ASTM E1232-07(2013)

(Test Method)Standard Test Method for Temperature Limit of Flammability of Chemicals

Standard Test Method for Temperature Limit of Flammability of Chemicals

SIGNIFICANCE AND USE

5.1 The lower temperature limit of flammability is the minimum temperature at which a liquid (or solid) chemical will evolve sufficient vapors to form a flammable mixture with air under equilibrium conditions. Knowledge of this temperature is important in determining guidelines for the safe handling of chemicals, particularly in closed process and storage vessels.Note 1—As a result of physical factors inherent in flash point apparatus and procedures, closed-cup flash point temperatures are not necessarily the minimum temperature at which a chemical will evolve flammable vapors (see Appendix X2 and Appendix X3, taken in part from Test Method E502). The temperature limit of flammability test is designed to supplement limitations inherent in flash point tests (Appendix X2). It yields a result closely approaching the minimum temperature of flammable vapor formation for equilibrium situations in the chemical processing industry such as in closed process and storage vessels.Note 2—As a result of flame quenching effects existing when testing in standard closed-cup flash point apparatus, there are certain chemicals that exhibit no flash point but do evolve vapors that will propagate a flame in vessels of adequate size (X3.2). The temperature limit of flammability test chamber is sufficiently large to overcome flame quenching effects in most cases of practical importance, thus, usually indicating the presence of vapor-phase flammability if it does exist (6.2).Note 3—The lower temperature limit of flammability (LTL) is only one of several characteristics that should be evaluated to determine the safety of a specific material for a specific application. For example, some materials are found to have an LTL by this test method when, in fact, other characteristics such as minimum ignition energy and heat of combustion should also be considered in an overall flammability evaluation.

5.2 The vapor concentration present at the lower temperature limit of flammability equals the lo...

SCOPE

1.1 This test method covers the determination of the minimum temperature at which vapors in equilibrium with a liquid (or solid) chemical will be sufficiently concentrated to form flammable mixtures in air at atmospheric pressure. This test method is written specifically for determination of the temperature limit of flammability of systems using air as the source of oxidant and diluent. It may also be used for other oxidant/diluent combinations, including air plus diluent mixtures; however, no oxidant/diluent combination stronger than air should be used. Also, no unstable chemical capable of explosive decomposition reactions should be tested (see 8.3).

1.2 This test method is designed and written to be run at local ambient pressure and is limited to a maximum initial pressure of 1 atm abs. It may also be used for reduced pressures with the practical lower pressure limit being approximately 13.3 kPa (100 mm Hg). The maximum practical operating temperature of this equipment is approximately 150°C (302°F) (Note A1.2).

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are mathematical conversions to inch-pound units are provided for information only and are not considered standard.

1.4 This standard should be used to measure and describe the properties of materials, products, or assemblies in response to heat and flame under controlled laboratory conditions, and should not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions. However, results of this test may be used as elements of a fire risk assessment which takes into account all of the factors which are pertinent to an assessment of the fire hazard of a particular end use.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to esta...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1232 − 07 (Reapproved 2013)

Standard Test Method for

Temperature Limit of Flammability of Chemicals

This standard is issued under the fixed designation E1232; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

The temperature limit of flammability test measures the minimum temperature at which liquid (or

solid) chemicals evolve sufficient vapors to form a flammable mixture with air under equilibrium

conditions. This temperature is applicable for assessing flammability in large process vessels and

similar equipment (Appendix X1 and Appendix X2).

1. Scope elements of a fire risk assessment which takes into account all

of the factors which are pertinent to an assessment of the fire

1.1 This test method covers the determination of the mini-

hazard of a particular end use.

mum temperature at which vapors in equilibrium with a liquid

1.5 This standard does not purport to address all of the

(or solid) chemical will be sufficiently concentrated to form

safety concerns, if any, associated with its use. It is the

flammable mixtures in air at atmospheric pressure. This test

responsibility of the user of this standard to establish appro-

methodiswrittenspecificallyfordeterminationofthetempera-

priate safety and health practices and determine the applica-

ture limit of flammability of systems using air as the source of

bility of regulatory limitations prior to use. Specific safety

oxidant and diluent. It may also be used for other oxidant/

precautions are given in Section 8.

diluent combinations, including air plus diluent mixtures;

1.6 This international standard was developed in accor-

however, no oxidant/diluent combination stronger than air

dance with internationally recognized principles on standard-

should be used. Also, no unstable chemical capable of explo-

ization established in the Decision on Principles for the

sive decomposition reactions should be tested (see 8.3).

