ASTM F1743-96(2003)

(Practice)Standard Practice for Rehabilitation of Existing Pipelines and Conduits by Pulled-in-Place Installation of Cured-in-Place Thermosetting Resin Pipe (CIPP)

Standard Practice for Rehabilitation of Existing Pipelines and Conduits by Pulled-in-Place Installation of Cured-in-Place Thermosetting Resin Pipe (CIPP)

SIGNIFICANCE AND USE

This practice is for use by designers and specifiers, regulatory agencies, owners, and inspection organizations who are involved in the rehabilitation of conduits through the use of a resin-impregnated fabric tube pulled-in-place through an existing conduit and secondarily inflated through the inversion of a calibration hose. Modifications may be required for specific job conditions.

SCOPE

1.1 This practice describes the procedures for the reconstruction of pipelines and conduits (4 to 96 in. (10 to 244 cm) diameter) by the pulled-in-place installation of a resin-impregnated, flexible fabric tube into an existing conduit and secondarily inflated through the inversion of a calibration hose by the use of a hydrostatic head or air pressure (see Fig. 1). The resin is cured by circulating hot water or by the introduction of controlled steam into the tube. When cured, the finished cured-in-place pipe will be continuous and tight fitting. This reconstruction process may be used in a variety of gravity and pressure applications such as sanitary sewers, storm sewers, process piping, electrical conduits, and ventilation systems.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for informational purposes only.

Note 1—There are no ISO standards covering the primary subject matter of this practice.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:F1743–96 (Reapproved 2003)

Standard Practice for

Rehabilitation of Existing Pipelines and Conduits by Pulled-

in-Place Installation of Cured-in-Place Thermosetting Resin

Pipe (CIPP)

This standard is issued under the fixed designation F 1743; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

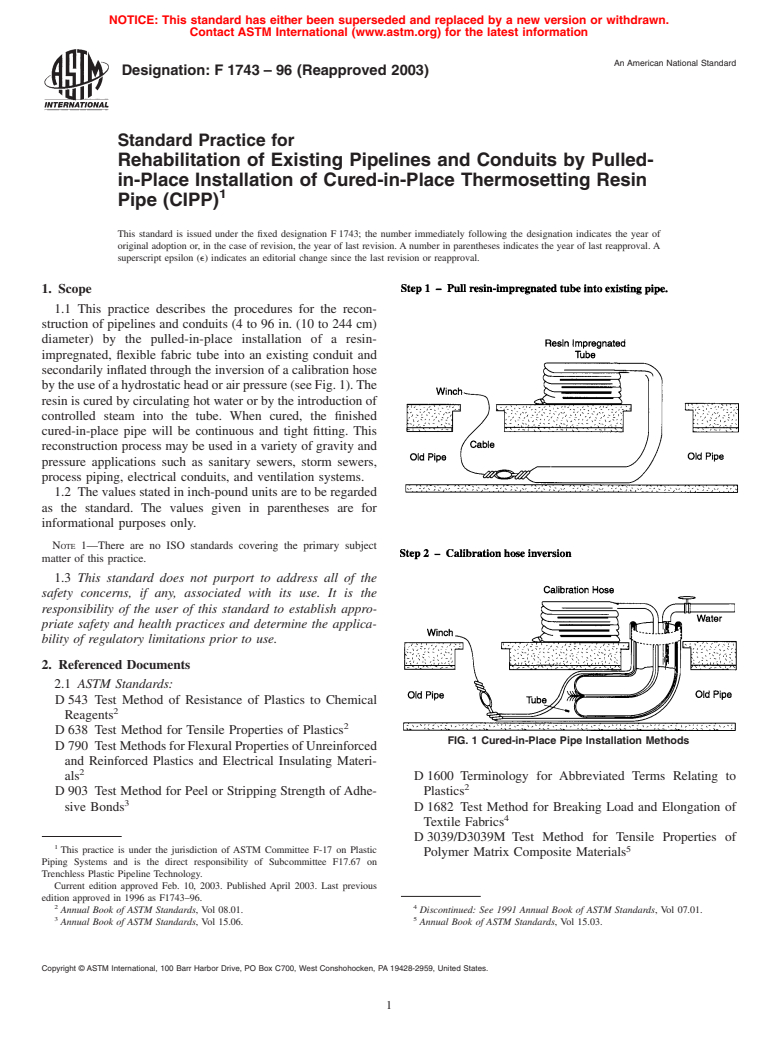

1.1 This practice describes the procedures for the recon-

struction of pipelines and conduits (4 to 96 in. (10 to 244 cm)

