ASTM F2905/F2905M-13

(Specification)Standard Specification for Black Crosslinked Polyethylene (PEX) Line Pipe, Fittings and Joints For Oil and Gas Producing Applications

Standard Specification for Black Crosslinked Polyethylene (PEX) Line Pipe, Fittings and Joints For Oil and Gas Producing Applications

ABSTRACT

This specification covers the requirements and test methods for outside diameter controlled, pressure rated, black metric-sized and IPS-sized crosslinked polyethylene (PEX) pipe, fittings and joints intended for oil and gas producing applications. It presents the criteria for materials made in pipe dimension ratios ranging from 6 to 17, along with workmanship, burst pressure, hydrostatic sustained pressure, bent-pipe hydrostatic pressure, stabilizer functionality, degree of crosslinking, and chemical resistance. It also includes guidelines for pipe and fittings markings.

SCOPE

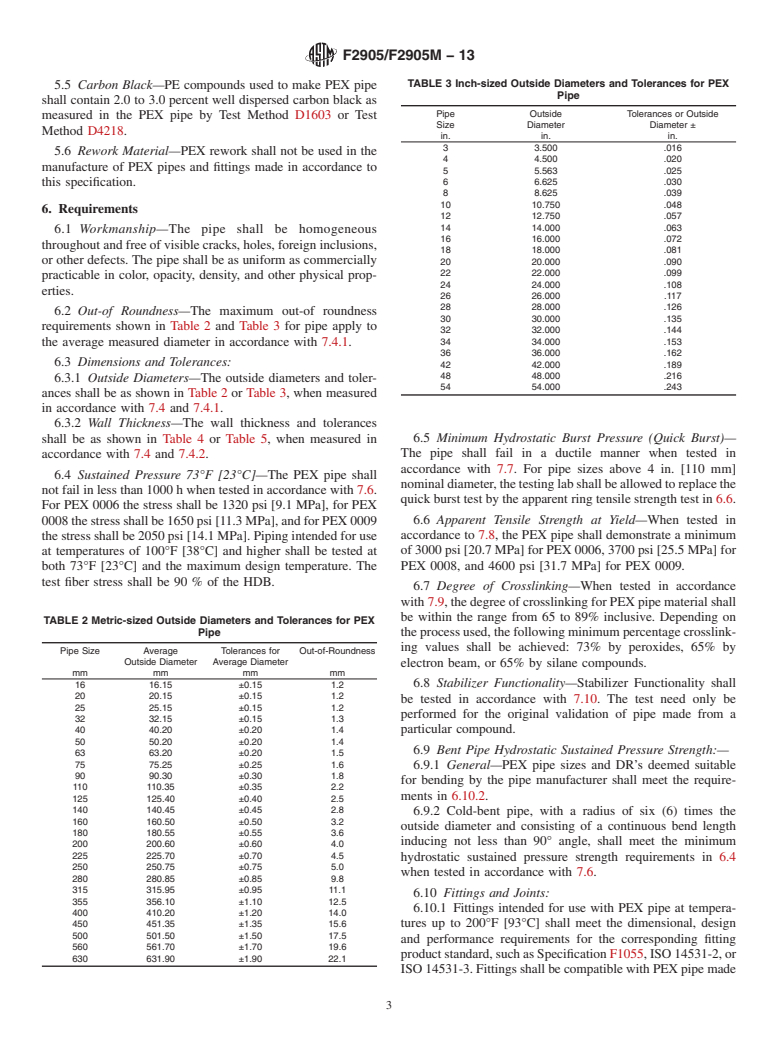

1.1 This specification covers outside diameter controlled, pressure rated, black metric-sized and IPS-sized crosslinked polyethylene (PEX) pipe, fittings and joints, made in pipe dimension ratios ranging from 6 to 17. Included are requirements and test methods for material, workmanship, dimensions, burst pressure, hydrostatic sustained pressure, stabilizer functionality, bent-pipe hydrostatic pressure, degree of crosslinking, and chemical resistance. Requirements for pipe and fittings markings are also given. The pipe, fittings and joints covered by this specification are intended for pressure or non-pressure oil and gas producing applications to convey fluids such as oil, dry or wet gas, gas gathering, multiphase fluids, and non-potable oilfield water. This specification does not cover pipe for gas distribution applications.

