ASTM F1743-96

(Practice)Standard Practice for Rehabilitation of Existing Pipelines and Conduits by Pulled-in-Place Installation of Cured-in-Place Thermosetting Resin Pipe (CIPP)

Standard Practice for Rehabilitation of Existing Pipelines and Conduits by Pulled-in-Place Installation of Cured-in-Place Thermosetting Resin Pipe (CIPP)

SCOPE

1.1 This practice describes the procedures for the reconstruction of pipelines and conduits (4 to 96 in. (10 to 244 cm) diameter) by the pulled-in-place installation of a resin-impregnated, flexible fabric tube into an existing conduit and secondarily inflated through the inversion of a calibration hose by the use of a hydrostatic head or air pressure (see Fig. 1). The resin is cured by circulating hot water or by the introduction of controlled steam into the tube. When cured, the finished cured-in-place pipe will be continuous and tight fitting. This reconstruction process may be used in a varietyof gravity and pressure applications such as sanitary sewers, storm sewers, process piping, electrical conduits, and ventilation systems.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for informational purposes only.

Note 1- There are no ISO standards covering the primary subject matter of this practice.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact

ASTM International (www.astm.org) for the latest information.

Designation: F 1743 – 96

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Practice for

Rehabilitation of Existing Pipelines and Conduits by Pulled-

in-Place Installation of Cured-in-Place Thermosetting Resin

1

Pipe (CIPP)

This standard is issued under the fixed designation F 1743; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

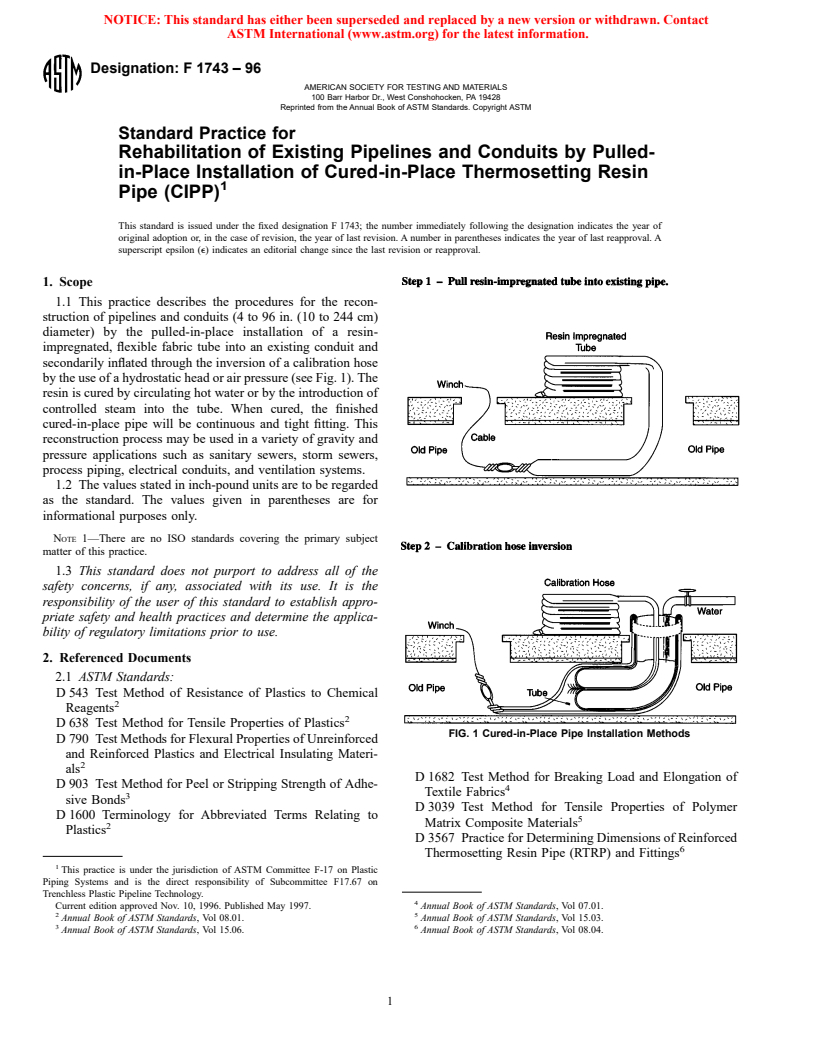

1.1 This practice describes the procedures for the recon-

struction of pipelines and conduits (4 to 96 in. (10 to 244 cm)

