ASTM D5842-95(2000)

(Practice)Standard Practice for Sampling and Handling of Fuels for Volatility Measurement

Standard Practice for Sampling and Handling of Fuels for Volatility Measurement

SCOPE

1.1 This practice covers procedures and equipment for obtaining, mixing, and handling representative samples of volatile fuels for the purpose of testing for compliance with the standards set forth for volatility related measurements applicable to light fuels. The applicable dry vapor pressure equivalent range of this practice is 13 to 105 kPa (2 to 16 psia).

1.2 This practice is applicable to the sampling, mixing, and handling of reformulated fuels including those containing oxygenates.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 The values stated in acceptable metric units are to be regarded as the standard except in some cases where drawings may show English measurements which are customary for that equipment.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D5842–95 (Reapproved 2000)

Designation: MPMS Chapter 8.4

Standard Practice for

Sampling and Handling of Fuels for Volatility Measurement

This standard is issued under the fixed designation D 5842; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope MPMS Chapter 8—Definitions

MPMS Chapter 8.1—Standard Practice for Manual Sam-

1.1 This practice covers procedures and equipment for

pling of Petroleum and Petroleum Products

obtaining, mixing, and handling representative samples of

MPMS Chapter 8.2—Standard Practice forAutomatic Sam-

volatile fuels for the purpose of testing for compliance with the

pling of Liquid Petroleum and Petroleum Products

standards set forth for volatility related measurements appli-

MPMS Chapter 8.3—Standard Practice for Mixing and

cable to light fuels. The applicable dry vapor pressure equiva-

Handling of Liquid Samples of Petroleum and Petroleum

lent range of this practice is 13 to 105 kPa (2 to 16 psia).

Products

1.2 This practice is applicable to the sampling, mixing, and

handling of reformulated fuels including those containing

3. Terminology

oxygenates.

3.1 Definitions of Terms Specific to This Standard:

1.3 The values stated in acceptable metric units are to be

3.1.1 bottom sample—a sample obtained from the material

regarded as the standard except in some cases where drawings

at the bottom of the tank, container, or line at its lowest point.

may show English measurements which are customary for that

3.1.1.1 Discussion—In practice the term bottom sample has

equipment.

a variety of meanings. As a result, it is recommended that the

1.4 This standard does not purport to address all of the

exact sampling location (for example, 15 cm [6 in.] from the

safety concerns, if any, associated with its use. It is the

bottom) should be specified when using this term.

responsibility of the user of this standard to establish appro-

3.1.2 dead legs—sections of pipe that, by design, do not

priate safety and health practices and determine the applica-

allow for the flow of material through them.

bility of regulatory limitations prior to use.

3.1.2.1 Discussion—Deadlegsarenotsuitableforobtaining

2. Referenced Documents representative samples.

3.1.3 relief lines—sections of pipe that lead to a pressure/

2.1 ASTM Standards:

vacuum relief valve.

D 323 Test Method for Vapor Pressure of Petroleum Prod-

2 3.1.3.1 Discussion—Relief lines are not suitable for obtain-

ucts (Reid Method)

ing representative samples.

D 4057 Practice for Manual Sampling of Petroleum and

3 3.1.4 stand pipes—vertical sections of pipe or tubing ex-

Petroleum Products

tending from the gaging platform to near the bottom of tanks

D 4953 Test Method for Vapor Pressure of Gasoline and

3 that are equipped with external or internal floating roofs. Stand

Gasoline-Oxygenate Blends (Dry Method)

pipes also may be found on ships and barges.

D 5190 Test Method for Vapor Pressure of Petroleum Prod-

3.1.4.1 Discussion—Stand pipes which are not slotted or

ucts (Automatic Method)

perforated will not yield representative samples. Further infor-

D 5191 Test Method for Vapor Pressure of Petroleum Prod-

mation on proper stand pipe design is given in 6.4.3.

ucts (Mini Method)

3.1.5 Other sample definitions are given in Practice D 4057.

2.2 API Documents:

4. Summary of Practice

This practice is under the jurisdiction of ASTM Committee D-2 on Petroleum 4.1 It is necessary that the samples be representative of the

Products and Lubricants and is the direct responsibility of Subcommittee D02.02 on

fuel in question. The basic principle of each sampling proce-

Static Petroleum Measurement.

dure involves obtaining a sample in such a manner and from

Current edition approved Nov. 10, 1995. Published February 1996.

such locations in the tank or other container that the sample

Annual Book of ASTM Standards, Vol 05.01.

