ASTM F476-84(2002)

(Test Method)Standard Test Methods for Security of Swinging Door Assemblies (Withdrawn 2011)

Standard Test Methods for Security of Swinging Door Assemblies (Withdrawn 2011)

SIGNIFICANCE AND USE

Crime statistics show that the majority of all burglary attacks are on residential property. These test methods are, therefore, designed to aid in identifying a level of physical restraint, by swinging door assemblies, that will help reduce this large increment of crime.

These test methods are not intended to provide a measure of resistance for a door assembly subjected to attacks by skilled burglars on high pay-off targets. These attacks and targets require higher level, more sophisticated resistance, which usually includes alarms, communication, and apprehension systems.

The wall assembly described in 7.3 is considered suitable for the scope of these test methods. Wall construction that differs in dynamic response from that described in 6.3 may require testing in accordance with Section 11.

The primary purpose of this standard is to provide detailed test methods. Acceptance criteria for performance levels are considered a matter for authorities having jurisdiction. Some potential guidelines may be found in Annex A1.

SCOPE

1.1 These test methods cover door assemblies of various materials and types of construction for use in wall openings to deter unwanted intruders.

1.2 Door assemblies, covered by these test methods, also include individual components such as the hinge, lock, door, jamb/strike, and jamb/wall.

1.3 These test methods are designed to measure the capability of a swinging door assembly to restrain or delay and to frustrate the commission of "break-in" crimes.

1.4 These test methods apply primarily to typical entry door assemblies in single- and multi-family residential housing.

1.5 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

Rationale

Formerly under the jurisdiction of Committee F12 on Security Systems and Equipment, these test methods were withdrawn in July 2011 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F476–84(Reapproved2002)

Standard Test Methods for

Security of Swinging Door Assemblies

ThisstandardisissuedunderthefixeddesignationF476;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.3 component—as distinguished from a part, a subassem-

bly that combines with other components to make up a total

1.1 These test methods cover door assemblies of various

door assembly. The prime components of a door assembly

materials and types of construction for use in wall openings to

include: door, lock, hinges, jamb/wall, jamb/strike, and wall.

deter unwanted intruders.

3.4 cylinder—the cylindrical subassembly of a lock, con-

1.2 Door assemblies, covered by these test methods, also

taining the cylinder core, tumbler mechanism, and the keyway.

include individual components such as the hinge, lock, door,

A double-cylinder lock is one which has a key-actuated

jamb/strike, and jamb/wall.

cylinder on both the exterior and interior of the door.

1.3 These test methods are designed to measure the capa-

3.5 cylinder core (or cylinder plug)—the central part of a

bility of a swinging door assembly to restrain or delay and to

cylinder, containing the keyway, which is rotated by the key to

frustrate the commission of “break-in” crimes.

operate the lock mechanism.

1.4 These test methods apply primarily to typical entry door

3.6 deadbolt—a lock bolt that does not have a spring action

assemblies in single- and multi-family residential housing.

as opposed to a latch bolt that does. The bolt must be actuated

1.5 This standard does not purport to address all of the

by a key or a knob, or both, or thumb turn, and when projected

safety concerns, if any, associated with its use. It is the

becomes locked against return by end pressure.

responsibility of the user of this standard to establish appro-

3.7 dead latch (or dead locking latch bolt)—a spring-

priate safety and health practices and determine the applica-

actuated latch bolt having a beveled end and incorporating a

bility of regulatory limitations prior to use.

plunger which, when depressed, automatically locks the pro-

2. Referenced Documents

jected latch bolt against return by end pressure.

