ASTM E1685-20

(Practice)Standard Practice for Measuring the Change in Length of Bolts Using the Ultrasonic Pulse-Echo Technique

Standard Practice for Measuring the Change in Length of Bolts Using the Ultrasonic Pulse-Echo Technique

SIGNIFICANCE AND USE

5.1 The techniques described provide for the measurement of change in length of a fastener. Such measurements are made from one end of the specimen without requiring access to the rear surface.

5.2 The Ultrasonic Pulse Echo technique is used to monitor changes in length of fasteners and as a tool for industrial quality control. Applications include fasteners used in turbines, petrochemical pressure vessels, aircraft, automotive manufacturing, general bolting within the nuclear industry, structural steel connections, and laboratory testing.

SCOPE

1.1 This practice covers a procedure for measuring changes in length of threaded bolts using the ultrasonic pulse-echo technique.

1.2 This procedure is normally intended for metal bolting 6.3 mm or more in nominal diameter with effective length-to-diameter ratios of 2:1 or greater.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E1685 − 20

Standard Practice for

Measuring the Change in Length of Bolts Using the

1

Ultrasonic Pulse-Echo Technique

This standard is issued under the fixed designation E1685; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* Measurement Systems for Use on Solids (Withdrawn

3

2012)

1.1 This practice covers a procedure for measuring changes

in length of threaded bolts using the ultrasonic pulse-echo

3. Terminology

technique.

3.1 The definitions of calibration, extensometer system,

1.2 This procedure is normally intended for metal bolting

metrological traceability, reference standard, testing machine,

6.3 mm or more in nominal diameter with effective length-to-

and verification, in this practice are used as defined in

diameter ratios of 2:1 or greater.

Terminology E6.

1.3 The values stated in SI units are to be regarded as 3.2 The definitions of attenuation, couplant, echo, longitu-

standard. No other units of measurement are included in this dinal wave, pulse, pulse echo method, reference block,

standard. reflector, resolution, time-of-flight, transducer, and ultrasonic

are used as defined in Section I of Terminology E1316.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the 3.3 Definitions of Terms Specific to This Standard:

3.3.1 change in length [L], n—physical change in length of

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter- a threaded fastener due to a change in tension within the

fastener.

mine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accor-

3.3.2 effective length [L], n—the length of a bolt that is

dance with internationally recognized principles on standard-

responsive to stress, defined here as the bolt length between

ization established in the Decision on Principles for the

head and nut plus half the thickness of the head plus half the

Development of International Standards, Guides and Recom-

thickness of the nut.

mendations issued by the World Trade Organization Technical

3.3.3 pulse-echo bolt-measuring instrument—an assembly

Barriers to Trade (TBT) Committee.

of ultrasonic instruments designed specifically to measure

changes in the lengths of bolts. See Appendix X1.

2. Referenced Documents

3.3.4 reference length [L], n—the ultrasonic time-of-flight

2

2.1 ASTM Standards: in the test specimen multiplied by a reference propagation

E6 Terminology Relating to Methods of Mechanical Testing

velocity.

E111 Test Method for Young’s Modulus, Tangent Modulus, 3.3.4.1 Discussion—The reference propagation velocity is

and Chord Modulus

the velocity of propagation of the ultrasonic wavefront in a

E1316 Terminology for Nondestructive Examinations

calibration test block or in the bolts whose changes of length

E1544 Practice for Construction of a Stepped Block and Its

are being measured.

Use to Estimate Errors Produced by Speed-of-Sound

4. Summary of Practice

4.1 This practice describes a procedure for determining the

1 change in length of a threaded fastener due to a change in

This practice is under the jurisdiction ofASTM Committee E28 on Mechanical

Testing and is the direct responsibility of Subcommittee E28.13 on Residual Stress tension in the fastener. Measurements of the ultrasonic time-

Measurement.

of-flight are made before and after the fastener tension is

Current edition approved Oct. 1, 2020. Published December 2020. Originally

changed, and a calculation of the change in length is made

approved in 1995. Last previous edition approved in 2013 as E1685–13. DOI:

from the change in the time-of-flight.

