ASTM A596/A596M-21

(Test Method)Standard Test Method for Direct-Current Magnetic Properties of Materials Using the Point by Point (Ballistic) Method and Ring Specimens

Standard Test Method for Direct-Current Magnetic Properties of Materials Using the Point by Point (Ballistic) Method and Ring Specimens

SIGNIFICANCE AND USE

3.1 Test methods using suitable ring-type specimens4 are the preferred methods of determining the basic magnetic properties of a material caused by the absence of demagnetizing effects and are well suited for specification acceptance, service evaluation, and research and development.

3.2 Provided the test specimen is representative of the bulk material as is usually the case for thin strip and wire, this test is also suitable for design purposes.

3.3 When the test specimen is not necessarily representative of the bulk material such as a ring machined from a large forging or casting, the results of this test method may not be an accurate indicator of the magnetic properties of the bulk material. In such instances, the test results when viewed in context of past performance history will be useful for judging the suitability of the current material for the intended application.

SCOPE

1.1 This test method covers dc testing for the determination of basic magnetic properties of materials in the form of ring, toroidal, link, double-lapped Epstein cores, or other standard shapes which may be cut, stamped, machined, or ground from cast, compacted, sintered, forged, or rolled materials. It includes tests for determination of the normal magnetization curve and hysteresis loop taken under conditions of steep wavefront reversals of the direct-current magnetic field strength.

1.2 This test method shall be used in conjunction with Practice A34/A34M.

1.3 This test method is suitable for a testing range from very low magnetic field strength up to 200 or more Oe [15.9 or more kA/m]. The lower limit is determined by integrator sensitivity and the upper limit by heat generation in the magnetizing winding. Special techniques and short duration testing may extend the upper limit of magnetic field strength.

1.4 Testing under this test method is inherently more accurate than other methods. When specified dimensional or shape requirements are observed, the measurements are a good approximation to absolute properties. Test accuracy available is primarily limited by the accuracy of instrumentation. In most cases, equivalent results may be obtained using Test Method A773/A773M or the test methods of IEC Publication 60404-4.

1.5 This test method permits a choice of test specimen to permit measurement of properties in any desired direction relative to the direction of crystallographic orientation without interference from external yoke systems.

