ASTM D3043-17

(Test Method)Standard Test Methods for Structural Panels in Flexure

Standard Test Methods for Structural Panels in Flexure

SIGNIFICANCE AND USE

3.1 These methods give the flexural properties, principally strength and stiffness, of structural panels. These properties are of primary importance in most structural uses of panels whether in construction for floors, wall sheathing, roof decking, concrete form, or various space plane structures; packaging and materials handling for containers, crates, or pallets; or structural components such as stress-skin panels.

3.2 To control or define other variables influencing flexure properties, moisture content and time to failure must be determined. Conditioning of test material at controlled atmospheres to control test moisture content and determination of specific gravity are recommended. Comparisons of results of plywood, veneer composites, and laminates with solid wood or other plywood constructions will be greatly assisted if the thickness of the individual plies is measured to permit computation of section properties.

SCOPE

1.1 These test methods determine the flexural properties of strips cut from structural panels or panels up to 4 by 8 ft in size. Structural panels in use include plywood, waferboard, oriented strand board, and composites of veneer and of wood-based layers. Four methods of tests are included:

Sections

Method A—Center-Point Flexure Test

5

Method B—Two-Point Flexure Test

6

Method C—Large Panel Test

7

Method D—Flexure Test for Quality Assurance

8

The choice of method will be dictated by the purpose of the test, type of material, and equipment availability. All methods are applicable to material that is relatively uniform in strength and stiffness properties. Only Method C should be used to test material suspected of having strength or stiffness variations within a panel caused by density variations, knots, knot-holes, areas of distorted grain, fungal attack, or wide growth variations. However, Method B may be used to evaluate certain features such as core gaps and veneer joints in plywood panels where effects are readily projected to full panels. Method C generally is preferred where size of test material permits. Moments applied to fail specimens tested by Method A, B or D in which large deflections occur can be considerably larger than nominal. An approximate correction can be made.

1.2 Method A, Center-Point Flexure Test—This method is applicable to material that is uniform with respect to elastic and strength properties. Total deflection, and modulus of elasticity computed from it, include a relatively constant component attributable to shear deformation. It is well suited to investigations of many variables that influence properties uniformly throughout the panel in controlled studies and to test small, defect-free control specimens cut from large panels containing defects tested by the large-specimen method.

1.3 Method B, Two-Point Flexure Test—This method, like Method A, is suited to the investigation of factors that influence strength and elastic properties uniformly throughout the panel, in controlled studies, and to testing small, defect free control specimens cut from large specimens tested by Method C. However, it may be used to determine the effects of finger joints, veneer joints and gaps, and other features which can be placed entirely between the load points and whose effects can be projected readily to full panel width. Deflection and modulus of elasticity obtained from this method are related to flexural stress only and do not contain a shear component. Significant errors in modulus of rupture can occur when nominal moment is used (see Appendix X1).

1.4 Method C, Large Panel Test—This method is ideally suited for evaluating effects of knots, knot-holes, areas of sloping grain, and patches for their effect on standard full-size panels. It is equally well suited for testing uniform or clear material whenever specimen size is adequate. Specimen size and span above certain minimums are quite flexibl...

General Information

- Status

- Published

- Publication Date

- 14-Nov-2017

- Technical Committee

- D07 - Wood

- Drafting Committee

- D07.03 - Panel Products

- Current Stage

Relations

- Effective Date

- 15-Nov-2017

- Effective Date

- 01-Mar-2020

- Effective Date

- 01-Apr-2019

- Effective Date

- 01-Nov-2018

- Effective Date

- 15-Nov-2016

- Effective Date

- 01-Jun-2015

- Effective Date

- 01-May-2014

- Effective Date

- 01-May-2014

- Effective Date

- 01-Apr-2013

- Effective Date

- 15-Jul-2011

- Effective Date

- 15-Nov-2007

- Refers

ASTM D2395-07ae1 - Standard Test Methods for Specific Gravity of Wood and Wood-Based Materials - Effective Date

- 01-Jul-2007

- Effective Date

- 01-Jul-2007

- Effective Date

- 01-Apr-2007

- Effective Date

- 01-Oct-2006

ASTM D3043-17 - Standard Test Methods for Structural Panels in Flexure

REDLINE ASTM D3043-17 - Standard Test Methods for Structural Panels in Flexure

Frequently Asked Questions

ASTM D3043-17 is a standard published by ASTM International. Its full title is "Standard Test Methods for Structural Panels in Flexure". This standard covers: SIGNIFICANCE AND USE 3.1 These methods give the flexural properties, principally strength and stiffness, of structural panels. These properties are of primary importance in most structural uses of panels whether in construction for floors, wall sheathing, roof decking, concrete form, or various space plane structures; packaging and materials handling for containers, crates, or pallets; or structural components such as stress-skin panels. 3.2 To control or define other variables influencing flexure properties, moisture content and time to failure must be determined. Conditioning of test material at controlled atmospheres to control test moisture content and determination of specific gravity are recommended. Comparisons of results of plywood, veneer composites, and laminates with solid wood or other plywood constructions will be greatly assisted if the thickness of the individual plies is measured to permit computation of section properties. SCOPE 1.1 These test methods determine the flexural properties of strips cut from structural panels or panels up to 4 by 8 ft in size. Structural panels in use include plywood, waferboard, oriented strand board, and composites of veneer and of wood-based layers. Four methods of tests are included: Sections Method A—Center-Point Flexure Test 5 Method B—Two-Point Flexure Test 6 Method C—Large Panel Test 7 Method D—Flexure Test for Quality Assurance 8 The choice of method will be dictated by the purpose of the test, type of material, and equipment availability. All methods are applicable to material that is relatively uniform in strength and stiffness properties. Only Method C should be used to test material suspected of having strength or stiffness variations within a panel caused by density variations, knots, knot-holes, areas of distorted grain, fungal attack, or wide growth variations. However, Method B may be used to evaluate certain features such as core gaps and veneer joints in plywood panels where effects are readily projected to full panels. Method C generally is preferred where size of test material permits. Moments applied to fail specimens tested by Method A, B or D in which large deflections occur can be considerably larger than nominal. An approximate correction can be made. 1.2 Method A, Center-Point Flexure Test—This method is applicable to material that is uniform with respect to elastic and strength properties. Total deflection, and modulus of elasticity computed from it, include a relatively constant component attributable to shear deformation. It is well suited to investigations of many variables that influence properties uniformly throughout the panel in controlled studies and to test small, defect-free control specimens cut from large panels containing defects tested by the large-specimen method. 1.3 Method B, Two-Point Flexure Test—This method, like Method A, is suited to the investigation of factors that influence strength and elastic properties uniformly throughout the panel, in controlled studies, and to testing small, defect free control specimens cut from large specimens tested by Method C. However, it may be used to determine the effects of finger joints, veneer joints and gaps, and other features which can be placed entirely between the load points and whose effects can be projected readily to full panel width. Deflection and modulus of elasticity obtained from this method are related to flexural stress only and do not contain a shear component. Significant errors in modulus of rupture can occur when nominal moment is used (see Appendix X1). 1.4 Method C, Large Panel Test—This method is ideally suited for evaluating effects of knots, knot-holes, areas of sloping grain, and patches for their effect on standard full-size panels. It is equally well suited for testing uniform or clear material whenever specimen size is adequate. Specimen size and span above certain minimums are quite flexibl...

