ASTM E2454-20

(Guide)Standard Guide for Sensory Evaluation Methods to Determine Sensory Shelf Life of Consumer Products

Standard Guide for Sensory Evaluation Methods to Determine Sensory Shelf Life of Consumer Products

SIGNIFICANCE AND USE

5.1 Sensory shelf life is the time period during which the product’s sensory characteristics and performance are as intended by the manufacturer. The product is consumable or usable during this period, providing the end-user with the intended sensory characteristics, performance, and benefits. After this period, however, the product has characteristics or attributes that are not as intended, or it does not perform the same functions as fresh products or those consumed or used before the end of shelf life.

5.2 The goal of all shelf life determination is to estimate the time at which a consumer product is no longer usable, unfit for consumption, or no longer has the intended sensory characteristics.

5.3 Prior to the commencement of sensory shelf life study, the criteria/criterion that are/is used to define shelf life end must be defined. The criterion or criteria could be sensory attributes, consumer acceptance or product performance. Once the criteria are defined, the test methodology for measuring the sensory shelf life can be selected. The criterion operationally defining the end of shelf life is generally chosen based on one or more of the following changes in the product’s sensory or functional parameters, or both: (1) the aged product is perceptibly different from the fresh product overall, (2) the aged product has changed in specific sensory or functional attributes, either increasing some, decreasing others, or the appearance of new attributes compared to the fresh product, or (3) product acceptability of the aged product has decreased to a specific degree from that of the fresh product. The determination of these sensory end-points is a function of the criteria selected, the test method used, and sampling and statistical risks chosen by the researcher.

5.4 The three following test methods are most commonly used for the three end-point criteria cited above: (1) discrimination, (2) descriptive, and (3) affective. Researchers have to select criteria and...

SCOPE

1.1 This guide provides recommended sensory testing approaches and decision criteria for establishing the sensory shelf life of consumable products, including food, personal care, and household products, to manage business risk. It describes research considerations that include: product selection and handling, appropriate application of specific sensory test methods, selection of test intervals, and data analysis techniques for the determination of a product’s sensory shelf life end-point. This guide will focus on the practical considerations and approaches, risks, and criteria that must be considered in designing, executing, and interpreting sensory shelf life results.

1.2 This guide is not intended to provide a detailed description of how to conduct reliable sensory testing. It assumes knowledge of basic sensory and statistical analysis techniques, focusing instead on special considerations for the specific application of sensory testing methods to shelf life determination.

1.3 The shelf life measures in this guide refer to foods, household and personal care products stored as the manufacturer intended and do not account for changes in sensory properties occurring after opening, partial consumption/use or in-home storage. Once products have been manufactured, packaged and sent through the distribution channels, the condition of the products is not typically under study. However, a company may wish to include such variables in their shelf life studies when there is a need to evaluate the sensory quality of their products as they go through distribution channels or in-home storage, or both, and use.

1.4 This guide is not intended to address non-sensory issues related to the shelf life of food, including microbial contamination and chemical changes of products associated with aging, nor is it intended to address potential safety issues associated with aging food and non-food consumer products.

1.5 This interna...

General Information

- Status

- Published

- Publication Date

- 31-Mar-2020

- Technical Committee

- E18 - Sensory Evaluation

- Drafting Committee

- E18.05 - Method Applications - Specific Uses or Assessors

- Current Stage

Relations

- Effective Date

- 15-Oct-2019

- Effective Date

- 01-Oct-2018

- Effective Date

- 15-Jun-2018

- Effective Date

- 01-May-2017

- Effective Date

- 01-Jun-2016

- Effective Date

- 01-Dec-2015

- Effective Date

- 01-Jun-2015

- Effective Date

- 15-Jan-2015

- Effective Date

- 01-Nov-2013

- Effective Date

- 01-May-2013

- Effective Date

- 01-Nov-2012

- Effective Date

- 01-May-2012

- Effective Date

- 01-Dec-2011

- Effective Date

- 15-Apr-2011

- Effective Date

- 01-Dec-2010

ASTM E2454-20 - Standard Guide for Sensory Evaluation Methods to Determine Sensory Shelf Life of Consumer Products

REDLINE ASTM E2454-20 - Standard Guide for Sensory Evaluation Methods to Determine Sensory Shelf Life of Consumer Products

Frequently Asked Questions

ASTM E2454-20 is a guide published by ASTM International. Its full title is "Standard Guide for Sensory Evaluation Methods to Determine Sensory Shelf Life of Consumer Products". This standard covers: SIGNIFICANCE AND USE 5.1 Sensory shelf life is the time period during which the product’s sensory characteristics and performance are as intended by the manufacturer. The product is consumable or usable during this period, providing the end-user with the intended sensory characteristics, performance, and benefits. After this period, however, the product has characteristics or attributes that are not as intended, or it does not perform the same functions as fresh products or those consumed or used before the end of shelf life. 5.2 The goal of all shelf life determination is to estimate the time at which a consumer product is no longer usable, unfit for consumption, or no longer has the intended sensory characteristics. 5.3 Prior to the commencement of sensory shelf life study, the criteria/criterion that are/is used to define shelf life end must be defined. The criterion or criteria could be sensory attributes, consumer acceptance or product performance. Once the criteria are defined, the test methodology for measuring the sensory shelf life can be selected. The criterion operationally defining the end of shelf life is generally chosen based on one or more of the following changes in the product’s sensory or functional parameters, or both: (1) the aged product is perceptibly different from the fresh product overall, (2) the aged product has changed in specific sensory or functional attributes, either increasing some, decreasing others, or the appearance of new attributes compared to the fresh product, or (3) product acceptability of the aged product has decreased to a specific degree from that of the fresh product. The determination of these sensory end-points is a function of the criteria selected, the test method used, and sampling and statistical risks chosen by the researcher. 5.4 The three following test methods are most commonly used for the three end-point criteria cited above: (1) discrimination, (2) descriptive, and (3) affective. Researchers have to select criteria and... SCOPE 1.1 This guide provides recommended sensory testing approaches and decision criteria for establishing the sensory shelf life of consumable products, including food, personal care, and household products, to manage business risk. It describes research considerations that include: product selection and handling, appropriate application of specific sensory test methods, selection of test intervals, and data analysis techniques for the determination of a product’s sensory shelf life end-point. This guide will focus on the practical considerations and approaches, risks, and criteria that must be considered in designing, executing, and interpreting sensory shelf life results. 1.2 This guide is not intended to provide a detailed description of how to conduct reliable sensory testing. It assumes knowledge of basic sensory and statistical analysis techniques, focusing instead on special considerations for the specific application of sensory testing methods to shelf life determination. 1.3 The shelf life measures in this guide refer to foods, household and personal care products stored as the manufacturer intended and do not account for changes in sensory properties occurring after opening, partial consumption/use or in-home storage. Once products have been manufactured, packaged and sent through the distribution channels, the condition of the products is not typically under study. However, a company may wish to include such variables in their shelf life studies when there is a need to evaluate the sensory quality of their products as they go through distribution channels or in-home storage, or both, and use. 1.4 This guide is not intended to address non-sensory issues related to the shelf life of food, including microbial contamination and chemical changes of products associated with aging, nor is it intended to address potential safety issues associated with aging food and non-food consumer products. 1.5 This interna...

