ASTM D7158-05

(Test Method)Standard Test Method for Wind Resistance of Sealed Asphalt Shingles(Uplift Force/Uplift Resistance Method)

Standard Test Method for Wind Resistance of Sealed Asphalt Shingles(Uplift Force/Uplift Resistance Method)

SCOPE

1.1 This test method covers the procedure for calculating the wind resistance of asphalt shingles when applied in accordance with the manufacturer's instructions, and sealed under defined conditions. The method calculates the uplift force exerted on the shingle by the action of wind at a specified velocity, and compares that to the mechanical uplift resistance of the shingle. A shingle is determined to be wind resistant at a specified basic wind speed when the measured uplift resistance exceeds the calculated uplift force for that velocity (3-second gust, ASCE 7).

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 7158 – 05

Standard Test Method for

Wind Resistance of Sealed Asphalt Shingles (Uplift Force/

Uplift Resistance Method)

This standard is issued under the fixed designation D7158; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 ASCE Standard:

ASCE 7–02 Minimum Design Loads for Buildings and

1.1 This test method covers the procedure for calculating

Other Structures

the wind resistance of asphalt shingles when applied in

2.3 ANSI/UL Standard:

accordance with the manufacturer’s instructions, and sealed

ANSI/UL2390–04 TestMethodforWindResistantAsphalt

under defined conditions. The method calculates the uplift

Shingles with Sealed Tabs

forceexertedontheshinglebytheactionofwindataspecified

velocity, and compares that to the mechanical uplift resistance

3. Terminology

of the shingle. A shingle is determined to be wind resistant at

3.1 Definitions:

a specified basic wind speed when the measured uplift resis-

3.1.1 For definition of terms used in this test method, refer

tance exceeds the calculated uplift force for that velocity

to Terminology D1079.

(3-second gust, ASCE 7).

3.2 Definitions of Terms Specific to This Standard:

1.2 The values stated in SI units are to be regarded as the

3.2.1 sealant—as it relates to steep roofing shingles,is

standard. The values given in parentheses are for information

defined as factory-applied or field-applied typically asphaltic

only.

material designed to seal the shingles to each other under the

1.3 This standard does not purport to address all of the

action of time and temperature after the shingles are applied to

safety concerns, if any, associated with its use. It is the

a roof.

responsibility of the user of this standard to establish appro-

3.2.2 seal—as it relates to steep roofing shingles,isthe

priate safety and health practices and determine the applica-

bondingthatresultsfromtheactivationofthesealantunderthe

bility of regulatory limitations prior to use.

action of time and temperature.

2. Referenced Documents

4. Types and Classes of Shingles

2.1 ASTM Standards:

4.1 Shingles are classified based on their resistance to wind

D225 Specification for Asphalt Shingles (Organic Felt)

velocities determined from measured data (Section 11), calcu-

Surfaced with Mineral Granules

lationsofupliftforce(Section12),andinterpretationofresults

D228 Test Methods for Sampling, Testing, andAnalysis of

(Section 13), as follows:

Asphalt Roll Roofing, Cap Sheets, and Shingles Used in

4.1.1 Class D—Passed at basic wind speeds up to and

Roofing and Waterproofing

including 145 km/h (90 mph).

D1079 Terminology Relating to Roofing, Waterproofing,

4.1.2 Class G—Passed at basic wind speeds up to and

and Bituminous Materials

including 193 km/h (120 mph).

D 3161 Test Method for Wind-Resistance of Asphalt

4.1.3 Class H—Passed at basic wind speeds up to and

Shingles (Fan-Induced Method)

including 242 km/h (150 mph).

D3462 SpecificationforAsphaltShinglesmadefromGlass

Felt and Surfaced with Mineral Granules

5. Summary of Test Method

D6381 Test Method for Measurement of Asphalt Shingle

5.1 The uplift force induced by wind passing over the

Mechanical Uplift Resistance

surfaceofasphaltshinglesisdeterminedbycalculationinvolv-

ing the uplift coefficients obtained from pressures measured

1 aboveandbelowtheshingleatthewindwardandleewardsides

ThistestmethodisunderthejurisdictionofASTMCommitteeD08onRoofing

and Waterproofing and is the direct responsibility of Subcommittee D08.02 on

Prepared Roofings, Shingles and Siding Materials.

