ASTM D5842-04

(Practice)Standard Practice for Sampling and Handling of Fuels for Volatility Measurement

Standard Practice for Sampling and Handling of Fuels for Volatility Measurement

SIGNIFICANCE AND USE

The dry vapor pressure equivalent (DVPE) of volatile motor fuels is regulated by federal and state air pollution control agencies. In order to meet the letter of these regulations, it is necessary to sample, handle, and test these products in a very precise manner.

SCOPE

1.1 This practice covers procedures and equipment for obtaining, mixing, and handling representative samples of volatile fuels for the purpose of testing for compliance with the standards set forth for volatility related measurements applicable to light fuels. The applicable dry vapor pressure equivalent range of this practice is 13 to 105 kPa (2 to 16 psia).

1.2 This practice is applicable to the sampling, mixing, and handling of reformulated fuels including those containing oxygenates.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 The values stated in acceptable metric units are to be regarded as the standard except in some cases where drawings may show English measurements which are customary for that equipment.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5842–04

Designation: Manual of Petroleum Measurement Standards (MPMS) Chapter 8.4

Standard Practice for

1

Sampling and Handling of Fuels for Volatility Measurement

This standard is issued under the fixed designation D5842; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* of Petroleum and Petroleum Products

1.1 This practice covers procedures and equipment for

3

2.2 API Standards:

obtaining, mixing, and handling representative samples of

MPMS Chapter 8.1—Practice for Manual Sampling of Pe-

volatile fuels for the purpose of testing for compliance with the

troleum and Petroleum Products (ASTM Practice D4057)

standards set forth for volatility related measurements appli-

MPMS Chapter 8.2—Practice for Automatic Sampling of

cable to light fuels. The applicable dry vapor pressure equiva-

Petroleum and Petroleum Products (ASTM Practice

lent range of this practice is 13 to 105 kPa (2 to 16 psia).

D4177)

1.2 This practice is applicable to the sampling, mixing, and

MPMS Chapter 8.3—Practice for Mixing and Handling of

handling of reformulated fuels including those containing

Liquid Samples of Petroleum and Petroleum Products

oxygenates.

(ASTM Practice D5854)

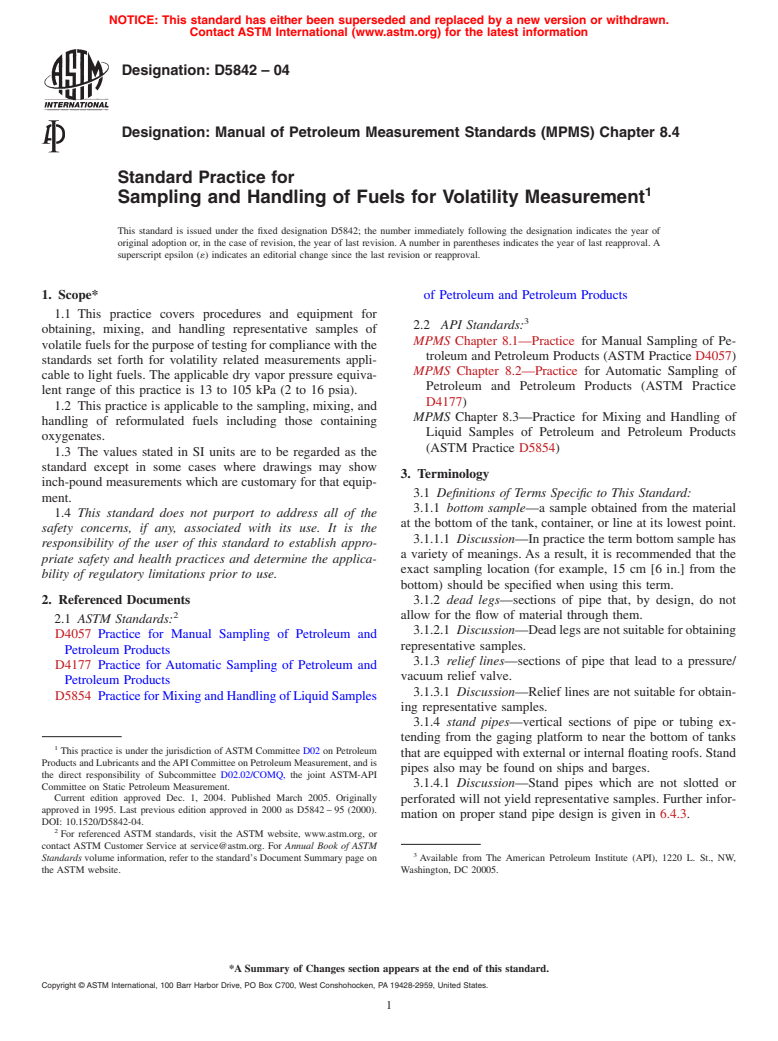

1.3 The values stated in SI units are to be regarded as the

standard except in some cases where drawings may show

3. Terminology

inch-pound measurements which are customary for that equip-

3.1 Definitions of Terms Specific to This Standard:

ment.