Annual Book of ASTM Standards, Vol 05.02.

will be representative of the fuel. A summary of the sampling

Available from theAmerican Petroleum Institute, 1220 LSt., NW,Washington,

procedures and their application is presented in Table 1. Each

DC 20005.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D5842–95 (2000)

TABLE 1 Summary of Gasoline Sampling Procedures and

6. General Comments

Applicability

6.1 Sample Containers:

Type of Container Procedure Paragraph

6.1.1 Sample containers are clear or brown glass bottles,

Storage tanks, ship and barge all-levels sampling 7.2.1.2

tanks, tank cars, tank trucks fluorinated high-density polyethylene bottles, or metal cans.

running sample 7.2.1.2

The clear glass bottle is advantageous because it is easily

upper, middle and lower 7.2.1.2

examined visually for cleanliness, and also makes visual

samples

top sample 7.2.1.2

inspection of the sample for free water or solid impurities

grab sampling 7.5

possible. The brown glass bottle affords some protection from

Storage tanks with taps tap sampling 7.2.2

Pipes and lines line sampling 7.3 light. The only cans acceptable are those with the seams

automatic sampling 7.4

soldered on the exterior surface.

time proportional 7.4.1

flow proportional 7.4.2

6.1.2 Cork stoppers, or screw caps of plastic or metal, are

grab sampling 7.5

used for glass bottles; screw caps with inserted seals only are

Retail outlet and wholesale nozzle sampling 7.6

used for cans to provide a vapor-tight closure seal. Corks must

purchaser-consumer facility

storage tanks

be of good quality, clean, and free from holes and loose bits of

cork.Neveruserubberstoppers.Contactofthesamplewiththe

corkcanbepreventedbywrappingtinoraluminumfoilaround

procedure is suitable for sampling a material under definite

the cork before forcing it into the bottle. Screw caps must be

storage, transportation, or container conditions. The precau-

protected by a cork disk faced with tin or aluminum foil, an

tions required to ensure the representative character of the

inverted cone polyseal or other material that will not affect

samples are numerous and depend upon the tank, carrier,

petroleum or petroleum products. The fluorinated bottles are

container, or line from which the sample is being obtained, the

supplied with polypropylene screw caps.

type and cleanliness of the sample container, and the sampling

6.1.3 Sample size is dictated by the test method to be used.

procedure that is to be used.

One litre (32 oz) bottles or cans are generally used for manual

vapor pressure testing. The mini-vapor pressure methods need

5. Significance and Use

a much smaller sample and it can be taken in a 125 mL (4 oz)

5.1 The dry vapor pressure equivalent (DVPE) of volatile

bottle. See Fig. 1 .

motor fuels is regulated by federal and state air pollution

6.1.4 All sample containers must be absolutely clean and

control agencies. In order to meet the letter of these regula-

tions, it is necessary to sample, handle, and test these products free of foreign matter. Before reusing a container, wash it with

in a very precise manner. strong soap solution, rinse it thoroughly with tap water, and