SIGNIFICANCE AND USE 3.1 These methods give the flexural properties, principally strength and stiffness, of structural panels. These properties are of primary importance in most structural uses of panels whether in construction for floors, wall sheathing, roof decking, concrete form, or various space plane structures; packaging and materials handling for containers, crates, or pallets; or structural components such as stress-skin panels. 3.2 To control or define other variables influencing flexure properties, moisture content and time to failure must be determined. Conditioning of test material at controlled atmospheres to control test moisture content and determination of specific gravity are recommended. Comparisons of results of plywood, veneer composites, and laminates with solid wood or other plywood constructions will be greatly assisted if the thickness of the individual plies is measured to permit computation of section properties. SCOPE 1.1 These test methods determine the flexural properties of strips cut from structural panels or panels up to 4 by 8 ft in size. Structural panels in use include plywood, waferboard, oriented strand board, and composites of veneer and of wood-based layers. Four methods of tests are included: Sections Method A—Center-Point Flexure Test 5 Method B—Two-Point Flexure Test 6 Method C—Large Panel Test 7 Method D—Flexure Test for Quality Assurance 8 The choice of method will be dictated by the purpose of the test, type of material, and equipment availability. All methods are applicable to material that is relatively uniform in strength and stiffness properties. Only Method C should be used to test material suspected of having strength or stiffness variations within a panel caused by density variations, knots, knot-holes, areas of distorted grain, fungal attack, or wide growth variations. However, Method B may be used to evaluate certain features such as core gaps and veneer joints in plywood panels where effects are readily projected to full panels. Method C generally is preferred where size of test material permits. Moments applied to fail specimens tested by Method A, B or D in which large deflections occur can be considerably larger than nominal. An approximate correction can be made. 1.2 Method A, Center-Point Flexure Test—This method is applicable to material that is uniform with respect to elastic and strength properties. Total deflection, and modulus of elasticity computed from it, include a relatively constant component attributable to shear deformation. It is well suited to investigations of many variables that influence properties uniformly throughout the panel in controlled studies and to test small, defect-free control specimens cut from large panels containing defects tested by the large-specimen method. 1.3 Method B, Two-Point Flexure Test—This method, like Method A, is suited to the investigation of factors that influence strength and elastic properties uniformly throughout the panel, in controlled studies, and to testing small, defect free control specimens cut from large specimens tested by Method C. However, it may be used to determine the effects of finger joints, veneer joints and gaps, and other features which can be placed entirely between the load points and whose effects can be projected readily to full panel width. Deflection and modulus of elasticity obtained from this method are related to flexural stress only and do not contain a shear component. Significant errors in modulus of rupture can occur when nominal moment is used (see Appendix X1). 1.4 Method C, Large Panel Test—This method is ideally suited for evaluating effects of knots, knot-holes, areas of sloping grain, and patches for their effect on standard full-size panels. It is equally well suited for testing uniform or clear material whenever specimen size is adequate. Specimen size and span above certain minimums are quite flexibl...

ASTM D3043-17 is classified under the following ICS (International Classification for Standards) categories: 79.060.01 - Wood-based panels in general. The ICS classification helps identify the subject area and facilitates finding related standards.

ASTM D3043-17 has the following relationships with other standards: It is inter standard links to ASTM D3043-00(2011), ASTM D4442-20, ASTM D4761-19, ASTM D4761-18, ASTM D4442-16, ASTM D4442-15, ASTM D2395-14, ASTM D2395-14e1, ASTM D4761-13, ASTM D4761-11, ASTM D4442-07, ASTM D2395-07ae1, ASTM D2395-07a, ASTM D2395-07, ASTM D2395-06. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

ASTM D3043-17 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3043 − 17

Standard Test Methods for

Structural Panels in Flexure

This standard is issued under the fixed designation D3043; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope in controlled studies, and to testing small, defect free control

specimens cut from large specimens tested by Method C.

1.1 These test methods determine the flexural properties of

However, it may be used to determine the effects of finger

stripscutfromstructuralpanelsorpanelsupto4by8ftinsize.

joints, veneer joints and gaps, and other features which can be

Structural panels in use include plywood, waferboard, oriented

placed entirely between the load points and whose effects can

strand board, and composites of veneer and of wood-based

be projected readily to full panel width. Deflection and

layers. Four methods of tests are included:

modulus of elasticity obtained from this method are related to

Sections

flexural stress only and do not contain a shear component.

Method A—Center-Point Flexure Test 5 Significant errors in modulus of rupture can occur when

Method B—Two-Point Flexure Test 6

nominal moment is used (see Appendix X1).

Method C—Large Panel Test 7

Method D—Flexure Test for Quality Assurance 8

1.4 Method C, Large Panel Test—This method is ideally

The choice of method will be dictated by the purpose of the

suited for evaluating effects of knots, knot-holes, areas of

test, type of material, and equipment availability. All methods

sloping grain, and patches for their effect on standard full-size

are applicable to material that is relatively uniform in strength

panels. It is equally well suited for testing uniform or clear

and stiffness properties. Only Method C should be used to test

material whenever specimen size is adequate. Specimen size

material suspected of having strength or stiffness variations

and span above certain minimums are quite flexible. It is

within a panel caused by density variations, knots, knot-holes,

preferred when equipment is available.

areas of distorted grain, fungal attack, or wide growth varia-

1.5 Method D, Flexure Test for Quality Assurance—This

tions. However, Method B may be used to evaluate certain

method, like Method A, is well suited to the investigation of

features such as core gaps and veneer joints in plywood panels

factors that influence bending strength and stiffness properties.

where effects are readily projected to full panels. Method C

Also like Method A, this method uses small specimens in a

generally is preferred where size of test material permits.