diameter) by the pulled-in-place installation of a resin-

impregnated, flexible fabric tube into an existing conduit and

secondarily inflated through the inversion of a calibration hose

bytheuseofahydrostaticheadorairpressure(seeFig.1).The

resin is cured by circulating hot water or by the introduction of

controlled steam into the tube. When cured, the finished

cured-in-place pipe will be continuous and tight fitting. This

reconstruction process may be used in a variety of gravity and

pressure applications such as sanitary sewers, storm sewers,

process piping, electrical conduits, and ventilation systems.

1.2 The values stated in inch-pound units are to be regarded

as the standard. The values given in parentheses are for

informational purposes only.

NOTE 1—There are no ISO standards covering the primary subject

matter of this practice.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D 543 Test Method of Resistance of Plastics to Chemical

Reagents

D 638 Test Method for Tensile Properties of Plastics

FIG. 1 Cured-in-Place Pipe Installation Methods

D 790 TestMethodsforFlexuralPropertiesofUnreinforced

and Reinforced Plastics and Electrical Insulating Materi-

als D 1600 Terminology for Abbreviated Terms Relating to

D 903 Test Method for Peel or Stripping Strength of Adhe- Plastics

sive Bonds D 1682 Test Method for Breaking Load and Elongation of

Textile Fabrics

D 3039/D3039M Test Method for Tensile Properties of

This practice is under the jurisdiction of ASTM Committee F-17 on Plastic

Polymer Matrix Composite Materials

Piping Systems and is the direct responsibility of Subcommittee F17.67 on

Trenchless Plastic Pipeline Technology.

Current edition approved Feb. 10, 2003. Published April 2003. Last previous

edition approved in 1996 as F1743–96.

2 4

Annual Book of ASTM Standards, Vol 08.01. Discontinued: See 1991 Annual Book of ASTM Standards, Vol 07.01.

3 5

Annual Book of ASTM Standards, Vol 15.06. Annual Book of ASTM Standards, Vol 15.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F1743–96 (2003)

D 3567 Practice for Determining Dimensions of Reinforced a resin-impregnated fabric tube pulled-in-place through an

Thermosetting Resin Pipe (RTRP) and Fittings existing conduit and secondarily inflated through the inversion

D 4814 Specification for Automotive Spark—Ignition En- of a calibration hose. Modifications may be required for

gine Fuel specific job conditions.

D 5813 Specification for Cured-in-Place Thermosetting

Resin Sewer Pipe 5. Recommended Materials and Manufacture

F 412 Terminology Relating to Plastic Piping Systems

5.1 General—Theresins,fabrictube,tubecoatings,orother

F 1216 Practice for Rehabilitation of Existing Pipelines and

materials, such as the permanent calibration hose when com-

Conduits by the Inversion and Curing of a Resin-

bined as a composite structure, shall produce CIPP that meets

Impregnated Tube

the requirements of this specification.

2.2 AWWA Standard:

5.2 CIPP Wall Composition—The wall shall consist of a

M28 Manual on Cleaning and Lining Water Mains

plastic coated fabric tube filled with a thermosetting (cross-

2.3 NASSCO Standard:

linked) resin, and if used, a filler.

