ASTM B918/B918M-20a

(Practice)Standard Practice for Heat Treatment of Wrought Aluminum Alloys

Standard Practice for Heat Treatment of Wrought Aluminum Alloys

ABSTRACT

This practice is intended for use in the heat treatment of wrought aluminum alloys for general purpose applications. Aluminum alloys are typically heated in air chamber furnaces or molten salt baths. Though lead baths, oil baths, or fluidized beds may be used, uncontrolled heating is not permitted. The furnace temperature uniformity and calibration shall conform to the specified requirements. Preparation for heat treatment of alloys shall follow the racking, spacing, and cleanliness requirements. Solution heat treatment shall follow the recommended soaking times and quenching procedures. Precipitation heat treatment shall conform to the prescribed times, temperatures, and annealing procedures. The alloys shall be subjected to tensile testing, eutectic melting and heat-treat-induced porosity analysis, intergranular corrosion test, and Alclad diffusion test.

SCOPE

1.1 This practice is intended for use in the heat treatment of wrought aluminum alloys for general purpose applications.

1.1.1 The heat treatment of wrought aluminum alloys used in specific aerospace applications is covered in AMS2772.

1.1.2 Heat treatment of aluminum alloy castings for general purpose applications is covered in Practice B917/B917M.

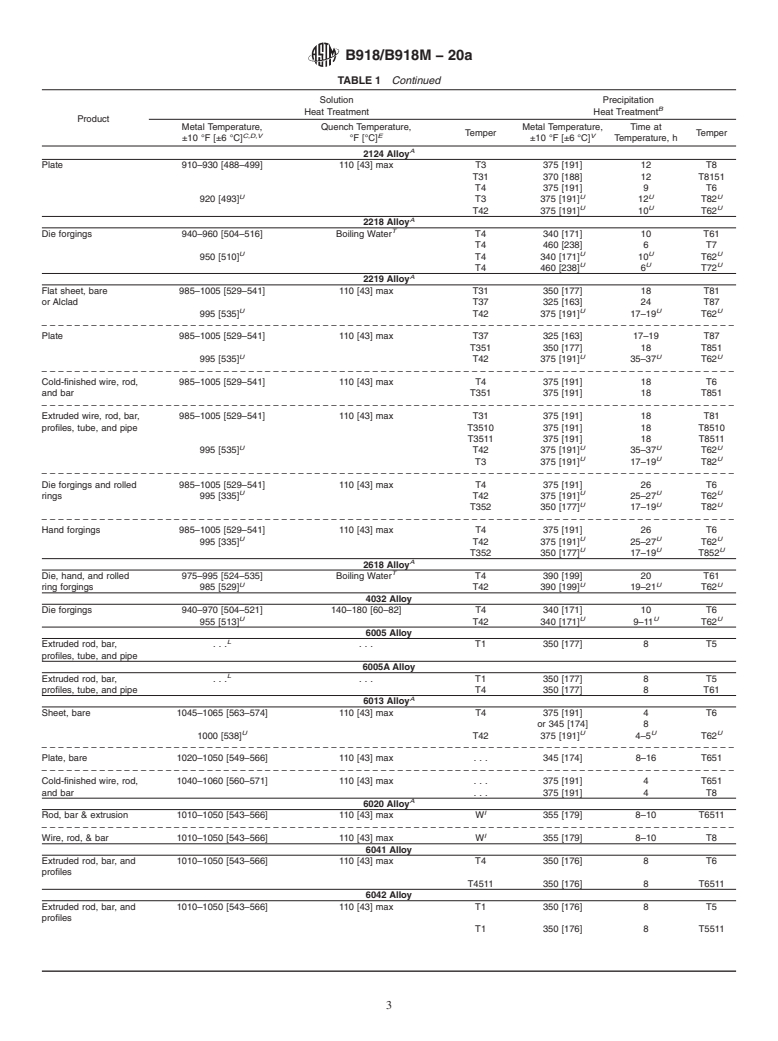

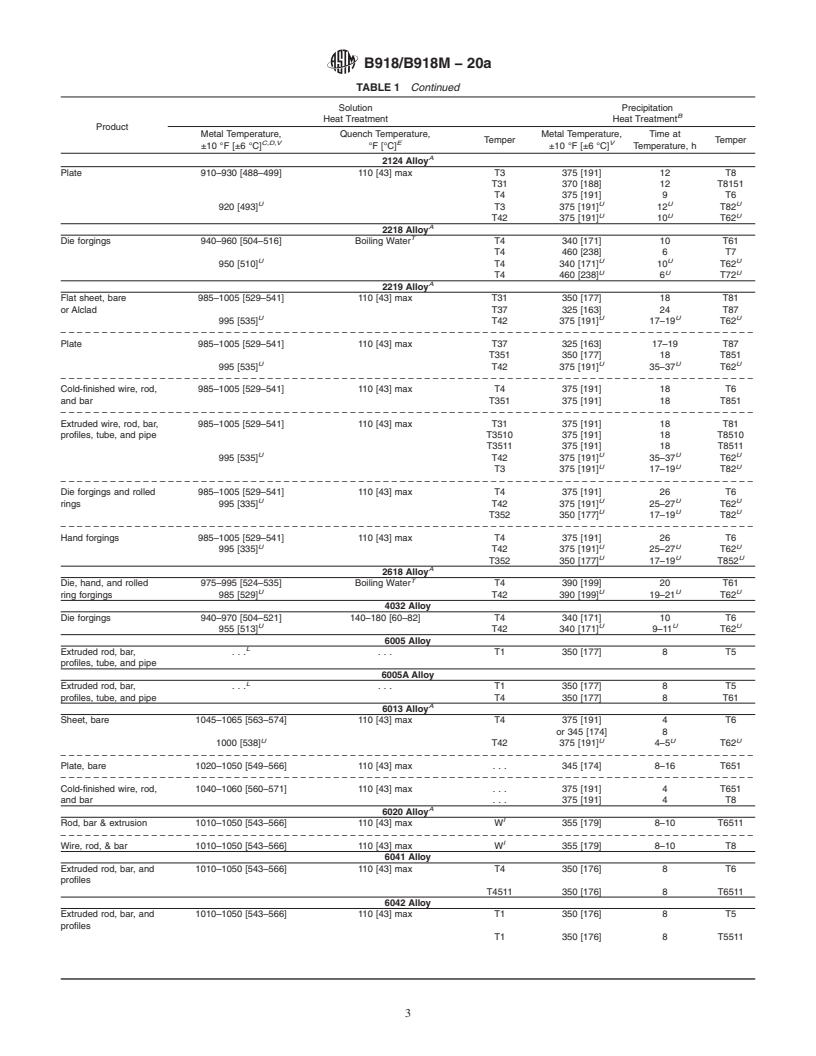

1.2 Times and temperatures appearing in the heat-treatment tables are typical for various forms, sizes, and manufacturing methods and may not provide the optimum heat treatment for a specific item.

1.3 Some alloys in the 6xxx series may achieve the T4 temper by quenching from within the solution temperature range during or immediately following a hot working process, such as upon emerging from an extrusion die. Such alternatives to furnace heating and immersion quenching are indicated in Table 1, by footnote L, for heat treatment of wrought aluminum alloys. However, this practice does not cover the requirements for a controlled extrusion press or hot rolling mill solution heat treatment; it only covers the requirements of artificial aging, annealing and associated pyrometry of those processes for products solution heat treated in accordance with Practices B807/B807M and B947. (Refer to Practice B807/B807M for extrusion press solution heat treatment of aluminum alloys and to Practice B947 for hot rolling mill solution heat treatment of aluminum alloys and associated pyrometry.)

1.4 Units—The values stated in either Metric or US Customary units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B918/B918M − 20a