center-pointsimplespantestconfiguration.Thismethodusesa

MomentsappliedtofailspecimenstestedbyMethodA,BorD

span to depth ratio, specimen width, test fixture and test speed

in which large deflections occur can be considerably larger

that make the method well suited for quality assurance. The

than nominal. An approximate correction can be made.

method is frequently used for quality assurance testing of

1.2 Method A, Center-Point Flexure Test—This method is

oriented strand board.

applicabletomaterialthatisuniformwithrespecttoelasticand

1.6 All methods can be used to determine modulus of

strength properties. Total deflection, and modulus of elasticity

elasticity with sufficient accuracy. Modulus of rupture deter-

computed from it, include a relatively constant component

mined by Methods A, B or D is subject to errors up to and

attributable to shear deformation. It is well suited to investi-

sometimes exceeding 20% depending upon span, loading, and

gations of many variables that influence properties uniformly

deflectionatfailureunlessmomentiscomputedintherigorous

throughout the panel in controlled studies and to test small,

manner outlined in Appendix X1 or corrections are made in

defect-free control specimens cut from large panels containing

other ways. These errors are not present in Method C.

defects tested by the large-specimen method.

1.7 Whencomparisonsaredesiredbetweenresultsofspeci-

1.3 Method B, Two-Point Flexure Test—This method, like

men groups, it is good practice to use the same method of test

MethodA,issuitedtotheinvestigationoffactorsthatinfluence

for all specimens, thus eliminating possible differences relat-

strength and elastic properties uniformly throughout the panel,

able to test method.

1.8 This standard does not purport to address all of the

These methods are under the jurisdiction of ASTM Committee D07 on Wood

safety concerns, if any, associated with its use. It is the

and are the direct responsibility of Subcommittee D07.03 on Panel Products.

responsibility of the user of this standard to establish appro-

Current edition approved Nov. 15, 2017. Published December 2017. Originally

priate safety, health, and environmental practices and deter-

approved in 1972. Last previous edition approved in 2011 as D3043–00 (2011).

DOI: 10.1520/D3043-17. mine the applicability of regulatory limitations prior to use.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3043 − 17

1.9 This international standard was developed in accor- 5.2 Test Specimen—The test specimen shall be rectangular

dance with internationally recognized principles on standard- incrosssection.Thedepthofthespecimenshallbeequaltothe

ization established in the Decision on Principles for the thickness of material, and the width shall be 1 in. (25 mm) for

Development of International Standards, Guides and Recom- depths less than ⁄4 in. (6 mm) and 2 in. (50 mm) for greater

mendations issued by the World Trade Organization Technical depths (Note 1).When the principal direction of the face plies,

Barriers to Trade (TBT) Committee. laminations,strands,orwafersisparalleltothespan,thelength

of the specimen (Note 2) shall be not less than 48 times the

2. Referenced Documents

depth plus 2 in.; when the principal direction of the face plies,

laminations,strands,orwafersisperpendiculartothespan,the

2.1 ASTM Standards:

specimen length shall be not less than 24 times the depth plus

D2395TestMethodsforDensityandSpecificGravity(Rela-

2 in. (Note 3).

tive Density) of Wood and Wood-Based Materials

D4442Test Methods for Direct Moisture Content Measure-

NOTE 1—In certain specific instances, it may be necessary or desirable

ment of Wood and Wood-Based Materials to test specimens having a width greater than 1 or 2 in. (25 or 50 mm).To

eliminate plate action when wider specimens are tested, the specimen

D4761Test Methods for Mechanical Properties of Lumber

widthshallnotexceedonethirdofthespanlengthandprecautionshallbe

and Wood-Base Structural Material

takentoensureuniformbearingacrosstheentirewidthofthespecimenat

the load and reaction points.

3. Significance and Use

NOTE 2—In cutting specimens to meet the length requirement, it is not

intended that the length be changed for small variations in thickness.

3.1 These methods give the flexural properties, principally

Rather, it is intended that the nominal thickness of the material under test

strengthandstiffness,ofstructuralpanels.Thesepropertiesare

should be used for determining the specimen length.

of primary importance in most structural uses of panels

5.2.1 Measurements—Measure specimen thickness at mid-

whether in construction for floors, wall sheathing, roof

span at two points near each edge and record the average.

decking, concrete form, or various space plane structures;

Measure to the nearest 0.001 in. (0.02 mm) or 0.3%. Measure

packaging and materials handling for containers, crates, or

width at mid-span to the nearest 0.3%.

pallets; or structural components such as stress-skin panels.

5.2.1.1 When needed for interpretation of test results for

3.2 To control or define other variables influencing flexure

plywood, veneer composites, and laminates measure thickness

properties, moisture content and time to failure must be

of each layer to the nearest 0.001 in. (0.02 mm) at mid-span at

determined. Conditioning of test material at controlled atmo-

each edge and record the average.

spheres to control test moisture content and determination of

5.3 Span—The span shall be at least 48 times the nominal

specific gravity are recommended. Comparisons of results of

depth when the principal direction of the face plies,

plywood,veneercomposites,andlaminateswithsolidwoodor

laminations, strands, or wafers of the test specimen is parallel

other plywood constructions will be greatly assisted if the

to the span and at least 24 times the nominal depth when the

thickness of the individual plies is measured to permit compu-

principal direction of the face plies, laminations, strands, or

tation of section properties.

wafers is perpendicular to the span (Note 3).

4. Control of Moisture Content

NOTE 3—Establishment of a span-depth ratio is required to allow an

accuratecomparisonoftestvaluesformaterialsofdifferentthicknesses.It

4.1 Structural panel samples to be tested at a specific

should be noted that the span is based on the nominal thickness of the

moisture content or relative humidity shall be conditioned to

material and it is not intended that the spans be changed for small

approximate constant mass in controlled atmospheric condi-

variations in thickness.

tions before testing. For structural panels used under dry

5.4 End Supports—Reaction points shall be capable of

conditions,arelativehumidityof65 65%atatemperatureof

freely compensating for warp of the test specimen by turning

68 6 6°F (20 6 3°C) is recommended.

laterally in a plane perpendicular to the specimen length so as

to apply load uniformly across its width. Design of end

5. Method A—Center-Point Flexure Test

supports shall place the center of rotation near the neutral axis

5.1 Summary—Aconventionalcompressiontestingmachine

ofthespecimenofaveragethickness.Constructionisshownin

is used to apply and measure a load at mid-span of a small

detail in Fig. 1. Bearing points shall be rounded where they

flexure specimen; and the resulting deflection at mid span is

contact the specimen.

measured or recorded. The test proceeds at a constant rate of

5.4.1 Useofbearingplatesisgenerallyrecommendedandis

head motion until either sufficient deflection data in the elastic

required wherever significant local deformation may occur.

range have been gathered or until specimen failure occurs.The

5.4.2 Use of roller bearings or plates and rollers to preclude

specimen is supported on reaction bearings which permit the

friction forces between end support and specimen is recom-

specimen and bearing plate to roll freely over the reactions as

mendedinadditiontotherequirementoflateralcompensation.

the specimen deflects.

