ASTM D1078-99

(Test Method)Standard Test Method for Distillation Range of Volatile Organic Liquids

Standard Test Method for Distillation Range of Volatile Organic Liquids

SCOPE

1.1 This test method covers the determination of the distillation range of liquids boiling between 30 and 350oC, that are chemically stable during the distillation process, by manual or automatic distillation procedures.

1.2 This test method is applicable to organic liquids such as hydrocarbons, oxygenated compounds, chemical intermediates, and blends thereof.

1.3 For hazard information and guidance, see the supplier's Material Safety Data Sheet.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 1078 – 99

Designation: 195/98

Standard Test Method for

Distillation Range of Volatile Organic Liquids

This standard is issued under the fixed designation D 1078; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope * sate leaves the condenser tube.

3.1.2 dry point—the temperature indicated at the instant the

1.1 This test method covers the determination of the distil-

last drop of liquid evaporates from the lowest point in the

lation range of liquids boiling between 30 and 350°C, that are

distillation flask, disregarding any liquid on the side of the

chemically stable during the distillation process, by manual or

flask.

automatic distillation procedures.

3.1.3 decomposition point—the thermometer reading that

1.2 This test method is applicable to organic liquids such as

coincides with the first indications of thermal decomposition of

hydrocarbons, oxygenated compounds, chemical intermedi-

the liquid in the flask.

ates, and blends thereof.

3.2 Definitions of Terms Specific to This Standard:

1.3 For hazard information and guidance, see the supplier’s

3.2.1 final boiling point—the maximum thermometer read-

Material Safety Data Sheet.

ing obtained during the test.

1.4 This standard does not purport to address all of the

3.2.1.1 Discussion—This usually occurs after the evapora-

safety concerns, if any, associated with its use. It is the

tion of all liquid from the bottom of the flask. The term

responsibility of the user of this standard to establish appro-

“maximum temperature” is a frequently used synonym.

priate safety and health practices and determine the applica-

3.2.2 end point 5 minutes—the thermometer reading ob-

bility of regulatory limitations prior to use. Specific hazard

tained 5 min after the 95 % distillation point if no dry or final

statements are given in Section 7.

boiling point occurs.

2. Referenced Documents

4. Summary of Test Method

2.1 ASTM Standards:

4.1 A 100-mL specimen is distilled under conditions equiva-

D 86 Test Method for Distillation of Petroleum Products at

lent to a simple batch differential distillation. The temperature

Atmospheric Pressure

of the mercury in the thermometer is equilibrated with that of

E 1 Specification for ASTM Thermometers

the refluxing liquid before the distillate is taken over. Boiling

E 133 Specification for Distillation Equipment

temperatures observed on a partial immersion thermometer are

E 299 Test Method for Trace Amounts of Peroxides in

corrected to standard atmospheric pressure to give true boiling

Organic Solvents

temperatures.

E 691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

5. Significance and Use

3. Terminology 5.1 This test method provides a method of measurement of

distillation range of volatile organic liquids. The relative

3.1 Definitions:

volatility of organic liquids can be used with other tests for

3.1.1 initial boiling point—the temperature indicated by the

identification and measurement of quality. Therefore, this test

distillation thermometer at the instant the first drop of conden-

method provides a test procedure for assessing compliance

with a specification.

This test method is under the jurisdiction of ASTM Committee D-1 on Paint

5.2 This test method also provides an empirical value of

and Related Coatings, Materials, and Applications and is the direct responsibility of

residue, solvent recovery capacity, and loss (or non-recovery)

Subcommittee D01.35 on Solvents, Plasticizers, and Chemical Intermediates.

on heating. Organic liquids are used as solvents in many

Current edition approved July 10, 1999. Published September 1999. Originally

published as D 1078 – 49 T. Last previous edition D 1078 – 97.

chemical processes. As the relative volatility, residual matter

Annual Book of ASTM Standards, Vol 05.01.

and recovery capability affect the efficiency of these processes,

Annual Book of ASTM Standards, Vol 14.03.

this test method is useful in manufacturing control.

Annual Book of ASTM Standards, Vol 14.02.

