ASTM D446-97e1

(Specification)Standard Specifications and Operating Instructions for Glass Capillary Kinematic Viscometers

Standard Specifications and Operating Instructions for Glass Capillary Kinematic Viscometers

SCOPE

1.1 This standard gives specifications and operating instructions for glass capillary kinematic viscometers of all the types described in detail in Annex A1, Annex A2, and Annex A3 as follows:Modified Ostwald viscometers, Annex A1Suspended-level viscometers, Annex A2Reverse-flow viscometers, Annex A3

1.2 The calibration of the viscometers is described in Section .

1.3 This standard covers some widely used viscometers suitable for use in accordance with Test Method D445. Other viscometers of the glass capillary type which are capable of measuring kinematic viscosity within the limits of precision given in Test Method D 445 may be used.

1.4 The values stated in SI units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: D 446 – 97

Designation: 71S2/95

Standard Specifications and Operating Instructions for

Glass Capillary Kinematic Viscometers

This standard is issued under the fixed designation D 446; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e NOTE—Footnote 5 was added editorially in March 1999.

1. Scope ISO Guide 25 General Requirements for the Calibration and

Testing Laboratories

1.1 This standard gives specifications and operating instruc-

tions for glass capillary kinematic viscometers of all the types

3. Materials and Manufacture

described in detail in Annex A1, Annex A2, and Annex A3 as

3.1 Fully annealed, low-expansion borosilicate glass shall

follows:

be used for the construction of all viscometers. The size

Modified Ostwald viscometers, Annex A1

number, serial number, and manufacturer’s designation shall be

Suspended-level viscometers, Annex A2

Reverse-flow viscometers, Annex A3

permanently marked on each viscometer. All timing marks

shall be etched and filled with an opaque color, or otherwise

1.2 The calibration of the viscometers is described in

made a permanent part of the viscometer. See detailed descrip-

Section 6.

tion of each type of viscometer in Annex A1, Annex A2, and

1.3 This standard covers some widely used viscometers

Annex A3.

suitable for use in accordance with Test Method D 445. Other

3.2 With the exception of the FitzSimons and Atlantic

viscometers of the glass capillary type which are capable of

viscometers, all viscometers are designed to fit through a

measuring kinematic viscosity within the limits of precision

51-mm hole in the lid of a constant-temperature bath having a

given in Test Method D 445 may be used.

liquid depth of at least 280 mm; and it is assumed that the

1.4 The values stated in SI units are to be regarded as the

surface of the liquid will be not more than 45 mm from the top

standard.

of the bath lid. For certain constant-temperature baths, espe-

2. Referenced Documents cially at low or high temperatures, it may be necessary to

construct the viscometers with the uppermost tubes longer than

2.1 ASTM Standards:

shown to ensure adequate immersion in the constant-

D 445 Test Method for Kinematic Viscosity of Transparent

temperature bath. Viscometers so modified can be used to

and Opaque Liquids (and the Calculation of Dynamic

measure kinematic viscosity within the precision of the test

Viscosity)

method. The lengths of tubes and bulbs on the figures should be

D 2162 Test Method for Basic Calibration of Master Vis-

held within6 10 % or 610 mm, whichever is less, such that

cometers and Viscosity Oil Standards

the calibration constant of the viscometer does not vary by

2.2 ISO Documents:

more than 615 % from the nominal value.

ISO 3105 Glass Capillary Kinematic Viscometers—

Specifications and Operating Instructions

4. Nomenclature for Figures

ISO 3104 Petroleum Products—Transparent and Opaque

4.1 The figures in the annexes contain letters to designate

Liquids—Determination of Kinematic Viscosity and Cal-

specific parts of each viscometer. These letters are also used in

culation of Dynamic Viscosity

the text of the standard when reference to the viscometers is

given. The more frequently used letters on the figures in the

These specifications and operating instructions are under the jurisdiction of

annexes are as follows:

ASTM Committee D-2 on Petroleum Products and Lubricants and are the direct

responsibility of Subcommittee D02.07 on Flow Properties. A lower reservoir

Current edition approved Dec. 10, 1997. Published October 1998. Originally B suspended level

bulb

published as D 2515 – 66. Last previous edition D 446 – 93a. Redesignated D 446

in 1977. C and J timing bulbs

D upper reservoir

Annual Book of ASTM Standards, Vol 05.01.