Recommended Specifications for Sewer Collection System

5.2.1 Fabric Tube—The fabric tube should consist of one or

Rehabilitation

more layers of flexible needled felt, or equivalent, woven or

NOTE 2—An ASTM specification for cured-in-place pipe materials

nonwoven material(s), or both, capable of carrying resin,

appropriate for use in this practice is under preparation and will be

withstanding installation pressures, and curing temperatures.

referenced in this practice when published.

The material(s) of construction should be able to stretch to fit

irregular pipe sections and negotiate bends. Longitudinal and

3. Terminology

circumferential joints between multiple layers of fabric should

3.1 General—Definitions are in accordance with Terminol-

be staggered so as not to overlap. The outside layer of the

ogy F 412. Abbreviations are in accordance with Terminology

fabric tube should have an impermeable flexible coating(s)

D 1600, unless otherwise indicated.

whose function is to contain the resin during and after fabric

3.2 Definitions of Terms Specific to This Standard:

tube impregnation. The outer coating(s) must facilitate moni-

3.2.1 calibration hose—an impermeable bladder which is

toring of resin saturation of the material(s) of construction of

inverted within the resin-impregnated fabric tube by hydro-

the fabric tube. The fabric tube should be fabricated to a size

static head or air pressure and may optionally be removed or

that, when installed, will tightly fit the internal circumference

remain in place as a permanent part of the installed cured-in-

and the length of the original conduit. Allowance should be

place pipe as described in 5.2.2.

made for circumferential and longitudinal stretching of the

3.2.2 cured-in-place pipe (CIPP)—a hollow cylinder con-

fabric tube during installation. As required, the fabric tube

sisting of a fabric tube with cured (cross-linked) thermosetting

should meet minimum tensile strength requirements in the

resin. Interior or exterior plastic coatings, or both, may be

longitudinal and transverse directions as specified in 7.1. All

included.The CIPPis formed within an existing pipe and takes

the material(s) of construction for the fabric tube should be

the shape of and fits tightly to the pipe.

compatible with the resin system used.

3.2.3 delamination—separation of layers of the CIPP.

5.2.2 Calibration Hose:

3.2.4 dry spot—an area of fabric of the finished CIPPwhich

5.2.2.1 Removable Calibration Hose—The removable cali-

is deficient or devoid of resin.

bration hose should consist of an impermeable plastic, or

3.2.5 fabric tube—flexible needled felt, or equivalent, wo-

impermeable plastic coating(s) on flexible woven or nonwoven

ven or nonwoven material(s), or both, formed into a tubular

material(s), or both, that do not absorb resin and are capable of

shape which during the installation process is saturated with

being removed from the CIPP.

resin and holds the resin in place during the installation and

5.2.2.2 Permanent Calibration Hose—The permanent cali-

curing process.

bration hose should consist of an impermeable plastic coating

3.2.6 inversion—the process of turning the calibration hose

on a flexible needled felt or equivalent woven or nonwoven

inside out by the use of water pressure or air pressure.

material(s), or both, that are capable of absorbing resin and are

3.2.7 lift—a portion of the CIPPthat is a departure from the

of a thickness to become fully saturated with resin. The

existing conduit wall forming a section of reverse curvature in

calibration hose should be translucent to facilitate post-

the CIPP.

installation inspection. The calibration hose should be fabri-

cated to a size that, when installed, will tightly fit the internal

4. Significance and Use

circumference and the length of the resin saturated fabric tube.

4.1 This practice is for use by designers and specifiers,

Once inverted, the calibration hose becomes part of the fabric

regulatory agencies, owners, and inspection organizations who

tube, and once properly cured, should bond permanently with

are involved in the rehabilitation of conduits through the use of

the fabric tube. The properties of the calibration hose should

meet minimum tensile strength requirements in the longitudi-

nal and transverse directions as specified in 7.1. All the

Annual Book of ASTM Standards, Vol 08.04.

Annual Book of ASTM Standards, Vol 05.03.

material(s) of construction for the calibration hose should be

Available from theAmericanWaterWorksAssociation, 6666W. QuinceyAve.,

compatible with the resin system used.

Denver, CO 80235.