SIGNIFICANCE AND USE 5.1 Sensory shelf life is the time period during which the product’s sensory characteristics and performance are as intended by the manufacturer. The product is consumable or usable during this period, providing the end-user with the intended sensory characteristics, performance, and benefits. After this period, however, the product has characteristics or attributes that are not as intended, or it does not perform the same functions as fresh products or those consumed or used before the end of shelf life. 5.2 The goal of all shelf life determination is to estimate the time at which a consumer product is no longer usable, unfit for consumption, or no longer has the intended sensory characteristics. 5.3 Prior to the commencement of sensory shelf life study, the criteria/criterion that are/is used to define shelf life end must be defined. The criterion or criteria could be sensory attributes, consumer acceptance or product performance. Once the criteria are defined, the test methodology for measuring the sensory shelf life can be selected. The criterion operationally defining the end of shelf life is generally chosen based on one or more of the following changes in the product’s sensory or functional parameters, or both: (1) the aged product is perceptibly different from the fresh product overall, (2) the aged product has changed in specific sensory or functional attributes, either increasing some, decreasing others, or the appearance of new attributes compared to the fresh product, or (3) product acceptability of the aged product has decreased to a specific degree from that of the fresh product. The determination of these sensory end-points is a function of the criteria selected, the test method used, and sampling and statistical risks chosen by the researcher. 5.4 The three following test methods are most commonly used for the three end-point criteria cited above: (1) discrimination, (2) descriptive, and (3) affective. Researchers have to select criteria and... SCOPE 1.1 This guide provides recommended sensory testing approaches and decision criteria for establishing the sensory shelf life of consumable products, including food, personal care, and household products, to manage business risk. It describes research considerations that include: product selection and handling, appropriate application of specific sensory test methods, selection of test intervals, and data analysis techniques for the determination of a product’s sensory shelf life end-point. This guide will focus on the practical considerations and approaches, risks, and criteria that must be considered in designing, executing, and interpreting sensory shelf life results. 1.2 This guide is not intended to provide a detailed description of how to conduct reliable sensory testing. It assumes knowledge of basic sensory and statistical analysis techniques, focusing instead on special considerations for the specific application of sensory testing methods to shelf life determination. 1.3 The shelf life measures in this guide refer to foods, household and personal care products stored as the manufacturer intended and do not account for changes in sensory properties occurring after opening, partial consumption/use or in-home storage. Once products have been manufactured, packaged and sent through the distribution channels, the condition of the products is not typically under study. However, a company may wish to include such variables in their shelf life studies when there is a need to evaluate the sensory quality of their products as they go through distribution channels or in-home storage, or both, and use. 1.4 This guide is not intended to address non-sensory issues related to the shelf life of food, including microbial contamination and chemical changes of products associated with aging, nor is it intended to address potential safety issues associated with aging food and non-food consumer products. 1.5 This interna...

ASTM E2454-20 is classified under the following ICS (International Classification for Standards) categories: 03.080.30 - Services for consumers. The ICS classification helps identify the subject area and facilitates finding related standards.

ASTM E2454-20 has the following relationships with other standards: It is inter standard links to ASTM E253-19, ASTM E253-18a, ASTM E253-18, ASTM E253-17, ASTM E253-16, ASTM E253-15b, ASTM E253-15a, ASTM E253-15, ASTM E253-13a, ASTM E253-13, ASTM E253-12a, ASTM E253-12, ASTM E253-11a, ASTM E253-11, ASTM E253-10a. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ASTM E2454-20 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2454 − 20

Standard Guide for

Sensory Evaluation Methods to Determine Sensory Shelf

Life of Consumer Products

This standard is issued under the fixed designation E2454; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.5 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 This guide provides recommended sensory testing ap-

ization established in the Decision on Principles for the

proachesanddecisioncriteriaforestablishingthesensoryshelf

Development of International Standards, Guides and Recom-

life of consumable products, including food, personal care, and

mendations issued by the World Trade Organization Technical

household products, to manage business risk. It describes

Barriers to Trade (TBT) Committee.

research considerations that include: product selection and

handling, appropriate application of specific sensory test

2. Referenced Documents

methods, selection of test intervals, and data analysis tech-

2.1 ASTM Standards:

niques for the determination of a product’s sensory shelf life

E253 Terminology Relating to Sensory Evaluation of Mate-

end-point.This guide will focus on the practical considerations

rials and Products

and approaches, risks, and criteria that must be considered in

designing,executing,andinterpretingsensoryshelfliferesults.

2.2 ASTM Manuals:

MNL 13 Descriptive Analysis Testing

1.2 This guide is not intended to provide a detailed descrip-

MNL 26 Sensory Testing Methods

tion of how to conduct reliable sensory testing. It assumes

MNL 30 Relating Consumer, Descriptive, and Laboratory

knowledge of basic sensory and statistical analysis techniques,

Data to Better Understand Consumer Responses

focusing instead on special considerations for the specific

STP 682 Manual on Consumer Sensory Evaluation

application of sensory testing methods to shelf life determina-

STP 758 Guidelines for the Selection and Training of Sen-

tion.

sory Panel Members

1.3 The shelf life measures in this guide refer to foods,

household and personal care products stored as the manufac-

3. Terminology

turer intended and do not account for changes in sensory

3.1 Definitions:

properties occurring after opening, partial consumption/use or

3.1.1 For definitions of terms used in this guide see Termi-

in-home storage. Once products have been manufactured,

nology E253.

packaged and sent through the distribution channels, the

3.2 Definitions of Terms Specific to This Standard:

conditionoftheproductsisnottypicallyunderstudy.However,

3.2.1 accelerated storage/aging, n—subjecting a product to

acompanymaywishtoincludesuchvariablesintheirshelflife

extreme or stressed conditions, such as elevated temperatures

studies when there is a need to evaluate the sensory quality of

or humidity, exposure to sunlight or other light, to speed up

their products as they go through distribution channels or

those changes in product characteristics that are assumed to be

in-home storage, or both, and use.

related to aging the product.

1.4 This guide is not intended to address non-sensory issues

3.2.2 controlparametersforsensoryshelflifedetermination

related to the shelf life of food, including microbial contami-

(known as “control”), n—specificproductordataset(basedon

nationandchemicalchangesofproductsassociatedwithaging,

previous sensory research) designated as the one to which the

nor is it intended to address potential safety issues associated

data from stored products are to be compared.

with aging food and non-food consumer products.

3.2.3 controlled conditions, n—set of environmental param-

eters (including but not limited to temperature, humidity, light,

This guide is under the jurisdiction of ASTM Committee E18 on Sensory

Evaluation and is the direct responsibility of Subcommittee E18.05 on Sensory

Applications--General. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 1, 2020. Published April 2020. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2005. Last previous edition approved in 2019 as E2454 – 19a. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/E2454-20. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2454 − 20

andoxygen)thataremaintainedandmonitoredsothatchanges when it has. A consequence of the former incorrect decision

in product attributes can be evaluated relative to these param- could be loss of potential income from the product’s sale as it

eters. will be pulled from shelves and not sold when it still could be.

The manufacturer will lose sales.Aconsequence of the second

3.2.4 end-point criterion/criteria, n—the parameter(s) that

error could be consumer rejection of a too-old product, as it

will be used to determine the end of sensory shelf life.

will continue to be sold after the sensory shelf life has been

3.2.5 pull out date(s), n—predetermined point(s) in time at

reached. Consumer repeat purchase of the same brand may be

which the product is removed from storage for evaluation.

atstake.Beforetheresearcherembarksonashelflifestudy,the

3.2.6 sampling plan, n—the protocol that indicates which

risk to the consumer franchise must be balanced with the risk

products are to be tested at which time intervals in a shelf life

of costs associated with pulling sensory acceptable products

study.

from the shelf, prior to the end of sensory shelf life.