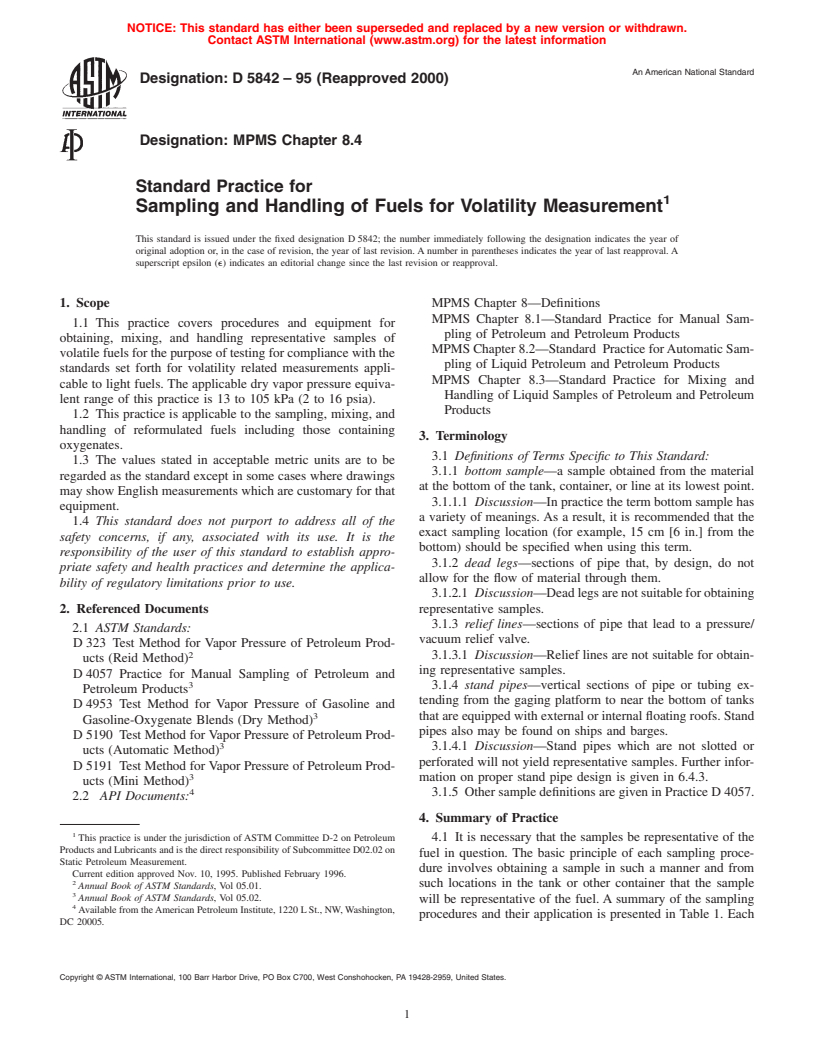

NOTE 1—All dimensions are in inches.

NOTE 2—All decimal dimensions represent minimum and maximum.

NOTE 3—Tolerance for all other dimensions is 6 ⁄32 in.

NOTE 4—Made of non-ferrous material, unaffected by gasoline.

Scale—0.700 in. = 1 in.

FIG. 1 Nozzle Extension for Nozzle Sampling with 4 oz Bottle

D5842–95 (2000)

finally with distilled water. Dry completely, stopper, or cap the collected. Leaking sample containers are not suitable for

container immediately. testing. Cool volatile samples to 0 to 1°C (32 to 34°F) after

6.2 Sampling Apparatus—Sampling apparatus is described delivery to the laboratory and before opening the container.

in detail under each of the specific sampling procedures. Clean, Maintain at this temperature throughout transfer and handling,

dry, and free all sampling apparatus from any substance that if at all possible.

might contaminate the material. If necessary, use the clean 6.5.2 Never completely fill a sample container. Fill the

procedure described in 6.4. container to 70 to 85 % capacity to allow adequate room for

6.3 Time and Place of Sampling: expansion. Subsequent testing for vapor pressure requires this

6.3.1 Storage Tanks—When loading or discharging fuels, level of container fill.

take samples from both shipping and receiving tanks, and from 6.5.3 The first sample aliquot removed is for vapor pressure

the pipelines if required. testing. The remaining sample in the container is not suitable

6.3.2 Ship or Barge Tanks—Sample each product after the for a vapor pressure determination but is suitable for other

vessel is loaded or just before unloading. testing.

6.3.3 Tank Cars—Sample the product after the car is loaded 6.6 Shipping Samples—To prevent loss of liquid and vapors

or just before unloading. during shipment, place internal seals in the metal containers,

screw the caps down tightly and check for leakage. Observe all

NOTE 1—Time, place, and other details of sampling not covered in this

shipping regulations applying to the transportation of flam-

practice are normally determined by contractual agreement or regulatory

mable liquids.

requirements.