10.1520/E1685-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

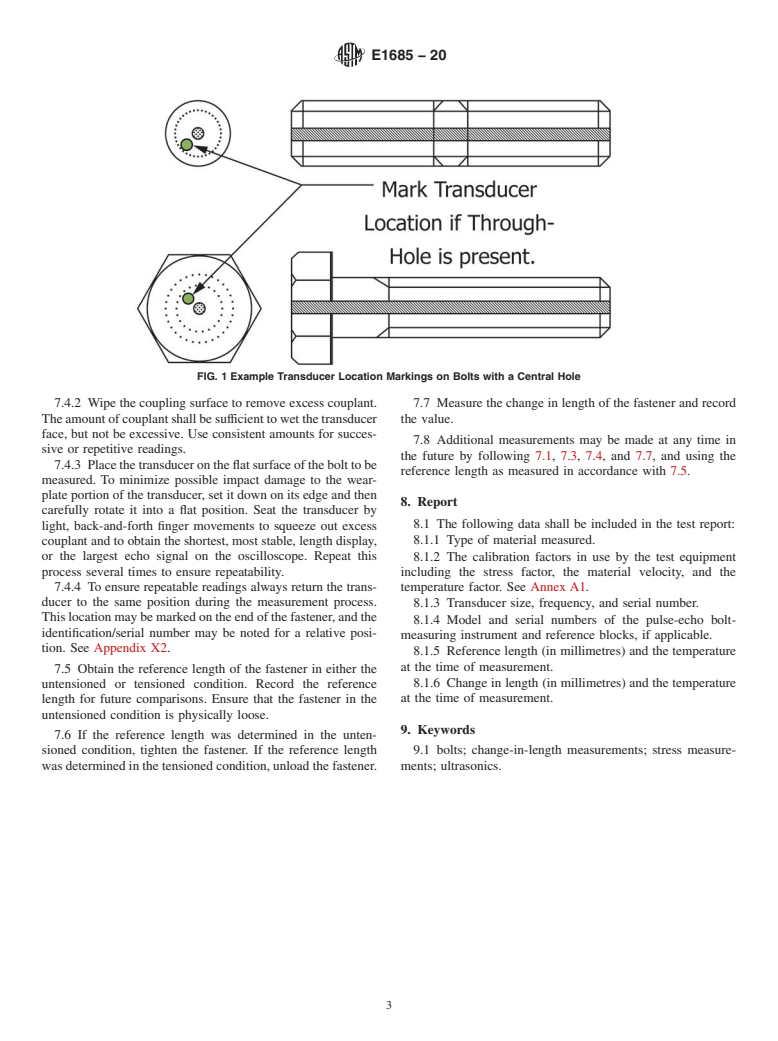

E1685 − 20

4.1.1 Brief bursts of ultrasound (pulses) are generated by 6.1.5.2 Conversely, the frequency should be low enough so

applying high-voltage

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E1685 − 13 E1685 − 20

Standard Practice for

Measuring the Change in Length of FastenersBolts Using

1

the Ultrasonic Pulse-Echo Technique

This standard is issued under the fixed designation E1685; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This practice covers a procedure for measuring changes in length of threaded fastenersbolts using conventional ultrasonic

pulse-echo bolt-measuring instrumentation which has been properly calibrated.the ultrasonic pulse-echo technique.

1.2 This procedure is normally intended for metal bolting 6.3 mm or more in nominal diameter with effective length-to-diameter

ratios of 2:1 or greater.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E6 Terminology Relating to Methods of Mechanical Testing

E111 Test Method for Young’s Modulus, Tangent Modulus, and Chord Modulus

E1316 Terminology for Nondestructive Examinations

E1544 Practice for Construction of a Stepped Block and Its Use to Estimate Errors Produced by Speed-of-Sound Measurement

3

Systems for Use on Solids (Withdrawn 2012)

4

2.2 ASME Standards:

ASME B46.1–2009 Surface Texture (Surface Roughness, Waviness, and Lay)

3. Terminology

3.1 The definitions of calibration, extensometer system, metrological traceability, reference standard, testing machine, and

verification, in this practice are in accordance with used as defined in Terminology E6 and Section I of Terminology E1316.

1

This practice is under the jurisdiction of ASTM Committee E28 on Mechanical Testing and is the direct responsibility of Subcommittee E28.13 on Residual Stress

Measurement.

Current edition approved Nov. 1, 2013Oct. 1, 2020. Published January 2014December 2020. Originally approved in 1995. Last previous edition approved in 20062013

as E1685–00(2006).E1685–13. DOI: 10.1520/E1685-13.10.1520/E1685-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E1685 − 20

3.2 The definitions of attenuation, couplant, echo, longitudinal wave, pulse, pulse echo method, reference block, reflector,

resolution, time-of-flight, transducer, and ultrasonic are used as defined in Section I of Terminology E1316.

3.3 Definitions of Terms Specific to This Standard:

3.3.1 change in length [L], n—physical change in length of a threaded fastener due to a change in tension within the fastener.

3.3.2 effective length [L], n—the length of a bolt that is responsive to stress. stress, defined here as the bolt length between head

and nut plus half the thickness of the head plus half the thickness of the nut.

3.2.2.1 Discussion—

This quantity lies somewhere between the overall length of the bolt and the grip length. It is usually estimated as the grip length

plus one half the thickness of the head and one half the thickness of the nut.

3.2.3 longitudinal wave, n—those waves in which the particle motion of the material is in the same direction as the wave

propagation.

3.3.3 pulse-echo bolt-measuring instrument—an assembly of ultrasonic instruments designed specifically to measure changes in

the lengths of bolts. See Appendix

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.