3.2.7 sensory characteristics, n—any attributes of the prod-

4.4 Select Criteria/Criterion to Determine the End-point—

ucts that are assessed using the sensory methods that measure

All products change over time. End-point criteria can refer

the human response to that product.

either to the product’s sensory attributes or to consumer

3.2.8 sensory end-point (end of shelf-life), n—pointatwhich

acceptance, or both.

a product no longer meets predetermined sensory attributes as

4.4.1 The product’s overall sensory profile has changed.

defined by the set end-point criterion or criteria (for example,

4.4.2 Product attribute(s) that is (are) known or suspected to

discrimination, descriptive, or affective, or a combination

be key to consumers’perception and acceptance of the product

thereof).

has (have) changed, This includes decreases in the product’s

characterizing or expected sensory attributes or sensory signals

3.2.9 shelf life, n—time period that a product may be stored

(for example, “strawberry flavor” in a strawberry-flavored

before reaching its end-point.

beverage or “meltability” of a processed cheese slice; for

3.2.10 shelf life testing, n—method(s) to determine the

non-food products, end-point criteria may include attributes

effects of aging or storage conditions, or both, on product(s)

that signal product performance such as lather attributes in

characteristics for purposes of determining a product’s shelf

cleansers, including lather amount or stability, or surface feel

life.

after rinsing), increases in attributes that negatively impact the

3.2.11 uncontrolled ambient, n—also known as room

sensory perception of the product (for example, increased “red

temperature, uncontrolled conditions (that is, temperature of

pepper heat” in a mildly spiced product), loss of functionality

storage location, humidity, or environmental factors, or both)

(a cleaning pad that no longer removes dirt), or the appearance

which fluctuate with changes in weather, time of day, location,

of “off-notes,” sensory properties that are not associated with

and so forth (see 3.2.3).

the product (for example, “fish flavor” in vegetable oil,

3.2.12 use by date, n—the date, usually stamped on the

“cardboard flavor” in a box of cookies, or an off-odor in a skin

product by the manufacturer, indicating that the product

care cream.)

remains consumable or usable as it delivers sensory attributes

4.4.3 The product’s acceptability has decreased, either sig-

as desired by the manufacturer; in some countries, this is

nificantly or to a specific degree, compared to the fresh

referred to as the “best before date.”

product.

3.2.13 zero time point, n—time when the shelf life testing

4.5 Select Sensory Test Method—Discrimination,

begins.

descriptive, or affective methods or a combination of these

methods, can be used to determine the sensory shelf life of a

4. Summary of Guide

product. Selection of the method depends on the chosen

end-point criteria. For example, affective testing is required if

4.1 This guide is intended to cover the basic issues and

a given consumer acceptance is the chosen end-point criterion

practicalrequirementsofconductingashelflifestudydesigned

(see 6.2).

to identify sensory end-points in a product’s shelf life.

4.6 Define Appropriate Assessors—Appropriate assessors

4.2 Define Research Objective—The purpose/objective of a

shelf life study should be clearly stated before the study is are essential for the determination of sensory shelf life,

depending on the chosen evaluation method. For discrimina-

implemented. The objectives are generally related to the

criteria selected for defining the product’s end of shelf life, tion and descriptive methods, best practice requires screened

and trained assessors (see STP 758). For acceptability

which are determined prior to the study’s inception. Common

measures, best practice requires screened and qualified asses-

objectives are as follows: “determine the amount of elapsed

sors (see MNL 26, STP 682).

time a product remains acceptable to consumers,” or “deter-

mine specific use-by dates,” or “understand the amount of time

4.7 Select Representative Products—Products selected for

elapsed before a sensory defect is detectable.”

shelf life testing must be from representative production

4.3 Identify Decision Risk—Decision risk is defined as batches and production dates which are appropriately pro-

making an incorrect shelf life decision.There are two incorrect cessed and packaged. In some situations, products should be

decisions associated with shelf life testing: (1) stating the subjected to typical distribution conditions (including, but not

product has reached the end of shelf life when it has not, and limitedto,vibration,temperatureelevation/reduction,tempera-

(2) stating that the product has not reached the end of shelf life ture cycling). If testing an experimental product (for example,

E2454 − 20

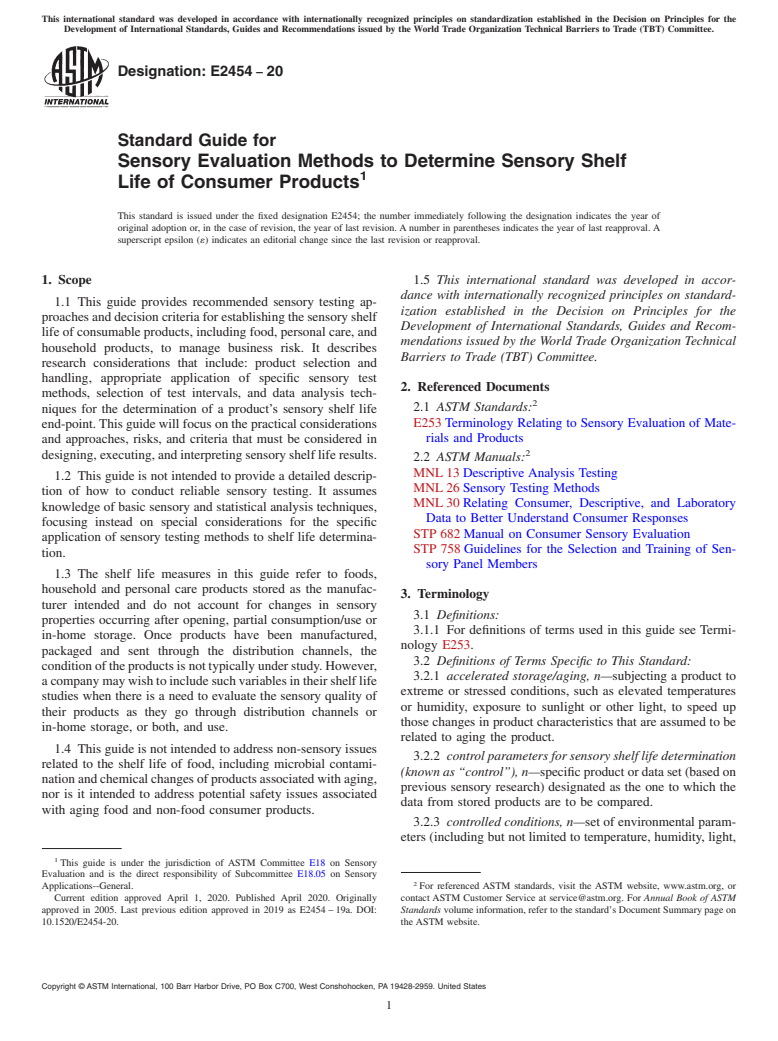

FIG. 1 Planning for Shelf-life Evaluations—Process Flow Determination With Section References

a product with changes in ingredients, formulation, processing, functional parameters, or both: (1) the aged product is percep-

or packaging), samples should be representative of production tibly different from the fresh product overall, (2) the aged

batches of the experimental product. The amount of product product has changed in specific sensory or functional

required from each production batch is dependent on the attributes, either increasing some, decreasing others, or the

estimated length of storage, number of storage conditions, appearance of new attributes compared to the fresh product, or

methods of evaluation, and frequency of testing. Collecting (3) product acceptability of the aged product has decreased to

productsofvariousagesfromretailestablishmentsisgenerally a specific degree from that of the fresh product. The determi-

not recommended for determining a product’s shelf life, as nation of these sensory end-points is a function of the criteria

conditions that the product has experienced may not be known selected, the test method used, and sampling and statistical

and may be atypical. This does not, however, preclude collect- risks chosen by the researcher.

ing such samples for a product audit. Another consideration is

5.4 The three following test methods are most commonly

product variation and the number of batches required to make

used for the three end-point criteria cited above: (1)

a reasonable determination of the shelf life. When testing

discrimination, (2) descriptive, and (3) affective. Researchers

products with more batch-to-batch variation, more than one

have to select criteria and methods that best suit the business

batch might be needed to assess shelf life. Testing more than

risksassociatedwiththeselectionofafinalshelflifeend-point.

one batch will be more resource intensive than testing only one

5.5 Once a product is made, underlying chemical and

batch of product. When testing products with less batch-to-

physical processes continue: Time, temperature, oxygen,

batch variation, one batch may be sufficient.

humidity, or light are some of the variables that can contribute

4.8 Determine the Sensory End-point—The end-point is

to these chemical changes. The interaction of the product with

selected based on the chosen end-point criteria, the type of

the packaging may also impact the sensory shelf life of the

producttested,thetestmethodselected,previousknowledgeof

product. These are often the independent variables included in

product changes over time, and the company’s assessment of

a shelf life study. However, research techniques designed to

the risk/opportunities.

identify the causes of sensory shelf life changes or to develop

predictive models of shelf life are beyond the scope of this

5. Significance and Use

document.

