ASTM A255-02e1

(Test Method)Standard Test Methods for Determining Hardenability of Steel

Standard Test Methods for Determining Hardenability of Steel

SCOPE

1.1 These test methods cover the identification and description of test methods for determining the hardenability of steels. The two test methods include the quantitative end-quench or Jominy Test and a method for calculating the hardenability of steel from the chemical composition based on the original work by M. A. Grossman.

1.2 The selection of the test method to be used for determining the hardenability of a given steel shall be agreed upon between the supplier and user. The Certified Material Test Report shall state the method of hardenability determination.

1.3 The calculation method described in these test methods is applicable only to the range of chemical compositions that follow:ElementRange, %Carbon0.10-0.70Manganese0.50-1.65Silicon0.15-0.60Chromium1.35 maxNickel1.50 maxMolybdenum0.55 max

1.4 Hardenability is a measure of the depth to which steel will harden when quenched from its austenitizing temperature (). It is measured quantitatively, usually by noting the extent or depth of hardening of a standard size and shape of test specimen in a standardized quench. In the end-quench test the depth of hardening is the distance along the specimen from the quenched end which correlates to a given hardness level.

1.5 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation: A 255 – 02

Standard Test Methods for

1

Determining Hardenability of Steel

This standard is issued under the fixed designation A 255; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

e NOTE—Adjunct reference was corrected editorially in April 2006.

1. Scope* 2. Referenced Documents

2

1.1 These test methods cover the identification and descrip- 2.1 ASTM Standards:

tion of test methods for determining the hardenability of steels. E18 Test Methods for Rockwell Hardness and Rockwell

The two test methods include the quantitative end-quench or Superficial Hardness of Metallic Materials

Jominy Test and a method for calculating the hardenability of E112 Test Methods for Determining Average Grain Size

steelfromthechemicalcompositionbasedontheoriginalwork 2.2 ASTM Adjuncts:

3

by M. A. Grossman. ASTM Hardenability Chart

1.2 The selection of the test method to be used for deter-

END-QUENCH OR JOMINYTEST

mining the hardenability of a given steel shall be agreed upon

between the supplier and user. The Certified Material Test

3. Description

Report shall state the method of hardenability determination.

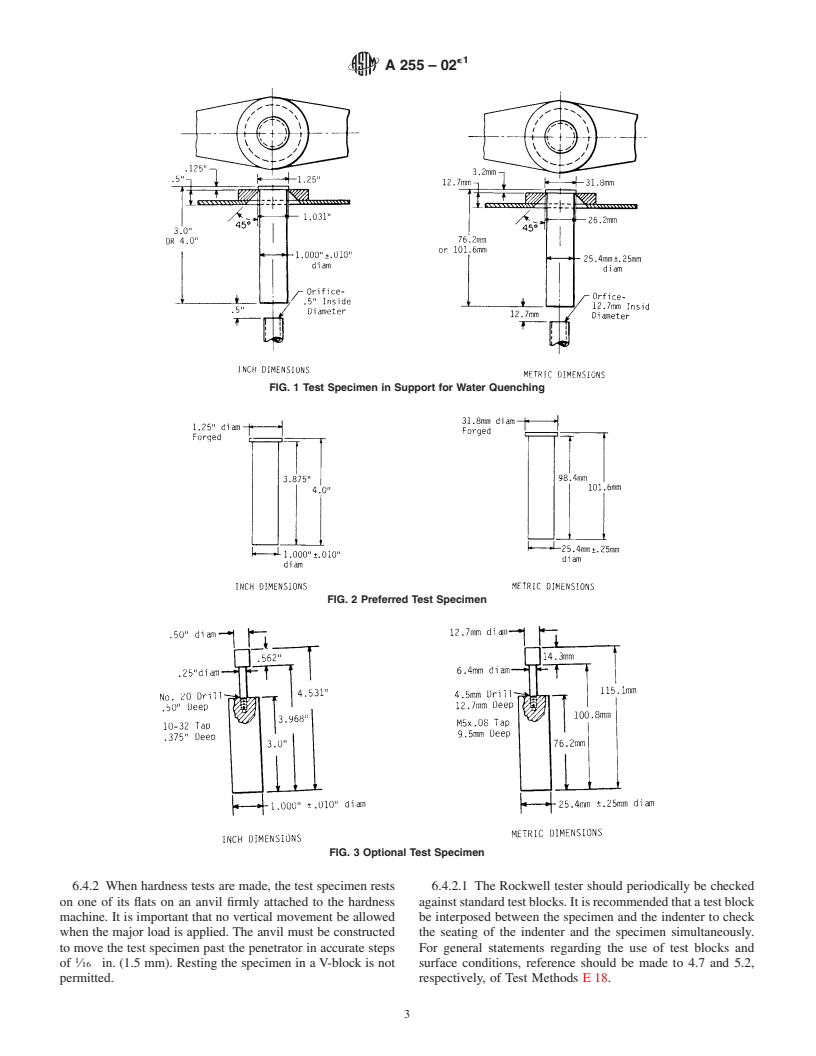

3.1 This test method covers the procedure for determining

1.3 The calculation method described in these test methods

thehardenabilityofsteelbytheend-quenchorJominytest.The

is applicable only to the range of chemical compositions that

test consists of water quenching one end of a cylindrical test

follow:

specimen 1.0 in. in diameter and measuring the hardening

Element Range, %

response as a function of the distance from the quenched end.