Current edition approved Oct. 15, 2005. Published November 2005.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican Society of Civil Engineers (ASCE), 1801Alexander

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Bell Dr., Reston, VA 20191.

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7158–05

installed. If environmental factors are outside those used in the calcula-

ofthesealant,takingintoaccountthedesiredbasicwindspeed

tions for these classes, such as ground roughness D, building heights

classification and the uplift rigidity of the shingle. The calcu-

greaterthan60fttall,buildingusecategoriesIIIorIVandotherexposures

lated uplift force (F ) for each of the possible classifications is

T

asdefinedbyASCE-7,othercalculationsarerequired.Consulttheshingle

compared to the measured uplift resistance (R ) of the sealed

T

manufacturer for the specific shingle’s DCp, EI, L, L1, and L2 values

shingle to establish the wind resistance classification of the

needed to complete these calculations.

shingle.

6.4 The test to determine uplift coefficients is conducted

5.2 The method involves three steps:

withawindvelocityof15.6 61.3m/s(35 63mph).Research

5.2.1 Uplift coefficients are determined by measuring pres-

data obtained during the development of this test procedure, as

suredifferencesaboveandbelowtheshingleasairmovesover

well as standard wind modeling practices, provides for data

the surface of a deck of sealed shingles under controlled

extrapolation to other wind speeds. In order to simulate the

conditions.

raised shingle edge that is inherent behavior under high wind

5.2.2 The uplift forces acting on the shingle are calculated,

exposure, shims are inserted under the windward edge of the

using the wind uplift coefficients, shingle sealant configuration

shingle as appropriate based on wind speed and uplift rigidity

and a specific basic wind speed.

of the shingle being investigated. This test method provides a

5.2.3 Shingle uplift resistance to that specific basic wind

means of measuring shingle uplift rigidity which is used to

speed is determined by comparing the calculated uplift forces

determine the correct shim thickness. Additionally, this test

acting on the sealant to the uplift resistances measured with

method allows for the use of a default value for uplift rigidity

Test Method D6381. Uplift resistances from ProcedureAand

2 2

(EI) of 7175 N-mm (2.5 lbf-in. ), if a rigidity measurement is

Procedure B are applied against the uplift forces in a manner

notmade.ThisdefaultvalueisconservativesincethelowestEI

detailed in the calculation section.

measured in the development of this program was 14350

5.3 This test method is applicable to any asphalt shingle

2 2

N-mm (5.0 lbf-in. ).

surfaced with mineral granules where the shingle above is

affixed to the surface of the shingle below with a sealant

NOTE 3— The entire field of wind engineering is based on use of

(factoryorfieldapplied)appliedinapatternalignedparallelto small-scale models in wind tunnels using wind speeds much lower than

the full-scale values. Building Codes permit testing of this type to replace

the windward edge of the shingle.

the analytical provisions of the Building Code through the provisions of

NOTE 1—It is not prohibited to use this test method for research

ASCE 7. (See Appendix X1 for details and references.)

purposesusingvariationsinthenumberandplacementoffasteners.Ifthis

is done, the report shall include details of the number and placement of

7. Apparatus

fasteners.

7.1 The apparatus described in Test Method D6381, Proce-

dure A, modified as described below, is used to determine the

6. Significance and Use

uplift rigidity of the shingle being evaluated.