Annual Book of ASTM Standards, Vol 15.05.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 1078

6. Apparatus and accuracy as the appropriate and calibrated mercury-in-

glass thermometer. Confirmation of the calibration of these

6.1 Distillation Apparatus—See Condenser and Cooling

temperature sensors shall be done at regular intervals. This can

Bath section, Figs. 1 and Figs. 2, and Metal Shield or Enclosure

be accomplished potentiometrically by the use of standard

for Flask section of Specification E 133.

precision resistance, depending on the type of probe. Another

6.2 Distillation Flasks, 200-mL of borosilicate glass com-

technique is to distill pure toluene (99.9 + % purity) and

plying with the specifications given in Distillation Flask

compare the temperature indicated by the thermocouple or

section, Fig. 3, and Flask C of Specification E 133.

resistance thermometer with that shown by the mercury-in-

NOTE 1—Liquid superheating in a new flask may be prevented by

glass thermometer.

depositing a small amount of carbon in the bottom of the flask. This may

be accomplished by heating and decomposing a pinch of tartaric acid in NOTE 2—Toluene is shown in reference manuals as boiling at 110.6°C

the bottom of the flask. The flask is then prepared for use by washing with (corrected for barometric pressure) under the conditions of a manual

water, rinsing with acetone, and drying. D 1078 distillation that uses a partial immersion thermometer.

6.3 Source of Heat—An adjustable gas burner or electric

7. Hazards

heater so constructed that sufficient heat can be obtained to

7.1 Precaution—Certain solvents and chemical intermedi-

distill the product at the uniform rate specified in Section 8. For

ates, particularly, but not only ethers and unsaturated com-

narrow-range (less than 2°C) liquids, an electric heater may be

pounds, may form peroxides during storage. These peroxides

used only if it has been proven to give results comparable to

may present a violent explosion hazard when the chemical is

those obtained when using gas heat. (See Section 9 for factors

distilled, especially as the dry point is approached. When

that cause superheating, and Appendix X1 for a discussion on

peroxide formation is likely because of chemical type or length

the use of electric heaters.)

of storage, the material should be analyzed for peroxides (See

6.4 Distillation Receiver:

Test Method E 299.) and if they exist in hazardous concentra-

6.4.1 Manual Distillation Receiver—A 100-mL cylinder

tions, appropriate precautions should be taken such as destroy-

graduated in 1 mL subdivision and having an overall height of

ing the peroxide before distillation, shielding, or destroying the

250 to 260 mm.

sample and not running the test.

6.4.2 Automatic Distillation Receiver—A receiver to be

7.2 Most organic solvents and chemical intermediates will

used with automatic distillation in accordance with the instru-

burn. In the operation of the distillation apparatus, use a

ment manufacturer’s instructions, conforming to the dimen-

suitable catch pan and shielding to contain spilled liquid in the

sions given in 6.4.1, with the exception of the graduations.

event of accidental breakage of the distillation flask.

6.4.2.1 Automatic Distillation Level Follower—The level

7.3 Provide adequate ventilation to maintain solvent vapor

follower/recording mechanism of the automatic apparatus shall

concentrations below the lower explosive limit in the immedi-

have a resolution of 0.1 mL with an accuracy of 6 1 mL.

ate vicinity of the distillation apparatus, and below the thresh-

6.5 Temperature Measurement Devices:

old limit value in the general work area.

6.5.1 Manual Distillation Thermometers—Partial immer-

8. Preparation of Apparatus

sion thermometers as listed in Table 1, conforming to Specifi-

cation E 1. Both bore corrections and either ice or steam 8.1 Manual Distillation Apparatus:

standardization corrections are recommended. 8.1.1 Clean and dry the condenser tube by swabbing with a

piece of soft lint-free cloth attached to a wire or cord, or by any

6.5.2 Automatic Distillation Temperature Sensors—

Temperature measurement systems using thermocouples or other suitable means.

resistance thermometers shall exhibit the same temperature lag 8.1.2 Use the thermometer listed in the material specifica-

tion for the product under study. If no thermometer is specified,

select one from Table 1 with the smallest graduations that will

TABLE 1 Thermometers

cover the entire distillation range of the material. Center the

ASTM Sub-

thermometer into the neck of the flask through a tight-fitting

Thermometer IP Range, °C division,

cork stopper so that the upper end of the contraction chamber

Number °C

(or bulb if Thermometer 2C or IP thermometer 62C is used) is

A A

2C 62C −5 to + 300 1.0

A A B

3C 73C −5 to + 400 level with the lower side of the vapor tube at its junction with

14C . 38 to 82 0.1

the neck of the flask. (See Fig. 1 of Test Method D 86.)

