ASTM D8503-23

(Test Method)Standard Test Method for Determining the Scuffing Temperature Limit of Lubricating Oils Using the SRV Test Machine

Standard Test Method for Determining the Scuffing Temperature Limit of Lubricating Oils Using the SRV Test Machine

SIGNIFICANCE AND USE

5.1 This test method can be used to determine scuffing temperature limit and the evolution of coefficient of friction of lubricating oils with increasing temperatures for use in tribological contacts in which high-speed vibrational or start-stop motions are present for extended periods of time under initial high Hertzian line contact pressures. It has found application as a screening test for engine oils, gear lubricants and turbine oils. The test temperature may reach up to 300 °C. Users of this test method should determine whether results correlate with field performance or other applications. In comparison to the ball-on-disk geometry in accordance with Test Method D6425, the initial contact pressure is better retained over test time in this roller-on-disk geometry.

SCOPE

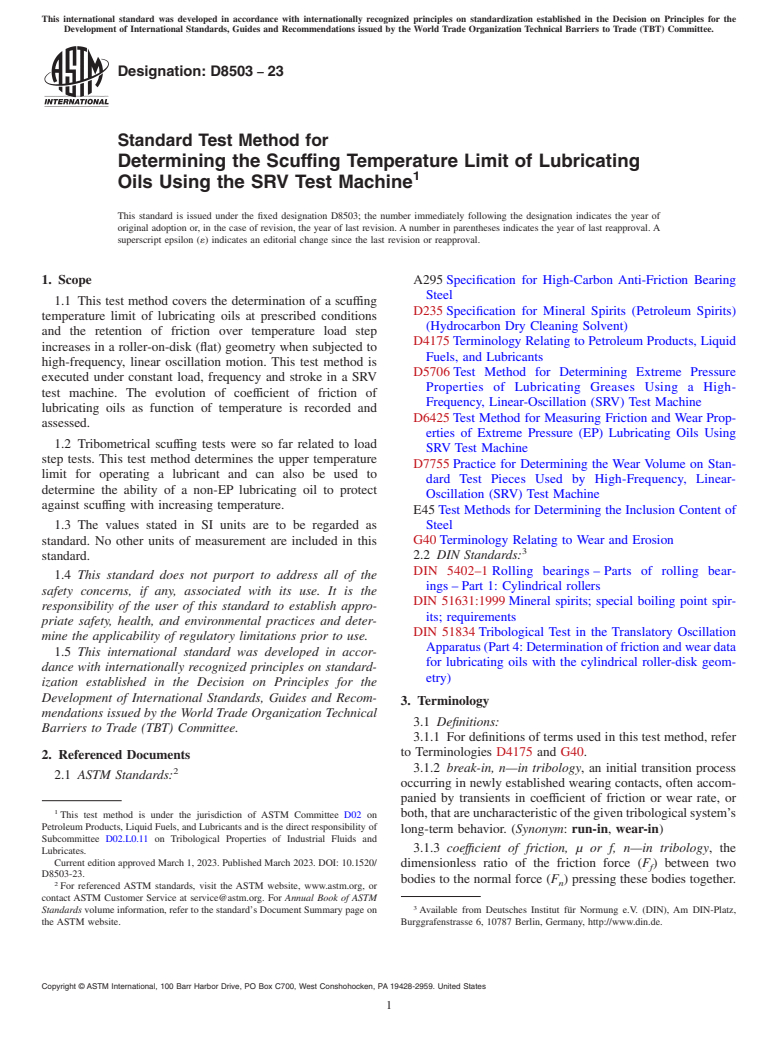

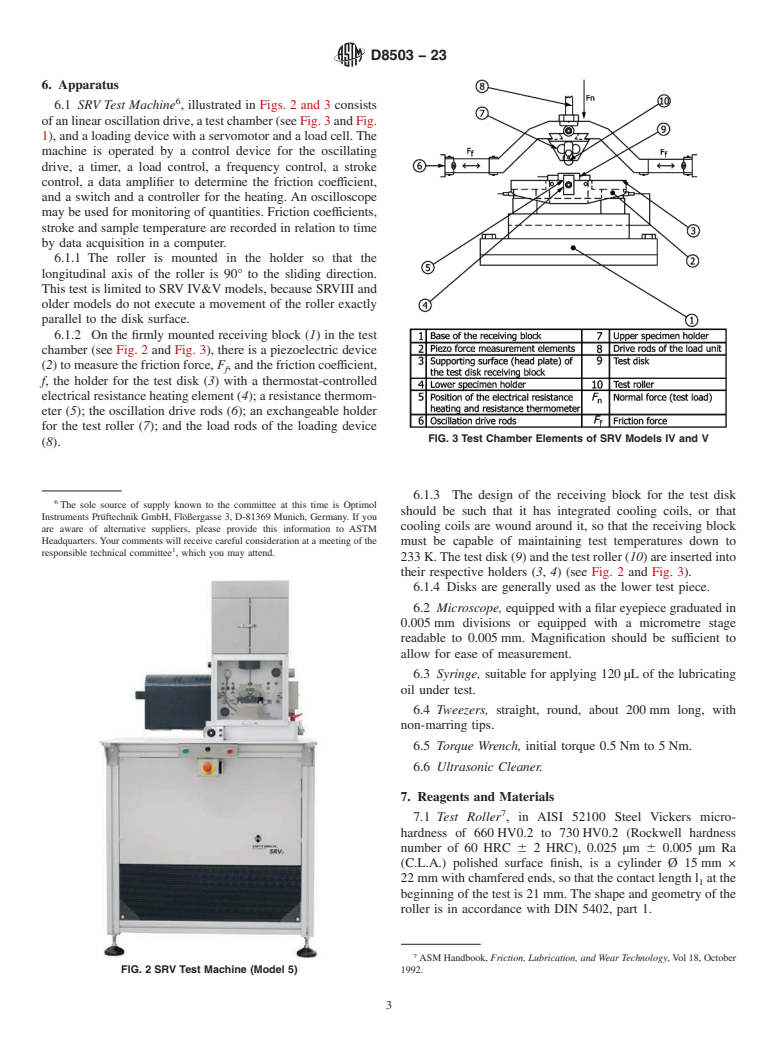

1.1 This test method covers the determination of a scuffing temperature limit of lubricating oils at prescribed conditions and the retention of friction over temperature load step increases in a roller-on-disk (flat) geometry when subjected to high-frequency, linear oscillation motion. This test method is executed under constant load, frequency and stroke in a SRV test machine. The evolution of coefficient of friction of lubricating oils as function of temperature is recorded and assessed.

1.2 Tribometrical scuffing tests were so far related to load step tests. This test method determines the upper temperature limit for operating a lubricant and can also be used to determine the ability of a non-EP lubricating oil to protect against scuffing with increasing temperature.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D8503 − 23

Standard Test Method for

Determining the Scuffing Temperature Limit of Lubricating

1

Oils Using the SRV Test Machine

This standard is issued under the fixed designation D8503; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope A295 Specification for High-Carbon Anti-Friction Bearing

Steel

1.1 This test method covers the determination of a scuffing

D235 Specification for Mineral Spirits (Petroleum Spirits)

temperature limit of lubricating oils at prescribed conditions

(Hydrocarbon Dry Cleaning Solvent)

and the retention of friction over temperature load step

D4175 Terminology Relating to Petroleum Products, Liquid

increases in a roller-on-disk (flat) geometry when subjected to

Fuels, and Lubricants

high-frequency, linear oscillation motion. This test method is

D5706 Test Method for Determining Extreme Pressure

executed under constant load, frequency and stroke in a SRV

Properties of Lubricating Greases Using a High-

test machine. The evolution of coefficient of friction of

Frequency, Linear-Oscillation (SRV) Test Machine

