ASTM D7214-23

(Test Method)Standard Test Method for Determination of the Oxidation of Used Lubricants by FT-IR Using Peak Area Increase Calculation

Standard Test Method for Determination of the Oxidation of Used Lubricants by FT-IR Using Peak Area Increase Calculation

SIGNIFICANCE AND USE

5.1 The PAI is representative of the quantity of all the compounds containing a carbonyl function that have formed by the oxidation of the lubricant (aldehydes, ketones, carboxylic acids, esters, anhydrides, etc.). The PAI gives representative information on the chemical degradation of the lubricant which has been caused by oxidation.

5.2 This test method was developed for transmission oils and is used in the CEC L-48-A-00 test (Oxidation Stability of Lubricating Oils Used in Automotive Transmissions by Artificial Aging) as a parameter for the end of test evaluation.

SCOPE

1.1 This test method covers the determination of the oxidation of used lubricants by FT-IR (Fourier Transform Infrared Spectroscopy). It measures the concentration change of constituents containing a carbonyl function that have formed during the oxidation of the lubricant.

1.2 This test method may be used to indicate relative changes that occur in an oil under oxidizing conditions. The test method is not intended to measure an absolute oxidation property that can be used to predict performance of an oil in service.

1.3 This test method was developed for transmission oils which have been degraded either in service, or in a laboratory test, for example a bulk oxidation test. It may be used for other in-service oils, but the stated precision may not apply.

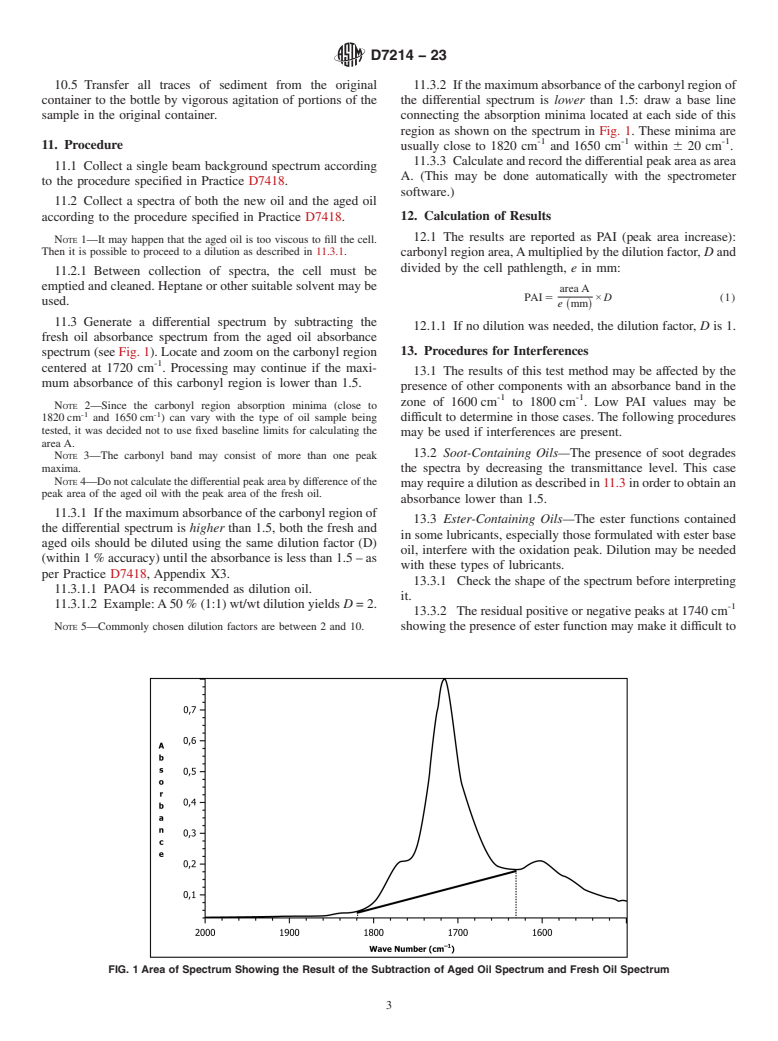

1.4 The results of this test method may be affected by the presence of other components with an absorbance band in the zone of 1600 cm-1 to 1800 cm-1. Low PAI values may be difficult to determine in those cases. Section 6 describes these possible interferences in more detail.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D7214 − 23

Standard Test Method for

Determination of the Oxidation of Used Lubricants by FT-IR

1

Using Peak Area Increase Calculation

This standard is issued under the fixed designation D7214; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This test method was jointly developed with “Groupement Francais de Coordination” (GFC),

technical committee LM5 and “Coordinating European Council” (CEC) Surveillance Group T-048 for

the purpose of monitoring the oxidation stability of artificially aged automotive transmission fluids.

This test method has been used in the CEC L-48-A-00 method as an end of test measurement

parameter.

1. Scope* responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

1.1 This test method covers the determination of the oxida-

mine the applicability of regulatory limitations prior to use.

tion of used lubricants by FT-IR (Fourier Transform Infrared

1.7 This international standard was developed in accor-

Spectroscopy). It measures the concentration change of con-

dance with internationally recognized principles on standard-

stituents containing a carbonyl function that have formed

ization established in the Decision on Principles for the

during the oxidation of the lubricant.