3.8 door assembly—a unit composed of a group of parts or

2.1 ASTM Standards:

components that make up a closure for a passageway through

F471 Terminology Relating to Combination Locks

a wall. For the purposes of these test methods, a door assembly

3. Terminology Definitions

consists of the following parts: door, hinges, locking device or

devices, operation contacts (such as handles, knobs, push

3.1 bolt—a metal bar which, when actuated, is projected (or

plates), miscellaneous hardware and closures, the frame, in-

thrown) either horizontally or vertically into a retaining mem-

cluding the head and jambs plus the anchorage devices to the

ber, such as a strike plate, to impede a door from moving or

surrounding wall, and a portion of the surrounding wall

opening.

extending900mm(36in.)fromeachsideofthejambsand400

3.2 bolt projection (or bolt throw)—the distance from the

mm (16 in.) above the head.

edge of the door, at the bolt center line, to the farthest point on

3.9 jamb—the vertical members of a door frame (such as,

the bolt in the projected position, when subjected to end

those fixed members to which the door is secured).

pressure.

3.10 jamb/strike—that component of a door assembly

which receives and holds securely the extended lock bolt. The

This method is under the jurisdiction of ASTM Committee F12 on Security

strike and jamb, used together, are considered a unit.

Systems and Equipment and is the direct responsibility of Subcommittee F12.50 on

3.11 jamb/wall—that component of a door assembly to

Locking Devices.

Current edition approved March 10, 2002. Published July 1984. Originally which a door is attached and secured. The wall and jamb, used

published as F476 – 76. Last previous edition F476 – 76. DOI: 10.1520/F0476-

together, are considered a unit.

84R02.

3.12 key-in-knob—a lockset having the key cylinder and

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

other lock mechanisms, such as a push or turn button,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on contained in the knobs.

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F476–84 (2002)

3.13 latch (or latch bolt)—a beveled, spring-actuated bolt, 5.1.3 Vertical Impactor—The vertical pendulum system

that may or may not have a dead locking device. shall employ a steel weight and be capable of delivering

3.14 lock (or lockset)—a keyed device (complete with vertical (downward) impacts of up to 100 J (74 ft·lbf) to a door

cylinder,latchordeadboltmechanism,andtrimsuchasknobs, knob installed in a door assembly.

levers, thumb turns, escutcheons, etc.) for securing a door in a 5.1.4 Torque Applicator—The portable torque applicator

closed position against forced entry. For the purposes of this shall be capable of delivering and measuring up to 160 N·m

standard, a lock does not include the strike plate. (118 lbf·ft) of torque to both door knobs and lock cylinders.

3.15 lock front—the outer plate through which the locking The torque loading adapters shall be designed to grip the knobs

bolt projects and which is usually flush with the edge of the and cylinders.

door. 5.1.5 Tension Loading Device—The tension loading device

3.16 part—as distinguished from component, a unit (or shall be capable of delivering and measuring tensile forces of

subassembly) that combines with other units to make up a up to 18 kN (4000 lbf).

component. 5.1.6 Compression Loading Device—The compression

3.17 strike—a metal plate attached to, or mortised into a loading device shall be capable of delivering and measuring

door jamb to receive and to hold a projected latch bolt or dead compressive forces of up to 900 N (200 lbf).

bolt, or both, in order to secure the door to the jamb. 5.1.7 Jamb Spreading Device—The jamb spreading device

3.18 swinging door—a stile (side)-hinged door. shall be capable of delivering to door jambs and measuring

3.19 Type A lock—a lock that uses a single bolt, or separate spreading forces of up to 22 kN (4950 lbf) with a means of

latch and lock bolts that are mechanically interconnected. measuring up to 13 mm ( ⁄2 in.) of increase in lock-front to

3.20 Type B lock—a lock in which the latch bolt is mechani- strike distance. The device shall have on each end either a load

cally independent from the lock bolt. bearing plate or pressure foot that provides a minimum contact

3.21 For definitions of other terms used in these test surface of 40 by 120 mm (1 ⁄2 by 5 in.).

methods, refer to Terminology F471. 5.1.8 Instrument Accuracy—The tension loading and jamb

spreading devices shall have a combined calibration and

4. Significance and Use

reading error no greater than 200 N (45 lbf). The compression

4.1 Crime statistics show that the majority of all burglary

loading device shall have a combined calibration and reading

attacks are on residential property. These test methods are,

error of no greater than 40 N (9 lbf). The torquemeter shall

therefore, designed to aid in identifying a level of physical

have a combined error no greater than 3.4N·m (2.5 lbf·ft).

restraint, by swinging door assemblies, that will help reduce

The impact energy of each pendulum system shall be con-

this large increment of crime.

trolled to within 61%.

