ASTM F1864-21

(Test Method)Standard Test Method for Dust Erosion Resistance of Optical and Infrared Transparent Materials and Coatings

Standard Test Method for Dust Erosion Resistance of Optical and Infrared Transparent Materials and Coatings

SIGNIFICANCE AND USE

5.1 All materials on exterior aircraft surfaces are subject to abrasion from airborne particles of various sizes and shapes. Transparent materials are particularly vulnerable to abrasion, since their performance is based on their ability to transmit light with a minimal amount of scatter. Scratches, pitting, and coating removal and delamination as a result of abrasion may increase scatter, reduce transmission, and degrade the performance of transparent materials. Visually transparent materials are required for pilot and air crew enclosures, such as canopies, windshields, and viewpoints. Materials transparent in the IR region (8 to 12 μm) are required for tracking, targeting, and navigational instrumentation.

5.2 This test method is intended to provide a calibrated and repeatable means of determining the relative abrasion resistance of materials and coatings for optical and IR transparent materials and coatings. The test parameters for this test method can be directly related to dust cloud densities and velocities to which transparent materials are exposed in the field.

SCOPE

1.1 This test method covers the resistance of transparent plastics and coatings used in aerospace windscreens, canopies, and viewports to surface erosion as a result of dust impingement. This test method simulates flight through a defined particle cloud environment by means of independent control of particle size, velocity, impact angle, mass loading, and test duration.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1864 − 21

Standard Test Method for

Dust Erosion Resistance of Optical and Infrared Transparent

1

Materials and Coatings

This standard is issued under the fixed designation F1864; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

3.1 Definitions of Terms Specific to This Standard:

1.1 This test method covers the resistance of transparent

plastics and coatings used in aerospace windscreens, canopies,

3.1.1 mass loading, n—the mass of dust per unit of total

and viewports to surface erosion as a result of dust impinge-

exposed surface area (including the sample holder) that im-

ment. This test method simulates flight through a defined

pinges on the specimens.

particlecloudenvironmentbymeansofindependentcontrolof

3.1.2 mean IR transmission, n—for the purposes of this

particle size, velocity, impact angle, mass loading, and test

standard, the average percentage of light transmitted by a

duration.

material in the 8 to 12µm bandwidth.

1.2 This standard does not purport to address all of the

3.1.3 sweep time, n—the time required for one translation

safety concerns, if any, associated with its use. It is the

pass.

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter- 3.1.4 translation pass, n—the translation of the specimen

mine the applicability of regulatory limitations prior to use. platformfromtheverticalorhorizontallimittothecorrespond-

1.3 This international standard was developed in accor- ing vertical or horizontal limit.

dance with internationally recognized principles on standard-

3.1.5 translation cycle, n—the translation of the specimen

ization established in the Decision on Principles for the

platformfromtheverticalorhorizontallimittothecorrespond-

Development of International Standards, Guides and Recom-

ingverticalorhorizontallimitandbacktotheinitialverticalor

mendations issued by the World Trade Organization Technical

horizontal limit. Two translation passes are equivalent to one

Barriers to Trade (TBT) Committee.

translation cycle.

3.2 Symbols:

2. Referenced Documents

2

2.1 ASTM Standards:

2

A = reference surface area of specimen platform (cm ),

D618Practice for Conditioning Plastics for Testing

s

3

C = simulated cloud concentration (g/m ),

D1003Test Method for Haze and Luminous Transmittance

c

h = percent haze before exposure,

of Transparent Plastics o

h = percent haze after exposure,

D1193Specification for Reagent Water e

m˙ = rate of particle mass impacting the reference surface

p

E11Specification forWovenWireTest Sieve Cloth andTest

area (g/min),

Sieves

2

m˙ = incremental mass loading (g/cm ),

i

E168Practices for General Techniques of Infrared Quanti-

2

m = total mass loading (g/cm ),

T

tative Analysis

N = number of increments,

V = particle impact velocity (m/s),

p

t = sweep time(s),

s

1

T = optical or mean infrared (IR) transmission after expo-

This test method is under the jurisdiction of ASTM Committee F07 on

e

Aerospace andAircraft and is the direct responsibility of Subcommittee F07.08 on

sure (%),

Transparent Enclosures and Materials.