3.1.1 bottom sample—a sample obtained from the material

1.4 This standard does not purport to address all of the

at the bottom of the tank, container, or line at its lowest point.

safety concerns, if any, associated with its use. It is the

3.1.1.1 Discussion—In practice the term bottom sample has

responsibility of the user of this standard to establish appro-

a variety of meanings. As a result, it is recommended that the

priate safety and health practices and determine the applica-

exact sampling location (for example, 15 cm [6 in.] from the

bility of regulatory limitations prior to use.

bottom) should be specified when using this term.

2. Referenced Documents 3.1.2 dead legs—sections of pipe that, by design, do not

2 allow for the flow of material through them.

2.1 ASTM Standards:

3.1.2.1 Discussion—Deadlegsarenotsuitableforobtaining

D4057 Practice for Manual Sampling of Petroleum and

representative samples.

Petroleum Products

3.1.3 relief lines—sections of pipe that lead to a pressure/

D4177 Practice for Automatic Sampling of Petroleum and

vacuum relief valve.

Petroleum Products

3.1.3.1 Discussion—Relief lines are not suitable for obtain-

D5854 PracticeforMixingandHandlingofLiquidSamples

ing representative samples.

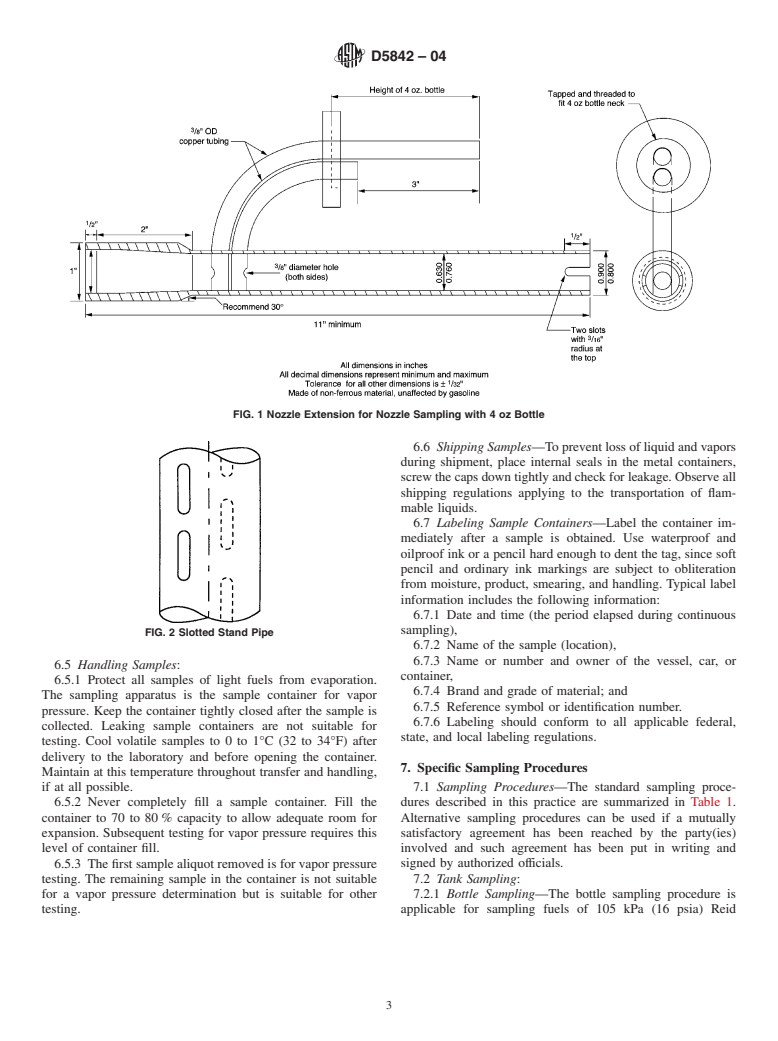

3.1.4 stand pipes—vertical sections of pipe or tubing ex-

tending from the gaging platform to near the bottom of tanks

1

This practice is under the jurisdiction of ASTM Committee D02 on Petroleum

that are equipped with external or internal floating roofs. Stand

Products and Lubricants and theAPI Committee on Petroleum Measurement, and is

pipes also may be found on ships and barges.

the direct responsibility of Subcommittee D02.02/COMQ, the joint ASTM-API

3.1.4.1 Discussion—Stand pipes which are not slotted or

Committee on Static Petroleum Measurement.

Current edition approved Dec. 1, 2004. Published March 2005. Originally

perforated will not yield representative samples. Further infor-

approved in 1995. Last previous edition approved in 2000 as D5842 – 95 (2000).

mation on proper stand pipe design is given in 6.4.3.

DOI: 10.1520/D5842-04.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from The American Petroleum Institute (API), 1220 L. St., NW,

the ASTM website. Washington, DC 20005.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D5842–04

3.1.5 Other sample definitions are given in Practice D4057/ the cork before forcing it into the bottle. Screw caps must be

API MPMS Chapter 8.1. protected by a cork disk faced with tin or aluminum foil, an

inverted cone polyseal or other material that will not affect

4. Summary of Practice

petroleum or petroleum products. The fluorinated bottles are

4.1 It is necessary that the samples be representative of the

supplied with polypropylene screw caps.

fuel in question. T

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.