E, F, and I timing marks

Available from the American National Standards Institute, 11 West 42nd St.,

New York, NY 10036.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 446

6.2.3.1 The calibration of the reference viscometer should

G and H filling marks

K overflow tube

only be carried out by a reputable laboratory meeting the

L mounting tube

requirements of, for example, ISO Guide 25.

M lower vent tube

6.2.4 Calculate the viscometer constant C as follows:

N upper vent tube

P connecting tube

C 5 ~t 3 C !/t (1)

1 2 2 1

R working capillary

5. Viscometer Holder and Alignment

where:

C 5 the constant of the viscometer being calibrated,

5.1 All viscometers which have the upper meniscus directly 1

t 5 the flow time to the nearest 0.1 s in the viscometer

above the lower meniscus (Cannon-Fenske routine in Annex

being calibrated,

A1 and all in Annex A2) shall be mounted in a constant

C 5 the constant of the calibrated viscometer, and

temperature bath with tube L held within 1° of the vertical as

t 5 the flow time to the nearest 0.1 s in the calibrated

observed with a plumb bob or other equally accurate inspection

viscometer.

means. A number of commercially available holders are so

6.2.5 Repeat 6.2.1-6.2.3 with a second oil whose flow times

designed that the tube L is held perpendicular to the lid of a

are at least 50 % longer than the first oil. If the two values of

constant-temperature bath; nevertheless, the viscometer should

C differ by less than 0.2 % for those viscometers listed in

be tested with a plumb line in order to ensure that the tube L is

Annex A1 and Annex A2 and less than 0.3 % for those

in a vertical position.

viscometers listed in Annex A3, use the average. If the

5.1.1 Those viscometers whose upper meniscus is offset

constants differ by more than this value, repeat the procedure

from directly above the lower meniscus (all others in Annex A1

taking care to examine all possible sources of errors.

and all in Annex A3) shall be mounted in a constant-

6.2.5.1 The calibration constant, C, is dependent upon the

temperature bath with tube L held within 0.3° of the vertical.

gravitational acceleration at the place of calibration and this

5.2 Round metal tops, designed to fit above a 51-mm hole in

must, therefore, be supplied by the standardization laboratory

the lid of the bath, are frequently cemented on to the Zeitfuchs,

together with the instrument constant. Where the acceleration

Zeitfuchs cross-arm, and Lantz-Zeitfuchs viscometers which

of gravity, g, differs by more than 0.1 %, correct the calibration

then are permanently mounted on the lid of the bath. Also a

constant as follows:

rectangular metal top, 25 mm 3 59 mm, is often cemented on

C 5 ~g /g ! 3 C (2)

to the Zeitfuchs cross-arm and Zeitfuchs viscometers. Viscom-

2 2 1 1

eters fitted with metal tops should also be set vertically in the

where subscripts 1 and 2 indicate respectively the standard-

constant-temperature bath with the aid of a plumb line.

ization laboratory and the testing laboratory.