T = optical or mean IR transmission before exposure (%),

o

Current edition approved May 1, 2021. Published May 2021. Originally

α = impact angle (normal incidence=90°),

approved in 1998. Last previous edition approved in 2016 as F1864–16. DOI:

∆t = exposure time (min) for loading increment i,

10.1520/F1864-21. i

2

2

φ = incremental dust load (g/cm ) for loading increment i,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

i

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

Standards volume information, refer to the standard’s Document Summary page on

Φ = total dust load (g/cm ),

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

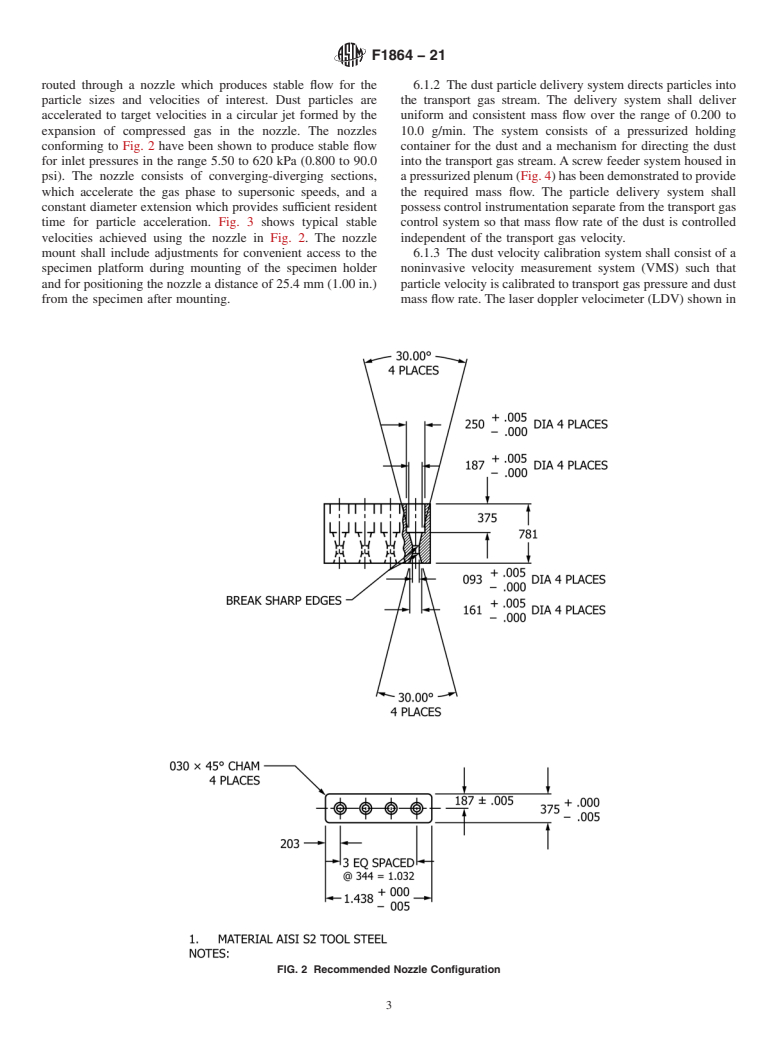

---------------------- Page: 1 ----------------------

F1864 − 21

coating removal and delamination as a result of abrasion may

∆h = change in percent haze, and

increase scatter, reduce transmission, and degrade the perfor-

∆T = change in optical or IR transmission.

mance of transparent materials. Visually transparent materials

4. Summary of Test Method

arerequiredforpilotandaircrewenclosures,suchascanopies,

windshields, and viewpoints. Materials transparent in the IR

4.1 This test method consists of: (1) measuring and record-

region (8 to 1

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1864 − 16 F1864 − 21

Standard Test Method for

Dust Erosion Resistance of Optical and Infrared Transparent

1

Materials and Coatings

This standard is issued under the fixed designation F1864; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the resistance of transparent plastics and coatings used in aerospace windscreens, canopies, and

viewports to surface erosion as a result of dust impingement. This test method simulates flight through a defined particle cloud

environment by means of independent control of particle size, velocity, impact angle, mass loading, and test duration.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

D1003 Test Method for Haze and Luminous Transmittance of Transparent Plastics

D1193 Specification for Reagent Water

E11 Specification for Woven Wire Test Sieve Cloth and Test Sieves

E168 Practices for General Techniques of Infrared Quantitative Analysis

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 mass loading, n—the mass of dust per unit of total exposed surface area (including the sample holder) that impinges on the

specimens.

3.1.2 mean IR transmission, n—for the purposes of this standard, the average percentage of light transmitted by a material in the

8-8 to 12-μm12 μm bandwidth.

3.1.3 sweep time, n—the time required for one translation pass.

1

This test method is under the jurisdiction of ASTM Committee F07 on Aerospace and Aircraft and is the direct responsibility of Subcommittee F07.08 on Transparent

Enclosures and Materials.