4.2 These test methods are not intended to provide a

6. Construction and Size

measure of resistance for a door assembly subjected to attacks

6.1 The construction and size of the test door assemblies,

by skilled burglars on high pay-off targets. These attacks and

consistingofsingledoors,doorsinpairs,special-purposedoors

targets require higher level, more sophisticated resistance,

(such as Dutch doors), jambs and headers, and all hardware

which usually includes alarms, communication, and apprehen-

components shall be representative of the classification or

sion systems.

rating that is desired.

4.3 The wall assembly described in 7.3 is considered

6.2 The door assembly support fixture shall simulate the

suitable for the scope of these test methods. Wall construction

rigidity normally provided to a door assembly in a building by

that differs in dynamic response from that described in 6.3 may

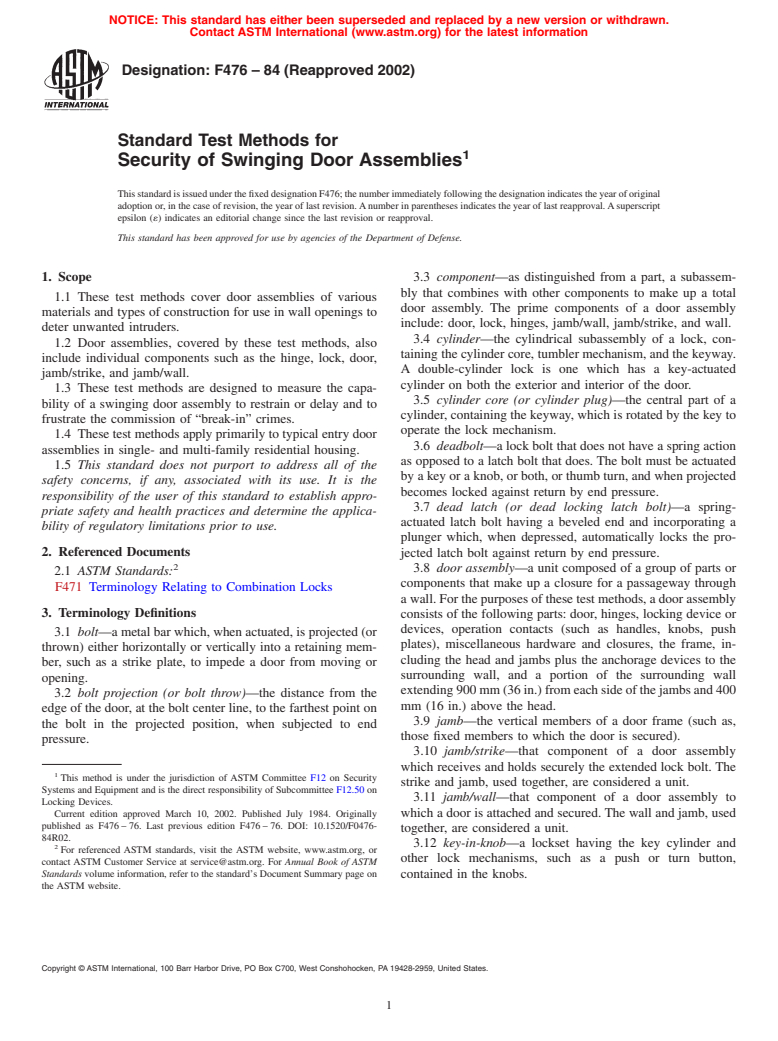

the ceiling, floor and walls. Fig. 1 shows an acceptable fixture.

require testing in accordance with Section 11.