6.1 The wind resistance of asphalt shingles is directly

7.2 The apparatus described in Test Method D3161, modi-

related to the ability of the sealed shingle to resist the force of

fied as described below, is used to determine the wind uplift

the wind acting to lift the shingle from the shingle below. This

coefficient of the shingle being evaluated.

test method employs the measured resistance of the shingle to

7.3 Air flow instrumentation capable of continuously mea-

mechanical uplift after sealing under defined conditions, in a

suringandrecordingtime-averagedvelocityaccurateto 60.45

calculation which determines whether this resistance exceeds

m/s (61.0 mph) and a method of traversing the measurement

the calculated force induced by wind passing over the surface

device above the test deck is used to measure velocities of the

of the shingle. Natural wind conditions differ with respect to

air flow.

intensity,duration,andturbulence;whiletheseconditionswere

considered, and safety factors introduced, extreme natural

7.4 Air pressure instrumentation capable of continuously

variationsarebeyondthemeansofthistestmethodtosimulate.

measuringandelectronicallyrecordingthetime-averagedpres-

6.2 Many factors influence the sealing characteristics of

sures of 2.5 to 311 Pa (0.01 to 1.25 in. of water) is use to

shinglesinthefield;forexample,temperature,time,roofslope, measure the pressure above and below the shingle on the test

contamination by dirt and debris, and fasteners that are

deck.

misaligned or under driven and interfere with sealing. It is

7.5 Shims of thickness 1 6 0.05 mm (0.04 6 0.002 in.) and

beyond the scope of this test method to address all of these

a maximum length and width of 5.1 by 5.1 mm (0.2 by 0.2 in.)

influences. The classification determined in this test method is

are used to lift the windward edge of the shingle during part of

based on the mechanical uplift resistance determined when

thewindupliftcoefficientmeasurements(see11.2.5).Shimsof

representative samples of shingles are sealed under defined

other thicknesses, but a minimum of 0.1 mm (0.004 in.), and a

conditions before testing.

maximum width and length of 5.1 by 5.1 mm (0.2 by 0.2 in.),

6.3 The calculations that support the Classes in 4.1 use

are used as required, alone or in combination, to lift the

several standard building environment factors. These include

windward edge to the height calculated from the shingle

the 3-s wind gust exposure from ASCE-7, installation on

deflection (see 11.2.12).

CategoryIorIIbuildingsforallslopes,groundroughnessBor

NOTE 4—The modifications to the Test Method D3161 apparatus to

C, and installation on buildings 60 ft tall or less.

induceturbulence,theairflowandpressuremeasurementinstrumentation,

NOTE 2—Theassumptionsusedinthecalculationsfortheclassesin4.1 and the shims employed, are consistent with the procedure developed for

cover the requirements for the majority of the asphalt shingle roofs Test Method ANSI/UL 2390 for shingle wind resistance testing.

D7158–05

7.6 The apparatus described in Test Method D6381 is used 8.2.1.3 The overall arrangement of a modified Test Method

to determine the mechanical uplift resistance of the shingle D3161 apparatus is shown schematically in Fig. 4.

being evaluated. The selection of Procedure A or B in Test

8.2.1.4 Test decks shall be constructed in accordance with

Method D6381 is dictated by the magnitude of the forces in

Test Method D3161, with the shingles applied in accordance

frontof(F )andbehind(F )thesealantascalculatedusingthe

F B

with the manufacturer’s instructions. The test deck sits on an

measured wind uplift coefficient and the geometry of the

adjustable stand, and is fixed at 0.91 m (36 in.) from the air

shingle being evaluated (see 12.2).