Current edition approved April 1, 2016May 1, 2021. Published April 2016May 2021. Originally approved in 1998. Last previous edition approved in 20102016 as

F1864 – 05 (2010).F1864 – 16. DOI: 10.1520/F1864-16.10.1520/F1864-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

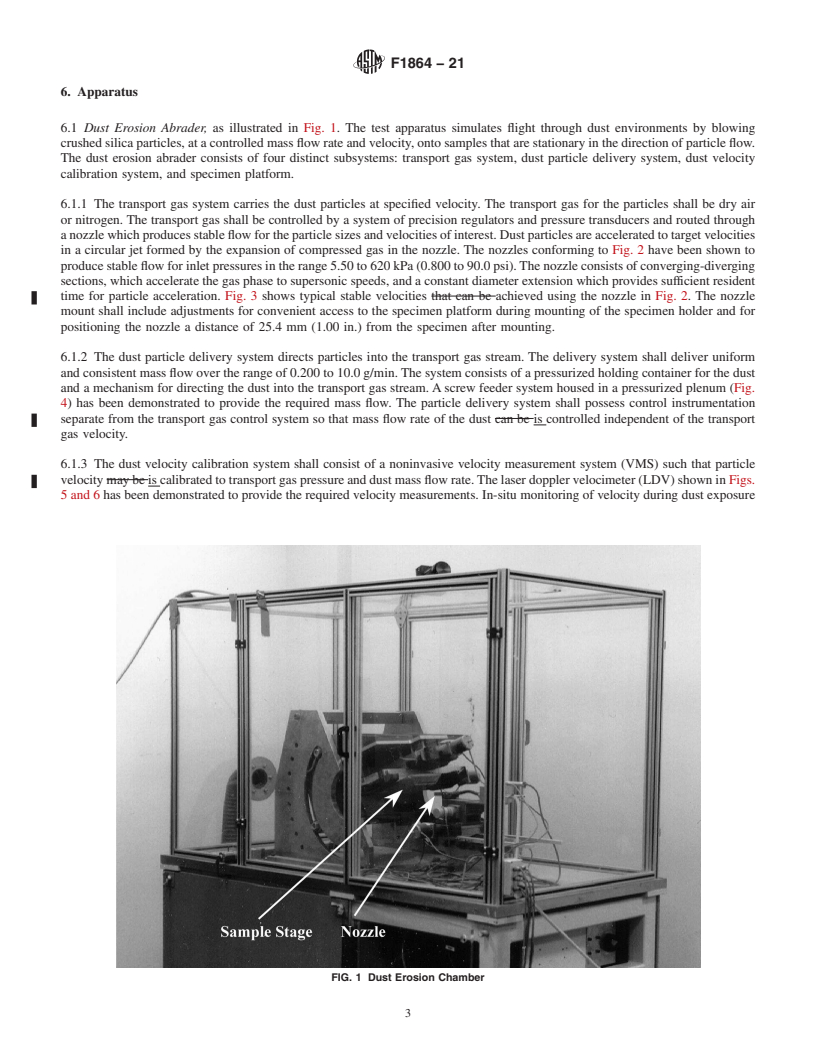

F1864 − 21

3.1.4 translation pass, n—the translation of the specimen platform from the vertical or horizontal limit to the corresponding

vertical or horizontal limit.

3.1.5 translation cycle, n—the translation of the specimen platform from the vertical or horizontal limit to the corresponding

vertical or horizontal limit and back to the initial vertical or horizontal limit. Two translation passes are equivalent to one

translation cycle.

3.2 Symbols:

2

A = reference surface area of specimen platform (cm ),

s

3

C = simulated cloud concentration (g/m ),

c

h = percent haze before exposure,

o

h = percent haze after exposure,

e

m˙ = rate of particle mass impacting the reference surface area (g/min),

p

2

m˙ = incremental mass loading (g/cm ),

i

2

m = total mass loading (g/cm ),

T

N = number of increments,

V = particle impact velocity (m/s),

p

t = sweep time(s),

s

T = optical or mean infrared (IR) transmission after exposure (%),

e

T = optical or mean IR transmission before exposure (%),

o

α = impact angle (normal incidence = 90°),

Δt = exposure time (min) for loading increment i,

i

2

φ = incremental dust load (g/cm ) for loading increment i,

i

2

Φ = total dust load (g/cm ),

Δh = change in percent haze, and

ΔT = change in optical or IR transmission.

4. Summary of Test Method

4.1 This test method consists of: (1) measuring and recording the light transmission properties, at visual or infrared wavelengths

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.