5.3 In each figure, the numbers which follow the tube

6.3 Viscosity Oil Standards:

designation indicate the outside tube diameter in millimetres. It

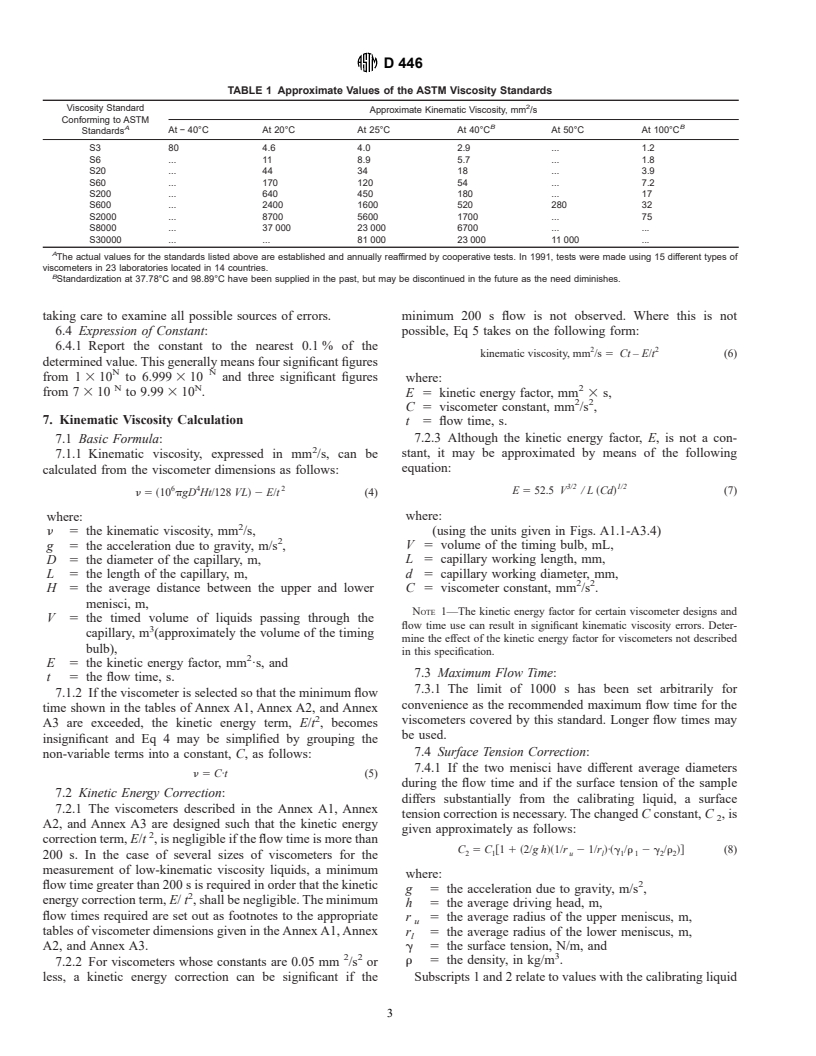

6.3.1 Kinematic viscosity oil standards are available hav-

is important to maintain these diameters and the designated

ing the approximate kinematic viscosity shown in Table 1.

spacing to ensure that holders will be interchangeable.

Certified kinematic viscosity values are established by coop-

erative tests and are supplied with each delivery.

6. Calibration of Viscometers

6.3.2 Select from Table 1 a viscosity oil standard with a

6.1 Procedures:

kinematic viscosity at the calibration temperature within the

6.1.1 Calibrate the kinematic glass capillary viscometers

kinematic viscosity range of the viscometer to be calibrated

covered by this standard using the procedures described in

and a minimum flow time greater than that specified in the

Annex A1, Annex A2, and Annex A3.

appropriate table of the annex. Determine the flow time to the

6.2 Reference Viscometers:

nearest 0.1 s in accordance with Test Method D 445 and

6.2.1 Select a clear petroleum oil, free from solid particles

calculate the viscometer constant, C, as follows:

and possessing Newtonian flow characteristics, with a kine-

C5n/t (3)

matic viscosity within the range of both the reference viscom-

eter and the viscometer to be calibrated. The minimum flow

where:

time shall be greater than that specified in the appropriate table

n5 the kinematic viscosity, mm /s, for the standard liquid,

of the annex in both the reference viscometer and the viscom-

and

eter which is to be calibrated in order that the kinetic energy

t 5 the flow time, s.

correction (see 7.1 and 7.2) may be less than 0.2 %.

6.3.3 Repeat with a second oil standard whose flow times

6.2.2 Select a calibrated viscometer of known viscometer

are at least 50 % longer than the first oil standard. If the two

constant C . This viscometer may be a reference viscometer

1 values of C differ by less than 0.2 % for those viscometers

(driving head at least 400 mm) that has been calibrated by the

listed in Annex A1 and Annex A2 and less than 0.3 % for those

step-up procedure using viscometers of successively larger

viscometers listed in Annex A3, use the average as the

capillary diameters, starting with distilled water as the basic

viscometer constant for the viscometer being calibrated. If the

kinematic viscosity standard or a routine viscometer of the

constants differ by more than this value, repeat the procedure

same type that has been calibrated by comparison with a

reference viscometer. See Test Method D 2162.

The ASTM Viscosity Oil Standards as listed in Table 1 are available in 1-pt

6.2.3 Mount the calibrated viscometer together with the

containers. Purchase orders should be addressed to the Cannon Instrument Co., P.O.

viscometer to be calibrated in the same bath and determine the

Box 16, State College, PA 16804-0016. Shipment will be made as specified or by

flow times of the oil in accordance with Test Method D 445. best means.

D 446

TABLE 1 Approximate Values of the ASTM Viscosity Standards

Viscosity Standard

Approximate Kinematic Viscosity, mm /s

Conforming to ASTM

B B

A

At − 40°C At 20°C At 25°C At 40°C At 50°C At 100°C

Standards

S3 80 4.6 4.0 2.9 . 1.2

S6 . 11 8.9 5.7 . 1.8

S20 . 44 34 18 . 3.9

S60 . 170 120 54 . 7.2

S200 . 640 450 180 . 17

S600 . 2400 1600 520 280 32

S2000 . 8700 5600 1700 . 75

S8000 . 37 000 23 000 6700 . .