6.7 Labeling Sample Containers—Label the container im-

6.4 Obtaining Samples:

mediately after a sample is obtained. Use waterproof and

6.4.1 Directions for sampling cannot be made explicit

oilproof ink or a pencil hard enough to dent the tag, since soft

enough to cover all cases. Extreme care and good judgment are

pencil and ordinary ink markings are subject to obliteration

necessary to ensure samples that represent the general charac-

from moisture, product, smearing, and handling. Typical label

ter and average condition of the material. Use lint-free wiping

information includes the following information:

cloths to prevent contaminating samples.

6.7.1 Date and time (the period elapsed during continuous

6.4.2 Many petroleum vapors are toxic and flammable.

sampling),

Avoid breathing them or igniting them from an open flame or

6.7.2 Name of the sample (location),

a spark. Follow all safety precautions specific to the material

6.7.3 Name or number and owner of the vessel, car, or

being sampled.

container,

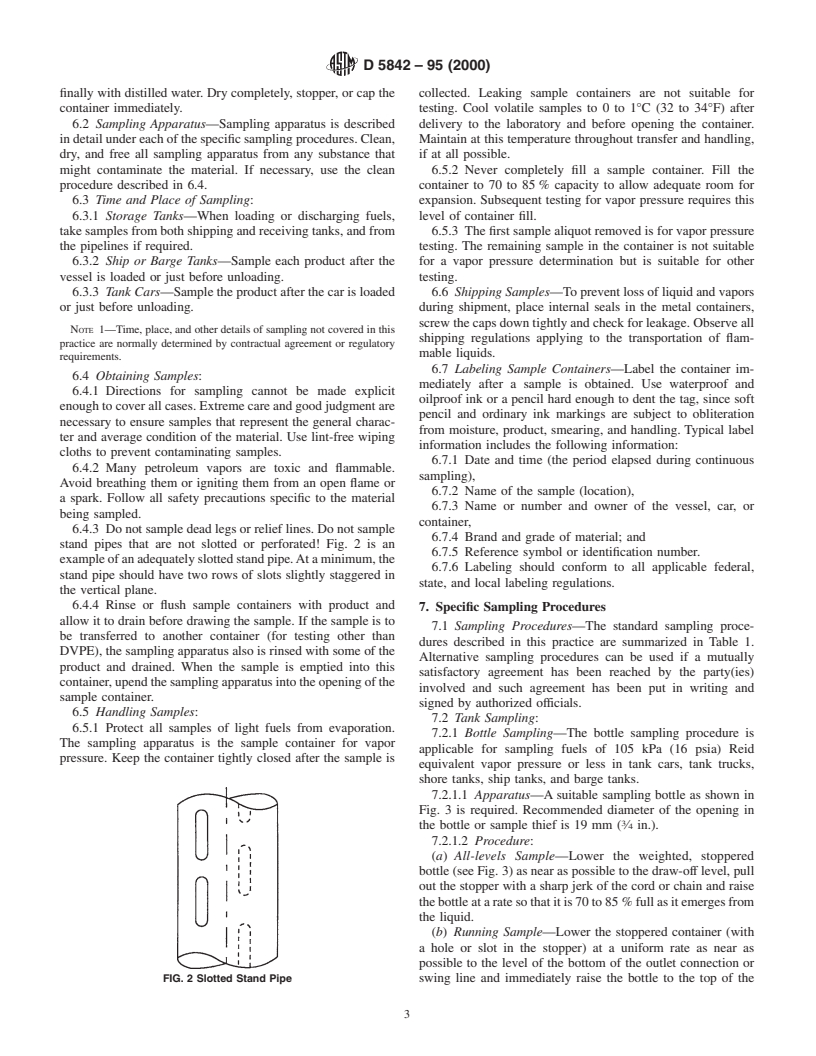

6.4.3 Do not sample dead legs or relief lines. Do not sample

6.7.4 Brand and grade of material; and

stand pipes that are not slotted or perforated! Fig. 2 is an

6.7.5 Reference symbol or identification number.

exampleofanadequatelyslottedstandpipe.Ataminimum,the

6.7.6 Labeling should conform to all applicable federal,

stand pipe should have two rows of slots slightly staggered in

state, and local labeling regulations.

the vertical plane.