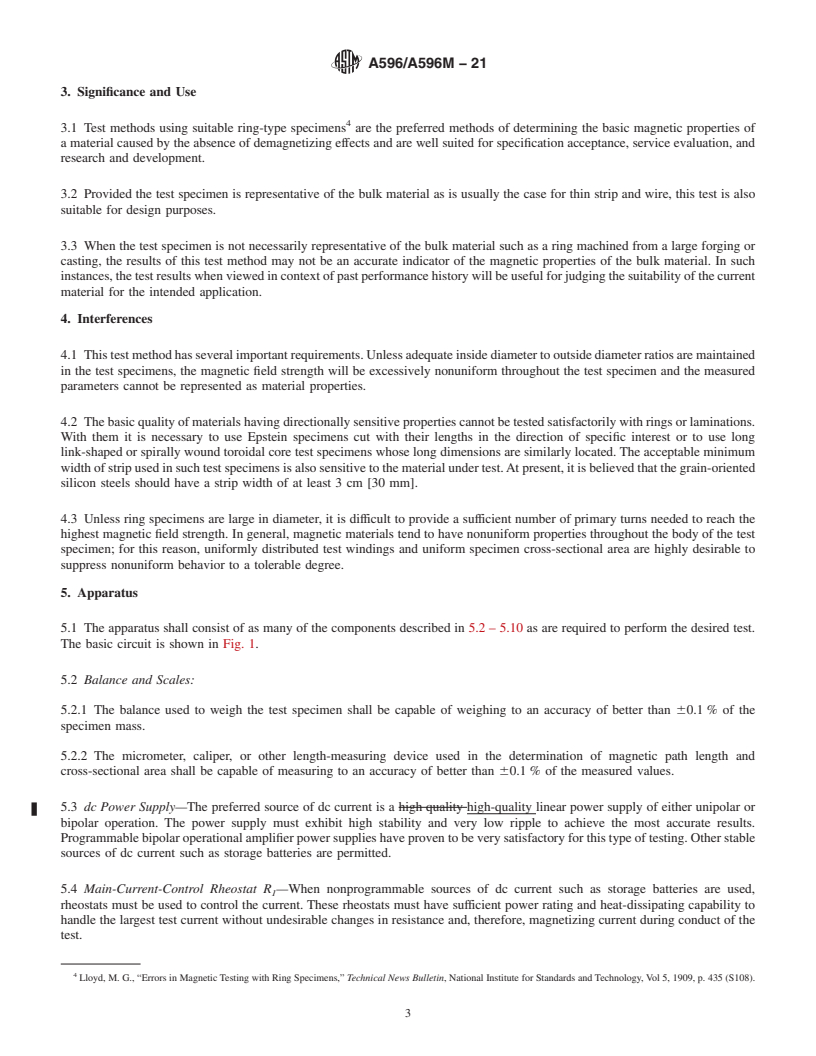

1.6 The symbols and abbreviated definitions used in this test method appear in Fig. 1 and Sections 5, 6, 9, and 10. For the official definitions see Terminology A340.

FIG. 1 Basic Circuit Using Ring-Type Cores

Note 1:

A1—Multirange ammeter, main-magnetizing current circuit

A2—Multirange ammeter, hysteresis-current circuit

N1—Magnetizing (primary) winding

N2—Flux-sensing (secondary) winding

F—Electronic integrator

R1—Main current control rheostat

R2—Hysteresis current control rheostat

S1—Reversing switch

S2—Shunting switch for hysteresis current control rheostat

1.7 Warning—Mercury has been designated by EPA and many state agencies as a hazardous material that can cause central nervous system, kidney, and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury-containing products. See the applicable product Material Safety Data Sheet (MSDS) for details and EPA’s website (http://www.epa.gov/mercury/faq.htm ) for additional information. Users should be aware that selling mercury or mercury-containing products, or both, in your state may be prohibited by state law.

1.8 The values stated in either customary (cgs-emu and inch-pound) units or SI units are to be regarded separately as standard. Within this test method, the SI units are shown in brackets except for the sections concerning calculations where there are separate sections fo...

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: A596/A596M − 21

Standard Test Method for

Direct-Current Magnetic Properties of Materials Using the

1

Point by Point (Ballistic) Method and Ring Specimens

This standard is issued under the fixed designationA596/A596M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope central nervous system, kidney, and liver damage. Mercury, or

its vapor, may be hazardous to health and corrosive to

1.1 This test method covers dc testing for the determination

materials.Cautionshouldbetakenwhenhandlingmercuryand

of basic magnetic properties of materials in the form of ring,

mercury-containing products. See the applicable product Ma-

toroidal, link, double-lapped Epstein cores, or other standard

terial Safety Data Sheet (MSDS) for details and EPA’s website

shapes which may be cut, stamped, machined, or ground from

(http://www.epa.gov/mercury/faq.htm)foradditionalinforma-

cast, compacted, sintered, forged, or rolled materials. It in-

tion. Users should be aware that selling mercury or mercury-

cludes tests for determination of the normal magnetization

containingproducts,orboth,inyourstatemaybeprohibitedby

curve and hysteresis loop taken under conditions of steep

state law.

wavefront reversals of the direct-current magnetic field

strength. 1.8 The values stated in either customary (cgs-emu and

inch-pound) units or SI units are to be regarded separately as

1.2 This test method shall be used in conjunction with

standard. Within this test method, the SI units are shown in

Practice A34/A34M.

brackets except for the sections concerning calculations where

1.3 Thistestmethodissuitableforatestingrangefromvery

there are separate sections for the respective unit systems. The

lowmagneticfieldstrengthupto200ormoreOe[15.9ormore

values stated in each system are not exact equivalents;

kA/m]. The lower limit is determined by integrator sensitivity

therefore,eachsystemshallbeusedindependentlyoftheother.

and the upper limit by heat generation in the magnetizing

Combiningvaluesfromthetwosystemsmayresultinnoncon-

winding. Special techniques and short duration testing may

formance with this method.

extend the upper limit of magnetic field strength.

1.9 This standard does not purport to address all of the

1.4 Testing under this test method is inherently more accu-

safety concerns, if any, associated with its use. It is the

rate than other methods. When specified dimensional or shape

responsibility of the user of this standard to establish appro-

requirements are observed, the measurements are a good

priate safety, health, and environmental practices and deter-

approximationtoabsoluteproperties.Testaccuracyavailableis

mine the applicability of regulatory limitations prior to use.

primarily limited by the accuracy of instrumentation. In most

1.10 This international standard was developed in accor-

cases, equivalent results may be obtained using Test Method

dance with internationally recognized principles on standard-

A773/A773M or the test methods of IEC Publication 60404-4.

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

1.5 This test method permits a choice of test specimen to

mendations issued by the World Trade Organization Technical

permit measurement of properties in any desired direction

Barriers to Trade (TBT) Committee.

relative to the direction of crystallographic orientation without

interference from external yoke systems.

