ASTM D3715/D3715M-98(2004)

(Practice)Standard Practice for Quality Assurance of Pressure-Sensitive Tapes

Standard Practice for Quality Assurance of Pressure-Sensitive Tapes

SCOPE

1.1 This practice contains uniform quality assurance provisions for pressure-sensitive tapes and establishes sampling plans and procedures for acceptance inspection.

1.2 Limitations

1.2.1 This practice only includes procedures for when an upper or a lower specification limit is given. It does not provide for double, both minimum and maximum, specification limits. Note 1When double specification limits are given (applies to variables testing only), use may be made of Table C-3 and Example C-3 of ANSI/ASQC Z1.9.

1.2.2 The variables sampling plans apply to a single quality characteristic. Having obtained the sample and the responses to the physical property tests, acceptance is determined on one quality characteristic at a time. The process is repeated for each additional characteristic.

1.2.3 The variables sampling plans require that the response to each quality characteristic is normally distributed either directly or by transformation. If this is not known, the potential user of this practice should seek the counsel of someone with sufficient understanding of statistical techniques to provide that information.

1.3 The values stated in either SI or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system must be used independently, without combining values in any way.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3715/D3715M – 98 (Reapproved 2004)

Standard Practice for

Quality Assurance of Pressure-Sensitive Tapes

This standard is issued under the fixed designation D3715/D3715M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2. Referenced Documents

1.1 This practice contains uniform quality assurance provi- 2.1 ASTM Standards:

sions for pressure-sensitive tapes and establishes sampling D996 Terminology of Packaging and Distribution Environ-

plans and procedures for acceptance inspection. ments

1.2 Limitations: 2.2 ANSI/ASQC Standards:

1.2.1 This practice only includes procedures for when an ANSI/ASQC A2 Terms, Symbols, and Definitions for Ac-

upperoralowerspecificationlimitisgiven.Itdoesnotprovide ceptance Sampling

for double, both minimum and maximum, specification limits. ANSI/ASQC A3 Quality Systems Terminology

ANSI/ASQCQ94 QualityManagementandQualitySystem

NOTE 1—When double specification limits are given (applies to vari-

Elements—Guidelines

ables testing only), use may be made of Table C-3 and Example C-3 of

ANSI/ASQC Z1.4 Sampling Procedures and Tables for

ANSI/ASQC Z1.9.

Inspection by Attributes

1.2.2 The variables sampling plans apply to a single quality

ANSI/ASQC Z1.9 Sampling and Tables for Inspection by

characteristic.Havingobtainedthesampleandtheresponsesto

Variables for Percent Defective

the physical property tests, acceptance is determined on one

qualitycharacteristicatatime.Theprocessisrepeatedforeach

3. Terminology

additional characteristic.

3.1 Definitions—General terms in this practice are defined

1.2.3 Thevariablessamplingplansrequirethattheresponse

in Terminology D996,ANSI/ASQCA2, andANSI/ASQCA3.

to each quality characteristic is normally distributed either

3.2 Definitions of Terms Specific to This Standard:

directlyorbytransformation.Ifthisisnotknown,thepotential

3.2.1 acceptability criterion—the comparison made be-

user of this practice should seek the counsel of someone with

tween a factor, number, or constant found in the sampling plan

sufficientunderstandingofstatisticaltechniquestoprovidethat

and the examination or test result information from a single

information.

qualitycharacteristictodetermineifthelotshouldbeaccepted

1.3 The values stated in either SI or inch-pound units are to

or rejected. For inspection by attributes the acceptability

be regarded separately as standard. The values stated in each

criterion is a comparison with the acceptability constant found

system may not be exact equivalents; therefore, each system

in Table 1.

must be used independently, without combining values in any

3.2.2 acceptable quality level (AQL)—a nominal value

way.

expressed in terms of percent defective or defects per hundred

1.4 This standard does not purport to address all of the

units, whichever is applicable, specified for a given group of

safety concerns, if any, associated with its use. It is the

defects of a product (see ANSI/ASQC A2).