5.1 Sensory shelf life is the time period during which the

5.6 Previous sensory research with similar products, mar-

product’s sensory characteristics and performance are as in-

keting research, product technology, manufacturing

tended by the manufacturer. The product is consumable or

considerations, marketing objectives, consumer comments,

usable during this period, providing the end-user with the

complaints, and other business criteria can all play a part in

intended sensory characteristics, performance, and benefits.

determining sensory end-point criteria.

After this period, however, the product has characteristics or

attributes that are not as intended, or it does not perform the 5.7 The decision risk, end-point criteria, and shelf life

testing procedure should be reviewed and agreed to by

same functions as fresh products or those consumed or used

before the end of shelf life. stakeholders, such as Marketing, Market Research, R&D,

Quality Assurance, and Manufacturing.

5.2 The goal of all shelf life determination is to estimate the

time at which a consumer product is no longer usable, unfit for

6. Procedures

consumption, or no longer has the intended sensory character-

istics. 6.1 See Figs. 1-4 for diagrams of the procedures needed to

conduct a sensory shelf life evaluation.

5.3 Prior to the commencement of sensory shelf life study,

the criteria/criterion that are/is used to define shelf life end 6.2 Select Criteria to Determine the Sensory End-point—

must be defined. The criterion or criteria could be sensory Determine the specific type of shelf life sensory end-point that

attributes, consumer acceptance or product performance. Once will be used. There are three common criteria used to define

the criteria are defined, the test methodology for measuring the operationally end of shelf life: (1) a difference is detected

sensory shelf life can be selected. The criterion operationally between the fresh and aged product (discrimination failure

defining the end of shelf life is generally chosen based on one mode), (2) a descriptive attribute(s) is/are changed so that

or more of the following changes in the product’s sensory or sensory experience/sensory signals of the product is/are no

E2454 − 20

FIG. 2 Multi-point Evaluations

FIG. 3 Single-point Evaluation—Staged Entry Design

longer as intended (descriptive attribute failure mode), or (3) descriptive,oraffectivetestingmethodsarethethreemajortest

the product acceptance lowers to a pre-determined level method options. Combinations of these methods may also be

(acceptability failure mode). Inputs from quality and manufac- used.

turing staff as well as review of consumer complaint data for

6.4 DetermineSensoryEnd-point—Thesensoryend-pointis

specific feedback on sensory attributes can be helpful in

established as a significant overall difference from the control

deciding the criteria for shelf life end (see Fig. 1).

basedonapre-stateddegreeofsensorydifference,asignificant

6.3 Identify Test Method to Be Used—The testing method is or pre-determined level of change in the intensity of one or

chosen based on the end-point criteria. Discrimination testing, more critical product attribute(s) or the appearance of specified

E2454 − 20

FIG. 4 Single-point Evaluation—Staged Exit Design

“new” attributes, or a predetermined level of decrease in pull out date. However, this type of control can only be used if

acceptability. The statistical criteria for measuring significance the difference between separate batches is demonstrated to be

shouldalsobeincludedintheend-pointdefinition(thatis,α,β, minimal prior to the study, or if product variability is well

and the size of the difference desired to detect) along with the understood and can be accounted for.

number of panelists needed at each testing interval.

6.6 Select Test Product—Choose the test product(s) for the

6.5 Select Control—Choose the type of control product that

study. The product used for the study should be representative

will be used for the study. A common comparison product

of the intended product. If a control product is used, the test

might be a freshly made product, or one stored in refrigerated/

products should be obtained from the same batch of

frozenconditions,orheldundercontrolledlightortemperature

ingredients, where possible, as the control product.

conditions. In the first case, the freshly made product repre-

Additionally,thetestandcontrolproductsshouldbeasclosein

sents the product at its best; in the case of the refrigerated/

production as possible (that is, same production date, same

frozen product, the product is expected to represent a product

product location, etc.). If this is not feasible, this added

thathashadagingstoppedorsloweddownsignificantly.While

variabilitymayobscurethedifferencesbetweenthecontroland

the presence of a control product or control data is

test product. Furthermore, at the start of the storage period, an

recommended, shelf life can still be determined without a

initial sensory test should be conducted to establish the relative

physical control product, as long as specific end of shelf life

sensory comparability of the test and control products.

parameters are chosen prior to the beginning of the shelf life

6.7 Select Storage Conditions:

study. When comparing a fresh product with an aged product,

6.7.1 Typical Life Cycle—The typical life cycle of the

batch to batch product variations must be considered.

product and the conditions to which it is exposed should be

6.5.1 Option 1 (Stable Control)—This is a typical product

takenintoconsiderationwhenashelflifetestisdesigned.Shelf

that is held under conditions that minimize changes over time,

life test designers may be aware of those conditions or not, but

such as frozen or refrigerated storage or specified environmen-

must gather as much information as possible before setting up

tal conditions (for example, temperature, light, humidity, and

a shelf life study. Shelf life storage conditions should reflect

oxygen exposure). If no storage condition is known to keep

those real-world exposure conditions as much as possible to

sensory changes to a minimum, this type of control cannot be

ensurethetestoutputsarerelevant.Estimatesofenvironmental

used.

extremes and time spent in the various stages of distribution

6.5.2 Option 2 (Statistical Control)—Thisisasetofnumeri-

can help determine appropriate conditions. Verification of test

cal values obtained from sensory testing at zero time. Sensory

storage conditions through the use of sensory or monitors us

data can be a degree of difference (d-prime) for discrimination

suggested, especially if ambient storage conditions are se-

testing, descriptive analysis attribute ratings or acceptance

lected.

scores, depending on the chosen testing method.

6.5.3 Option 3 (Fresh Control)—If none of the above 6.7.2 Controlled Storage Conditions—Products selected to

controls are feasible, a fresh control may be obtained at each berepresentativeshouldbestoredunderdefinedenvironmental

E2454 − 20

conditions that may include variations in temperature, 6.8.2.6 The age at which consumer complaint levels about

humidity, light, atmosphere, air pressure, and environmental sensory attributes of current or similar products reaches above

cycling (freeze/thaw, elevated temperature conditions, etc.). normal levels and are focused on sensory attributes or product

Environmental conditions typical of distribution can also be functionality.

considered.

6.8.3 Minimum Evaluation Points—Considering the zero

time and end-points as defined above, to be 100 % of the shelf

6.7.3 Accelerated Storage Conditions—Accelerated tests at-

tempt to achieve changes in product characteristics in a life period, choose appropriate time points for evaluations. A

shortened period of time compared to non-accelerated storage minimum of four evaluation points is recommended, for

conditions. Such tests can be valuable time savers if appropri- example,0 %(zerotime),50 %,100 %(end-point),andoneor

ately selected. However, these tests are only approximations of more time points a percentage beyond the sensory end-point,

how a product may behave under normal storage conditions. that is, 125 %. Evaluation points beyond the end-point are

included in the event that the product achieves the expected

6.7.3.1 Uses of accelerated conditions are often based on

shelf life and there is the possibility that the shelf life could be

untested “rules of thumb” or beliefs rather than empirical data.

extended. It is best to include a time point where product

Duringacceleratedstorage,productchangesmaytakeplace,or

failure is likely to occur. Even with these considerations, the

characteristics may develop that would not occur during

shelf life of the product might be beyond all the planned

non-accelerated storage conditions. Elevated temperatures or

evaluation points.

exposure to humidity or light sources may cause different

reactions than would ordinarily occur under more typical 6.8.4 Additional Evaluation Points—Additional evaluation

storage conditions. Before determining shelf life end-points points over the shelf life period are recommended. These

based on accelerated conditions, one should establish the additional evaluations should be timed at points where signifi-

sensory, chemical, and mathematical relationships between cant changes in the product are expected to occur. The

following examples demonstrate three sampling plans that

accelerated conditions and typical storage conditions to ensure

the utility of using accelerated conditions to establish sensory could be used for specific product applications. These ex-

amples are designed to illustrate that sampling plans should be

shelf life (see MNL 30).

developedandcustomizedbasedontheobjectivesandrequire-

6.8 Determine Sampling Plan and Evaluation Points—

mentsofthestudy,aswellastheresourcesavailabletoconduct

Sampling plans are drawn up at the start of a shelf life study to

the evaluations. In all cases of shelf life studies where

indicatehowmanyproductsareneeded,whichlots,thestorage

end-points for testing are planned, product safety is also a

conditions under which each sample will be held, and the time

consideration. In no case should a product sensory shelf life

intervals a specific quantity of product will be tested. A

testbeconductedwhenaproductmaybeunsafetoconsumeor

samplingplanisneededinashelflifestudytoensuresufficient

use.

quantities of each product is available for testing at each

6.8.4.1 For a product predicted to change most early in the

interval. Lot to lot variability should be considered when

shelf life period, emphasis is placed on earlier evaluations: 0,

establishing a sampling plan.

