ASTM G2-88(2002)

(Test Method)Standard Test Method for Corrosion Testing of Products of Zirconium, Hafnium, and Their Alloys in Water at 680°F or in Steam at 750°F

Standard Test Method for Corrosion Testing of Products of Zirconium, Hafnium, and Their Alloys in Water at 680°F or in Steam at 750°F

SCOPE

1.1 This test method covers (1) the determination of mass gain, and (2) the surface inspection of products of zirconium, hafnium, and their alloys when corrosion tested in water at 680°F or in steam at 750°F.

1.2 This test method is to be utilized in its entirety to the extent specified herein as a product acceptance test.

1.3 This test method may be used on wrought products, castings, powder metallurgy products, and weld metals.

1.4 A complete metric companion to this test method has been developed, Test Method G 2M. Therefore, no metric equivalents are shown. However, since the mass gain and surface area of the specimen and the electrical resistivity of water are always measured or calculated in SI units, these are given in SI units.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section 9.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:G2–88(Reapproved2002)

Standard Test Method for

Corrosion Testing of Products of Zirconium, Hafnium, and

Their Alloys in Water at 680°F or in Steam at 750°F

This standard is issued under the fixed designation G2; the number immediately following the designation indicates the year of original

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This test method covers (1) the determination of mass 3.1 Definitions of Terms Specific to This Standard:

gain, and (2) the surface inspection of products of zirconium, 3.1.1 control coupons, n—zirconium alloy specimens of

hafnium, and their alloys when corrosion tested in water at known performance used to monitor the validity of the test.

680°F or in steam at 750°F. 3.1.2 etching, n—a process for removal of surface metal by

1.2 This test method is to be utilized in its entirety to the action of acids in water.

extent specified herein as a product acceptance test. 3.1.3 Grade A water, n—purified water having a pH of 5.0

1.3 This test method may be used on wrought products, to 8.0 and an electrical resistivity of not less than 1.0 MV·cm.

castings, powder metallurgy products, and weld metals. 3.1.4 Grade B water, n—water prepared with deionized or

1.4 A complete metric companion to this test method has demineralized water having a minimum electrical resistivity of

been developed, Test Method G2M. Therefore, no metric 0.5 MV·cm.

equivalents are shown. However, since the mass gain and 3.1.5 ThestatedvaluesofpHandelectricalresistivityareto

surface area of the specimen and the electrical resistivity of be met after the measured values are corrected to 77°F.

water are always measured or calculated in SI units, these are 3.1.6 high mass gain coupons, n—zirconium alloy speci-

given in SI units. mens that have been specially heat-treated to produce a mass

1.5 This standard does not purport to address all of the gain higher than the maximum specified as acceptable value

safety concerns, if any, associated with its use. It is the used for verifying the severity of the test.

responsibility of the user of this standard to establish appro- 3.1.7 reagent grade, n—The grade of chemicals normally

priate safety and health practices and determine the applica- used for analytical purposes.

bility of regulatory limitations prior to use. For specific

4. Summary of Test Method

precautionary statements, see Section 9.

4.1 Specimens of zirconium, hafnium, or their alloys are

2. Referenced Documents

exposed to high-pressure water or steam at elevated tempera-

2.1 ASTM Standards: tures for 72 or 336 h. The corrosion is normally measured by

D888 Test Methods for Dissolved Oxygen in Water thegaininmassofthespecimensandbytheappearanceofthe

E29 Practice for Using Significant Digits in Test Data to oxidefilmonthespecimensurfaces.Insomeinstances,suchas

Determine Conformance with Specifications weld evaluation, mass gain measurements are either impracti-

G2M Test Method for Corrosion Testing of Products of cal to make or not required. When so specified, appearance of

Zirconium, Hafnium, and Their Alloys in Water at 633°K the specimen shall be the sole criterion for acceptance.

or in Steam at 673°K [Metric]

5. Significance and Use

5.1 This test method is primarily used as an acceptance test

ThistestmethodisunderthejurisdictionofASTMCommitteeB10onReactive

for products of zirconium, hafnium, and their alloys. This

and Refractory Metals andAlloys and is the direct responsibility of Subcommittee

standard has been widely used in the development of new

B10.02 on Zirconium and Hafnium.

