ASTM D1401-12

(Test Method)Standard Test Method for Water Separability of Petroleum Oils and Synthetic Fluids

Standard Test Method for Water Separability of Petroleum Oils and Synthetic Fluids

SIGNIFICANCE AND USE

This test method provides a guide for determining the water separation characteristics of oils subject to water contamination and turbulence. It is used for specification of new oils and monitoring of in-service oils.

SCOPE

1.1 This test method covers measurement of the ability of petroleum oils or synthetic fluids to separate from water. Although developed specifically for steam-turbine oils having viscosities of 28.8–90 mm2/s at 40°C, this test method may be used to test oils of other types having various viscosities and synthetic fluids at other test temperatures. It is recommended, however, that the test temperature be raised to 82 ± 1°C when testing products more viscous than 90 mm2/s at 40°C. For higher viscosity oils where there is insufficient mixing of oil and water, Test Method D2711 is recommended. Other test temperatures such as 25°C may also be used. A1% sodium choloride (NaCl) solution or synthetic seawater may be used in place of distilled water when testing certain oils or fuels used in marine applications.

1.2 When testing synthetic fluids whose relative densities are greater than that of water, the procedure is unchanged, but it should be noted that the water will probably float on the emulsion or liquid.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see Section 6.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D1401 − 12

StandardTest Method for

1

Water Separability of Petroleum Oils and Synthetic Fluids

This standard is issued under the fixed designation D1401; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* D665 Test Method for Rust-Preventing Characteristics of

Inhibited Mineral Oil in the Presence of Water

1.1 This test method covers measurement of the ability of

D1141 Practice for the Preparation of Substitute Ocean

petroleum oils or synthetic fluids to separate from water.

Water

Although developed specifically for steam-turbine oils having

2 D1193 Specification for Reagent Water

viscosities of 28.8–90 mm /s at 40°C, this test method may be

D2711 Test Method for Demulsibility Characteristics of

used to test oils of other types having various viscosities and

Lubricating Oils

synthetic fluids at other test temperatures. It is recommended,

D4057 Practice for Manual Sampling of Petroleum and

however, that the test temperature be raised to 82 6 1°C when

2 Petroleum Products

testing products more viscous than 90 mm /s at 40°C. For

3

2.2 ISO Standards:

higher viscosity oils where there is insufficient mixing of oil

BS EN ISO 3696:1995 Water for analytical laboratory use –

and water, Test Method D2711 is recommended. Other test

Specification and test methods

temperatures such as 25°C may also be used. A1% sodium

choloride (NaCl) solution or synthetic seawater may be used in

3. Summary of Test Method

place of distilled water when testing certain oils or fuels used

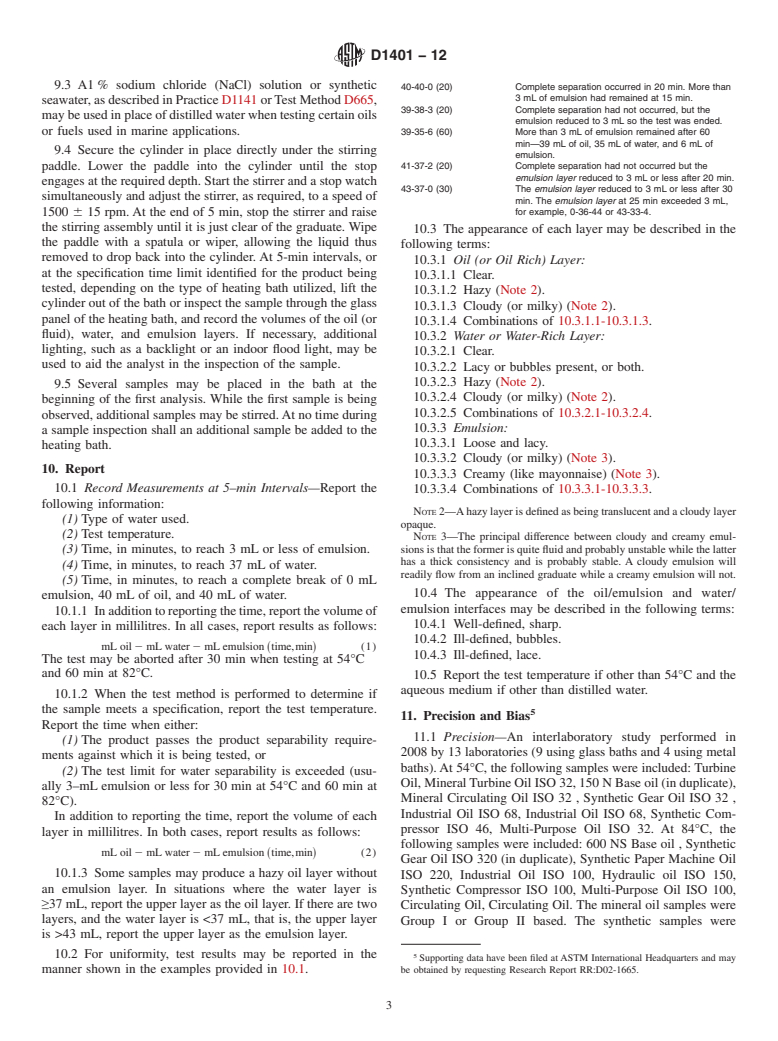

3.1 A test specimen consisting of a 40-mL sample and a

in marine applications.

40-mL quantity of distilled water, or 1% sodium chloride

1.2 When testing synthetic fluids whose relative densities

(NaCl) solution or synthetic seawater are stirred for 5 min in a

are greater than that of water, the procedure is unchanged, but

graduated cylinder at 54°C or 82°C, depending upon the

it should be noted that the water will probably float on the

viscosityofthetestspecimenorsamplespecification.Thetime

emulsion or liquid.

required for the separation of the emulsion thus formed is

1.3 The values stated in SI units are to be regarded as

recorded either after every 5 min or at the specification time

standard. No other units of measurement are included in this

limit. If complete separation or emulsion reduction to 3 mL or

standard.

less does not occur after standing for 30 min or some other

1.4 This standard does not purport to address all of the

specificationtimelimit,thevolumesofoil(orfluid),water,and

safety concerns, if any, associated with its use. It is the emulsion remaining at the time are reported.

responsibility of the user of this standard to establish appro-

4. Significance and Use

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. For specific

4.1 This test method provides a guide for determining the

warning statements, see Section 6.

water separation characteristics of oils subject to water con-

tamination and turbulence. It is used for specification of new

2. Referenced Documents

oils and monitoring of in-service oils.

2

2.1 ASTM Standards:

5. Apparatus

5.1 Cylinder, 100-mL, graduated from 5 to 100 mL in

1.0-mL divisions, made of glass, heat-resistant glass, like

1

This test method is under the jurisdiction of ASTM Committee D02 on

borosilicate glass, or a chemical equivalent. The inside diam-

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.C0.02 on Corrosion and Water/Air Separability.

eter shall be no less than 27 mm and no more than 30 mm

Current edition approved May 15, 2012. Published August 2012. Originally

throughout its length, measured from the top to a point 6 mm

approved in 1964. Last previous edition approved in 2010 as D1401–10. DOI:

10.1520/D1401-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from International Organization for Standardization (ISO), 1, ch. de

Standards volume information, refer to the standard’s Document Summary page on la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://

the ASTM website. www.iso.ch.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1401 − 12

from the bottom of the cylinder. The overall heigh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.