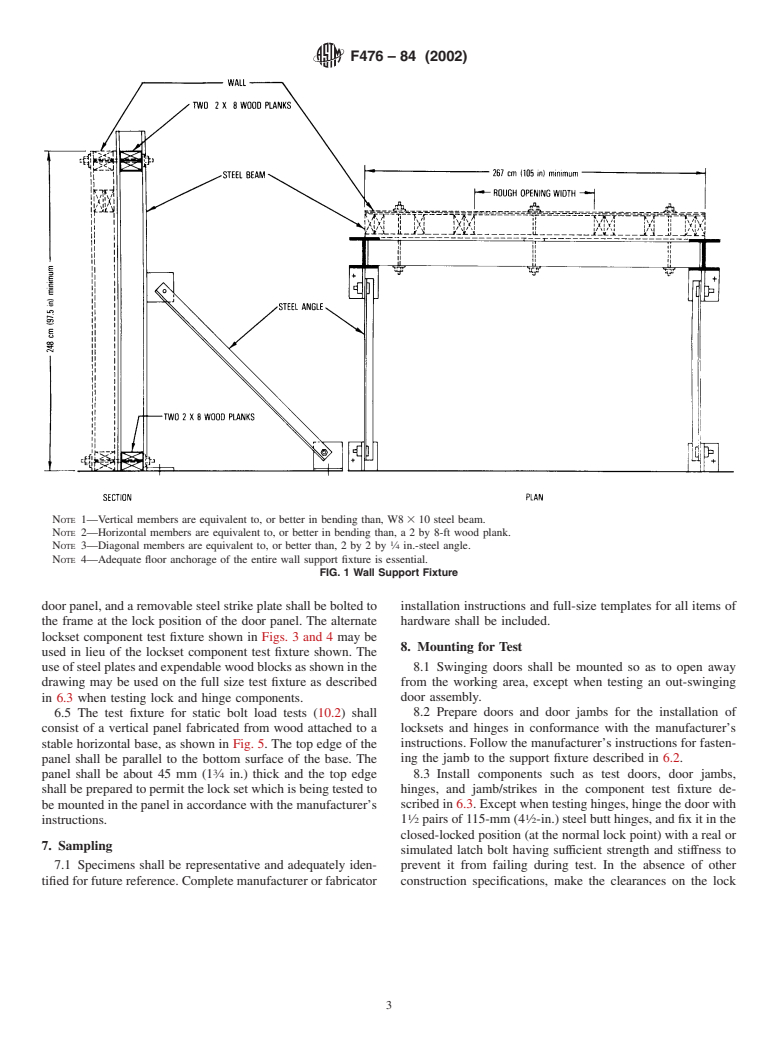

6.3 The test fixture for door, door jamb, hinge, lock, strike,

4.4 The primary purpose of this standard is to provide

and other components shall consist of a vertical wall section

detailed test methods. Acceptance criteria for performance

levels are considered a matter for authorities having jurisdic- constructedfrom2by4woodstuds,410mm(16in.)oncenter,

with a rough entry door opening, and shall be covered with

tion. Some potential guidelines may be found in Annex A1.

13-mm ( ⁄2-in.) exterior grade plywood sheathing on the

5. Apparatus 1

exterior and ⁄2-in. gypsum board on the interior. It shall be

5.1 Adetailed description of test equipment suitable for this constructed as shown in Fig. 2 and shall be secured to the wall

standard can be found in Appendix X1. In summary, the support fixture (at the sides and top) and to the laboratory floor.

equipment consists of the following: For tests of door, lock, strike, and hinge components, the

5.1.1 Door Ram—Thedoorramshallbeapendulumsystem fixture wall section shall also include a door jamb.

with a steel weight capable of delivering horizontal impacts of 6.4 The alternative test fixture for lockset components shall

up to 200 J (148 ft·lbf). The striking end of the weight shall be consist of a small door assembly, as shown in Figs. 3 and 4.

hemispherical and have a diameter of approximately 150 mm The frame shall be fabricated from steel angle and plate at least

(6 in.). 5mm( ⁄16 in.) thick. The test panel shall be 600 mm (24 in.)