5.2.3 Resin—Achemically resistant isophthalic based poly-

Available from the National Association of Sewer Service Companies, 101

Wymore Rd., Suite 501, Altamonte, FL 32714. ester, or vinyl ester thermoset resin and catalyst system or an

F1743–96 (2003)

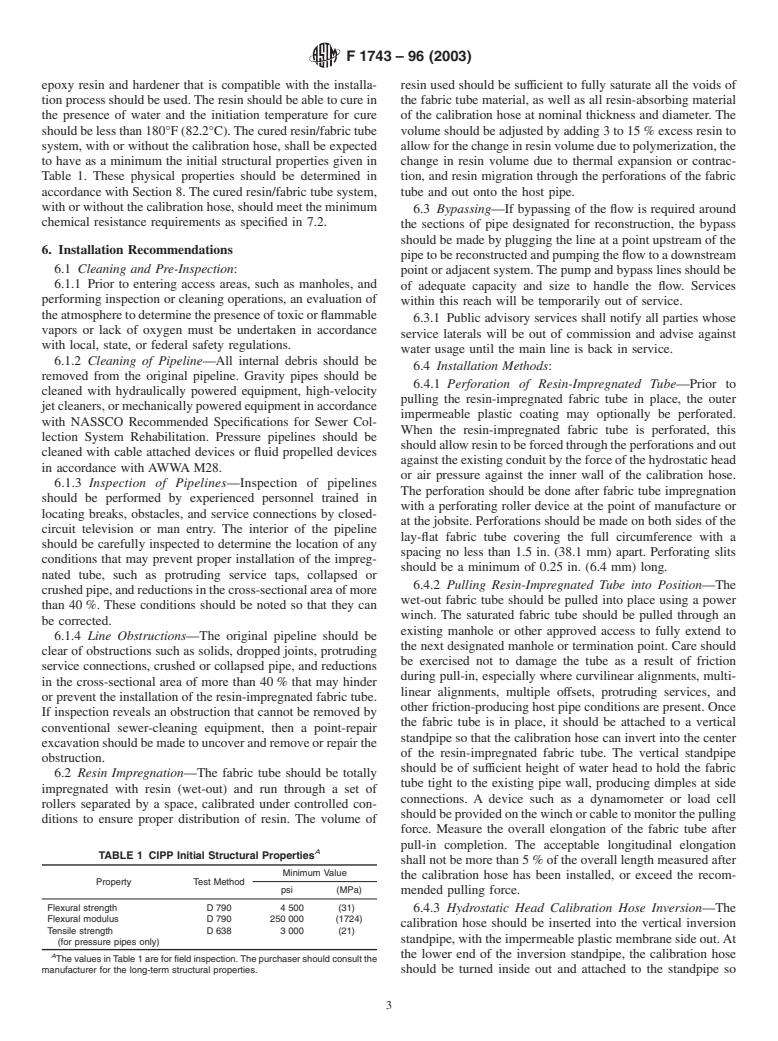

epoxy resin and hardener that is compatible with the installa- resin used should be sufficient to fully saturate all the voids of

tion process should be used.The resin should be able to cure in the fabric tube material, as well as all resin-absorbing material

the presence of water and the initiation temperature for cure of the calibration hose at nominal thickness and diameter. The

shouldbelessthan180°F(82.2°C).Thecuredresin/fabrictube volume should be adjusted by adding 3 to 15 % excess resin to

system, with or without the calibration hose, shall be expected allowforthechangeinresinvolumeduetopolymerization,the

to have as a minimum the initial structural properties given in change in resin volume due to thermal expansion or contrac-

Table 1. These physical properties should be determined in tion, and resin migration through the perforations of the fabric

accordance with Section 8. The cured resin/fabric tube system, tube and out onto the host pipe.

with or without the calibration hose, should meet the minimum

6.3 Bypassing—If bypassing of the flow is required around

chemical resistance requirements as specified in 7.2.