flow orifice.Arigid bridge with roughness strips (as shown in

Fig.4)isplacedbetweentheorificeandthetestdeck,andthere

8. Preparation of Apparatus

is no step between the bridge and the deck.The bridge and the

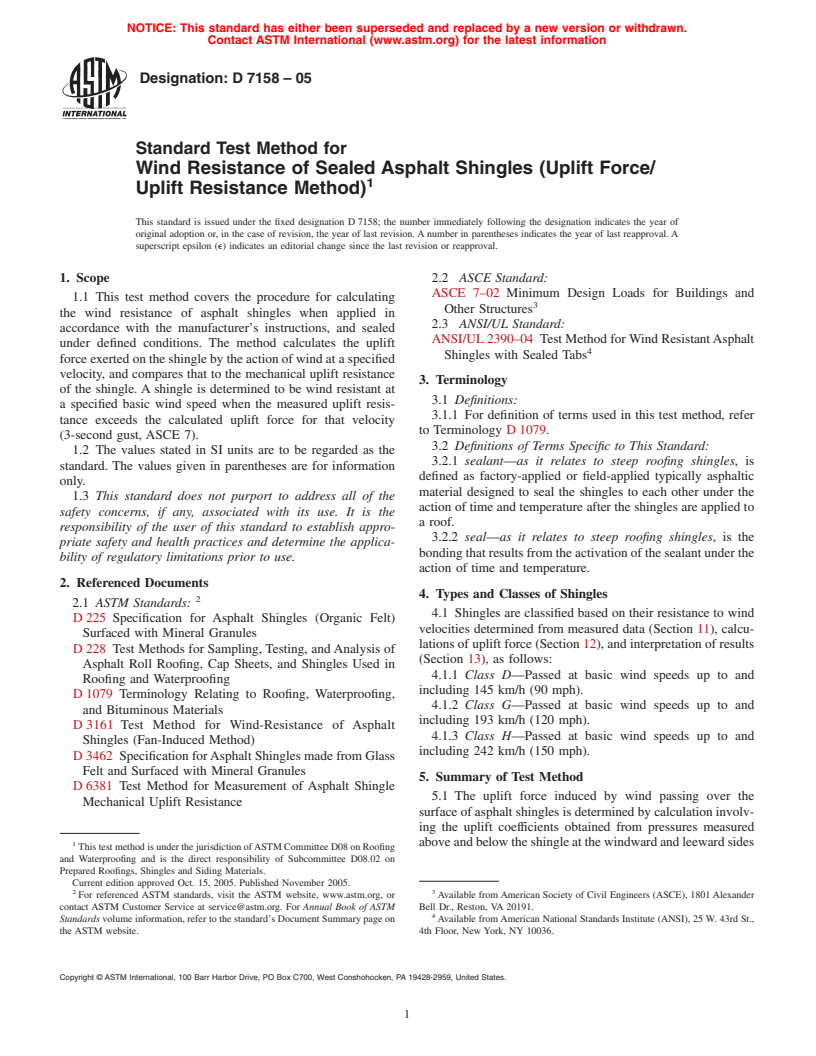

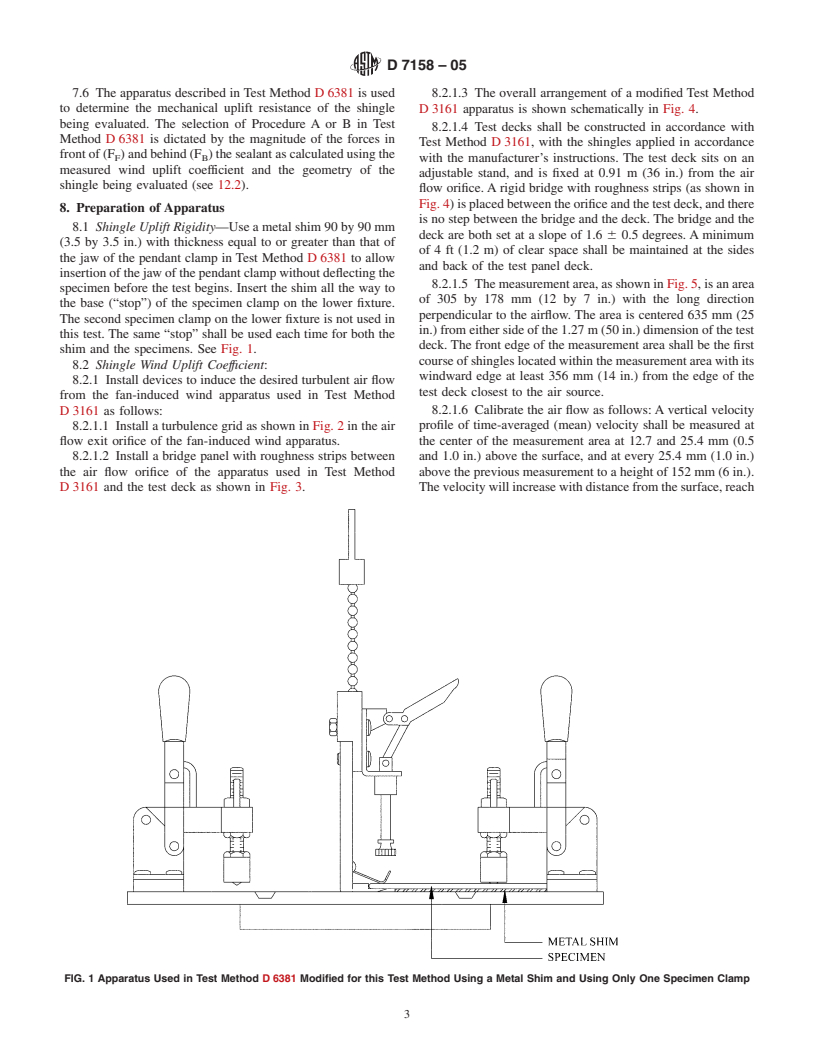

8.1 Shingle Uplift Rigidity—Useametalshim90by90mm

deck are both set at a slope of 1.6 6 0.5 degrees.Aminimum

(3.5 by 3.5 in.) with thickness equal to or greater than that of

of 4 ft (1.2 m) of clear space shall be maintained at the sides

the jaw of the pendant clamp in Test Method D6381 to allow

and back of the test panel deck.

insertionofthejawofthependantclampwithoutdeflectingthe

8.2.1.5 Themeasurementarea,asshowninFig.5,isanarea

specimen before the test begins. Insert the shim all the way to

of 305 by 178 mm (12 by 7 in.) with the long direction

the base (“stop”) of the specimen clamp on the lower fixture.

perpendicular to the airflow. The area is centered 635 mm (25

The second specimen clamp on the lower fixture is not used in

in.)fromeithersideofthe1.27m(50in.)dimensionofthetest

this test. The same “stop” shall be used each time for both the

deck. The front edge of the measurement area shall be the first

shim and the specimens. See Fig. 1.

courseofshingleslocatedwithinthemeasurementareawithits

8.2 Shingle Wind Uplift Coeffıcient:

windward edge at least 356 mm (14 in.) from the edge of the

8.2.1 Install devices to induce the desired turbulent air flow

test deck closest to the air source.

from the fan-induced wind apparatus used in Test Method

D3161 as follows: 8.2.1.6 Calibrate the air flow as follows:Avertical velocity