Development of International Standards, Guides and Recom-

1.2 This test method may be used to indicate relative

mendations issued by the World Trade Organization Technical

changes that occur in an oil under oxidizing conditions. The

Barriers to Trade (TBT) Committee.

test method is not intended to measure an absolute oxidation

property that can be used to predict performance of an oil in

2. Referenced Documents

service.

2

2.1 ASTM Standards:

1.3 This test method was developed for transmission oils

D4057 Practice for Manual Sampling of Petroleum and

which have been degraded either in service, or in a laboratory

Petroleum Products

test, for example a bulk oxidation test. It may be used for other

D4175 Terminology Relating to Petroleum Products, Liquid

in-service oils, but the stated precision may not apply.

Fuels, and Lubricants

D4177 Practice for Automatic Sampling of Petroleum and

1.4 The results of this test method may be affected by the

Petroleum Products

presence of other components with an absorbance band in the

-1 -1

D6299 Practice for Applying Statistical Quality Assurance

zone of 1600 cm to 1800 cm . Low PAI values may be

and Control Charting Techniques to Evaluate Analytical

difficult to determine in those cases. Section 6 describes these

Measurement System Performance

possible interferences in more detail.

D7418 Practice for Set-Up and Operation of Fourier Trans-

1.5 The values stated in SI units are to be regarded as

form Infrared (FT-IR) Spectrometers for In-Service Oil

standard. No other units of measurement are included in this

Condition Monitoring

standard.

E131 Terminology Relating to Molecular Spectroscopy

1.6 This standard does not purport to address all of the

2.2 CEC Standard:

safety concerns, if any, associated with its use. It is the

CEC L-48-A-00 Oxidation Stability of Lubricating Oils

3

Used in Automotive Transmissions by Artificial Aging

1

This test method is under the jurisdiction of ASTM Committee D02 on

2

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Subcommittee D02.96.03 on FTIR Testing Practices and Techniques Related to contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

In-Service Lubricants. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved March 1, 2023. Published March 2023. Originally the ASTM website.

3

approved in 2006. Last previous edition approved in 2022 as D7214 – 22. DOI: Available from Coordinating European Council (CEC), c/o Interlynk Admin-

10.1520/D7214-23. istrative Services, Ltd., P.O. Box 6475, Earl Shilton, Leicester, LE9 9ZB, U.K.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7214 − 23

3. Terminology 7.1.1.1 Other cell window types such as Zinc Selenide, with

a known pathlength of approximately 0.025 mm to 0.1 mm,

3.1 Definitions—For ter

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7214 − 22 D7214 − 23

Standard Test Method for

Determination of the Oxidation of Used Lubricants by FT-IR

1

Using Peak Area Increase Calculation

This standard is issued under the fixed designation D7214; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This test method was jointly developed with “Groupement Francais de Coordination” (GFC),

technical committee LM5 and “Coordinating European Council” (CEC) Surveillance Group T-048 for

the purpose of monitoring the oxidation stability of artificially aged automotive transmission fluids.

This test method has been used in the CEC L-48-A-00 method as an end of test measurement

parameter.

1. Scope*

1.1 This test method covers the determination of the oxidation of used lubricants by FT-IR (Fourier Transform Infrared

Spectroscopy). It measures the concentration change of constituents containing a carbonyl function that have formed during the

oxidation of the lubricant.

1.2 This test method may be used to indicate relative changes that occur in an oil under oxidizing conditions. The test method is

not intended to measure an absolute oxidation property that can be used to predict performance of an oil in service.

1.3 This test method was developed for transmission oils which have been degraded either in service, or in a laboratory test, for

example a bulk oxidation test. It may be used for other in-service oils, but the stated precision may not apply.

1.4 The results of this test method may be affected by the presence of other components with an absorbance band in the zone of

-1 -1

1600 cm to 1800 cm . Low PAI values may be difficult to determine in those cases. Section 6 describes these possible

interferences in more detail.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.96.03 on FTIR Testing Practices and Techniques Related to In-Service Lubricants.

Current edition approved Oct. 1, 2022March 1, 2023. Published October 2022March 2023. Originally approved in 2006. Last previous edition approved in 20202022 as

D7214D7214 – 22.–20. DOI: 10.1520/D7214-22.10.1520/D7214-23.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7214 − 23

2. Referenced Documents

2

2.1 ASTM Standards:

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

D4175 Terminology Relating to Petroleum Products, Liquid Fuels, and Lubricants

D4177 Practice for Automatic Sampling of Petroleum and Petroleum Products

D6299 Practice for Applying Statistical Quality Assurance and Control Charting Techniques to Evaluate Analytical Measure-

ment System Performance

D7418 Practice for Set-Up and Operation of Fourier Transform Infrared (FT-IR) Spectrometers for In-Service Oil Condition

Monitoring

E131 Terminology Relating to Molecular Spectroscopy

2.2 CEC Standard:

3

CEC L-48-A-00 Oxidation Stability of Lubricating Oils Used in Automotive Transmissions by Artificial Aging

3. Terminology

3.1 Definitions—For terminology relating to molecular spectroscopic methods, refer to Terminology E131. For definitions of terms

related to in-service oil condition monitoring, refer to Practice D7418 and Terminology D4175.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 carbonyl region, n—region of the FT-IR spectrum corresponding to the absorbance of compo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.