Carbon 0.10–0.70

Manganese 0.50–1.65

4. Apparatus

Silicon 0.15–0.60

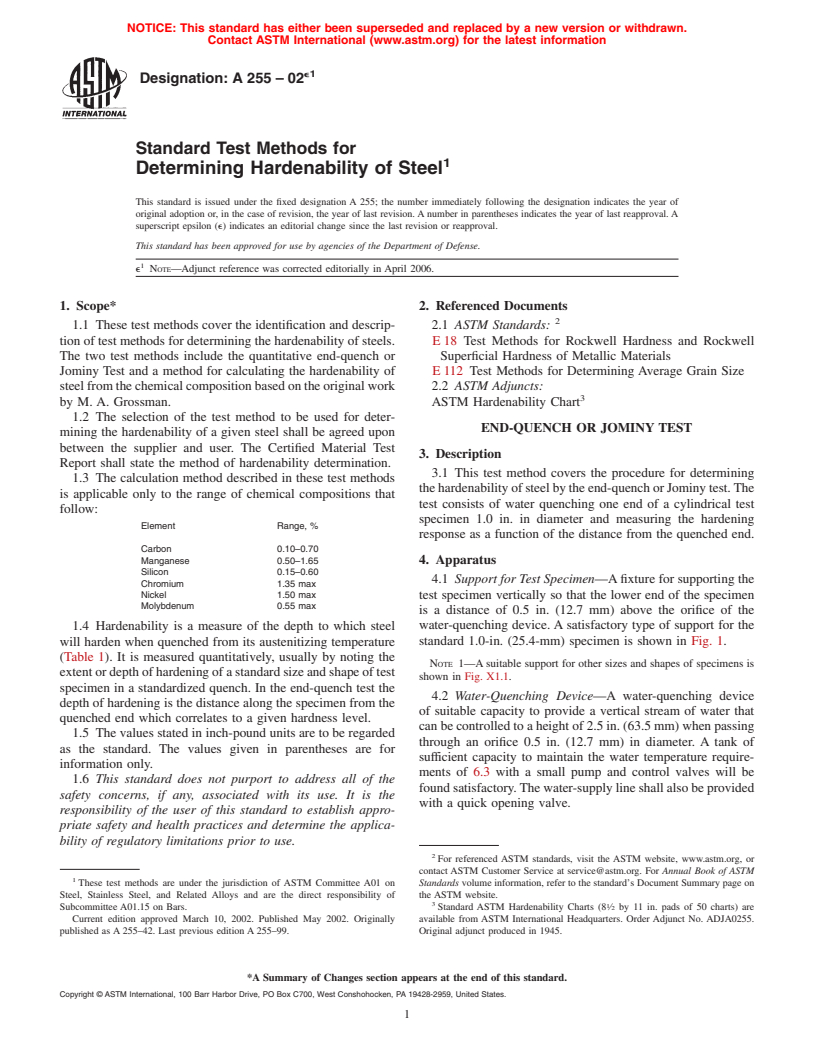

4.1 Support for Test Specimen—Afixture for supporting the

Chromium 1.35 max

Nickel 1.50 max

test specimen vertically so that the lower end of the specimen

Molybdenum 0.55 max

is a distance of 0.5 in. (12.7 mm) above the orifice of the

water-quenching device. A satisfactory type of support for the

1.4 Hardenability is a measure of the depth to which steel

standard 1.0-in. (25.4-mm) specimen is shown in Fig. 1.

will harden when quenched from its austenitizing temperature

(Table 1). It is measured quantitatively, usually by noting the

NOTE 1—Asuitable support for other sizes and shapes of specimens is

extentordepthofhardeningofastandardsizeandshapeoftest

shown in Fig. X1.1.

specimen in a standardized quench. In the end-quench test the

4.2 Water-Quenching Device—A water-quenching device

depth of hardening is the distance along the specimen from the

of suitable capacity to provide a vertical stream of water that

quenched end which correlates to a given hardness level.

canbecontrolledtoaheightof2.5in.(63.5mm)whenpassing

1.5 The values stated in inch-pound units are to be regarded

through an orifice 0.5 in. (12.7 mm) in diameter. A tank of

as the standard. The values given in parentheses are for

sufficient capacity to maintain the water temperature require-

information only.

ments of 6.3 with a small pump and control valves will be

1.6 This standard does not purport to address all of the

foundsatisfactory.Thewater-supplylineshallalsobeprovided

safety concerns, if any, associated with its use. It is the

with a quick opening valve.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

These test methods are under the jurisdiction of ASTM Committee A01 on Standards volume information, refer to the standard’s Document Summary page on

Steel, Stainless Steel, and Related Alloys and are the direct responsibility of the ASTM website.

3

1

Subcommittee A01.15 on Bars. Standard ASTM Hardenability Charts (8 ⁄2 by 11 in. pads of 50 charts) are

Current edition approved March 10, 2002. Published May 2002. Originally available from ASTM International Headquarters. Order Adjunct No. ADJA0255.

published as A 255–42. Last previous edition A 255–99. Original adjunct produced in 1945.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

e1

A 255–02

A

TABLE 1 Normalizing and Austenitizing Temperatures

results. It is important to heat the specimen in such an

Normalizing Austenitizing atmosphere that pract

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.