for Boiling Range Distribution of

nonaromatics fractions, as in Test Methods D 2425, D 2786,

Petroleum Fractions by Gas Chromatography

and D 3239. This test method provides a suitable separation

technique for this application.

This test method is under the jurisdiction of ASTM Committee D-2 on

Petroleum Products and Lubricantsand is the direct responsibility of Subcommittee

6. Apparatus

D02.04on Hydrocarbon Analysis.

Current edition approved March 15, 1991. Published June 1991. Originally

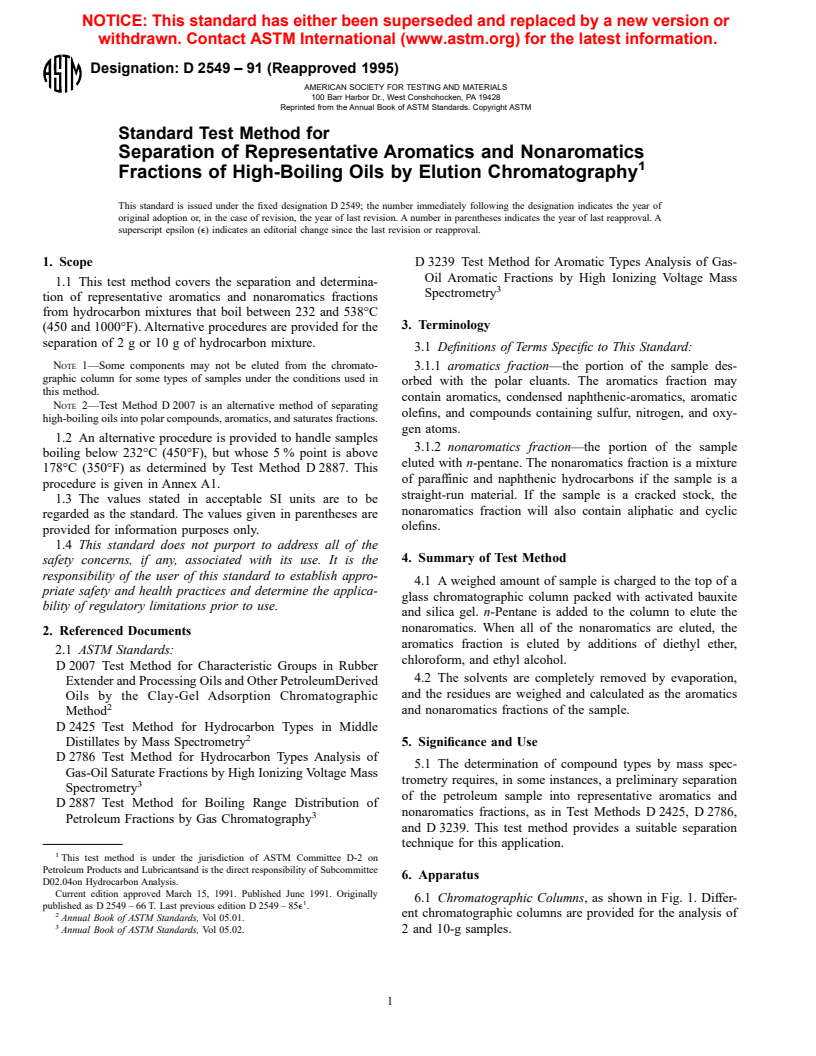

6.1 Chromatographic Columns, as shown in Fig. 1. Differ-

published as D 2549 – 66 T. Last previous edition D 2549 – 85e .

2 ent chromatographic columns are provided for the analysis of

Annual Book of ASTM Standards, Vol 05.01.

Annual Book of ASTM Standards, Vol 05.02. 2 and 10-g samples.

D 2549

FIG. 1 Chromatographic Columns

4 6

6.2 Beakers, 100, 250, and 600-mL, inverted-rim type. 7.2 Bauxite, 20 to 60-mesh. Before use, activate the

6.3 Steam Bath. bauxite by heating at 538°C (1000°F) for 16 h. Transfer the

6.4 Electric Vibrator, for packing column. activated material to an airtight container while still hot and

6.5 Weighing Bottles or Erlenmeyer Flasks, 25 and 50 mL. protect thereafter from atmospheric moisture.

7.3 Chloroform (Warning—Toxic. May be fatal if swal-

7. Reagents and Materials

lowed. See Annex A2.1.).