profile of time-averaged (mean) velocity shall be measured at

8.2.1.1 Install a turbulence grid as shown in Fig. 2 in the air

flow exit orifice of the fan-induced wind apparatus. the center of the measurement area at 12.7 and 25.4 mm (0.5

8.2.1.2 Install a bridge panel with roughness strips between and 1.0 in.) above the surface, and at every 25.4 mm (1.0 in.)

the air flow orifice of the apparatus used in Test Method abovethepreviousmeasurementtoaheightof152mm(6in.).

D3161 and the test deck as shown in Fig. 3. Thevelocitywillincreasewithdistancefromthesurface,reach

FIG. 1 Apparatus Used in Test Method D 6381 Modified for this Test Method Using a Metal Shim and Using Only One Specimen Clamp

D7158–05

NOTE—1 in. = 25.4 mm.

FIG. 2 Turbulence Grid Installed at Air Flow Exit Orifice of Apparatus Used in Test Method D 3161

NOTE—1 in. = 25.4 mm.

FIG. 3 Bridge Panel with Roughness Strips Installed Between Air Flow Exit Orifice of Apparatus Used in Test Method D 3161 and Test

Deck

FIG. 4 Overall Schematic of Test Arrangement for Determination of Wind Uplift Coefficient

a peak value, and begin to decrease with additional height. theboundariesofthe305-mm(12-in.)widemeasurementarea.

Record the maximum velocity and its height. This maximum

All velocities in the horizontal profile shall be within 65.0%

velocityshallbeatleast15.6m/s(35mph).Ahorizontalprofile of the maximum velocity recorded in the vertical profile.

of time-averaged velocities across the measurement area shall

NOTE 5—This height has been demonstrated to occur at approximately

be made at the height of maximum velocity (see Note 5)inthe

102 m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.