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

This practice is under the jurisdiction ofASTM Committee D10 on Packaging, the ASTM website.

and is the direct responsibility of Subcommittee D10.14 on Tape and Labels. AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

Current edition approved April 10, 1998. Published March 1999. Originally Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

´1 4

published as D3715–78. Last previous edition D3715–93 . DOI: 10.1520/ AvailablefromAmericanSocietyforQuality(ASQ),310WestWisconsinAve.,

D3715_D3715M-98R04. Milwaukee, WI 53203.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D3715/D3715M – 98 (2004)

A

TABLE 1 Sampling Plans for Inspection by Variables (Variability Unknown—Single Specification Limit)

Acceptable Quality Levels (Normal Inspection) Acceptable Quality Levels (Reduced Inspection)

2 2

Lot Size (100-m [yd ] Sample .65 1.00 1.50 2.50 4.00 6.50 10.00 Sample 1.00 1.50 2.50 4.00 6.50 10.00

Units) Size Size

kk k k kk k k k k k k k

1 to 300 3 l ↓ ↓ 0.587 0.502 0.401 0.296 3 l 0.587 0.502 0.401 0.296 0.178

301 to 500 4 l 0.651 0.598 0.525 0.450 0.364 0.276 3 l 0.587 0.502 0.401 0.296 0.178

↓ l

501 to 800 5 0.663 0.614 0.565 0.498 0.431 0.352 0.272 3 l 0.587 0.502 0.401 0.296 0.178

801 to 1 300 7 0.613 0.569 0.525 0.465 0.405 0.336 0.266 3 ↓ 0.587 0.502 0.401 0.296 0.178

1 301 to 3 200 10 0.755 0.703 0.650 0.579 0.507 0.424 0.341 4 0.598 0.525 0.450 0.364 0.276 0.176

3 201 to 8 000 15 0.792 0.738 0.684 0.610 0.536 0.452 0.368 5 0.565 0.498 0.431 0.352 0.272 0.184

8 001 to 22 000 25 0.815 0.779 0.723 0.647 0.571 0.484 0.398 7 0.525 0.465 0.405 0.336 0.266 0.189

1.00 1.50 2.50 4.00 6.50 10.00 15.00

Acceptable Quality Levels (tightened inspection)

A

This table contains information extracted from Tables A-2 (inspection level I), C-1, and C-2 from ANSI/ASQC Z1.9.

↓ = Use the first sampling plan below arrow including the larger sample size and the k value.

k = Acceptability constant.

3.2.3 defect—any nonconformance of the unit of product to 3.2.12 inspection lot—a collection of units of product from

specified requirements; it is classified according to its serious- which a sample is drawn and inspected to determine compli-

ness. ance with the acceptability criteria.

3.2.13 material specification—that document covering a

3.2.4 defects per hundred units—of any given quantity of

product or set of products and specifying the parameters that

units of product, is the number of defects contained therein

define the product(s) (see ANSI/ASQC A3).

divided by the total number of units of product, the quotient

3.2.14 percent defective—the number of defective units of

multiplied by one hundred (one or more defects being possible

product contained therein, divided by the total number of

in any unit of product). Expressed as an equation:

product, the quotient multiplied by one hundred (a unit being

numberofdefects 3100

Defectsperhundredunits 5 (1) considered defective if it contains one or more defects).

numberofunitsinspected

Expressed as an equation:

3.2.5 defective unit—a unit of product that contains one or

numberofdefectiveunits 3100

more defects. Percentdefective 5 (2)

numberofunitsinspected

3.2.6 enditem—theactualproductorcommoditybeingsold

3.2.15 quality characteristic—for inspection, that charac-

underthematerialspecification.Itisinitsmostcompleteform

teristic of a unit of product that is actually measured to

and may be either packed for shipping or at a production stage

determine conformance with a given requirement.

just preceding packing. It may or may not be the same as the

3.2.16 specification limit(s)—the requirement that a quality

unit of product defined in 3.2.17.

characteristicshouldmeet.Thisrequirementmaybeexpressed

3.2.7 end-item examination—the inspection of the roll of

as an upper specification limit, or a lower specification limit;

tapeforthosecharacteristicswhichareeithereasilydiscernible

called herein a single specification limit.

by visual inspection or can be simply measured by a hand rule

3.2.17 unit of product—the entity of product inspected in

(such as width).All characteristics of this type are considered

order to determine its measurable quality characteristic. For

as attributes.

this practice the unit of product will usually be a roll of tape.

3.2.8 end-item testing—theinspectionoftheunitofproduct

The unit of product may or may not be the same as the unit of

thatinvolvesmeasurementofphysicalpropertiesonacontinu-

purchase, supply production, or shipment. It is also called

ous scale. All characteristics of this type are considered as

sample unit in this practice.

variables.