Development of International Standards, Guides and Recom-

1.2 This test method is designed and written to be run at

mendations issued by the World Trade Organization Technical

local ambient pressure and is limited to a maximum initial

Barriers to Trade (TBT) Committee.

pressureof1atmabs.Itmayalsobeusedforreducedpressures

with the practical lower pressure limit being approximately

2. Referenced Documents

13.3 kPa (100 mm Hg). The maximum practical operating

2.1 ASTM Standards:

temperature of this equipment is approximately 150°C (302°F)

(Note A1.2). D3278 Test Methods for Flash Point of Liquids by Small

Scale Closed-Cup Apparatus

1.3 The values stated in SI units are to be regarded as

D3828 Test Methods for Flash Point by Small Scale Closed

standard. The values given in parentheses are mathematical

Cup Tester

conversions to inch-pound units are provided for information

D3941 Test Method for Flash Point by the Equilibrium

only and are not considered standard.

Method With a Closed-Cup Apparatus

1.4 This standard should be used to measure and describe

E220 Test Method for Calibration of Thermocouples By

the properties of materials, products, or assemblies in response

Comparison Techniques

to heat and flame under controlled laboratory conditions, and

E230 Specification and Temperature-Electromotive Force

shouldnotbeusedtodescribeorappraisethefirehazardorfire

(EMF) Tables for Standardized Thermocouples

risk of materials, products, or assemblies under actual fire

E502 Test Method for Selection and Use of ASTM Stan-

conditions. However, results of this test may be used as

dards for the Determination of Flash Point of Chemicals

by Closed Cup Methods

This test method is under the jurisdiction ofASTM Committee E27 on Hazard

Potential of Chemicals and is the direct responsibility of Subcommittee E27.04 on

Flammability and Ignitability of Chemicals. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Oct. 1, 2013. Published November 2013. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1991. Last previous edition approved in 2007 as E1232 – 07. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/E1232-07R13. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E1232 − 07 (2013)

and procedures, closed-cup flash point temperatures are not necessarily

E537 Test Method for The Thermal Stability of Chemicals

the minimum temperature at which a chemical will evolve flammable

by Differential Scanning Calorimetry

vapors (see Appendix X2 and Appendix X3, taken in part from Test

E681 Test Method for Concentration Limits of Flammability

Method E502). The temperature limit of flammability test is designed to

of Chemicals (Vapors and Gases)

supplement limitations inherent in flash point tests (Appendix X2). It

E698 Test Method for Kinetic Parameters for Thermally

yields a result closely approaching the minimum temperature of flam-

mable vapor formation for equilibrium situations in the chemical process-

Unstable Materials Using Differential Scanning Calorim-

ing industry such as in closed process and storage vessels.

etry and the Flynn/Wall/Ozawa Method

NOTE2—Asaresultofflamequenchingeffectsexistingwhentestingin

2.2 ANSI Standard:

standard closed-cup flash point apparatus, there are certain chemicals that

ANSI-MC96.1 Temperature Measurement Thermocouples

exhibit no flash point but do evolve vapors that will propagate a flame in

vessels of adequate size (X3.2).The temperature limit of flammability test

2.3 NFPA Standard:

chamber is sufficiently large to overcome flame quenching effects in most

NFPA 325 Fire Hazardous Properties Liquids

cases of practical importance, thus, usually indicating the presence of

vapor-phase flammability if it does exist (6.2).

3. Terminology

NOTE3—Thelowertemperaturelimitofflammability(LTL)isonlyone

of several characteristics that should be evaluated to determine the safety

3.1 Definitions:

of a specific material for a specific application. For example, some

3.1.1 flash point—the lowest temperature, corrected to a

materialsarefoundtohaveanLTLbythistestmethodwhen,infact,other

pressure of 101.3 kPa (760 mm Hg, 1013 mbar), at which

characteristics such as minimum ignition energy and heat of combustion

application of an ignition source causes the vapors of the

should also be considered in an overall flammability evaluation.

specimen to ignite under specified conditions of test.

5.2 The vapor concentration present at the lower tempera-

3.1.2 lower limit of flammability or lower flammable limit,

ture limit of flammability equals the lower flammable limit

(LFL)—the minimum concentration of a combustible sub-

concentration as measured by Test Method E681 and extrapo-

stance that is capable of propagating a flame through a

lated back to the same temperature. (This permits estimation of

homogeneous mixture of the combustible and a gaseous

lower temperature limits of flammability if vapor pressure and

oxidizer under the specified conditions of test.

concentrationlimitofflammabilitydataareavailable(A2.3).A

3.1.3 lower temperature limit of flammability, (LTL)—the comparison of results of the tests, thus, affords a check on test

lowest temperature, corrected to a pressure of 101.3 kPa (760

reliability, the reliability of vapor pressure data, or both.)

mm Hg, 1013 mbar), at which application of an ignition source

causes a homogeneous mixture of a gaseous oxidizer and

6. Interferences

vaporsinequilibriumwithaliquid(orsolid)specimentoignite

6.1 This test method is not applicable to materials that

and propagate a flame away from the ignition source under the

undergo chemical changes when mixed with air. Examples

specified conditions of test.

include, but are not limited to, oxidation and polymerization.