7.4 Cleaning Solution—Chromic- sulfuric acid

7.1 Purity of Reagents—Reagent grade chemicals shall be

used in this test. Unless otherwise indicated, it is intended that (Warning—Causes severe burns. A recognized carcinogen,

strong oxidizer, contact with organic material may cause fire.

all reagents shall conform to the specifications of the Commit-

tee on Analytical Reagents of the American Chemical Society, See Annex A2.2.).

7.5 Diethyl Ether, anhydrous, (Warning—Extremely flam-

where such specifications are available. Other grades may be

used, provided it is first ascertained that the reagent is of mable). The ethyl ether used in this test method should be free

of peroxides as determined byu the procedure in “Reagent

sufficiently high purity to permit its use without lessening the

accuracy of the determination. Chemical, American Chemical Society Specifications.”

7.6 Ethyl Alcohol, denatured, conforming to Formula 2B of

the U.S. Bureau of Internal Revenue (Warning—Flammable.).

Beakers available from Kontes Glass Co., Vineland, NJ, by ordering “Anti-

7.7 Pressuring Gas, dry air or nitrogen, delivered to the top

Creep” beakers and referring to Drawing No. 9413-A.

of the column at a regulated gage pressure of 0 to 2 psi (13.8

Reagent Chemicals, American Chemical Society Specifications, American

kPa) (Warning—Compressed gas.).

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

listed by the American Chemical Society, see Analar Standards for Laboratory 7.8 n-Pentane, commercial grade, aromatic-free. Some

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

and National Formulary, U.S. Pharmaceutical Convention, Inc. (USPC), Rockville,

MD. Bauxite available from Porocel Corp., Little Rock, AR.

D 2549

previous runs, gas pressure may be applied after addition of the last

samples of waxy stocks may not dissolve completely in

increment of n-pentane. Otherwise, gas pressure should be applied when

n-pentane, in which case cyclohexane, commercial grade,

n-pentane begins to elute from the column and should be adjusted to give

aromatic-free, may be substituted for n-pentane (Warning—

a flow rate of approximately 1 mL/min.

Extremely flammable liquid.).

8.4.4 When the n-pentane level reaches the top of the

7.9 Silica Gel, 100 to 200-mesh.

bauxite bed, add 80 mL of diethyl ether (Warning—Extremely

8. Procedure

flammable.). Connect the pressuring gas to the top of the

column and adjust the pressure to maintain an elution rate of 1

NOTE 3—The procedural details differ depending on the initial boiling

to 2 mL/min.

point of the sample. If the 5 % point is above 178°C (350°F), but below

8.4.5 Collect 50 mL of n-pentane eluate in the graduate.

232°C (450°F) use procedure described in Annex A1. If above 232°C

continue as written depending on amount of sample to be analyzed. Rinse the tip of the column with 1 to 2 mL of n-pentane, adding

Instructions specific for 2-g samples are given in 8.4.1-8.4.13, and

this to the 50 mL in the graduate (Note 5). Label the 50-mL

instructions specific for 10-g samples are given in 8.5.1 and 8.5.8.

graduate as n-pentane eluate.

8.1 Select the appropriate column, depending on whether 2

NOTE 5—The n-pentane will have reached the adsorbent bed before the

or 10 g of sample are to be analyzed. Clean the column with

required volume of eluate has been collected in the 50-mL receiver.

chromic-sulfuric acid, (Warning—Causes severe burns. See

Continue collection in this receiver after the addition of ether until the

Annex A2.2.) followed by distilled or demineralized water,

proper volume has been collected before changing to the 100-mL

acetone, and dry air or nitrogen. graduate.

8.2 Introduce a small plug of glass wool into the column,

8.4.6 When the ether level reaches the top of the bauxite

pressing it firmly into the lower end to prevent the flow of silica

bed, release the gas pressure and add 100 mL of chloroform

gel from the column.

(Warning—Toxic. May be fatal if swallowed.) to the top of the

8.3 Clamp the column in a vertical position. Add small

column. Reconnect the gas pressuring system and continue the

increments of silica gel, while vibrating the column along its

elution. When 80 mL of eluate have been collected in the

length, until the tightly packed silica gel extends to the lower

graduate, rinse the column tip with 1 mL of ether and add the

mark on the chromatographic column. Continue to vibrate the

rinse to the 100-mL graduate. Change the receiver to a 250-mL

column and add bauxite until the bauxite layer extends to the

graduate. Label the 100-mL graduate as ether-eluted fraction.

upper mark on the chromatographic column. Vibrate the

8.4.7 When the chloroform level reaches the top of the

column for an additional 3 min after filling is completed.