S30000 . . 81 000 23 000 11 000 .

A

The actual values for the standards listed above are established and annually reaffirmed by cooperative tests. In 1991, tests were made using 15 different types of

viscometers in 23 laboratories located in 14 countries.

B

Standardization at 37.78°C and 98.89°C have been supplied in the past, but may be discontinued in the future as the need diminishes.

taking care to examine all possible sources of errors. minimum 200 s flow is not observed. Where this is not

6.4 Expression of Constant: possible, Eq 5 takes on the following form:

6.4.1 Report the constant to the nearest 0.1 % of the

2 2

kinematic viscosity, mm /s 5 Ct – E/t (6)

determined value. This generally means four significant figures

N N

from 1 3 10 to 6.999 3 10 and three significant figures

where:

N N 2

from 7 3 10 to 9.99 3 10 . E 5 kinetic energy factor, mm 3 s,

2 2

C 5 viscometer constant, mm /s ,

7. Kinematic Viscosity Calculation

t 5 flow time, s.

7.2.3 Although the kinetic energy factor, E, is not a con-

7.1 Basic Formula:

stant, it may be approximated by means of the following

7.1.1 Kinematic viscosity, expressed in mm /s, can be

equation:

calculated from the viscometer dimensions as follows:

3/2 1/2

6 4 2

E 5 52.5 V /L ~Cd! (7)

n5 ~10 pgD Ht/128 VL! 2 E/t (4)

where:

where:

n5 the kinematic viscosity, mm /s, (using the units given in Figs. A1.1-A3.4)

V 5 volume of the timing bulb, mL,

g 5 the acceleration due to gravity, m/s ,

D 5 the diameter of the capillary, m, L 5 capillary working length, mm,

L 5 the length of the capillary, m, d 5 capillary working diameter, mm,

2 2

H 5 the average distance between the upper and lower C 5 viscometer constant, mm /s .

menisci, m,

NOTE 1—The kinetic energy factor for certain viscometer designs and

V 5 the timed volume of liquids passing through the

flow time use can result in significant kinematic viscosity errors. Deter-

capillary, m (approximately the volume of the timing

mine the effect of the kinetic energy factor for viscometers not described

bulb),

in this specification.

E 5 the kinetic energy factor, mm ·s, and

7.3 Maximum Flow Time:

t 5 the flow time, s.

7.3.1 The limit of 1000 s has been set arbitrarily for

7.1.2 If the viscometer is selected so that the minimum flow

convenience as the recommended maximum flow time for the

time shown in the tables of Annex A1, Annex A2, and Annex

viscometers covered by this standard. Longer flow times may

A3 are exceeded, the kinetic energy term, E/t , becomes

be used.

insignificant and Eq 4 may be simplified by grouping the

7.4 Surface Tension Correction:

non-variable terms into a constant, C, as follows:

7.4.1 If the two menisci have different average diameters

n5 C·t (5)

during the flow time and if the surface tension of the sample

7.2 Kinetic Energy Correction:

differs substantially from the calibrating liquid, a surface

7.2.1 The viscometers described in the Annex A1, Annex

tension correction is necessary. The changed C constant, C ,is

A2, and Annex A3 are designed such that the kinetic energy

given approximately as follows:

correction term, E/t , is negligible if the flow time is more than

C 5 C @1 1 ~2/gh!~1/r 2 1/r !·~g /r 2g /r !# (8)

2 1 u l 1 1 2 2

200 s. In the case of several sizes of viscometers for the

measurement of low-kinematic viscosity liquids, a minimum

where:

flow time greater than 200 s is required in order that the kinetic

g 5 the acceleration due to gravity, m/s ,

energy correction term, E/ t , shall be negligible. The minimum

h 5 the average driving head, m,

flow times required are set out as footnotes to the appropriate

r 5 the average radius of the upper meniscus, m,

u

tables of viscometer dimensions given in the Annex A1, Annex r 5 the average radius of the lower meniscus, m,

l

A2, and Annex A3. g5 the surface tension, N/m, and

2 2

r5 the density, in kg/m .

7.2.2 For viscometers whose constants are 0.05 mm /s or

less, a kinetic energy correction can be significant if the Subscripts 1 and 2 relate to values with the calibrating liquid

D 446

and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.