1.2 The text of this specification references notes, footnotes, and appendixes, which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.3 Units—The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.Note 1—Metric sized (SI units) pipe should only be joined with corresponding metric sized fittings, and inch sized pipe should only be joined with corresponding inch sized fittings. Inch sized fittings should not be used for metric sized pipe, and metric sized fittings should not be used for IPS inch sized pipe.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2905/F2905M −13

Standard Specification for

Black Crosslinked Polyethylene (PEX) Line Pipe, Fittings

1

and Joints For Oil and Gas Producing Applications

ThisstandardisissuedunderthefixeddesignationF2905/F2905M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This specification covers outside diameter controlled,

2.1 ASTM Standards:

pressure rated, black metric-sized and IPS-sized crosslinked

D618 Practice for Conditioning Plastics for Testing

polyethylene (PEX) pipe, fittings and joints, made in pipe

D792 Test Methods for Density and Specific Gravity (Rela-

dimension ratios ranging from 6 to 17. Included are require-

tive Density) of Plastics by Displacement

ments and test methods for material, workmanship,

D1505 Test Method for Density of Plastics by the Density-

dimensions, burst pressure, hydrostatic sustained pressure,

Gradient Technique

stabilizer functionality, bent-pipe hydrostatic pressure, degree

D1598 Test Method for Time-to-Failure of Plastic Pipe

ofcrosslinking,andchemicalresistance.Requirementsforpipe

Under Constant Internal Pressure

and fittings markings are also given. The pipe, fittings and

D1599 Test Method for Resistance to Short-Time Hydraulic

joints covered by this specification are intended for pressure or

Pressure of Plastic Pipe, Tubing, and Fittings

non-pressure oil and gas producing applications to convey

D1600 Terminology forAbbreviatedTerms Relating to Plas-

fluids such as oil, dry or wet gas, gas gathering, multiphase

tics

fluids, and non-potable oilfield water. This specification does

D1603 Test Method for Carbon Black Content in Olefin

not cover pipe for gas distribution applications.

Plastics

1.2 The text of this specification references notes, footnotes, D2122 Test Method for Determining Dimensions of Ther-

and appendixes, which provide explanatory material. These moplastic Pipe and Fittings

notesandfootnotes(excludingthoseintablesandfigures)shall D2290 Test Method for Apparent Hoop Tensile Strength of

not be considered as requirements of the specification. Plastic or Reinforced Plastic Pipe

D2765 Test Methods for Determination of Gel Content and

1.3 Units—The values stated in either SI units or inch-

Swell Ratio of Crosslinked Ethylene Plastics

pound units are to be regarded separately as standard. The

D2837 Test Method for Obtaining Hydrostatic Design Basis

values stated in each system may not be exact equivalents;

forThermoplasticPipeMaterialsorPressureDesignBasis

therefore,eachsystemshallbeusedindependentlyoftheother.

for Thermoplastic Pipe Products

Combining values from the two systems may result in non-

D4218 Test Method for Determination of Carbon Black

conformance with the standard.

Content in Polyethylene Compounds By the Muffle-

NOTE 1—Metric sized (SI units) pipe should only be joined with

Furnace Technique

corresponding metric sized fittings, and inch sized pipe should only be

F412 Terminology Relating to Plastic Piping Systems

joinedwithcorrespondinginchsizedfittings.Inchsizedfittingsshouldnot

F1055 Specification for Electrofusion Type Polyethylene

be used for metric sized pipe, and metric sized fittings should not be used

Fittings for Outside Diameter Controlled Polyethylene

for IPS inch sized pipe.

and Crosslinked Polyethylene (PEX) Pipe and Tubing

1.4 This standard does not purport to address all of the

F1948 Specification for Metallic Mechanical Fittings for

safety concerns, if any, associated with its use. It is the

Use on Outside Diameter Controlled Thermoplastic Gas

responsibility of the user of this standard to establish appro-

Distribution Pipe and Tubing

priate safety and health practices and determine the applica-

F2619 Specification for High-Density Polyethylene (PE)

bility of regulatory limitations prior to use.

Line Pipe

1

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

2

Piping Systems and is the direct responsibility of Subcommittee F17.68 on Energy For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Piping Systems. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Aug. 1, 2013. Published September 2013. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F2905-13 the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2905/F2905M−13

3

2.2 Federal Standard: 3.2.4 PEX pipe material designation code—The PEX pipe

FED-STD-123 Marking for Shipment (Civ

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.