3.2 Definitions of Terms Specific to This Standard:

6.2 Measured temperature limits are influenced by flame

3.2.1 propagation of flame—the upward and outward move-

quenching effects of the test vessel walls. The test vessel

ment of the flame front from the ignition source to the vessel

employed in this test method is of sufficient size to eliminate

walls, that is determined by visual observation.

these effects for most materials. For certain amines, haloge-

nated materials, etc., that have large ignition-quenching

4. Summary of Test Method

distances, tests should be conducted in vessels with larger

4.1 A pool of liquid is stirred in a closed vessel in an air

diameters than the one listed in this test method (A1.1).

atmosphere.The vapor-air mixture above this liquid is exposed

Quenching effects become increasingly significant as the test

to an ignition source and the upward and outward propagation

pressure decreases.

of flame away from the ignition source is noted by visual

6.3 Measured temperature limits of flammability of chemi-

observation. Temperature in the test vessel is varied between

cals can be greatly influenced, as are flash points, by the

trials until the minimum temperature at which flame will

presence of various impurities or known mixture components.

propagate away from the ignition source is determined.

Small quantities of volatile flammable impurities can reduce

5. Significance and Use

temperature limit values, and volatile inert diluents can raise

temperature limit values or produce complete inerting. (See

5.1 The lower temperature limit of flammability is the

8.2.3 and Annex A3 for a discussion of mixture testing.)

minimumtemperatureatwhichaliquid(orsolid)chemicalwill

evolve sufficient vapors to form a flammable mixture with air

7. Apparatus

under equilibrium conditions. Knowledge of this temperature

is important in determining guidelines for the safe handling of

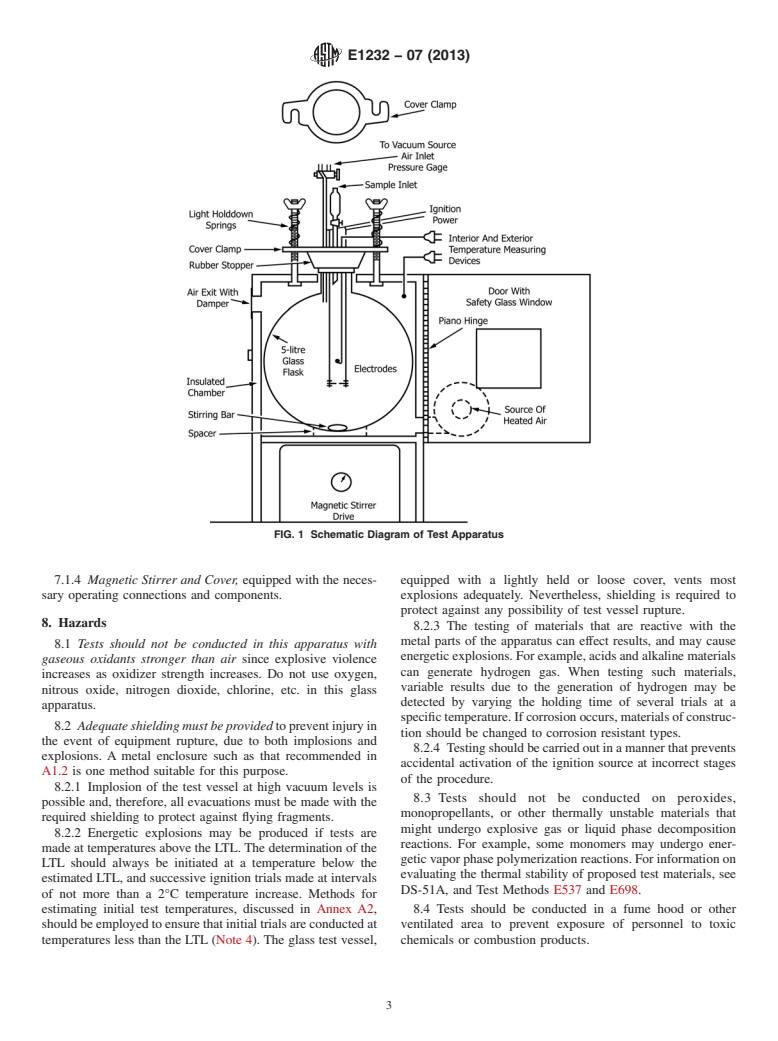

7.1 Fig. 1 is a schematic diagram of the apparatus; details

chemicals, particularly in closed process and storage vessels.

and dimensions are presented in Annex A1. The apparatus

consists of the following:

NOTE1—Asaresultofphysicalfactorsinherentinflashpointapparatus

7.1.1 Glass Test Vessel,

7.1.2 Insulated Chamber, equipped with a source of

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

controlled-temperature air,

4th Floor, New York, NY 10036, http://www.ansi.org.