Current edition approved Jan. 29, 1988. Published March 1988. Originally

alloys, heat treating practices, and for evaluation of welding

published as G2–67. Last previous edition G2–81. DOI: 10.1520/G0002-88R02.

techniques.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.2 Specimens are normally tested after careful etching and

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on rinsing. Specimens with as-manufactured surfaces may also be

the ASTM website.

tested without further surface removal.

Withdrawn.

Withdrawn. The last approved version of this historical standard is referenced

on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

G2–88 (2002)

5.3 When tubing with a second material clad on the inner organiccompounds,acidsandproductsofzirconium,hafnium,

surface is to be tested, the inner cladding shall be removed and their alloys should be obtained from competent sources.

prior to the test. 9.2 High-temperature, high-pressure autoclave operation

must be in accordance with government regulations and

6. Interferences

manufacturer’s instructions.

6.1 Autoclave loads that have one or more specimens 9.3 Hydrogen gas used for addition to the autoclave steam

supply must be handled in accordance with guidelines for

showing gross oxidation may affect results on other specimens

in the autoclave by contamination of the environment. explosives and flammables.

9.4 Donotaddcoldwaterdirectlytotheautoclavevesselin

7. Apparatus

order to accelerate cooling upon completion of testing.

7.1 The apparatus consists of equipment for (1) etching the

10. Sampling, Test Specimens, and Test Units

specimens when required, (2) measuring the specimen surface

area and mass, the water resistivity and pH, test temperature

10.1 The size and the quantity of the test specimens, the

and pressure, etch and rinse temperature, and (3) performing

method of selection, surface preparation, and test acceptance

the water or steam corrosion test at elevated temperature and

criteria shall be specified in the product specification or by

pressure.

agreement between the purchaser and the seller as stated in the

7.1.1 Etching—An acid bath, a flowing rinse, and a deion-

purchase contract.

ized water rinse are needed for proper metal removal and

10.2 Each specimen and control coupons shall be individu-

stain-free rinsing. Polyethylene or polypropylene tanks are

ally identified.

commonly used with a bottom feed for flowing water rinses.

Specimen hangers are generally made of Type 300 series

11. Preparation of Apparatus

stainless steel. When many specimens are processed, a me-

11.1 General requirements for new or reworked autoclaves

chanical dipper for the etching process is useful.

and parts of autoclaves previously used for testing materials

7.1.2 Autoclaves, constructed of Type 300 series stainless

other than to this standard are as follows:

steel or nickel base alloys such as UNS grade N06600 or

11.1.1 Before specimens are tested in a new or reworked

N06690andaremanufacturedtoconformtoASME(American

autoclave, or in one having new valves, tubing, gaskets, etc.,

SocietyforMechanicalEngineers)andgovernmentregulations

which contact the test specimen, clean the apparatus thor-

governingunfiredpressurevessels.Theautoclaveisfittedwith

oughly, wipe with reagent grade ethanol or acetone, and rinse

devices for measurement and control of pressure and tempera-

twice with Grade B water. Dry the autoclave or auxiliary

ture, safety devices, and venting valves. Control systems for

equipmentbyvacuumcleaningordrainandwipewithaclean,

pressure and temperature adequate to meet the requirements of

lint-free cloth, and inspect carefully to ensure freedom from

this standard are needed. Sample holders and other internal

contamination.Thereshallbenovisiblecontamination,suchas

accessories are also constructed of Type 300 or 400 series

lubricant, residues, dust or dirt, loose oxides or rust, and oil or

stainless steel, or nickel-base alloys such as UNS grade

grease film on the water surface, internal surface, gasket, or

N06600 or N06690.

head surfaces.

NOTE 1—Ifautoclaveheatingisperformedinanoven,theovenandnot 11.1.2 Clean all new and reworked fixtures and jigs to be

the autoclave will have the automatic temperature-control equipment.

usedintheautoclave,rinseinhotGradeBwater.Autoclavethe

fixtures and jigs for at least 1 day at 750°F in 1500 psi steam

7.1.3 Measuring Equipment, capable of measuring speci-

or at 680°F in water. Inspect the parts for corrosion product. If

mendimensionsto0.002in.andabalancecapableofweighing

−4

corrosion product is found or electrical resistivity of the

specimens to 1 310 g are needed.