Construction of a suitable end support using small roller

bearings in conjunction with a plate which clips to the end of

the specimen is illustrated in Fig. 2 and Fig. 3. The use of a

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

large ball bearing to provide lateral compensation for warp is

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

also illustrated. This method is particularly recommended for

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. thin specimens and small loads.

D3043 − 17

Metric Equiva- Metric Equiva-

Inch-Pound (in.) Inch-Pound (in.)

lents, (mm) lents, (mm)

1 1

⁄16 1.5 1 ⁄4 32

1 1

⁄8 31 ⁄2 38

⁄16 52 50

1 1

⁄4 62 ⁄16 52

⁄8 10 3 76

13 1

⁄32 10.3 5 ⁄2 140

⁄2 12 6 152

⁄8 23 12 305

⁄16 24 24 610

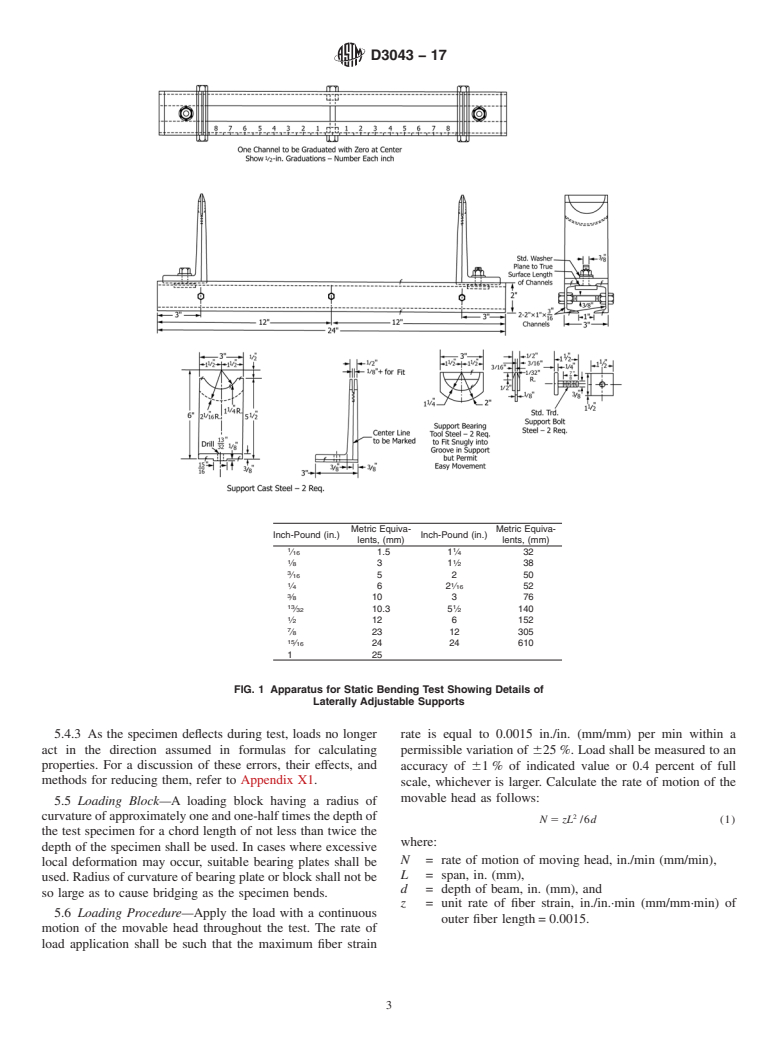

FIG. 1 Apparatus for Static Bending Test Showing Details of

Laterally Adjustable Supports

5.4.3 As the specimen deflects during test, loads no longer rate is equal to 0.0015 in./in. (mm/mm) per min within a

act in the direction assumed in formulas for calculating

permissible variation of 625%. Load shall be measured to an

properties. For a discussion of these errors, their effects, and

accuracy of 61% of indicated value or 0.4 percent of full

methods for reducing them, refer to Appendix X1.

scale, whichever is larger. Calculate the rate of motion of the

movable head as follows:

5.5 Loading Block—A loading block having a radius of

curvatureofapproximatelyoneandone-halftimesthedepthof

N 5 zL /6d (1)

the test specimen for a chord length of not less than twice the

where:

depth of the specimen shall be used. In cases where excessive

N = rate of motion of moving head, in./min (mm/min),

local deformation may occur, suitable bearing plates shall be

L = span, in. (mm),

used.Radiusofcurvatureofbearingplateorblockshallnotbe

d = depth of beam, in. (mm), and

so large as to cause bridging as the specimen bends.

z = unit rate of fiber strain, in./in.·min (mm/mm·min) of

5.6 Loading Procedure—Apply the load with a continuous

outer fiber length=0.0015.

motion of the movable head throughout the test. The rate of

load application shall be such that the maximum fiber strain

D3043 − 17

FIG. 2 Reaction Bearing for Small Flexure Test Specimens

EI 5 L /48 P/∆ (2)

5.6.1 Measure the elapsed time from initiation of loading to ~ !~ !

maximum load and record to the nearest ⁄2 min.

where:

5.7 Measurement of Deflection—Take data for load-

EI = modulus of elasticity, psi (MPa)×moment of inertia,

4 4

deflection curves to determine the modulus of elasticity,

in. (or mm ),

proportional limit, work to proportional limit, work to maxi-

P/∆ = slope of load—deflection curve, lbf/in. (N/mm),

4 4

mum load, and total work. Take deflections by the methods

I = moment of inertia, in. (mm ), and

indicated in Fig. 4 or Fig. 5, and take readings to the nearest

L = span, in. (mm).

