ASTM G215-16

(Guide)Standard Guide for Electrode Potential Measurement

Standard Guide for Electrode Potential Measurement

SIGNIFICANCE AND USE

5.1 Electrode potential is the reversible work that is required to transfer a unit of positive charge between the surface in question and a reference electrode through the electrolyte that is in contact with both electrodes. The sign of the electrode potential is determined by the Gibbs Stockholm Convention described in Practice G3.

5.2 The electrode potential of a surface is related to the Gibbs free energy of the oxidation/reduction reactions occurring at the surface in question compared to the Gibbs free energy of the reactions occurring on the reference electrode surface.4

5.3 Electrode potentials are used together with potential-pH (Pourbaix) diagrams to determine the corrosion products that would be in equilibrium with the environment and the electrode surface.5

5.4 Electrode potentials are used in the estimation of corrosion rates by several methods. One example is by means of Tafel line extrapolation, see Practices G3 and G102. Polarization resistance measurements are also determined using electrode potential measurements, see Test Method G59 and Guide G96.

5.5 Corrosion potential measurements are used to determine whether metal surfaces are passive in the environment in question, see Test Method C876.

5.6 Corrosion potential measurements are used in the evaluation of alloys to determine their resistance or susceptibility to various forms of localized corrosion, see Test Methods F746, F2129, G61, and G150.

5.7 Corrosion potentials are used to determine the metallurgical condition of some aluminum alloys, see Test Method G69. Similar measurements have been used with hot dipped galvanized steel to determine their ability to cathodically polarize steel. See Appendix X2.

5.8 Corrosion potentials are used to evaluate aluminum and magnesium alloys as sacrificial anodes for underground and immersion cathodic protection application, see Test Method G97 and NACE TM0190–2012.

5.9 Corrosion potentials are used to evaluate the galvanic performanc...

SCOPE

1.1 This guide provides guidance on the measurement of electrode potentials in laboratory and field studies both for corrosion potentials and polarized potentials.

1.2 The values stated in SI units are to be regarded as standard. Any other units of measurements included in this standard are present because of their wide usage and acceptance.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G215 − 16

Standard Guide for

1

Electrode Potential Measurement

This standard is issued under the fixed designation G215; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope G69Test Method for Measurement of Corrosion Potentials

of Aluminum Alloys

1.1 This guide provides guidance on the measurement of

G71Guide for Conducting and Evaluating Galvanic Corro-

electrode potentials in laboratory and field studies both for

sion Tests in Electrolytes

corrosion potentials and polarized potentials.

G82Guide for Development and Use of a Galvanic Series

1.2 The values stated in SI units are to be regarded as

for Predicting Galvanic Corrosion Performance

standard. Any other units of measurements included in this

G96Guide for Online Monitoring of Corrosion in Plant

standard are present because of their wide usage and accep-

Equipment (Electrical and Electrochemical Methods)

tance.

G97Test Method for Laboratory Evaluation of Magnesium

1.3 This standard does not purport to address all of the SacrificialAnodeTest Specimens for UndergroundAppli-

safety concerns, if any, associated with its use. It is the

cations

responsibility of the user of this standard to establish appro- G102Practice for Calculation of Corrosion Rates and Re-

priate safety and health practices and determine the applica-

lated Information from Electrochemical Measurements

bility of regulatory limitations prior to use. G106Practice for Verification of Algorithm and Equipment

for Electrochemical Impedance Measurements

2. Referenced Documents

G150Test Method for Electrochemical Critical PittingTem-

2

perature Testing of Stainless Steels

2.1 ASTM Standards:

G193Terminology and Acronyms Relating to Corrosion

C876Test Method for Corrosion Potentials of Uncoated

3

Reinforcing Steel in Concrete 2.2 NACE Standards:

F746Test Method for Pitting or Crevice Corrosion of

TM0497–2012Measurement Techniques Related to Criteria

Metallic Surgical Implant Materials for Cathodic Protection on Underground or Submerged

F2129Test Method for Conducting Cyclic Potentiodynamic

Metallic Piping Systems

Polarization Measurements to Determine the Corrosion

TM0101–2012Measurement Techniques Related to Criteria

Susceptibility of Small Implant Devices

for Cathodic Protection of Underground Storage Tank

F3044Test Method for Test Method for Evaluating the

Systems

Potential for Galvanic Corrosion for Medical Implants TM0108–2012Testing of Catalyzed Titanium Anodes for