residualwaterafterthetestmeasureslessthan0.1MV·cm,the

8. Reagents and Materials parts should be cleaned and autoclaved again.

11.2 General requirements for autoclaves and parts in con-

8.1 Argon Gas, welding grade.

tinuous use for corrosion testing under this standard are as

8.2 Grade A Water.

follows:

8.3 Grade B Water.

11.2.1 With Grade B water rinse all autoclaves, fixtures,

8.4 Detergents and Solvents, for specimen cleaning includ-

parts, and jigs that have been in continuous use and have

ing reagent grade ethanol and reagent grade acetone.

shown satisfactory behavior in prior tests. Inspect the fixtures

8.5 Hydrofluoric Acid (HF), reagent grade.

and jigs for corrosion products after each test and rework and

8.6 Nitric Acid (HNO ), reagent grade.

re-prepare items showing loose corrosion product.

8.7 Sulfuric Acid (H SO ), reagent grade.

2 4

8.8 Nitrogen Gas, for purging or controlling oxygen con-

12. Calibration and Standardization

tent.

8.9 Argon-Hydrogen Mixed Gas, for purging or controlling

12.1 High Mass Gain Coupon Preparation—Thesecoupons

oxygen content.

shall be selected from a previously tested lot. The selected

material shall be heat treated to produce the desired mass gain.

9. Hazards

Heating for8hat 1652 6 5°F and cooling to 572 6 5°F at a

9.1 The chemicals used in preparing specimens for this test rate not exceeding 6°F/min will normally produce the desired

are hazardous. Detailed information on safe handling of mass gain.

G2–88 (2002)

12.2 Autoclaves: established in 12.2.2.6 or may be calculated periodically using

12.2.1 Prior to use for product acceptance testing, an auto- all accepted values determined over the preceding 3-month

clave shall be profiled thermally as in 12.4.2 and shall period but not less than 21 values.

demonstrate acceptability by testing at least three control 12.2.3 An alternative method for establishing the mass gain

coupons, one each at the top, middle, and bottom of useful

meanandstandarddeviationforthecontrolcouponswhichare

volume. The test results shall be incorporated in the certifica- used repeatedly is:

tiondocumentfortheautoclaveacceptancetest.Whendesired,

12.2.3.1 Expose the control coupons to be used in three

high mass gain coupons may also be used.

different tests, once each in the top, middle, and bottom of an

12.2.2 Establishing Mass Gain Mean and Standard Devia-

autoclave, and determine mass gain.

tion of Control Coupons—The control coupon lot and, when

12.2.3.2 Themeanvalueofeachcontrolcouponisthemean

desired, the high mass gain coupon lot mass gain mean and

for the three tests.

standard deviation shall be established by a minimum of one

12.2.3.3 Thestandarddeviationforthecontrolcouponlotis

autoclave test as follows:

calculated by the (n-1) method using the data from all of the

12.2.2.1 Randomly select 12 specimens from the control

control coupons taken from the same material lot.

coupon lot or the high mass gain coupon lot respectively.

12.2.4 The new or used autoclave is considered acceptable

12.2.2.2 Prepare all specimens per the pretest requirements

if each control coupon mass gain is reproducible within the

of this test method.