0.001in.(0.02mm).Chooseincrementsofloadsothatnotless

5.8.1.1 Moment of inertia used in the computations in 5.8.1

than 12 and preferably 15 or more readings of load and

maybecalculatedinseveraldifferentwaysdependinguponthe

deflection are taken to the proportional limit.

requirementsoftheinvestigation.Itmaybebasedontheentire

5.7.1 Deflections also may be measured with transducer-

crosssection,mayincludeonlythemomentofinertiaoflayers

type gages and plotted simultaneously against load. In this

parallel to span, or may include all layers weighted in accor-

case, record deflection to an accuracy of at least 1 ⁄2%of

dance with modulus of elasticity in the direction of bending

deformation at proportional limit and the recorded trace below

the proportional limit shall be at least 2 ⁄2 in. (64 mm) long or stress. State clearly the method employed in the report.

⁄4offullscalemeasuredonthedeformationaxis,whicheveris

5.8.2 Calculate maximum moment (S I/c) by the following

b

larger. Similar requirements apply to the load axis.

equation:

5.8 Calculations:

S I/c 5 PL/4 (3)

b

5.8.1 Calculate specimen bending stiffness as follows:

D3043 − 17

6.2.1 Measurements—Measure specimen thickness at mid-

span at two points near each edge and record the average.

Measurements shall be to the nearest 0.001 in. (0.02 mm) or

0.3%. Measure width at mid-span to the nearest 0.3%.

6.2.1.1 When needed for interpretation of test results for

plywood,veneercomposites,andlaminates,measurethickness

of each layer to the nearest 0.001 in. (0.02 mm) at mid-span at

each edge and record the average.

6.3 Span—Span-depth ratio has relatively little influence on

the results of tests using two-point loading and the method of

measuring deformation described for it in this standard.

However, it is important that the distance between load point

and adjacent support be sufficient to prevent rolling shear

failures. The alternate 12-in. (300-mm) width will have a

midlength (constant moment section) at least 12 in. in length.

6.3.1 Specimenstestedforstiffnessonlyshallhaveaspanat

least 48 times nominal thickness if the principal direction is

parallel to span and 24 times nominal thickness if the principal

direction is perpendicular to span.

6.3.2 It is recommended that two-point loading tests to

failure be made on a span at least equal to the spacing between

load points plus 48 times specimen thickness or 24 times

specimen thickness for the principal direction parallel or

perpendicular respectively. Material having high rolling shear

strength or having all its plies, laminations, strands, or wafers

parallel to span may use closer spacing between loads and

supports.

6.4 Supports—Reaction supports shall meet the require-

FIG. 3 Apparatus for Two-Point Loading and Measurement of De-

ments of 5.4 and 5.4.1. Other comments as well as those of

flection (Method B)

5.4.2 and 5.4.3 apply.

where:

6.5 Loading—Apply two equal loads to the specimen equi-

S I/c = maximum moment, lbf·in. (N·mm), distant from the supports by cylindrical surfaces having a

b

S = modules of rupture, psi (MPa), 1

radius of curvature of at least 1 ⁄2 times specimen thickness

b

P = maximum load, lbf (N), and

wherever it may contact the specimen. The axes of these

c = distance from neutral axis to extreme fiber, in.

surfaces shall remain parallel and at least one of them shall be

(mm).

free to turn about its axis or be loaded through rollers to

prevent the application of friction forces to the surface of the

6. Method B—Two-Point Flexure Test

specimen. Construction of a satisfactory loading head is

6.1 Summary—The ends of a two-point flexure specimen

illustrated in Fig. 6 and Fig. 3. Locate the pivot point that

aresupportedonspecialreactionbearingswhichinturnreston

equalizes the two loads near the original neutral axis of the

the table of a conventional testing machine.Apivoted loading

specimen.

device applies equal loads at points ⁄4 of span from the

6.5.1 Space load points sufficiently to provide a deflection

reactions resulting from downward motion of the testing

whichcanbeadequatelymeasured.Aspacingofatleast24and

machine crosshead, and subjects the middle half of the speci-

men to conditions of nearly pure moment. Deflection of mid 12 times specimen thickness is recommended for specimens

span relative to two points just inside the load points is with the principal direction parallel and perpendicular to span

measured with a dial gage or transducer thus giving deforma-

respectively.

tion due to pure bending and unaffected by shear deformation.

6.5.2 Measure the sum of the two loads to an accuracy of at

least 1% of indicated value or 0.4% of full scale, whichever

6.2 Test Specimen—The test specimen shall be rectangular

is larger.

incrosssectionanditslengthshallexceedby2in.(50mm)the

spanonwhichitistobetestedasdeterminedin6.3.Thickness

6.6 Speed of Test—Apply load at a continuous rate of

shall be the thickness of the material. Width shall be 1 in. (25

motion of the load points with respect to the supports within a

mm) for material less than ⁄4 in. (6 mm) thick and 2 in. for

permissible range of 25% of the rate determined as follows:

material ⁄4 in. and over in thickness. The alternate width is 12

in. (300 mm). N 5 za/3d 3L 2 4a (4)

~ !~ !

D3043 − 17

FIG. 4 Static Bending Test Showing Adjustable Supports and One Method of Attaching Dial Gage for Observing Deflection of Thin Ma-

terial

FIG. 5 Static Bending Test Showing Roller Bearing at Supports and Special Yoke with Dial Gage for Measuring Deflection at the Neu-

tral Axis

D3043 − 17

FIG. 6 Two-Point Load Test (Method B)

where: where:

N = rate of motion, in./min (mm/min), L = span between load points, in. (mm)

z = unit rate of fiber strain, in./in.·min (mm/ L = span between deflection measurement points, in.

mm·min)=0.0015, (mm),

a = distance from support to adjacent load, in. (mm), P'/∆ = slope of load deflection curve where deflection is

d = depth of beam, in. (mm), and

mid-span relative to ends of span L , in. (mm), and

L = span, in. (mm).

other notation is as given in 5.8.1. Remarks of 5.8.2

apply.

6.6.1 Measure the elapsed time from initiation of loading to

maximum load and record to the nearest ⁄2 min.

6.8.2 Calculate maximum moment of the specimen as

follows:

6.7 Measurement of Deflection—Measuredeflectionofmid-

spanwithrespecttoalinebetweentwopointsequidistantfrom

S I/c 5 P L 2 L /4 (6)

~ !

b i

mid-span and just inside the two load points to an accuracy of

where:

at least 1 ⁄2% of total deflection if tested for stiffness only, or

1 P = maximum load, lbf (N),

1 ⁄2%ofdeflectionatapproximateproportionallimit.Allthree

points shall lie on the longitudinal axis of the specimen.

7. Method C—Large Panel Moment Test

Suitable equipment of the transducer type

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D3043 − 00 (Reapproved 2011) D3043 − 17

Standard Test Methods for

Structural Panels in Flexure

This standard is issued under the fixed designation D3043; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 These test methods determine the flexural properties of strips cut from structural panels or panels up to 4 by 8 ft in size.