bauxite bed, release the gas pressure and add 75 mL of ethyl

8.4 If2gof sample are to be analyzed, continue as in 8.4.1,

alcohol (Warning—Flammable liquid.). Reconnect the gas

otherwise continue as in 8.5.

pressuring system and continue the elution until the alcohol

8.4.1 If the sample is viscous, warm it with intermittent

level reaches the top of the bauxite bed. Release the gas

mixing or shaking until it is completely fluid. Transfer a

pressure. Rinse the column tip with 1 mL of chloroform adding

representative sample (approximately 2 g) to a 25-mL weigh-

this to the graduate. Label the 250-mL graduate as chloroform-

ing bottle or flask. Determine the weight of the sample to the

alcohol-eluted fraction.

nearest 1 mg by weighing the flask before and after sample

8.4.8 Weigh a 100-mL inverted-rim beaker to the nearest 1

transfer. Add 10 mL of n-pentane (Warning— Extremely

mg. Quantitatively transfer the n-pentane eluate to this beaker

flammable liquid.) to the flask and dissolve the sample. If the

and allow the n-pentane to evaporate at room temperature.

sample does not dissolve completely in cold n-pentane, warm

Cyclohexane, if used as the elution solvent, is evaporated on a

it in warm water or over a steam bath. If the sample does not

steam bath. Evaporation is accelerated in both cases by

dissolve in warm n-pentane, take a fresh sample and substitute

directing a controlled stream of dry nitrogen downward onto

cyclohexane for the n-pentane.

the surface of the liquid.

8.4.2 Add 10 mL of n-pentane to the top of the column to

8.4.9 When all the solvent appears to be evaporated, stop

prewet the adsorbent. When the liquid level reaches the top of

the nitrogen flow, allow the beaker to come to room tempera-

the bauxite bed, transfer the sample solution from the weighing

ture, and dry the outside of the beaker to remove any

flask to the top of the column. Rinse the flask with three

condensed moisture. Reweigh the beaker to the nearest 1 mg.

successive 3-mL washes of n-pentane. Add each wash to the

NOTE 6—Complete solvent evaporation is indicated by a tendency of

top of the column. Then rinse the walls of the column bulb with

the oil to creep up the side of the beaker.

two 3-mL portions of n-pentane, allowing the liquid level to

reach the top of the bauxite bed before adding the next portion. 8.4.10 Repeat the evaporation step for 5-min periods until

Finally add 35 mL of n-pentane to the column bulb. the weight loss between successive evaporations is less than 20

8.4.3 Place a 50-mL graduate beneath the column to collect mg. Heat from a steam bath is generally required during the

the eluate. The elution rate should be approximately 1 mL/min. final evaporation steps to remove completely the elution

solvent. The weight of the residue in the beaker is the quantity

NOTE 4—Gas pressure (Warning—Compressed gas.) can be applied to

of the nonaromatics fraction.

the top of the column as necessary to maintain the elution rate at

8.4.11 Weigh a 250-mL inverted-rim beaker to the nearest 1

approximately 1 mL/min. If the correct pressure setting is known from

mg. Quantitatively transfer the chloroform-alcohol-eluted frac-

tion to this beaker and evaporate on a steam bath with a

controlled stream of dry nitrogen directed downward onto the

Silica gel available from W.R. Grace and Co., Davison Chemical Div.,

Baltimore, MD 21203, by specifying Code 923. surface of the liquid. When the solvent is evaporated, remove

D 2549

the beaker from the steam bath, cool to room temperature, and bed, release the gas pressure and add 100 mL of chloroform to

add quantitatively the ether-eluted fraction. Evaporate the ether the top of the column. Reconnect the gas pressuring system and

at room temperature as described in 8.4.8, 8.4.9, and 8.4.10. continue with the elution. When 100 mL of eluate have been

Determine the weight of the residue (aromatics fraction) to the collected in the graduate, rinse the column tip with 1 mL of

nearest 1 mg. ether and then change the receiver to a 500-mL graduate. Label

8.4.12 The weight of the aromatics plus the nonaromatics the 100-mL graduate as ether-eluted fraction.

fraction recovered must equal at least 95 % of the sample 8.5.7 When the chloroform level reaches the top of the

charged. If 95 % recovery is not obtained, repeat the test. bauxite bed, release the gas pressure and add 175 mL of ethyl

Recoveries greater than 100 % indicates incomplete removal of alcohol. Reconnect the gas pressuring systems and continue the

solvent or the condensation of moisture in the beakers. elution until the alcohol level reaches the top of the bauxite

8.4.13 Transfer the aromatics and nonaromatics fractions bed. Release the gas pressure. Rinse

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.