15, 30, 50, 100 %, and some percentage beyond.

6.8.1 Determine Zero Time Point—The first step in devel-

6.8.4.2 For a product predicted to change later in the shelf

oping a sampling plan is to establish a baseline or “zero time”

life period, emphasis is placed on later evaluations: 0, 50, 65,

point. Choice of an appropriate zero time is determined by the

80, 100 %, and some percentage beyond.

nature of the product(s) and by the research objective. Ex-

6.8.4.3 For a new product with little, if any, prior shelf life

amples of zero time points include:

history, more frequent evaluation points are recommended to

6.8.1.1 The date the product is manufactured,

assure that the time of significant changes in the product are

6.8.1.2 The date the product reaches the retail shelf (the

capturedinevaluation.Aminimumof0,25,50,75,100 %,and

youngest product consumers would purchase),

one or more points beyond the expected shelf life should be

6.8.1.3 The date the product is typically purchased, and

planned. Even with these considerations, the shelf life of the

6.8.1.4 The date the product’s sensory profile reaches a

product might be beyond all the planned evaluation points.

steady state.

Additionally, if results of shelf life are needed to inform an

6.8.2 Determine Study End-point—The second step is to set

important business decision, such as an equipment purchase,

the expected end-point of the product’s shelf life using one or

frequent evaluation points might be useful.

more of the following criteria:

6.8.4.4 It is incumbent upon the researcher to determine

6.8.2.1 Historical data from current or similar products,

whether evaluations at all planned time points should occur.

6.8.2.2 The declared shelf life of the product or of competi-

The researcher may choose not to continue planned shelf life

tive products,

evaluation points if:

6.8.2.3 Advertising or label declaration requirements,

(1) The product has reached the failure point prior to the

6.8.2.4 Distribution requirements,

anticipated end of shelf life, or

(2) The product has not reached the failure point but the

6.8.2.5 Expected shelf life based on predicted stability of

the formulation considering the product’s ingredients, decision to set the shelf life at a point prior to failure has been

formulation, processing and packaging, and made.

E2454 − 20

6.9 Determine Product Quantities: preventanyfurtherchangesintheproduct.Again,productheld

6.9.1 To determine the total amount of product needed to continuously under the control storage condition represents the

completeashelflifestudy,onemusttakeintoconsiderationthe fresh or newly-made control product.

sampling plan test intervals, the storage conditions desired

6.10.2.4 Advantages of Single-point Evaluations:

(temperature, humidity, etc.), the experimental design, and the

(1) Single-point evaluations are efficient because all testing

sensory test methodologies best able to determine end-point

is completed in one evaluation, reducing the load on panel

criterion or criteria. Product quantities must be calculated to

testing resources.

allow for all possible combinations of testing needs.

(2) Single-point evaluations may be more sensitive to

6.9.2 It is often useful to include additional test product in

finding product differences due to contrasts effects among

each storage condition in case, for example, the product is

products of different ages.

more stable than expected or unexpected changes occur that

(3) Because single-point evaluations take place in one

warrant more in-depth study. An overage of 20 to 50 % is

evaluation in one evaluation the issue of individual respondent

common practice.

variation over time is minimized compared to multi-point

evaluations.

6.10 Determine Evaluation Plan (Multi-point Versus Single-

point Evaluation Plans)—Multi-point and single-point evalua-

6.10.2.5 Disadvantages of Single-point Evaluations:

tion plans are two different evaluation plans. Each has its own

(1) One disadvantage of a single-point evaluation is that

advantages and disadvantages and may suit specific situations.

this method forces comparative judgments to be made among

6.10.1 Multi-point Evaluations—Multi-point evaluation

the samples which can inflate or deflate product ratings. This

plansinvolveconductingtheshelflifetestingatmultipletimes,

disadvantage, however, does not apply if the end-point crite-

in accordance with the established pull-out schedule, either

rion is based on discrimination testing.

from a single batch or from multiple batches. If the objective is

(2) Another disadvantage of single-point evaluation is that

to compare the shelf life of a control and a comparative

a determination of the product’s sensory shelf life is not made

product, both products are tested at each evaluation period.

until the longest aged product is collected and evaluated. The

6.10.1.1 Advantages of Multi-point Evaluation Plans—

experimenter may wish to conduct an intermediate test, per-

Multi-point plans have the advantages of tracking the shelf life

haps halfway through the storage period, to address this

over the shelf life period and providing an early indication of

concern (a modified single-point evaluation).

product change during the shelf life evaluation period.

(3) A third disadvantage of single-point evaluations is that

6.10.1.2 Disadvantages of Multi-point Evaluation Plans—

they are effective only in situations where there is confidence

One disadvantage of the multi-point evaluation plans is the

that the aging process has been adequately stopped when using

large quantities of control and test products necessary for

either the staged exit or staged entry protocols.

multiple evaluations. Additionally, multiple evaluations are

resource intensive. These disadvantages can limit the time

7. Test Methods

points that ca

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2454 − 19a E2454 − 20

Standard Guide for

Sensory Evaluation Methods to Determine the Sensory

Shelf Life of Consumer Products

This standard is issued under the fixed designation E2454; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide provides recommended sensory testing approaches and decision criteria for establishing the sensory shelf life of

consumable products, including food, personal care, and household products, to manage business risk. It describes research

considerations that include: product selection and handling, appropriate application of specific sensory test methods, selection of

test intervals, and data analysis techniques for the determination of a product’s sensory shelf life end-point. This guide will focus

on the practical considerations and approaches, risks, and criteria that must be considered in designing, executing, and interpreting

sensory shelf life results.

1.2 This guide is not intended to provide a detailed description of how to conduct reliable sensory testing. It assumes knowledge

of basic sensory and statistical analysis techniques, focusing instead on special considerations for the specific application of

sensory testing methods to shelf life determination.

1.3 The shelf life measures in this guide refer to foods, household and personal care products stored as the manufacturer

intended and do not account for changes in sensory properties occurring after opening, partial consumption/use or in-home storage.

Once products have been manufactured, packaged and sent through the distribution channels, the condition of the products is not

typically under study. However, a company may wish to include such variables in their shelf life studies when there is a need to

evaluate the sensory quality of their products as they go through distribution channels and/or in-home storage or in-home storage,

or both, and use.

1.4 This guide is not intended to address non-sensory issues related to the shelf life of food, including microbial contamination

and chemical changes of products associated with aging, nor is it intended to address potential safety issues associated with aging

food and non-food consumer products.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

E253 Terminology Relating to Sensory Evaluation of Materials and Products

E460 Practice for Determining Effect of Packaging on Food and Beverage Products During Storage

E1871 Guide for Serving Protocol for Sensory Evaluation of Foods and Beverages

E2139 Test Method for Same-Different Test

E2164 Test Method for Directional Difference Test

E2263 Test Method for Paired Preference Test

E2610 Test Method for Sensory Analysis—Duo-Trio Test

E3005 Terminology for Body Armor

E2943 Guide for Two-Sample Acceptance and Preference Testing with Consumers

This guide is under the jurisdiction of ASTM Committee E18 on Sensory Evaluation and is the direct responsibility of Subcommittee E18.05 on Sensory

Applications--General.