6.4.4 Rinse or flush sample containers with product and

7. Specific Sampling Procedures

allow it to drain before drawing the sample. If the sample is to

7.1 Sampling Procedures—The standard sampling proce-

be transferred to another container (for testing other than

dures described in this practice are summarized in Table 1.

DVPE), the sampling apparatus also is rinsed with some of the

Alternative sampling procedures can be used if a mutually

product and drained. When the sample is emptied into this

satisfactory agreement has been reached by the party(ies)

container,upendthesamplingapparatusintotheopeningofthe

involved and such agreement has been put in writing and

sample container.

signed by authorized officials.

6.5 Handling Samples:

7.2 Tank Sampling:

6.5.1 Protect all samples of light fuels from evaporation.

7.2.1 Bottle Sampling—The bottle sampling procedure is

The sampling apparatus is the sample container for vapor

applicable for sampling fuels of 105 kPa (16 psia) Reid

pressure. Keep the container tightly closed after the sample is

equivalent vapor pressure or less in tank cars, tank trucks,

shore tanks, ship tanks, and barge tanks.

7.2.1.1 Apparatus—A suitable sampling bottle as shown in

Fig. 3 is required. Recommended diameter of the opening in

the bottle or sample thief is 19 mm ( ⁄4 in.).

7.2.1.2 Procedure:

(a) All-levels Sample—Lower the weighted, stoppered

bottle (see Fig. 3) as near as possible to the draw-off level, pull

out the stopper with a sharp jerk of the cord or chain and raise

thebottleataratesothatitis70to85 %fullasitemergesfrom

the liquid.

(b) Running Sample—Lower the stoppered container (with

a hole or slot in the stopper) at a uniform rate as near as

possible to the level of the bottom of the outlet connection or

FIG. 2 Slotted Stand Pipe swing line and immediately raise the bottle to the top of the

D5842–95 (2000)

(e) Handling—Cap and label bottle samples immediately

after taking them, and deliver to the laboratory in the original

sampling bottles. Multiple samples must be tested individually

for vapor pressure.Acomposite sample is acceptable for other

analytical tests. Inverting the sample container can aid in leak

detection. Sample may be placed in ice immediately for

cooling if practical (see Section 10 ).

7.2.2 Tap Sampling—The tap sampling procedure is appli-

cable for sampling liquids of 105 kPa (16 psia) DVPE, or less,

in tanks that are equipped with suitable sampling taps or lines.

This procedure is recommended for volatile stocks in tanks of

the breather and balloon roof type, spheroids, floating roof

tanks, and so forth. The assembly for tap sampling is shown in

Fig. 5.

7.2.2.1 Apparatus:

(a) Tank Taps—Equip the tank with at least three sampling

taps placed equidistant throughout the tank height. A standard

⁄4 in. pipe with a suitable valve is satisfactory. A sufficient

FIG. 3 Assembly for Bottle Sampling

number of sample taps are needed on the tank to make

sampling possible at various levels.

fuel at a rate of speed such that it is 70 to 85 % full when

(b) Tube—Use a delivery tube that will not contaminate the

withdrawn from the liquid.

product being sampled and is long enough to reach to the

NOTE 2—Running or all-level samples are not necessarily representa-

bottom of the sample container to allow submerged filling.

tive because the tank volume may not be proportional to the depth and

(c) Tube Chiller Assembly (Optional)—If a sampling

because the operator may not be able to raise the sampler at the required

chiller is used, it is a coil of tubing immersed in an ice bath to

rate.

chill a fuel sample as it is dispensed into the sample container.

(c) Upper, Middle, and Lower Samples—Lower the

(d) Sample Containers—Use clean, dry glass bot

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.