G3Practice for Conventions Applicable to Electrochemical

Use in Soils or Natural Waters

Measurements in Corrosion Testing TM0109–2009Aboveground Survey Techniques for the

G5Reference Test Method for Making Potentiodynamic

Evaluation of Underground Pipeline Coating Condition

Anodic Polarization Measurements TM0190–2012Impressed Current Laboratory Testing of

G59TestMethodforConductingPotentiodynamicPolariza-

Aluminum Alloy Anodes

tion Resistance Measurements TM0211–2011Durability Test for Copper/Copper Sulfate

G61Test Method for Conducting Cyclic Potentiodynamic

Permanent Reference Electrodes for Direct Burial Appli-

Polarization Measurements for Localized Corrosion Sus- cations

ceptibility of Iron-, Nickel-, or Cobalt-Based Alloys

TM0113–2013Evaluating theAccuracy of Field Grade Ref-

erence Electrode

1

This guide is under the jurisdiction ofASTM Committee G01 on Corrosion of

3. Terminology

Metals and is the direct responsibility of Subcommittee G01.11 on Electrochemical

3.1 Definitions—The terminology used herein shall be in

Measurements in Corrosion Testing.

Current edition approved May 1, 2016. Published May 2016. DOI: 10.1520/

accordance with Terminology G193.

G0215-16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on AvailablefromNACEInternational(NACE),15835ParkTenPl.,Houston,TX

the ASTM website. 77084, http://www.nace.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

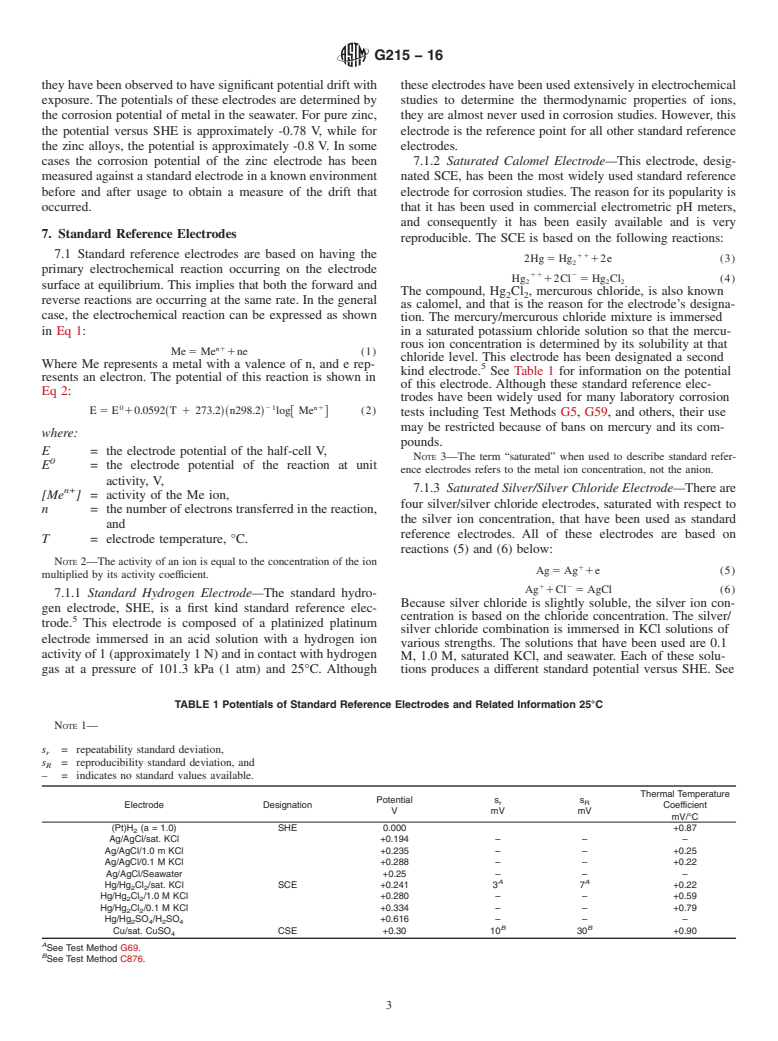

G215 − 16

4. Summary of Practice systems and to confirm the performance of these systems in

soils,concrete,andnaturalwaters,seeNACETM0497,NACE

4.1 Electrode potential measurements are made by electri-

TM0108, and NACE TM0109.

cally connecting a high impedance voltmeter or electrometer

between the specimen electrode and a suitable reference 5.11 Electrodepotentialmeasurementsarenecessaryforthe

half-cell electrode. See Practice G3. determ

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.