37C 77C −2 to + 52 0.2

38C 78C 24 to 78 0.2

NOTE 3—It is far more important that the greatest volume of mercury

39C 79C 48 to 102 0.2

be immersed in the refluxing zone than that the immersion mark on the

40C 80C 72 to 126 0.2

thermometer be placed at any specific point.

41C 81C 98 to 152 0.2

A A

42C 82C 95 to 255 0.5

8.1.3 Position the correct heat shield (see 9.1.3.1 and

102C 83C 123 to 177 0.2

9.1.3.2).

103C 84C 148 to 202 0.2

104C 85C 173 to 227 0.2

NOTE 4—For low-boiling materials, cool the apparatus to room tem-

105C 86C 198 to 252 0.2

perature before starting the test.

106C 87C 223 to 277 0.2

107C 88C 248 to 302 0.2

8.1.4 Fill the condenser bath with water of the appropriate

A

These thermometers have more temperature lag than the other thermometers

temperature shown in Table 2.

listed herein and are not satisfactory for use with narrow-boiling range liquids.

B

1 to 301°C; 1.5°C above 301°C. NOTE 5—When distilling pure compounds always ensure that the

D 1078

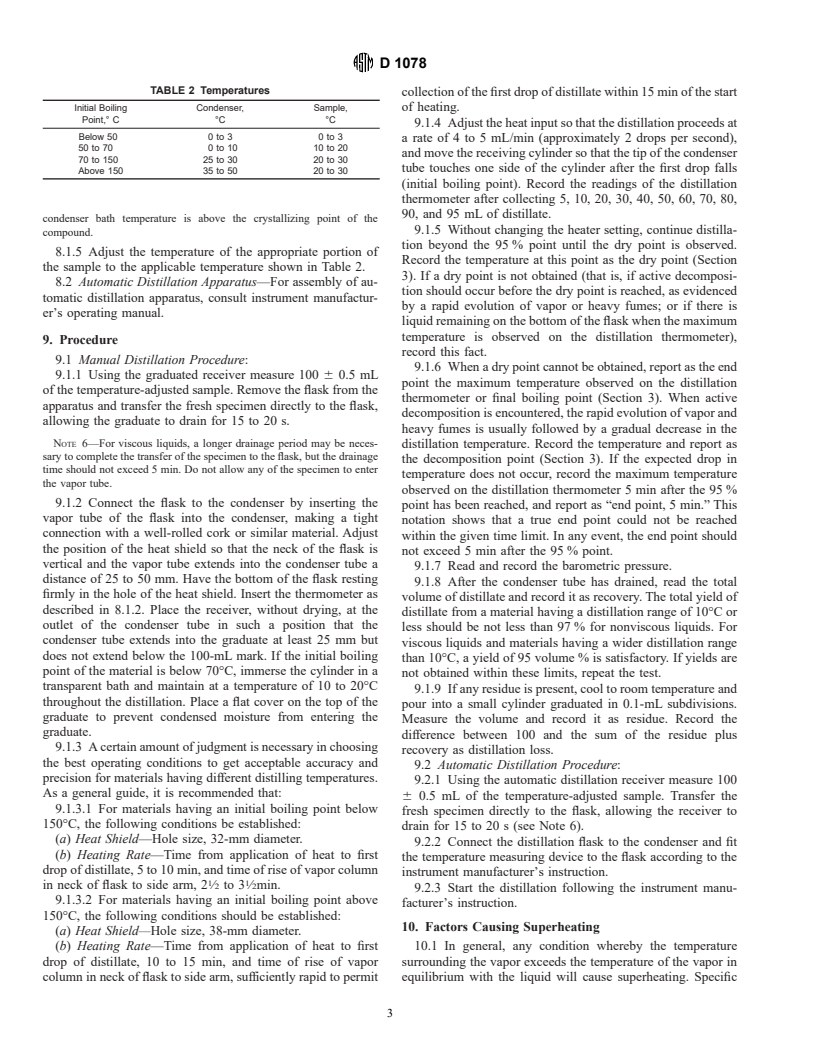

TABLE 2 Temperatures

collection of the first drop of distillate within 15 min of the start

Initial Boiling Condenser, Sample, of heating.