3.2.9 inspection—the process of measuring, examining,

4. Significance and Use

testing, gaging, or otherwise comparing the unit of product

4.1 The quality of a tape product is determined by the

with the applicable requirements (see ANSI/ASQC A2).

quality systems of the tape producer, including all processes

3.2.10 inspection by attributes—inspection whereby either

involvedintheengineeringandproductionoftheproduct.Itis

the unit of product is classified simply as defective or non-

recommendedthatappropriatesectionsofANSI/ASQCQ94be

defective or the number of defects in the unit of product is

includedinaproducer’squalitysystems.Thispracticedoesnot

counted, with respect to a given requirement or set of require-

intend to standardize these systems.Aproducer’s reputation, a

ments (see ANSI/ASQC A2).

producer’s certification of conformance, or evidence of a

3.2.11 inspection by variables—inspection wherein a speci- producer’s quality systems are often sufficient to ensure a

fied quality characteristic on a unit of product is measured on purchaser or user of a consistent quality.Acceptance sampling

a continuous scale, such as pounds, inches, feet per second, is useful when an objective basis of contract or specification

etc., and a measurement is recorded (see ANSI/ASQC A2). conformance is desired.

D3715/D3715M – 98 (2004)

4.2 The intention of this practice is to provide a reasonably 5. Procedure

simple document which can be used by both the buyer and

5.1 Where it can be demonstrated that a supplier’s quality

seller of pressure-sensitive tape to determine if the product

control system provides a similar degree of assurance as that

offeredforsalemeetssomepredeterminedspecificationforthe

obtained through the use of this practice, the supplier may use

product.Thispracticeofferstheproceduresfordeterminingthe

that system in place of the system described herein. In case of

size of the sample to be inspected and the criteria for

conflict, the system described in this practice shall be used.

determining whether the lot (amount of material offered for

5.2 Whereapplicable,inspection(examinationortesting)at

sale) should be accepted or rejected. This practice draws from

somepriorstageofmanufacture,forexamplein-processorraw

andisbasedonbothANSI/ASQCZ1.4andANSI/ASQCZ1.9.

material, can be used instead of inspection of the end item.An

4.3 Two forms of sampling plans are included: sampling by

example of this might be the use of the tensile strength test

attributes and sampling by variables. Sampling by attributes is performed at the raw material testing stage rather than on the

used for end-item examination and both are used where end item.

appropriateforend-itemtesting.Samplingbyattributeshasthe

5.3 End-Item Examination:

advantage of simplicity while sampling by variables has the 5.3.1 Sampling:

advantage of costing less for the equivalent assurance of the 5.3.1.1 Lot Size, for the purpose of determining the sample

correctness of decisions.