Current edition approved Nov. 15, 2019April 1, 2020. Published January 2020April 2020. Originally approved in 2005. Last previous edition approved in 2019 as

E2454 – 19.E2454 – 19a. DOI: 10.1520/E2454-19A.10.1520/E2454-20.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2454 − 20

2.2 ASTM Manuals:

MNL 13 Descriptive Analysis Testing

MNL 26 Sensory Testing Methods

MNL 30 Relating Consumer, Descriptive, and Laboratory Data to Better Understand Consumer Responses

STP 682 Manual on Consumer Sensory Evaluation

STP 758 Guidelines for the Selection and Training of Sensory Panel Members

3. Terminology

3.1 Definitions:

3.1.1 For definitions of terms used in this guide see Terminology E253.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 accelerated storage/aging—storage/aging, n—subjecting a product to extreme or stressed conditions, such as elevated

temperatures or humidity, exposure to sunlight or other light, to speed up those changes in product characteristics that are assumed

to be related to aging the product.

3.2.2 control parameters for sensory shelf life determination (known as “control”)—“control”), n—specific product or data set

(based on previous sensory research) designated as the one to which the data from stored products are to be compared .compared.

3.2.3 controlled conditions—conditions, n—set of environmental parameters (including but not limited to temperature,

humidity, light, and oxygen) that are maintained and monitored so that changes in product attributes can be evaluated relative to

these parameters.

3.2.4 sensory end-point (end of shelf-life)—point at which a product no longer meets predetermined sensory attributes as defined

by the set end-point criterion or criteria (for example, discrimination, descriptive, or affective, or a combination thereof).

3.2.4 end-point criterion/criteria—criterion/criteria, n—the parameter(s) that will be used to determine the end of sensory shelf

life.

3.2.5 pull out date(s)—date(s), n—predetermined point(s) in time at which the product is removed from storage for evaluation.

3.2.6 sampling plan, n—the protocol that indicates which products are to be tested at which time intervals in a shelf life study.

3.2.7 sensory characteristics—characteristics, n—any attributes of the products that are assessed using the sensory methods that

measure the human response to that product.

3.2.8 sensory end-point (end of shelf-life), n—point at which a product no longer meets predetermined sensory attributes as

defined by the set end-point criterion or criteria (for example, discrimination, descriptive, or affective, or a combination thereof).

3.2.9 shelf life—life, n—time period that a product may be stored before reaching its end-point.

3.2.10 shelf life testing—testing, n—method(s) to determine the effects of aging or storage conditions, or both, on product(s)

characteristics for purposes of determining a product’sproduct’s shelf life.

3.2.11 uncontrolled ambient—ambient, n—also known as room temperature, uncontrolled conditions (that is, temperature of

storage location, humidity, or environmental factors, or both) which fluctuate with changes in weather, time of day, location, and

so forth (see 3.2.3).

3.2.11 zero time point—time when the shelf life testing begins.

3.2.12 use by date—date, n—Thethe date, usually stamped on the product by the manufacturer, indicating that the product

remains consumable or usable as it delivers sensory attributes as desired by the manufacturer. Inmanufacturer; in some countries,

this is referred to as the ‘best“best before date.’date.”

3.2.13 sampling plan—zero time point, n—The protocol that indicates which products are to be tested at which time intervals

in a shelf life study. time when the shelf life testing begins.

4. Summary of Guide

4.1 This guide is intended to cover the basic issues and practical requirements of conducting a shelf life study designed to

identify sensory end-points in a product’s shelf life.

4.2 Define Research Objective—The purpose/objective of a shelf life study should be clearly stated before the study is

implemented. The objectives are generally related to the criteria selected for defining the product’s end of shelf life, which are

determined prior to the study’s inception. Common objectives are as follows: “determine the amount of elapsed time a product

remains acceptable to consumers,” or “determine specific use-by dates,” or “understand the amount of time elapsed before a

sensory defect is detectable.”

4.3 Identify Decision Risk—Decision risk is defined as making an incorrect shelf life decision. There are two incorrect decisions

associated with shelf life testing: (1) stating the product has reached the end of shelf life when it has not, and (2) stating that the

product has not reached the end of shelf life when it has. A consequence of the former incorrect decision could be loss of potential

income from the product’s sale as it will be pulled from shelves and not sold when it still could be. The manufacturer will lose

E2454 − 20

sales. A consequence of the second error could be consumer rejection of a too-old product, as it will continue to be sold after the

sensory shelf life has been reached. Consumer repeat purchase of the same brand may be at stake. Before the researcher embarks

on a shelf life study, the risk to the consumer franchise must be balanced with the risk of costs associated with pulling sensory

acceptable products from the shelf, prior to the end of sensory shelf life.

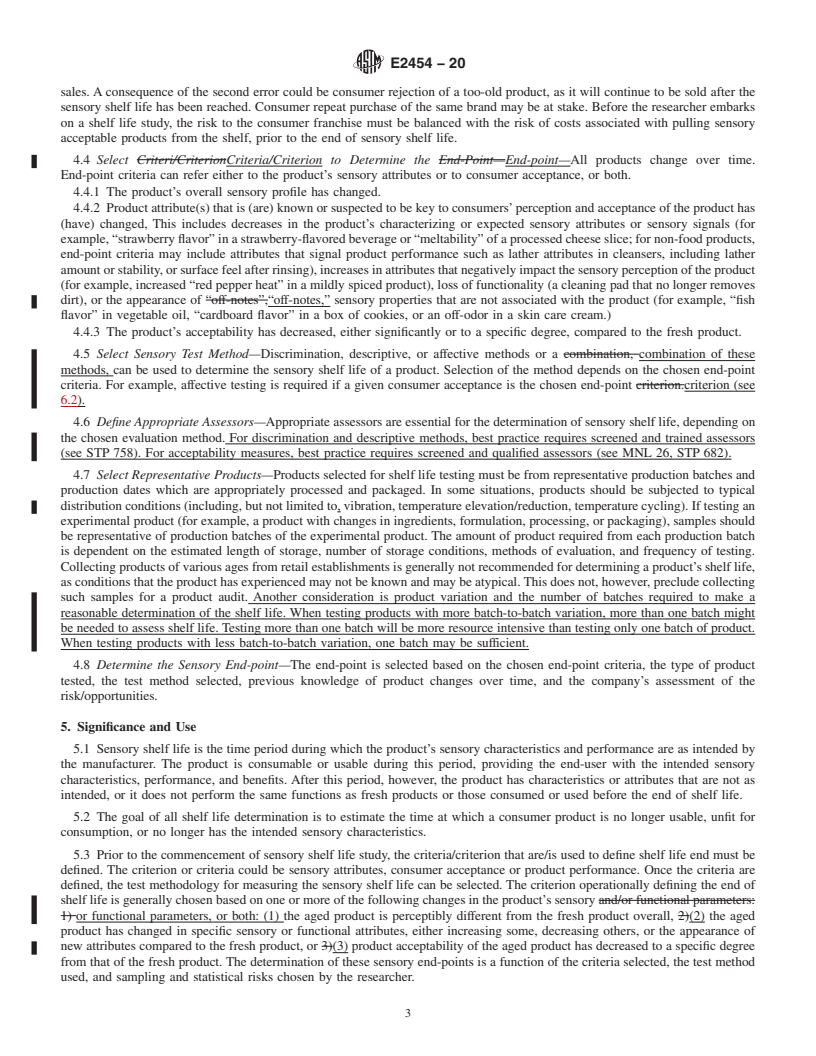

4.4 Select Criteri/CriterionCriteria/Criterion to Determine the End-Point—End-point—All products change over time.

End-point criteria can refer either to the product’s sensory attributes or to consumer acceptance, or both.