previously established control coupon mean mass gain 63

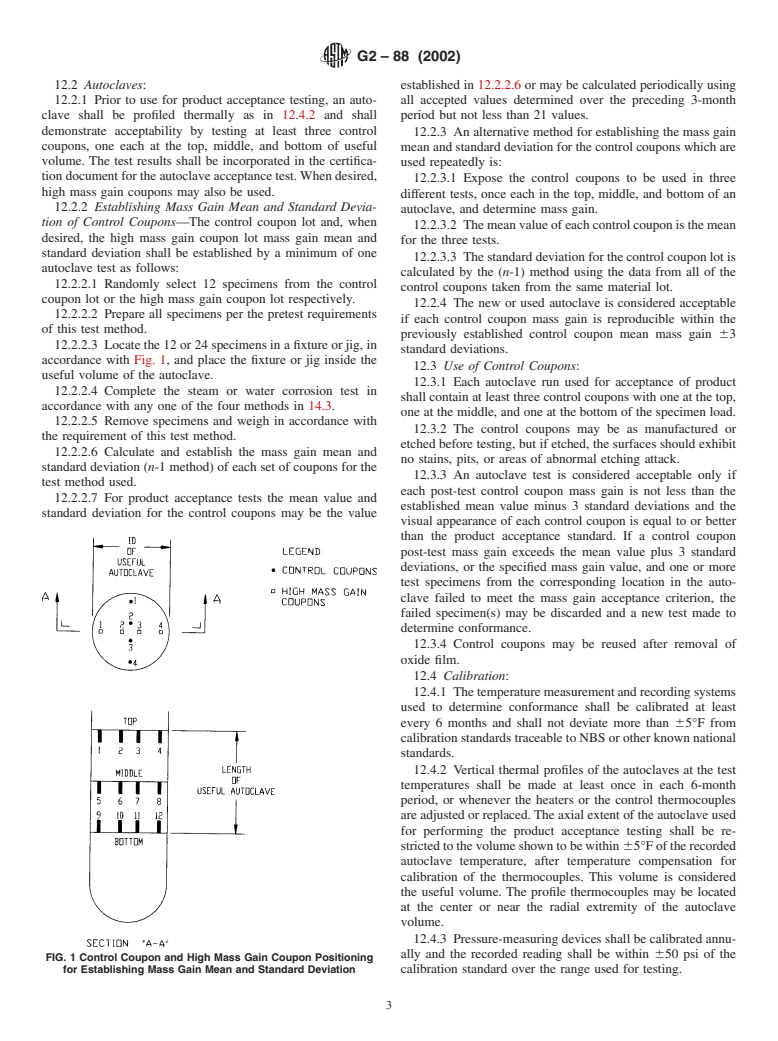

12.2.2.3 Locatethe12or24specimensinafixtureorjig,in

standard deviations.

accordance with Fig. 1, and place the fixture or jig inside the

12.3 Use of Control Coupons:

useful volume of the autoclave.

12.3.1 Each autoclave run used for acceptance of product

12.2.2.4 Complete the steam or water corrosion test in

shall contain at least three control coupons with one at the top,

accordance with any one of the four methods in 14.3.

one at the middle, and one at the bottom of the specimen load.

12.2.2.5 Remove specimens and weigh in accordance with

12.3.2 The control coupons may be as manufactured or

the requirement of this test method.

etched before testing, but if etched, the surfaces should exhibit

12.2.2.6 Calculate and establish the mass gain mean and

no stains, pits, or areas of abnormal etching attack.

standard deviation (n-1 method) of each set of coupons for the

12.3.3 An autoclave test is considered acceptable only if

test method used.

each post-test control coupon mass gain is not less than the

12.2.2.7 For product acceptance tests the mean value and

established mean value minus 3 standard deviations and the

standard deviation for the control coupons may be the value

visual appearance of each control coupon is equal to or better

than the product acceptance standard. If a control coupon

post-test mass gain exceeds the mean value plus 3 standard

deviations, or the specified mass gain value, and one or more

test specimens from the corresponding location in the auto-

clave failed to meet the mass gain acceptance criterion, the

failed specimen(s) may be discarded and a new test made to

determine conformance.

12.3.4 Control coupons may be reused after removal of

oxide film.

12.4 Calibration:

12.4.1 Thetemperaturemeasurementandrecordingsystems

used to determine conformance shall be calibrated at least

every 6 months and shall not deviate more than 65°F from

calibrationstandardstraceabletoNBSorotherknownnational

standards.

12.4.2 Vertical thermal profiles of the autoclaves at the test

temperatures shall be made at least once in each 6-month

period, or whenever the heaters or the control thermocouples

areadjustedorreplaced.Theaxialextentoftheautoclaveused

for performing the product acceptance testing shall be re-

strictedtothevolumeshowntobewithin 65°Foftherecorded

autoclave temperature, after temperature compensation for

calibration of the thermocouples. This volume is considered

the useful volume. The profile thermocouples may be located

at the center or near the radial extremity of the autoclave

volume.

12.4.3 Pressure-measuring devices shall be calibrated annu-

ally and the recorded reading shall be within 650 psi of the

FIG. 1 Control Coupon and High Mass Gain Coupon Positioning

for Establishing Mass Gain Mean and Standard Deviation calibration standard over the range used for testing.

G2–88 (2002)

13. Conditioning washers or wire mesh grids may be used

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.