7.1.3 Ignition Device, with an appropriate power supply,

Available from National Fire Protection Association (NFPA), 1 Batterymarch

Park, Quincy, MA 02169-7471, http://www.nfpa.org. and

E1232 − 07 (2013)

FIG. 1 Schematic Diagram of Test Apparatus

7.1.4 Magnetic Stirrer and Cover, equipped with the neces- equipped with a lightly held or loose cover, vents most

sary operating connections and components. explosions adequately. Nevertheless, shielding is required to

protect against any possibility of test vessel rupture.

8. Hazards

8.2.3 The testing of materials that are reactive with the

metal parts of the apparatus can effect results, and may cause

8.1 Tests should not be conducted in this apparatus with

energeticexplosions.Forexample,acidsandalkalinematerials

gaseous oxidants stronger than air since explosive violence

can generate hydrogen gas. When testing such materials,

increases as oxidizer strength increases. Do not use oxygen,

variable results due to the generation of hydrogen may be

nitrous oxide, nitrogen dioxide, chlorine, etc. in this glass

detected by varying the holding time of several trials at a

apparatus.

specifictemperature.Ifcorrosionoccurs,materialsofconstruc-

8.2 Adequateshieldingmustbeprovidedtopreventinjuryin

tion should be changed to corrosion resistant types.

the event of equipment rupture, due to both implosions and

8.2.4 Testingshouldbecarriedoutinamannerthatprevents

explosions. A metal enclosure such as that recommended in

accidental activation of the ignition source at incorrect stages

A1.2 is one method suitable for this purpose.

of the procedure.

8.2.1 Implosion of the test vessel at high vacuum levels is

8.3 Tests should not be conducted on peroxides,

possible and, therefore, all evacuations must be made with the

monopropellants, or other thermally unstable materials that

required shielding to protect against flying fragments.

might undergo explosive gas or liquid phase decomposition

8.2.2 Energetic explosions may be produced if tests are

reactions. For example, some monomers may undergo ener-

made at temperatures above the LTL. The determination of the

geticvaporphasepolymerizationreactions.Forinformationon

LTL should always be initiated at a temperature below the

evaluating the thermal stability of proposed test materials, see

estimated LTL, and successive ignition trials made at intervals

DS-51A, and Test Methods E537 and E698.

of not more than a 2°C temperature increase. Methods for

estimating initial test temperatures, discussed in Annex A2, 8.4 Tests should be conducted in a fume hood or other

shouldbeemployedtoensurethatinitialtrialsareconductedat ventilated area to prevent exposure of personnel to toxic

temperatures less than the LTL (Note 4). The glass test vessel, chemicals or combustion products.

E1232 − 07 (2013)

NOTE 6—If mixing is inadequate, vapor concentrations can vary

8.5 Precautions must be taken to ensure that the high

throughout the flask, and inconsistent results will be obtained. Some

voltage spark ignition source is always adequately insulated

regions may contain insufficient fuel to propagate a flame at temperatures

from other electrical circuits and metal parts of the apparatus,

above the true equilibrium flammable limit temperature.

fume hood, etc. to prevent electrical hazards to personnel and

10.2.5 Turn off the stirrer.

instrumentation. Careful attention to electrical insulation integ-

10.2.6 Record the test temperature and system pressure

rity plus the use of disconnection procedures are required to

(usually barometric pressure unless system is being operated at

achieve a satisfactory protection against electrical hazards.

sub-ambient pressure).

10.2.7 Disconnect instrumentation lines as required and

9. Calibration

connect the ignition wires.

9.1 System temperature and pressure and barometric pres-

10.2.8 Check for liquid condensation or mist in the vapor

sure measuring devices must be calibrated against adequate

regions of the flask. Heat, insulate, or both, to prevent

standards.Forinformationoncalibrationofthermocouples,see

condensation and then repeat the test (10.3).

Test Method E220, Specification E230, and ANSI-MC96.1.

The pressure sensing devices should be calibrated

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.