4.4.1 The product’s overall sensory profile has changed.

4.4.2 Product attribute(s) that is (are) known or suspected to be key to consumers’ perception and acceptance of the product has

(have) changed, This includes decreases in the product’s characterizing or expected sensory attributes or sensory signals (for

example, “strawberry flavor” in a strawberry-flavored beverage or “meltability” of a processed cheese slice; for non-food products,

end-point criteria may include attributes that signal product performance such as lather attributes in cleansers, including lather

amount or stability, or surface feel after rinsing), increases in attributes that negatively impact the sensory perception of the product

(for example, increased “red pepper heat” in a mildly spiced product), loss of functionality (a cleaning pad that no longer removes

dirt), or the appearance of “off-notes”,“off-notes,” sensory properties that are not associated with the product (for example, “fish

flavor” in vegetable oil, “cardboard flavor” in a box of cookies, or an off-odor in a skin care cream.)

4.4.3 The product’s acceptability has decreased, either significantly or to a specific degree, compared to the fresh product.

4.5 Select Sensory Test Method—Discrimination, descriptive, or affective methods or a combination, combination of these

methods, can be used to determine the sensory shelf life of a product. Selection of the method depends on the chosen end-point

criteria. For example, affective testing is required if a given consumer acceptance is the chosen end-point criterion.criterion (see

6.2).

4.6 Define Appropriate Assessors—Appropriate assessors are essential for the determination of sensory shelf life, depending on

the chosen evaluation method. For discrimination and descriptive methods, best practice requires screened and trained assessors

(see STP 758). For acceptability measures, best practice requires screened and qualified assessors (see MNL 26, STP 682).

4.7 Select Representative Products—Products selected for shelf life testing must be from representative production batches and

production dates which are appropriately processed and packaged. In some situations, products should be subjected to typical

distribution conditions (including, but not limited to, vibration, temperature elevation/reduction, temperature cycling). If testing an

experimental product (for example, a product with changes in ingredients, formulation, processing, or packaging), samples should

be representative of production batches of the experimental product. The amount of product required from each production batch

is dependent on the estimated length of storage, number of storage conditions, methods of evaluation, and frequency of testing.

Collecting products of various ages from retail establishments is generally not recommended for determining a product’s shelf life,

as conditions that the product has experienced may not be known and may be atypical. This does not, however, preclude collecting

such samples for a product audit. Another consideration is product variation and the number of batches required to make a

reasonable determination of the shelf life. When testing products with more batch-to-batch variation, more than one batch might

be needed to assess shelf life. Testing more than one batch will be more resource intensive than testing only one batch of product.

When testing products with less batch-to-batch variation, one batch may be sufficient.

4.8 Determine the Sensory End-point—The end-point is selected based on the chosen end-point criteria, the type of product

tested, the test method selected, previous knowledge of product changes over time, and the company’s assessment of the

risk/opportunities.

5. Significance and Use

5.1 Sensory shelf life is the time period during which the product’s sensory characteristics and performance are as intended by

the manufacturer. The product is consumable or usable during this period, providing the end-user with the intended sensory

characteristics, performance, and benefits. After this period, however, the product has characteristics or attributes that are not as

intended, or it does not perform the same functions as fresh products or those consumed or used before the end of shelf life.

5.2 The goal of all shelf life determination is to estimate the time at which a consumer product is no longer usable, unfit for

consumption, or no longer has the intended sensory characteristics.

5.3 Prior to the commencement of sensory shelf life study, the criteria/criterion that are/is used to define shelf life end must be

defined. The criterion or criteria could be sensory attributes, consumer acceptance or product performance. Once the criteria are

defined, the test methodology for measuring the sensory shelf life can be selected. The criterion operationally defining the end of

shelf life is generally chosen based on one or more of the following changes in the product’s sensory and/or functional parameters:

1) or functional parameters, or both: (1) the aged product is perceptibly different from the fresh product overall, 2)(2) the aged

product has changed in specific sensory or functional attributes, either increasing some, decreasing others, or the appearance of

new attributes compared to the fresh product, or 3)(3) product acceptability of the aged product has decreased to a specific degree

from that of the fresh product. The determination of these sensory end-points is a function of the criteria selected, the test method

used, and sampling and statistical risks chosen by the researcher.

E2454 − 20

FIG. 1 Planning for Shelf-LifeShelf-life Evaluations—Process Flow Determination withWith Section References

5.4 The three following test methods are most commonly used for the three end-point criteria cited above: (1) discrimination,

(2) descriptive, and (3) affective. Researchers have to select criteria and methods that best suit the business risks associated with

the selection of a final shelf life end-point.

5.5 Once a product is made, underlying chemical and physical processes continue: Time, temperature, oxygen, humidity, or light

are some of the variables that can contribute to these chemical changes. The interaction of the product with the packaging may

also impact the sensory shelf life of the product. These are often the independent variables included in a shelf life study. However,

research techniques designed to identify the causes of sensory shelf life changes or to develop predictive models of shelf life are

beyond the scope of this document.

5.6 Previous sensory research with similar products, marketing research, product technology, manufacturing considerations,

marketing objectives, consumer comments, complaints, and other business criteria can all play a part in determining sensory

end-point criteria.

5.7 The decision risk, end-point criteria, and shelf life testing procedure should be reviewed and agreed to by stakeholders, such

as Marketing, Market Research, R&D, Quality Assurance, and Manufacturing.

6. Procedures

See Figs. 1-4 for flowcharts of the procedures needed to conduct a sensory shelf life evaluation.

6.1 See Figs. 1-4 for diagrams of the procedures needed to conduct a sensory shelf life evaluation.

6.2 Select Criteria to Determine the Sensory End-point—Determine the specific type of shelf life sensory end-point that will be

used. There are three common criteria used to define operationally end of shelf life –life: (1) a difference is detected between the

fresh and aged product (discrimination failure mode), (2) a descriptive attribute(s)is/are attribute(s) is/are changed so that sensory

experience/sensory signals of the product is/are no longer as intended (descriptive attribute failure mode)mode), or (3) the product

acceptance lowers to a pre-determined level (acceptability failure mode). Inputs from quality and manufacturing staff as well as

review of consumer complaint data for specific feedback on sensory attributes can be helpful in deciding the criteria for shelf life

end. (Seeend (see Fig. 1.)).

6.3 Identify the Test Method to beBe Used—The testing method is chosen based on the end-point criteria. Discrimination testing,

descriptive, or affective testing methods are the three major test method options. Combinations of these methods may also be used.

6.4 Determine the Sensory End-point—The sensory end-point is established as a significant overall difference from the control

based on a pre-stated degree of sensory difference, a significant or pre-determined level of change in the intensity of one or more

critical product attribute(s) or the appearance of specified ‘new’“new” attributes, or a predetermined level of decrease in

acceptability. The statistical criteria for measuring significance should also be included in the end-point definition (that is, α, β, and

the size of the difference desired to detect) along with the number of panelists needed at each testing interval.

6.5 Select Control—Choose the type of control product that will be used for the study. A common comparison product might

be a freshly made product, or one stored in refrigerated/frozen conditions, or held under controlled light or temperature conditions.

In the first case, the freshly made product represents the product at its best; in the case of the refrigerated/frozen product, the

product is expected to represent a product that has had aging stopped or slowed down significantly. While the presence of a control

product or control data is recommended, shelf life can still be determined without a physical control product, as long as specific

end of shelf life parameters are chosen prior to the beginning of the shelf life study. When comparing a fresh product with an aged

product, batch to batch product variations must be considered.

6.5.1 Option 1—Stable Control—1 (Stable Control)—This is a typical product that is held under conditions that minimize

changes over time, such as frozen or refrigerated storage or specified environmental conditions (e.g., (for example, temperature,

light, humidity, and oxygen exposure).exposure). If no storage condition is known to keep sensory changes to a minimum, this

type of control cannot be used.

6.5.2 Option 2—Statistical Control—2 (Statistical Control)—This is a set of numerical values obtained from sensory testing at

zero time. Sensory data can be a degree of difference (d-prime) for discrimination testing, descriptive analysis attribute ratings or

acceptance scores, depending on the chosen testing method.