Structural panels in use include plywood, waferboard, oriented strand board, and composites of veneer and of wood-based layers.

Four methods of tests are included:

Sections

Method A—Center-Point Flexure Test 5

Method B—Two-Point Flexure Test 6

Method C—Large Panel Test 7

Method D—Flexure Test for Quality Assurance 8

The choice of method will be dictated by the purpose of the test, type of material, and equipment availability. All methods are

applicable to material that is relatively uniform in strength and stiffness properties. Only Method C should be used to test material

suspected of having strength or stiffness variations within a panel caused by density variations, knots, knot-holes, areas of distorted

grain, fungal attack, or wide growth variations. However, Method B may be used to evaluate certain features such as core gaps

and veneer joints in plywood panels where effects are readily projected to full panels. Method C generally is preferred where size

of test material permits. Moments applied to fail specimens tested by Method A, B or D in which large deflections occur can be

considerably larger than nominal. An approximate correction can be made.

Sections

Method A—Center-Point Flexure Test 5

Method B—Two-Point Flexure Test 6

Method C—Pure Moment Test 7

Method D—Flexure Test for Quality Assurance 8

The choice of method will be dictated by the purpose of the test, type of material, and equipment availability. All methods are

applicable to material that is relative uniform in strength and stiffness properties. Only Method C should be used to test mate-

rial suspected of having strength or stiffness variations within a panel caused by density variations, knots, knot-holes, areas of

distorted grain, fungal attack, or wide growth variations. However, Method B may be used to evaluate certain features such as

core gaps and veneer joints in plywood panels where effects are readily projected to full panels. Method C generally is pre-

ferred where size of test material permits. Moments applied to fail specimens tested by Method A, B or D in which large de-

flections occur can be considerably larger than nominal. An approximate correction can be made.

1.2 Method A, Center-Point Flexure Test—This method is applicable to material that is uniform with respect to elastic and

strength properties. Total deflection, and modulus of elasticity computed from it, include a relatively constant component

attributable to shear deformation. It is well suited to investigations of many variables that influence properties uniformly

throughout the panel in controlled studies and to test small, defect-free control specimens cut from large panels containing defects

tested by the large-specimen method.

1.3 Method B, Two-Point Flexure Test—This method, like Method A, is suited to the investigation of factors that influence

strength and elastic properties uniformly throughout the panel, in controlled studies, and to testing small, defect free control

specimens cut from large specimens tested by Method C. However, it may be used to determine the effects of finger joints, veneer

joints and gaps, and other features which can be placed entirely between the load points and whose effects can be projected readily

to full panel width. Deflection and modulus of elasticity obtained from this method are related to flexural stress only and do not

contain a shear component. Significant errors in modulus of rupture can occur when nominal moment is used (see Appendix X1).

These methods are under the jurisdiction of ASTM Committee D07 on Wood and are the direct responsibility of Subcommittee D07.03 on Panel Products.

Current edition approved Nov. 1, 2011Nov. 15, 2017. Published November 2011December 2017. Originally approved in 1972. Last previous edition approved in 20002011

as D3043 – 00 (2006).(2011). DOI: 10.1520/D3043-00R11.10.1520/D3043-17.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3043 − 17

1.4 Method C, Pure MomentLarge Panel Test—This method is ideally suited for evaluating effects of knots, knot-holes, areas

of sloping grain, and patches for their effect on standard full-size panels. It is equally well suited for testing uniform or clear

material whenever specimen size is adequate. Measured deformation and elastic constants are free of shear deformation effects;

and panels can be bent to large deflections without incurring errors from horizontal force components occurring in other methods.

Specimen size and span above certain minimums are quite flexible. It is preferred when equipment is available.

1.5 Method D, Flexure Test for Quality Assurance—This method, like Method A, is well suited to the investigation of factors

that influence bending strength and stiffness properties. Also like Method A, this method uses small specimens in a center-point

simple span test configuration. This method uses a span to depth ratio, specimen width, test fixture and test speed that make the

method well suited for quality assurance. The method is frequently used for quality assurance testing of oriented strand board.

1.6 All methods can be used to determine modulus of elasticity with sufficient accuracy. Modulus of rupture determined by

Methods A, B or D is subject to errors up to and sometimes exceeding 20 % depending upon span, loading, and deflection at failure

unless moment is computed in the rigorous manner outlined in Appendix X1 or corrections are made in other ways. These errors

are not present in Method C.

1.7 When comparisons are desired between results of specimen groups, it is good practice to use the same method of test for

all specimens, thus eliminating possible differences relatable to test method.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D2395 Test Methods for Density and Specific Gravity (Relative Density) of Wood and Wood-Based Materials

D4442 Test Methods for Direct Moisture Content Measurement of Wood and Wood-Based Materials

D4761 Test Methods for Mechanical Properties of Lumber and Wood-Base Structural Material

3. Significance and Use

3.1 These methods give the flexural properties, principally strength and stiffness, of structural panels. These properties are of

primary importance in most structural uses of panels whether in construction for floors, wall sheathing, roof decking, concrete

form, or various space plane structures; packaging and materials handling for containers, crates, or pallets; or structural

components such as stress-skin panels.

3.2 To control or define other variables influencing flexure properties, moisture content and time to failure must be determined.

Conditioning of test material at controlled atmospheres to control test moisture content and determination of specific gravity are

recommended. Comparisons of results of plywood, veneer composites, and laminates with solid wood or other plywood

constructions will be greatly assisted if the thickness of the individual plies is measured to permit computation of section

properties.

4. Control of Moisture Content

4.1 Structural panel samples to be tested at a specific moisture content or relative humidity shall be conditioned to approximate

constant mass in controlled atmospheric conditions before testing. For structural panels used under dry conditions, a relative

humidity of 65 6 5 % at a temperature of 68 6 6°F (20 6 3°C) is recommended.

5. Method A—Center-Point Flexure Test

5.1 Summary—A conventional compression testing machine is used to apply and measure a load at mid-span of a small flexure

specimen; and the resulting deflection at mid span is measured or recorded. The test proceeds at a constant rate of head motion

until either sufficient deflection data in the elastic range have been gathered or until specimen failure occurs. The specimen is

supported on reaction bearings which permit the specimen and bearing plate to roll freely over the reactions as the specimen

deflects.