diameter) by the pulled-in-place installation of a resin-

impregnated, flexible fabric tube into an existing conduit and

secondarily inflated through the inversion of a calibration hose

by the use of a hydrostatic head or air pressure (see Fig. 1). The

resin is cured by circulating hot water or by the introduction of

controlled steam into the tube. When cured, the finished

cured-in-place pipe will be continuous and tight fitting. This

reconstruction process may be used in a variety of gravity and

pressure applications such as sanitary sewers, storm sewers,

process piping, electrical conduits, and ventilation systems.

1.2 The values stated in inch-pound units are to be regarded

as the standard. The values given in parentheses are for

informational purposes only.

NOTE 1—There are no ISO standards covering the primary subject

matter of this practice.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D 543 Test Method of Resistance of Plastics to Chemical

2

Reagents

2

D 638 Test Method for Tensile Properties of Plastics

FIG. 1 Cured-in-Place Pipe Installation Methods

D 790 Test Methods for Flexural Properties of Unreinforced

and Reinforced Plastics and Electrical Insulating Materi-

2

als

D 1682 Test Method for Breaking Load and Elongation of

D 903 Test Method for Peel or Stripping Strength of Adhe-

4

Textile Fabrics

3

sive Bonds

D 3039 Test Method for Tensile Properties of Polymer

D 1600 Terminology for Abbreviated Terms Relating to

5

Matrix Composite Materials

2

Plastics

D 3567 Practice for Determining Dimensions of Reinforced

6

Thermosetting Resin Pipe (RTRP) and Fittings

1

This practice is under the jurisdiction of ASTM Committee F-17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.67 on

Trenchless Plastic Pipeline Technology.

4

Current edition approved Nov. 10, 1996. Published May 1997. Annual Book of ASTM Standards, Vol 07.01.

2 5

Annual Book of ASTM Standards, Vol 08.01. Annual Book of ASTM Standards, Vol 15.03.

3 6

Annual Book of ASTM Standards, Vol 15.06. Annual Book of ASTM Standards, Vol 08.04.

1

---------------------- Page: 1 ----------------------

NOTICE:¬This¬standard¬has¬either¬been¬superceded¬and¬replaced¬by¬a¬new¬version¬or¬discontinued.¬

Contact¬ASTM¬International¬(www.astm.org)¬for¬the¬latest¬information.¬

F 1743

D 4814 Specification for Automotive Spark—Ignition En- specific job conditions.

7

gine Fuel

5. Recommended Materials and Manufacture

D 5813 Specification for Cured-in-Place Thermosetting

6

5.1 General—The resins, fabric tube, tube coatings, or other

Resin Sewer Pipe

6

materials, such as the permanent calibration hose when com-

F 412 Terminology Relating to Plastic Piping Systems

bined as a composite structure, shall produce CIPP that meets

F 1216 Practice for Rehabilitation of Existing Pipelines and

the requirements of this specification.

Conduits by the Inversion and Curing of a Resin-

6

5.2 CIPP Wall Composition—The wall shall consist of a

Impregnated Tube

plastic coated fabric tube filled with a thermosetting (cross-

2.2 AWWA Standard:

8

linked) resin, and if used, a filler.

M28 Manual on Cleaning and Lining Water Mains

5.2.1 Fabric Tube—The fabric tube should consist of one or

2.3 NASSCO Standard:

more layers of flexible needled felt, or equivalent, woven or

Recommended Specifications for Sewer Collection System

9

nonwoven material(s), or both, capable of carrying resin,

Rehabilitation

withstanding installation pressures, and curing temperatures.

NOTE 2—An ASTM specification for cured-in-place pipe materials

The material(s) of construction should be able to stretch to fit

appropriate for use in this practice is under preparation and will be

irregular pipe sections and negotiate bends. Longitudinal and

re

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.