5.1.2 Component Ram—The component ram shall be a square and 45 mm (1 ⁄4 in.) thick, made by bonding three

pendulum system with a steel weight capable of delivering pieces of plywood together or by cutting a section from a

horizontal impacts of up to 100 J (74 ft·lbf). The striking end 45-mm (1 ⁄4-in.) solid wood core door (such as, glued block

of the weight shall have an impact nose approximately 32 mm core construction NWMA IS-1). A50 by 50 by 3-mm (2 by 2

1 1

(1 ⁄4 in.) in diameter. by ⁄8-in.) steel angle shall be bolted to the hinge edge of the

F476–84 (2002)

NOTE 1—Vertical members are equivalent to, or better in bending than, W8 3 10 steel beam.

NOTE 2—Horizontal members are equivalent to, or better in bending than,a2by 8-ft wood plank.

NOTE 3—Diagonal members are equivalent to, or better than, 2 by 2 by ⁄4 in.-steel angle.

NOTE 4—Adequate floor anchorage of the entire wall support fixture is essential.

FIG. 1 Wall Support Fixture

door panel, and a removable steel strike plate shall be bolted to installation instructions and full-size templates for all items of

the frame at the lock position of the door panel. The alternate hardware shall be included.

lockset component test fixture shown in Figs. 3 and 4 may be

8. Mounting for Test

used in lieu of the lockset component test fixture shown. The

use of steel plates and expendable wood blocks as shown in the 8.1 Swinging doors shall be mounted so as to open away

from the working area, except when testing an out-swinging

drawing may be used on the full size test fixture as described

in 6.3 when testing lock and hinge components. door assembly.

8.2 Prepare doors and door jambs for the installation of

6.5 The test fixture for static bolt load tests (10.2) shall

consist of a vertical panel fabricated from wood attached to a locksets and hinges in conformance with the manufacturer’s

instructions. Follow the manufacturer’s instructions for fasten-

stable horizontal base, as shown in Fig. 5. The top edge of the

panel shall be parallel to the bottom surface of the base. The ing the jamb to the support fixture described in 6.2.

8.3 Install components such as test doors, door jambs,

panel shall be about 45 mm (1 ⁄4 in.) thick and the top edge

shall be prepared to permit the lock set which is being tested to hinges, and jamb/strikes in the component test fixture de-

scribed in 6.3. Except when testing hinges, hinge the door with

be mounted in the panel in accordance with the manufacturer’s

1 1

instructions. 1 ⁄2 pairs of 115-mm (4 ⁄2-in.) steel butt hinges, and fix it in the

closed-locked position (at the normal lock point) with a real or

7. Sampling

simulated latch bolt having sufficient strength and stiffness to

7.1 Specimens shall be representative and adequately iden- prevent it from failing during test. In the absence of other

tified for future reference. Complete manufacturer or fabricator construction specifications, make the clearances on the lock

F476–84 (2002)

NOTE 1—All studs, plates and headers are 2-by-4s.

NOTE 2—Nail sole plate and lower member of top plate to each stud with 2—16d end nails.

NOTE 3—Nail upper member of top plate to the lower member with 16d nails, one nail near each stud and two near each end.

NOTE 4—Nail the double studs together with 16d nails not more than 610 mm (24 in.) on centers.

NOTE 5—Nail the header (two 2-by-4s) to each full length stud with 4—16d end nails.

NOTE 6—Nail ⁄2 in. plywood sheathing to plates and studs with 6d nails at 150 mm (6 in.) on centers around the perimeter and at 300 mm (12 in.)

on centers along intermediate supports.

NOTE 7—Nail ⁄2-in. gypsum drywall to all supports with threaded drywall nails at 200 mm (8 in.) on centers.

NOTE 8—Security blocking may be necessary to achieve successful jamb/wall stiffness test results. If blocking is used, it shall be reported in the test

report. The nature of the blocking shall be indicated.

FIG. 2 Door, Door Jamb, Hinge, and Lock Strike Component Fixture

1 1

side, hinge side, and top of the door 3.2 6 0.4 mm ( ⁄8 6 ⁄64 spacer, and hold it in that position with a piece of tape, or by

in.). Clearance at the threshold is not considered critical in another suitable means.

these tests.

10.2 Place the lock, in the test fixture, in a compression

8.4 To test locksets as

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.