E2454 − 20

FIG. 2 Multi-PointMulti-point Evaluations

FIG. 3 Single Point Evaluation: Staged Single-point Evaluation—Staged Entry Design

6.5.3 Option 3—Fresh Control—3 (Fresh Control)—If none of the above controls are feasible, a fresh control may be obtained

at each pull out date. However, this type of control can only be used if the difference between separate batches is demonstrated

to be minimal prior to the study, or if product variability is well understood and can be accounted for.

6.6 Select Test Product—Choose the test product(s) for the study. The product used for the study should be representative of

the intended product. If a control product is used, the test products should be obtained from the same batch of ingredients, where

possible, as the control product. Additionally, the test and control products should be as close in production as possible (that is,

same production date, same product location, etc.). If this is not feasible, this added variability may obscure the differences between

the control and test product. Furthermore, at the start of the storage period, an initial sensory test should be conducted to establish

the relative sensory comparability of the test and control products.

E2454 − 20

FIG. 4 Single Point Evaluation: Staged Single-point Evaluation—Staged Exit Design

6.7 Select Storage Conditions:

6.7.1 Typical Life Cycle—The typical life cycle of the product and the conditions to which it is exposed should be taken into

consideration when a shelf life test is designed. Shelf life test designers may be aware of those conditions or not, but must gather

as much information as possible before setting up a shelf life study. Shelf life storage conditions should reflect those real-world

exposure conditions as much as possible to ensure the test outputs are relevant. Estimates of environmental extremes and time spent

in the various stages of distribution can help determine appropriate conditions. Verification of test storage conditions through the

use of sensory or monitors us suggested, especially if ambient storage conditions are selected.

6.7.2 Controlled Storage Conditions—Products selected to be representative should be stored under defined environmental

conditions that may include variations in temperature, humidity, light, atmosphere, air pressure, and environmental cycling

(freeze/thaw, elevated temperature conditions, etc.). Environmental conditions typical of distribution can also be considered.

6.7.3 Accelerated Storage Conditions—Accelerated tests attempt to achieve changes in product characteristics in a shortened

period of time compared to non-accelerated storage conditions. Such tests can be valuable time savers if appropriately selected.

However, these tests are only approximations of how a product may behave under normal storage conditions.

6.7.3.1 Uses of accelerated conditions are often based on untested “rules of thumb” or beliefs rather than empirical data. During

accelerated storage, product changes may take place, or characteristics may develop that would not occur during non-accelerated

storage conditions. Elevated temperatures or exposure to humidity or light sources may cause different reactions than would

ordinarily occur under more typical storage conditions. Before determining shelf life end-points based on accelerated conditions,

one should establish the sensory, chemical, and mathematical relationships between accelerated conditions and typical storage

conditions to ensure the utility of using accelerated conditions to establish Sensory Shelfsensory shelf life (see ASTM MNL 30).

6.8 Determine Sampling Plan and Evaluation Points—Sampling plans are drawn up at the start of a shelf life study to indicate

how many products are needed, which lots, the storage conditions under which each sample will be held, and the time intervals

a specific quantity of product will be tested. A sampling plan is needed in a shelf life study to ensure sufficient quantities of each

product is available for testing at each interval. Lot to lot variability should be considered when establishing a sampling plan.

6.8.1 Determine Zero Time Point—The first step in developing a sampling plan is to establish a baseline or “zero time” point.

Choice of an appropriate zero time is determined by the nature of the product(s) and by the research objective. Examples of zero

time points include:

6.8.1.1 The date the product is manufactured,

6.8.1.2 The date the product reaches the retail shelf (the youngest product consumers would purchase),

6.8.1.3 The date the product is typically purchased, and

6.8.1.4 The date the product’s sensory profile reaches a steady state.

6.8.2 Determine Study End-point—The second step is to set the expected end-point of the product’s shelf life using one or more

of the following criteria:

6.8.2.1 Historical data from current or similar products,

E2454 − 20

6.8.2.2 The declared shelf life of the product or of competitive products,

6.8.2.3 Advertising or label declaration requirements,

6.8.2.4 Distribution requirements,

6.8.2.5 Expected shelf life based on predicted stability of the formulation considering the product’s ingredients, formulation,

processing and packaging, and

6.8.2.6 The age at which consumer complaint levels about sensory attributes of current or similar products reaches above normal

levels and are focused on sensory attributes or product functionality.

6.8.3 Minimum Evaluation Points—Considering the zero time and end-points as defined above, to be 100 % of the shelf life

period, choose appropriate time points for evaluations. A minimum of four evaluation points is recommended, for example, 0 %

(zero time), 50 %, 100 % (end-point), and one or more time points a percentage beyond the sensory endpoint,end-point, that is,

125 %. Evaluation points beyond the end-point are included in the event that the product achieves the expected shelf life and there

is the possibility that the shelf life could be extended. It is best to include a time point where product failure is likely to occur.

Even with these considerations, the shelf life of the product might be beyond all the planned evaluation points.

6.8.4 Additional Evaluation Points—Additional evaluation points over the shelf life period are recommended. These additional

evaluations should be timed at points where significant changes in the product are expected to occur. The following examples

demonstrate three sampling plans that could be used for specific product applications. These examples are designed to illustrate

that sampling plans should be developed and customized based on the objectives and requirements of the study, as well as the

resources available to conduct the evaluations. In all cases of shelf life studies where end-points for testing are planned, product

safety is also a consideration. In no case should a product sensory shelf life test be conducted when a product may be unsafe to

consume or use.

6.8.4.1 For a product predicted to change most early in the shelf life period, emphasis is placed on earlier evaluations: 0 %,

15 %, 30 %, 50 %,0, 15, 30, 50, 100 %, and some percentage beyond.

6.8.4.2 For a product predicted to change later in the shelf life period, emphasis is placed on later evaluations: 0 %, 50 %, 65 %,

80 %,0, 50, 65, 80, 100 %, and some percentage beyond.

6.8.4.3 For a new product with little, if any, prior shelf life history, more frequent evaluation points are recommended to assure

that the time of significant changes in the product are captured in evaluation. A minimum of 0 %, 25 %, 50 %, 75 %,0, 25, 50, 75,

100 %, and one or more points beyond the expected shelf life should be planned. Even with these considerations, the shelf life of

the product might be beyond all the planned evaluation points. Additionally, if results of shelf life are needed to inform an

important business decision, such as an equipment purchase, frequent evaluation points might be useful.

6.8.4.4 It is incumbent upon the researcher to determine whether evaluations at all planned time points should occur. The

researcher may choose not to continue planned shelf life evaluation points if:

(1) theThe product has reached the failure point prior to the anticipated end of shelf life, or

(2) theThe product has not reached the failure point but the decision to set the shelf-life shelf life at a point prior to failure has

been made.

E2454 − 20

6.9 Determine Product Quantities:

6.9.1 To determine the total amount of product needed to complete a shelf life study, one must take into consideration the

sampling plan test intervals, the storage temperature conditions desired, conditions desired (temperature, humidity, etc.), the

experimental design, and the sensory test methodologies best able to determine end-point criterion or criteria. Product quantities

must be calculated to allow for all possible combinations of testing needs.

6.9.2 It is often useful to include additional test product in each storage condition in case, for example, the product is more stable

than expected or unexpected changes occur that warrant more in-depth study. An overage of 20 %20 to 50 % is common practice.

6.10 Determine the Evaluation Plan: Multi-Point versus Single-Point Evaluation Plans—Evaluation Plan (Multi-point Versus

Single-point Evaluation Plans)—Multi-point and single-point evaluation plans are two different evaluation plans. Each has its own

advantages and disadvantages and may suit specific situations.

6.10.1 Multi-PointMulti-point Evaluations—Multi-point evaluation plans involve conducting the shelf life testing at multiple

times, according to the established pull out schedule. in accordance with the established pull-out schedule, either from a single