Point,° C °C °C

9.1.4 Adjust the heat input so that the distillation proceeds at

Below 50 0 to 3 0 to 3

a rate of 4 to 5 mL/min (approximately 2 drops per second),

50 to 70 0to10 10to20

and move the receiving cylinder so that the tip of the condenser

70 to 150 25 to 30 20 to 30

tube touches one side of the cylinder after the first drop falls

Above 150 35 to 50 20 to 30

(initial boiling point). Record the readings of the distillation

thermometer after collecting 5, 10, 20, 30, 40, 50, 60, 70, 80,

90, and 95 mL of distillate.

condenser bath temperature is above the crystallizing point of the

9.1.5 Without changing the heater setting, continue distilla-

compound.

tion beyond the 95 % point until the dry point is observed.

8.1.5 Adjust the temperature of the appropriate portion of

Record the temperature at this point as the dry point (Section

the sample to the applicable temperature shown in Table 2.

3). If a dry point is not obtained (that is, if active decomposi-

8.2 Automatic Distillation Apparatus—For assembly of au-

tion should occur before the dry point is reached, as evidenced

tomatic distillation apparatus, consult instrument manufactur-

by a rapid evolution of vapor or heavy fumes; or if there is

er’s operating manual.

liquid remaining on the bottom of the flask when the maximum

temperature is observed on the distillation thermometer),

9. Procedure

record this fact.

9.1 Manual Distillation Procedure:

9.1.6 When a dry point cannot be obtained, report as the end

9.1.1 Using the graduated receiver measure 100 6 0.5 mL

point the maximum temperature observed on the distillation

of the temperature-adjusted sample. Remove the flask from the

thermometer or final boiling point (Section 3). When active

apparatus and transfer the fresh specimen directly to the flask,

decomposition is encountered, the rapid evolution of vapor and

allowing the graduate to drain for 15 to 20 s.

heavy fumes is usually followed by a gradual decrease in the

NOTE 6—For viscous liquids, a longer drainage period may be neces- distillation temperature. Record the temperature and report as

sary to complete the transfer of the specimen to the flask, but the drainage

the decomposition point (Section 3). If the expected drop in

time should not exceed 5 min. Do not allow any of the specimen to enter

temperature does not occur, record the maximum temperature

the vapor tube.

observed on the distillation thermometer 5 min after the 95 %

9.1.2 Connect the flask to the condenser by inserting the

point has been reached, and report as “end point, 5 min.” This

vapor tube of the flask into the condenser, making a tight

notation shows that a true end point could not be reached

connection with a well-rolled cork or similar material. Adjust

within the given time limit. In any event, the end point should

the position of the heat shield so that the neck of the flask is

not exceed 5 min after the 95 % point.

vertical and the vapor tube extends into the condenser tube a

9.1.7 Read and record the barometric pressure.

distance of 25 to 50 mm. Have the bottom of the flask resting

9.1.8 After the condenser tube has drained, read the total

firmly in the hole of the heat shield. Insert the thermometer as

volume of distillate and record it as recovery. The total yield of

described in 8.1.2. Place the receiver, without drying, at the

distillate from a material having a distillation range of 10°C or

outlet of the condenser tube in such a position that the

less should be not less than 97 % for nonviscous liquids. For

condenser tube extends into the graduate at least 25 mm but

viscous liquids and materials having a wider distillation range

does not extend below the 100-mL mark. If the initial boiling

than 10°C, a yield of 95 volume % is satisfactory. If yields are

point of the material is below 70°C, immerse the cylinder in a

not obtained within these limits, repeat the test.

transparent bath and maintain at a temperature of 10 to 20°C

9.1.9 If any residue is present, cool to room temperature and

throughout the distillation. Place a flat cover on the top of the

pour into a small cylinder graduated in 0.1-mL subdivisions.

graduate to prevent condensed moisture from entering the

M

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.