size, shall be expressed in units of rolls for examination under

5.3.2.1-5.3.2.3 inclusive, and shall consist of all the tape

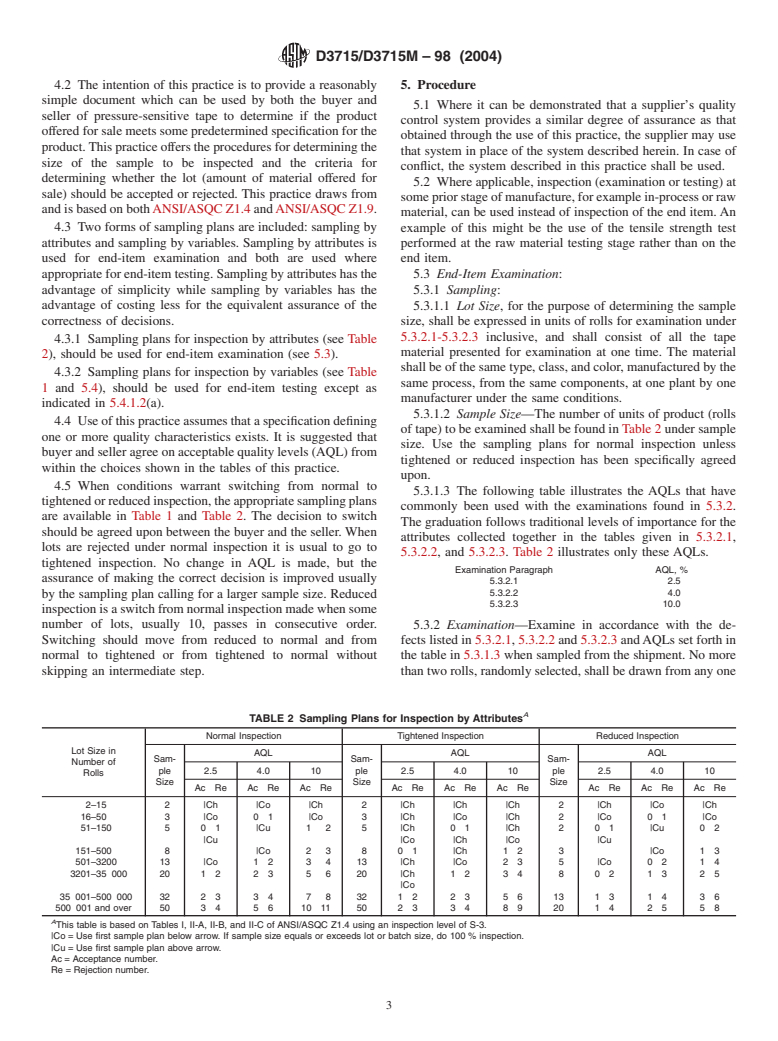

4.3.1 Sampling plans for inspection by attributes (see Table

material presented for examination at one time. The material

2), should be used for end-item examination (see 5.3).

shallbeofthesametype,class,andcolor,manufacturedbythe

4.3.2 Sampling plans for inspection by variables (see Table

same process, from the same components, at one plant by one

1 and 5.4), should be used for end-item testing except as

manufacturer under the same conditions.

indicated in 5.4.1.2(a).

5.3.1.2 Sample Size—The number of units of product (rolls

4.4 Useofthispracticeassumesthataspecificationdefining

oftape)tobeexaminedshallbefoundinTable2undersample

one or more quality characteristics exists. It is suggested that

size. Use the sampling plans for normal inspection unless

buyerandselleragreeonacceptablequalitylevels(AQL)from

tightened or reduced inspection has been specifically agreed

within the choices shown in the tables of this practice.

upon.

4.5 When conditions warrant switching from normal to

5.3.1.3 The following table illustrates the AQLs that have

tightenedorreducedinspection,theappropriatesamplingplans

commonly been used with the examinations found in 5.3.2.

are available in Table 1 and Table 2. The decision to switch

The graduation follows traditional levels of importance for the

should be agreed upon between the buyer and the seller.When

attributes collected together in the tables given in 5.3.2.1,

lots are rejected under normal inspection it is usual to go to

5.3.2.2, and 5.3.2.3. Table 2 illustrates only these AQLs.

tightened inspection. No change in AQL is made, but the

Examination Paragraph AQL, %

assurance of making the correct decision is improved usually

5.3.2.1 2.5

5.3.2.2 4.0

by the sampling plan calling for a larger sample size. Reduced

5.3.2.3 10.0

inspectionisaswitchfromnormalinspectionmadewhensome

number of lots, usually 10, passes in consecutive order.

5.3.2 Examination—Examine in accordance with the de-

Switching should move from reduced to normal and from fectslistedin5.3.2.1,5.3.2.2and5.3.2.3andAQLssetforthin

normal to tightened or from tightened to normal without the table in 5.3.1.3 when sampled from the shipment. No more

skipping an intermediate step. thantworolls,randomlyselected,shallbedrawnfromanyone

A

TABLE 2 Sampling Plans for Inspection by Attributes

Normal Inspection Tightened Inspection Reduced Inspection

Lot Size in

AQL AQL AQL

Sam- Sam- Sam-

Number of

ple 2.5 4.0 10 ple 2.5 4.0 10 ple 2.5 4.0 10

Rolls

Size Size Size

Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re Ac Re

2–15 2 |Ch |Co |Ch 2 |Ch |Ch |Ch 2 |Ch |Co |Ch

16–50 3 |Co 0 1 |Co 3 |Ch |Co |Ch 2 |Co 0 1 |Co

51–150 5 0 1 |Cu 1 2 5 |Ch 0 1 |Ch 2 0 1 |Cu 0 2

|Cu |Co |Ch |Co |Cu

151–500 8 |Co 2 3 8 0 1 |Ch 1 2 3 |Co 1 3

501–3200 13 |Co 1 2 3 4 13 |Ch |Co 2 3 5 |Co 0 2 1 4

3201–35 000 20 1 2 2 3 5 6 20 |Ch 1 2 3 4 8 0 2 1 3 2 5

|Co

35 001–500 000 32 2 3 3 4 7 8 32 1 2 2 3 5 6 13 1 3 1 4 3 6

500 001 and over 50 3 4 5 6 10 11 50 2 3 3 4 8 9 20 1 4 2 5 5 8

A

This table is based on Tables I, II-A, II-B, and II-C of ANSI/ASQC Z1.4 using an inspection level of S-3.

|Co = Use first sample plan below arrow. If sample size equals or exceeds lot or batch size, do 100 % inspection.

|Cu = Use first sample plan above arrow.

Ac = Acceptance number.

Re = Rejection number.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.