Standard Practice for

1

Heat Treatment of Wrought Aluminum Alloys

This standard is issued under the fixed designation B918/B918M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

1.1 This practice is intended for use in the heat treatment of

1.6 This international standard was developed in accor-

wrought aluminum alloys for general purpose applications.

dance with internationally recognized principles on standard-

1.1.1 The heat treatment of wrought aluminum alloys used

ization established in the Decision on Principles for the

in specific aerospace applications is covered in AMS2772.

Development of International Standards, Guides and Recom-

1.1.2 Heat treatment of aluminum alloy castings for general

mendations issued by the World Trade Organization Technical

purpose applications is covered in Practice B917/B917M.

Barriers to Trade (TBT) Committee.

1.2 Times and temperatures appearing in the heat-treatment

tables are typical for various forms, sizes, and manufacturing

2. Referenced Documents

methods and may not provide the optimum heat treatment for

2.1 The following documents, of the issue in effect on the

a specific item.

date of material purchase, form a part of this practice to the

1.3 Some alloys in the 6xxx series may achieve the T4

extent referenced herein:

temper by quenching from within the solution temperature

2

2.2 ASTM Standards:

range during or immediately following a hot working process,

B557Test Methods for Tension Testing Wrought and Cast

suchasuponemergingfromanextrusiondie.Suchalternatives

Aluminum- and Magnesium-Alloy Products

to furnace heating and immersion quenching are indicated in

B557MTest Methods forTensionTestingWrought and Cast

Table1,byfootnote L,forheattreatmentofwroughtaluminum

Aluminum- and Magnesium-Alloy Products (Metric)

alloys. However, this practice does not cover the requirements

B807/B807MPractice for Extrusion Press Solution Heat

foracontrolledextrusionpressorhotrollingmillsolutionheat

Treatment for Aluminum Alloys

treatment; it only covers the requirements of artificial aging,

B881Terminology Relating toAluminum- and Magnesium-

annealing and associated pyrometry of those processes for

Alloy Products

products solution heat treated in accordance with Practices

B917/B917MPractice for Heat Treatment of Aluminum-

B807/B807M and B947. (Refer to Practice B807/B807M for

Alloy Castings From All Processes

extrusionpresssolutionheattreatmentofaluminumalloysand

B947Practice for Hot Rolling Mill Solution HeatTreatment

to Practice B947 for hot rolling mill solution heat treatment of

for Aluminum Alloy Plate

aluminum alloys and associated pyrometry.)