5.2 Test Specimen—The test specimen shall be rectangular in cross section. The depth of the specimen shall be equal to the

thickness of material, and the width shall be 1 in. (25 mm) for depths less than ⁄4 in. (6 mm) and 2 in. (50 mm) for greater depths

(Note 1). When the principal direction of the face plies, laminations, strands, or wafers is parallel to the span, the length of the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

D3043 − 17

specimen (Note 2) shall be not less than 48 times the depth plus 2 in.; when the principal direction of the face plies, laminations,

strands, or wafers is perpendicular to the span, the specimen length shall be not less than 24 times the depth plus 2 in. (Note 3).

NOTE 1—In certain specific instances, it may be necessary or desirable to test specimens having a width greater than 1 or 2 in. (25 or 50 mm). To

eliminate plate action when wider specimens are tested, the specimen width shall not exceed one third of the span length and precaution shall be taken

to ensure uniform bearing across the entire width of the specimen at the load and reaction points.

NOTE 2—In cutting specimens to meet the length requirement, it is not intended that the length be changed for small variations in thickness. Rather,

it is intended that the nominal thickness of the material under test should be used for determining the specimen length.

5.2.1 Measurements—Measure specimen thickness at mid-span at two points near each edge and record the average. Measure

to the nearest 0.001 in. (0.02 mm) or 0.3 %. Measure width at mid-span to the nearest 0.3 %.

5.2.1.1 When needed for interpretation of test results for plywood, veneer composites, and laminates measure thickness of each

layer to the nearest 0.001 in. (0.02 mm) at mid-span at each edge and record the average.

5.3 Span—The span shall be at least 48 times the nominal depth when the principal direction of the face plies, laminations,

strands, or wafers of the test specimen is parallel to the span and at least 24 times the nominal depth when the principal direction

of the face plies, laminations, strands, or wafers is perpendicular to the span (Note 3).

NOTE 3—Establishment of a span-depth ratio is required to allow an accurate comparison of test values for materials of different thicknesses. It should

be noted that the span is based on the nominal thickness of the material and it is not intended that the spans be changed for small variations in thickness.

5.4 End Supports—Reaction points shall be capable of freely compensating for warp of the test specimen by turning laterally

in a plane perpendicular to the specimen length so as to apply load uniformly across its width. Design of end supports shall place

the center of rotation near the neutral axis of the specimen of average thickness. Construction is shown in detail in Fig. 1. Bearing

points shall be rounded where they contact the specimen.

5.4.1 Use of bearing plates is generally recommended and is required wherever significant local deformation may occur.

5.4.2 Use of roller bearings or plates and rollers to preclude friction forces between end support and specimen is recommended

in addition to the requirement of lateral compensation. Construction of a suitable end support using small roller bearings in

conjunction with a plate which clips to the end of the specimen is illustrated in Fig. 2 and Fig. 3. The use of a large ball bearing

to provide lateral compensation for warp is also illustrated. This method is particularly recommended for thin specimens and small

loads.

5.4.3 As the specimen deflects during test, loads no longer act in the direction assumed in formulas for calculating properties.

For a discussion of these errors, their effects, and methods for reducing them, refer to Appendix X1.

5.5 Loading Block—A loading block having a radius of curvature of approximately one and one-half times the depth of the test

specimen for a chord length of not less than twice the depth of the specimen shall be used. In cases where excessive local

deformation may occur, suitable bearing plates shall be used. Radius of curvature of bearing plate or block shall not be so large

as to cause bridging as the specimen bends.

5.6 Loading Procedure—Apply the load with a continuous motion of the movable head throughout the test. The rate of load

application shall be such that the maximum fiber strain rate is equal to 0.0015 in./in. (mm/mm) per min within a permissible

variation of 625 %. Load shall be measured to an accuracy of 61 % of indicated value or 0.4 percent of full scale, whichever is

larger. Calculate the rate of motion of the movable head as follows:

N 5 zL /6d (1)

where:

N = rate of motion of moving head, in./min (mm/min),

L = span, in. (mm),

d = depth of beam, in. (mm), and

z = unit rate of fiber strain, in./in.·min (mm/mm·min) of outer fiber length = 0.0015.

5.6.1 Measure the elapsed time from initiation of loading to maximum load and record to the nearest ⁄2 min.

5.7 Measurement of Deflection—Take data for load-deflection curves to determine the modulus of elasticity, proportional limit,

work to proportional limit, work to maximum load, and total work. Take deflections by the methods indicated in Fig. 4 or Fig. 5,

and take readings to the nearest 0.001 in. (0.02 mm). Choose increments of load so that not less than 12 and preferably 15 or more

readings of load and deflection are taken to the proportional limit.

5.7.1 Deflections also may be measured with transducer-type gages and plotted simultaneously against load. In this case, record

deflection to an accuracy of at least 1 ⁄2 % of deformation at proportional limit and the recorded trace below the proportional limit

1 1

shall be at least 2 ⁄2 in. (64 mm) long or ⁄4 of full scale measured on the deformation axis, whichever is larger. Similar requirements

apply to the load axis.

5.8 Calculations:

5.8.1 Calculate specimen bending stiffness as follows:

EI 5 L /48 P/Δ (2)

~ !~ !

D3043 − 17

Metric Equiva- Metric Equiva-

Inch-Pound (in.) Inch-Pound (in.)

lents, (mm) lents, (mm)

1 1

⁄16 1.5 1 ⁄4 32

1 1

⁄8 3 1 ⁄2 38

⁄16 5 2 50

1 1

⁄4 6 2 ⁄16 52

⁄8 10 3 76

13 1

⁄32 10.3 5 ⁄2 140

⁄2 12 6 152

⁄8 23 12 305

⁄16 24 24 610

1 25

FIG. 1 Apparatus for Static Bending Test Showing Details of

Laterally Adjustable Supports

where:

4 4

EI = modulus of elasticity, psi (MPa) × moment of inertia, in. (or mm ),

P/Δ = slope of load—deflection curve, lbf/in. (N/mm),

4 4

I = moment of inertia, in. (mm ), and

L = span, in. (mm).

5.8.1.1 Moment of inertia used in the computations in 5.8.1 may be calculated in several different ways depending upon the

requirements of the investigation. It may be based on the entire cross section, may include only the moment of inertia of layers

parallel to span, or may include all layers weighted in accordance with modulus of elasticity in the direction of bending stress. State

clearly the method employed in the report.

5.8.2 Calculate maximum moment (S I/c) by the following equation:

b

S I/c 5 PL/4 (3)

b

where:

S I/c = maximum moment, lbf·in. (N·mm),

b

S = modules of rupture, psi (MPa),

b

D3043 − 17

FIG. 2 Reaction Bearing for Small Flexure Test Specimens

P = maximum load, lbf (N), and

c = distance from neutral axis to extreme fiber, in. (mm).