the sections of pipe designated for reconstruction, the bypass

should be made by plugging the line at a point upstream of the

6. Installation Recommendations

pipetobereconstructedandpumpingtheflowtoadownstream

6.1 Cleaning and Pre-Inspection:

point or adjacent system.The pump and bypass lines should be

6.1.1 Prior to entering access areas, such as manholes, and

of adequate capacity and size to handle the flow. Services

performing inspection or cleaning operations, an evaluation of

within this reach will be temporarily out of service.

theatmospheretodeterminethepresenceoftoxicorflammable

6.3.1 Public advisory services shall notify all parties whose

vapors or lack of oxygen must be undertaken in accordance

service laterals will be out of commission and advise against

with local, state, or federal safety regulations.

water usage until the main line is back in service.

6.1.2 Cleaning of Pipeline—All internal debris should be

6.4 Installation Methods:

removed from the original pipeline. Gravity pipes should be

6.4.1 Perforation of Resin-Impregnated Tube—Prior to

cleaned with hydraulically powered equipment, high-velocity

pulling the resin-impregnated fabric tube in place, the outer

jetcleaners,ormechanicallypoweredequipmentinaccordance

impermeable plastic coating may optionally be perforated.

with NASSCO Recommended Specifications for Sewer Col-

When the resin-impregnated fabric tube is perforated, this

lection System Rehabilitation. Pressure pipelines should be

shouldallowresintobeforcedthroughtheperforationsandout

cleaned with cable attached devices or fluid propelled devices

againsttheexistingconduitbytheforceofthehydrostatichead

in accordance with AWWA M28.

or air pressure against the inner wall of the calibration hose.

6.1.3 Inspection of Pipelines—Inspection of pipelines

The perforation should be done after fabric tube impregnation

should be performed by experienced personnel trained in

with a perforating roller device at the point of manufacture or

locating breaks, obstacles, and service connections by closed-

at the jobsite. Perforations should be made on both sides of the

circuit television or man entry. The interior of the pipeline

lay-flat fabric tube covering the full circumference with a

should be carefully inspected to determine the location of any

spacing no less than 1.5 in. (38.1 mm) apart. Perforating slits

conditions that may prevent proper installation of the impreg-

should be a minimum of 0.25 in. (6.4 mm) long.

nated tube, such as protruding service taps, collapsed or

6.4.2 Pulling Resin-Impregnated Tube into Position—The

crushedpipe,andreductionsinthecross-sectionalareaofmore

wet-out fabric tube should be pulled into place using a power

than 40 %. These conditions should be noted so that they can

winch. The saturated fabric tube should be pulled through an

be corrected.

existing manhole or other approved access to fully extend to

6.1.4 Line Obstructions—The original pipeline should be

the next designated manhole or termination point. Care should

clear of obstructions such as solids, dropped joints, protruding

be exercised not to damage the tube as a result of friction

service connections, crushed or collapsed pipe, and reductions

during pull-in, especially where curvilinear alignments, multi-

in the cross-sectional area of more than 40 % that may hinder

linear alignments, multiple offsets, protruding services, and

or prevent the installation of the resin-impregnated fabric tube.

other friction-producing host pipe conditions are present. Once

If inspection reveals an obstruction that cannot be removed by

the fabric tube is in place, it should be attached to a vertical

conventional sewer-cleaning equipment, then a point-repair

standpipe so that the calibration hose can invert into the center

excavationshouldbemadetouncoverandremoveorrepairthe

of the resin-impregnated fabric tube. The vertical standpipe

obstruction.

should be of sufficient height of water head to hold the fabric

6.2 Resin Impregnation—The fabric tube should be totally

tube tight to the existing pipe wall, producing dimples at side

impregnated with resin (wet-out) and run through a set of

connections. A device such as a dynamometer or load cell

rollers separated by a space, calibrated under controlled con-

shouldbeprovidedonthewinchorcabletomonitorthepulling

ditions to ensure proper distribution of resin. The volume of

force. Measure the overall elongation of the fabric tube after

pull-in completion. The acceptable longitudinal elongation

A

T

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.