lubricating oils as function of temperature is recorded and

D6425 Test Method for Measuring Friction and Wear Prop-

assessed.

erties of Extreme Pressure (EP) Lubricating Oils Using

1.2 Tribometrical scuffing tests were so far related to load

SRV Test Machine

step tests. This test method determines the upper temperature

D7755 Practice for Determining the Wear Volume on Stan-

limit for operating a lubricant and can also be used to

dard Test Pieces Used by High-Frequency, Linear-

determine the ability of a non-EP lubricating oil to protect

Oscillation (SRV) Test Machine

against scuffing with increasing temperature.

E45 Test Methods for Determining the Inclusion Content of

1.3 The values stated in SI units are to be regarded as Steel

G40 Terminology Relating to Wear and Erosion

standard. No other units of measurement are included in this

3

standard. 2.2 DIN Standards:

DIN 5402–1 Rolling bearings – Parts of rolling bear-

1.4 This standard does not purport to address all of the

ings – Part 1: Cylindrical rollers

safety concerns, if any, associated with its use. It is the

DIN 51631:1999 Mineral spirits; special boiling point spir-

responsibility of the user of this standard to establish appro-

its; requirements

priate safety, health, and environmental practices and deter-

DIN 51834 Tribological Test in the Translatory Oscillation

mine the applicability of regulatory limitations prior to use.

Apparatus (Part 4: Determination of friction and wear data

1.5 This international standard was developed in accor-

for lubricating oils with the cylindrical roller-disk geom-

dance with internationally recognized principles on standard-

etry)

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

3. Terminology

mendations issued by the World Trade Organization Technical

3.1 Definitions:

Barriers to Trade (TBT) Committee.

3.1.1 For definitions of terms used in this test method, refer

to Terminologies D4175 and G40.

2. Referenced Documents

3.1.2 break-in, n—in tribology, an initial transition process

2

2.1 ASTM Standards:

occurring in newly established wearing contacts, often accom-

panied by transients in coefficient of friction or wear rate, or

1

This test method is under the jurisdiction of ASTM Committee D02 on both, that are uncharacteristic of the given tribological system’s

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

long-term behavior. (Synonym: run-in, wear-in)

Subcommittee D02.L0.11 on Tribological Properties of Industrial Fluids and

3.1.3 coeffıcient of friction, μ or f, n—in tribology, the

Lubricates.

Current edition approved March 1, 2023. Published March 2023. DOI: 10.1520/

dimensionless ratio of the friction force (F ) between two

f

D8503-23.

bodies to the normal force (F ) pressing these bodies together.

n

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from Deutsches Institut für Normung e.V. (DIN), Am DIN-Platz,

the ASTM website. Burggrafenstrasse 6, 10787 Berlin, Germany, http://www.din.de.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.