6. Method B—Two-Point Flexure Test

6.1 Summary—The ends of a two-point flexure specimen are supported on special reaction bearings which in turn rest on the

table of a conventional testing machine. A pivoted loading device applies equal loads at points ⁄4 of span from the reactions

resulting from downward motion of the testing machine crosshead, and subjects the middle half of the specimen to conditions of

nearly pure moment. Deflection of mid span relative to two points just inside the load points is measured with a dial gage or

transducer thus giving deformation due to pure bending and unaffected by shear deformation.

6.2 Test Specimen—The test specimen shall be rectangular in cross section and its length shall exceed by 2 in. (50 mm) the span

on which it is to be tested as determined in 6.3. Thickness shall be the thickness of the material. Width shall be 1 in. (25 mm) for

1 1

material less than ⁄4 in. (6 mm) thick and 2 in. for material ⁄4 in. and over in thickness. The alternate width is 12 in. (300 mm).

6.2.1 Measurements—Measure specimen thickness at mid-span at two points near each edge and record the average.

Measurements shall be to the nearest 0.001 in. (0.02 mm) or 0.3 %. Measure width at mid-span to the nearest 0.3 %.

6.2.1.1 When needed for interpretation of test results for plywood, veneer composites, and laminates, measure thickness of each

layer to the nearest 0.001 in. (0.02 mm) at mid-span at each edge and record the average.

6.3 Span—Span-depth ratio has relatively little influence on the results of tests using two-point loading and the method of

measuring deformation described for it in this standard. However, it is important that the distance between load point and adjacent

support be sufficient to prevent rolling shear failures. The alternate 12-in. (300-mm) width will have a midlength (constant moment

section) at least 12 in. in length.

6.3.1 Specimens tested for stiffness only shall have a span at least 48 times nominal thickness if the principal direction is parallel

to span and 24 times nominal thickness if the principal direction is perpendicular to span.

D3043 − 17

FIG. 3 Apparatus for Two-Point Loading and Measurement of Deflection (Method B)

6.3.2 It is recommended that two-point loading tests to failure be made on a span at least equal to the spacing between load

points plus 48 times specimen thickness or 24 times specimen thickness for the principal direction parallel or perpendicular

respectively. Material having high rolling shear strength or having all its plies, laminations, strands, or wafers parallel to span may

use closer spacing between loads and supports.

6.4 Supports—Reaction supports shall meet the requirements of 5.4 and 5.4.1. Other comments as well as those of 5.4.2 and

5.4.3 apply.

6.5 Loading—Apply two equal loads to the specimen equidistant from the supports by cylindrical surfaces having a radius of

curvature of at least 1 ⁄2 times specimen thickness wherever it may contact the specimen. The axes of these surfaces shall remain

parallel and at least one of them shall be free to turn about its axis or be loaded through rollers to prevent the application of friction

forces to the surface of the specimen. Construction of a satisfactory loading head is illustrated in Fig. 6 and Fig. 3. Locate the pivot

point that equalizes the two loads near the original neutral axis of the specimen.

6.5.1 Space load points sufficiently to provide a deflection which can be adequately measured. A spacing of at least 24 and 12

times specimen thickness is recommended for specimens with the principal direction parallel and perpendicular to span

respectively.

6.5.2 Measure the sum of the two loads to an accuracy of at least 1 % of indicated value or 0.4 % of full scale, whichever is

larger.

6.6 Speed of Test—Apply load at a continuous rate of motion of the load points with respect to the supports within a permissible

range of 25 % of the rate determined as follows:

N 5 za/3d 3L 2 4a (4)

~ ! ~ !

where:

N = rate of motion, in./min (mm/min),

z = unit rate of fiber strain, in./in.·min (mm/mm·min) = 0.0015,

a = distance from support to adjacent load, in. (mm),

D3043 − 17

FIG. 4 Static Bending Test Showing Adjustable Supports and One Method of Attaching Dial Gage for Observing Deflection of Thin Ma-

terial

FIG. 5 Static Bending Test Showing Roller Bearing at Supports and Special Yoke with Dial Gage for Measuring Deflection at the Neu-

tral Axis

D3043 − 17

FIG. 6 Two-Point Load Test (Method B)

d = depth of beam, in. (mm), and

L = span, in. (mm).

6.6.1 Measure the elapsed time from initiation of loading to maximum load and record to the nearest ⁄2 min.

6.7 Measurement of Deflection—Measure deflection of mid-span with respect to a line between two points equidistant from

1 1

mid-span and just inside the two load points to an accuracy of at least 1 ⁄2 % of total deflection if tested for stiffness only, or 1 ⁄2 %

of deflection at approximate proportional limit. All three points shall lie on the longitudinal axis of the specimen. Suitable

equipment of the transducer type is illustrated in Fig. 6 and shown in Fig. 3. A dial gage could replace the transducer for manual

reading. If individual gage readings are taken, at least 12 and preferably 15 or more load and deflection readings shall be taken

below approximate proportional limit or for determining specimen stiffness.

6.8 Calculations:

6.8.1 Calculate the specimen bending stiffness as follows:

EI 5 L 2 L L /32 P'/Δ (5)

@~ ! #~ !

1 2

where:

L = span between load points, in. (mm)

L = span between deflection measurement points, in. (mm),

P'/Δ = slope of load deflection curve where deflection is mid-span relative to ends of span L , in. (mm), and other notation is

as given in 5.8.1. Remarks of 5.8.2 apply.

6.8.2 Calculate maximum moment of the specimen as follows:

S I/c 5 P~L 2L !/4 (6)

b i

where:

P = maximum load, lbf (N),

D3043 − 17

7. Method C—Pure C—Large Panel Moment Test

7.1 Summary—A specially designed testing machine applies pure moments to opposite ends of the test panel through loading

frames. Frames are frames that rotate the panel out-of-plane. Depending upon the machine configuration, the rotating loading

frames are either fixed with respect to translation or free to move toward or away from each other during the test to preclude

application of other than pure moments to the center span of the panel. Between loading frames deflection of the neutral axis

follows a circular arc. Rotational deformation test. Between loading frames, panel deflection of the neutral axis follows a circular

arc. The panel stiffness is measured using either the panel centerline deflection across a fixed gauge length or using rotational

deflection between points near the ends of the arc arc. The latter is measured during the test by special sensing gages resting on

pins projecting from the face of the panel at these points. The test is simple and flexible, and results are directly relatable to basic

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...