G69Test Method for Measurement of Corrosion Potentials

1.4 Units—The values stated in either Metric or US Cus-

of Aluminum Alloys

tomary units are to be regarded separately as standard. The

3

2.3 ANSI Standard:

values stated in each system may not be exact equivalents;

H35.1/H35.1MAlloy and Temper Designation Systems for

therefore,eachsystemshallbeusedindependentlyoftheother.

Aluminum

Combining values from the two systems may result in non-

4

2.4 SAE Standard:

conformance with the standard.

AMS2750Pyrometry

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

This practice is under the jurisdiction of ASTM Committee B07 on Light Standards volume information, refer to the standard’s Document Summary page on

Metals and Alloys and is the direct responsibility of Subcommittee B07.03 on the ASTM website.

3

Aluminum Alloy Wrought Products. Available fromAluminumAssociation, 1400 Crystal Dr., Suite 430,Arlington,

Current edition approved Dec. 1, 2020. Published January 2021. Originally VA 22202, http://www.aluminum.org.

4

approved in 2001. Last previous edition approved in 2020 as B918/B918M–20. AvailablefromSAEInternational(SAE),400CommonwealthDr.,Warrendale,

DOI: 10.1520/B0918_B0918M-20A. PA 15096, http://www.sae.org.

*A Summary of Changes section appears at the e

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B918/B918M − 20 B918/B918M − 20a

Standard Practice for

1

Heat Treatment of Wrought Aluminum Alloys

This standard is issued under the fixed designation B918/B918M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This practice is intended for use in the heat treatment of wrought aluminum alloys for general purpose applications.

1.1.1 The heat treatment of wrought aluminum alloys used in specific aerospace applications is covered in AMS2772.

1.1.2 Heat treatment of aluminum alloy castings for general purpose applications is covered in Practice B917/B917M.

1.2 Times and temperatures appearing in the heat-treatment tables are typical for various forms, sizes, and manufacturing methods

and may not provide the optimum heat treatment for a specific item.

1.3 Some alloys in the 6xxx series may achieve the T4 temper by quenching from within the solution temperature range during

or immediately following a hot working process, such as upon emerging from an extrusion die. Such alternatives to furnace heating

and immersion quenching are indicated in Table 1, by footnote L, for heat treatment of wrought aluminum alloys. However, this

practice does not cover the requirements for a controlled extrusion press or hot rolling mill solution heat treatment; it only covers

the requirements of artificial aging, annealing and associated pyrometry of those processes for products solution heat treated in

accordance with Practices B807/B807M and B947. (Refer to Practice B807/B807M for extrusion press solution heat treatment of

aluminum alloys and to Practice B947 for hot rolling mill solution heat treatment of aluminum alloys and associated pyrometry.)

1.4 Units—The values stated in either Metric or US Customary units are to be regarded separately as standard. The values stated

in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values

from the two systems may result in non-conformance with the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 The following documents, of the issue in effect on the date of material purchase, form a part of this practice to the extent

referenced herein:

1

This practice is under the jurisdiction of ASTM Committee B07 on Light Metals and Alloys and is the direct responsibility of Subcommittee B07.03 on Aluminum Alloy

Wrought Products.

Current edition approved May 1, 2020Dec. 1, 2020. Published July 2020January 2021. Originally approved in 2001. Last previous edition approved in 20172020 as

B918/B918M – 17a.B918/B918M – 20. DOI: 10.1520/B0918_B0918M-20.10.1520/B0918_B0918M-20A.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B918/B918M − 20a

A,W

TABLE 1 Recommended Heat Treatment for Wrought Aluminum Alloys

Solution Precipitation

B

Heat Treatment Heat Treatment

Product

Metal Temperature, Quench Temperature, Metal Temperature, Time at

Temper Temper

C,D,V E V

±10 °F [±6 °C] °F [°C] ±10 °F [±6 °C] Temperature, h

A

2011 Alloy

Cold-finished wire, rod, 945–995 [507–535] 110 [43] max T3 320 [160] 14 T8

and bar T4 . . . . . . . . .

T451 . . . . . . . . .

– – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – – –

Drawn tube and pipe 975 [524] 110 [43] max T3 320 [160] 14 T8

T4511 . . . . . . . . .

A

2014 Alloy

Flat sheet, bare 925–945 [496–507] 110 [43] max T3

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.