2. Referenced Documents

1.6 Thesymbolsandabbreviateddefinitionsusedinthistest

2

2.1 ASTM Standards:

method appear in Fig. 1 and Sections 5, 6, 9, and 10. For the

A34/A34MPractice for Sampling and Procurement Testing

official definitions see Terminology A340.

of Magnetic Materials

1.7 Warning—Mercury has been designated by EPA and

A340Terminology of Symbols and Definitions Relating to

many state agencies as a hazardous material that can cause

Magnetic Testing

A341/A341MTest Method for Direct Current Magnetic

1

This test method is under the jurisdiction of ASTM Committee A06 on

MagneticPropertiesandisthedirectresponsibilityofSubcommitteeA06.01onTest

2

Methods. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Feb. 1, 2021. Published February 2021. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1969. Last previous edition approved in 2014 as A596/A596M–14. Standards volume information, refe

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A596/A596M − 14 A596/A596M − 21

Standard Test Method for

Direct-Current Magnetic Properties of Materials Using the

Ballistic Point by Point (Ballistic) Method and Ring

1

Specimens

This standard is issued under the fixed designation A596/A596M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers dc ballistic testing for the determination of basic magnetic properties of materials in the form of ring,

toroidal, link, double-lapped Epstein cores, or other standard shapes which may be cut, stamped, machined, or ground from cast,

compacted, sintered, forged, or rolled materials. It includes tests for normal induction determination of the normal magnetization

curve and hysteresis loop taken under conditions of steep wavefront reversals of the direct-current magnetic field strength.

1.2 This test method shall be used in conjunction with Practice A34/A34M.

1.3 This test method is suitable for a testing range from very low magnetic field strength up to 200 or more Oe [15.9 or more

kA/m]. The lower limit is determined by integrator sensitivity and the upper limit by heat generation in the magnetizing winding.

Special techniques and short duration testing may extend the upper limit of magnetic field strength.

1.4 Testing under this test method is inherently more accurate than other methods. When specified dimensional or shape

requirements are observed, the measurements are a good approximation to absolute properties. Test accuracy available is primarily

limited by the accuracy of instrumentation. In most cases, equivalent results may be obtained using Test Method A773/A773M or

the test methods of IEC Publication 60404-4.

1.5 This test method permits a choice of test specimen to permit measurement of properties in any desired direction relative to

the direction of crystallographic orientation without interference from external yoke systems.

1.6 The symbols and abbreviated definitions used in this test method appear in Fig. 1 and Sections 5, 6, 9, and 10. For the official

definitions see Terminology A340. Note that the term flux density used in this document is synonymous with the term magnetic

induction.

1.7 Warning—WarningMercury—Mercury has been designated by EPA and many state agencies as a hazardous material that can

cause central nervous system, kidney, and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to

materials. Caution should be taken when handling mercury and mercury-containing products. See the applicable product Material

Safety Data Sheet (MSDS) for details and EPA’s website (http://www.epa.gov/mercury/faq.htm ) for additional information. Users

should be aware that selling mercury or mercury-containing products, or both, in your state may be prohibited by state law.

1

This test method is under the jurisdiction of ASTM Committee A06 on Magnetic Properties and is the direct responsibility of Subcommittee A06.01 on Test Methods.

Current edition approved May 1, 2014Feb. 1, 2021. Published June 2014February 2021. Originally approved in 1969. Last previous edition approved in 20092014 as

ε1

A596/A596M–95(2009)A596/A596M – 14. . DOI: 10.1520/A0596_A0596M-14.10.1520/A0596_A0596M-21.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A596/A596M − 21

NOTE 1—

A —Multirange ammeter, main-magnetizing current circuit

1

A —Multirange ammeter, hysteresis-current circuit

2

N —Magnetizing (primary) winding

1

N —Flux-sensing (secondary) winding

2

F—Electronic integrator

R —Main current control rheostat

1

R —Hysteresis current control rheostat

2

S —Reversing switch

1

S —Shunting switch for hysteresis current control rheostat

2

FIG. 1 Basic Circuit Using Ring-Type Cores

1.8 The values stated in either customary (cgs-emu and inch-pound) units or SI units are to be regarded separately as standard.

Within this test method, the SI units are shown in brackets except for the sections concerning calculations where there are separate

sections for the respective unit systems. The values stated in each system are not exact equivalents; therefore, each system shall

be used independently of the other. Combining values from the two systems may result in nonconforma

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.