oSIST prEN 215:2017

(Main)Thermostatic radiator valves - Requirements and test methods

Thermostatic radiator valves - Requirements and test methods

Mutual understanding and communication. Interchangeability. Performance. Quality. Energy economy. Consumer protection.

Thermostatische Heizkörperventile - Anforderungen und Prüfung

Verstaendigung und Kommunikation. Austauschbarkeit. Gebrauchstauglichkeit. Qualitaet. Energie-Einsparung. Verbraucherschutz.

Robinets thermostatiques d'équipement du corps de chauffe - Exigences et méthodes d'essai

Compréhension mutuelle et communication. Interchangeabilité. Performance. Qualité. Economie d'énergie. Protection des consommateurs.

Termostatni ventili za ogrevala - Zahteve in preskusne metode

General Information

- Status

- Not Published

- Public Enquiry End Date

- 28-Feb-2017

- Technical Committee

- OGS - Heating for buildings

- Current Stage

- 98 - Abandoned project (Adopted Project)

- Start Date

- 17-Jan-2018

- Due Date

- 22-Jan-2018

- Completion Date

- 17-Jan-2018

Relations

- Effective Date

- 08-Jun-2022

- Effective Date

- 01-Feb-2017

Overview

Standard Reference: prEN 215

Title: Thermostatic radiator valves - requirements and test methods

Organization: CEN (Technical Committee CEN/TC 130)

prEN 215 specifies definitions, performance requirements and test methods for thermostatic radiator valves used in wet central heating installations. It applies to two‑port valves (with or without pre‑setting) and to thermostatic integrated valves for radiators, rated for water temperatures up to 120 °C and nominal pressure PN 10. The draft standard supersedes EN 215:2004 and can serve as a reference for CEN/CENELEC certification schemes.

Key Topics

- Scope and types: Covers straight and angle pattern valves, integrated radiator valves, valves with integral or remote sensors and selectors, and valves with pre‑setting facilities.

- Dimensions and connections: Standardizes dimensions, materials and connection details for four series of valves; annexes include dimension tables and connection types.

- Mechanical requirements: Tests and criteria for valve body strength, resistance to pressure, leak‑tightness, stem seal integrity, bending moment and torque on selectors, and exchangeability of stem seals.

- Operating characteristics: Specifies hydraulic performance testing including nominal and characteristic flow rates, flow at S‑1, hysteresis, differential‑pressure and static‑pressure influences, sensor temperatures at selector end stops, response time, and effects of ambient and water temperature.

- Endurance and temperature resistance: Mechanical and thermal endurance tests and temperature resistance checks to ensure long‑term performance and consumer protection.

- Test apparatus & methods: Detailed test rigs and procedures (hydraulic apparatus, water bath, air stream setups), methods for determining characteristic curves and plotting theoretical curves.

- Manufacturer information: Required technical information to be published by manufacturers, including CA value calculation and marking guidance.

Applications

Who uses prEN 215 and why:

- Manufacturers: to design, test and mark thermostatic radiator valves that meet European performance, safety and interchangeability expectations.

- Test laboratories & certification bodies: to perform standardized tests for product approval and CEN/CENELEC certification.

- Specifier, HVAC engineers & installers: to select appropriate valves for central heating systems ensuring energy economy, compatibility and consumer protection.

- Regulators & purchasers: to reference uniform requirements for procurement and compliance checks.

Practical benefits include improved interchangeability, predictable hydraulic performance, better energy economy of space heating systems, and enhanced consumer safety and product quality.

Related Standards

Normative references cited include key materials and thread standards such as EN 1982 (copper alloys), EN ISO 228‑1, ISO 7‑1 and ISO 965‑1, and prEN 15316‑2 for heating system energy calculations. prEN 215 is intended to replace EN 215:2004.

Frequently Asked Questions

oSIST prEN 215:2017 is a draft published by the Slovenian Institute for Standardization (SIST). Its full title is "Thermostatic radiator valves - Requirements and test methods". This standard covers: Mutual understanding and communication. Interchangeability. Performance. Quality. Energy economy. Consumer protection.

Mutual understanding and communication. Interchangeability. Performance. Quality. Energy economy. Consumer protection.

oSIST prEN 215:2017 is classified under the following ICS (International Classification for Standards) categories: 23.060.01 - Valves in general; 91.140.10 - Central heating systems. The ICS classification helps identify the subject area and facilitates finding related standards.

oSIST prEN 215:2017 has the following relationships with other standards: It is inter standard links to SIST EN 215:2004, SIST EN 215:2004. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

oSIST prEN 215:2017 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-februar-2017

Termostatni ventili za ogrevala - Zahteve in preskusne metode

Thermostatic radiator valves - Requirements and test methods

Thermostatische Heizkörperventile - Anforderungen und Prüfung

Robinets thermostatiques d'équipement du corps de chauffe - Exigences et méthodes

d'essai

Ta slovenski standard je istoveten z: prEN 215

ICS:

23.060.01 Ventili na splošno Valves in general

91.140.10 Sistemi centralnega Central heating systems

ogrevanja

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

DRAFT

EUROPEAN STANDARD

NORME EUROPÉENNE

EUROPÄISCHE NORM

January 2017

ICS 91.140.10 Will supersede EN 215:2004

English Version

Thermostatic radiator valves - Requirements and test

methods

Robinets thermostatiques d'équipement du corps de Thermostatische Heizkörperventile - Anforderungen

chauffe - Exigences et méthodes d'essai und Prüfung

This draft European Standard is submitted to CEN members for enquiry. It has been drawn up by the Technical Committee

CEN/TC 130.

If this draft becomes a European Standard, CEN members are bound to comply with the CEN/CENELEC Internal Regulations

which stipulate the conditions for giving this European Standard the status of a national standard without any alteration.

This draft European Standard was established by CEN in three official versions (English, French, German). A version in any other

language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC

Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania,

Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and

United Kingdom.

Recipients of this draft are invited to submit, with their comments, notification of any relevant patent rights of which they are

aware and to provide supporting documentation.

Warning : This document is not a European Standard. It is distributed for review and comments. It is subject to change without

notice and shall not be referred to as a European Standard.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Avenue Marnix 17, B-1000 Brussels

© 2017 CEN All rights of exploitation in any form and by any means reserved Ref. No. prEN 215:2017 E

worldwide for CEN national Members.

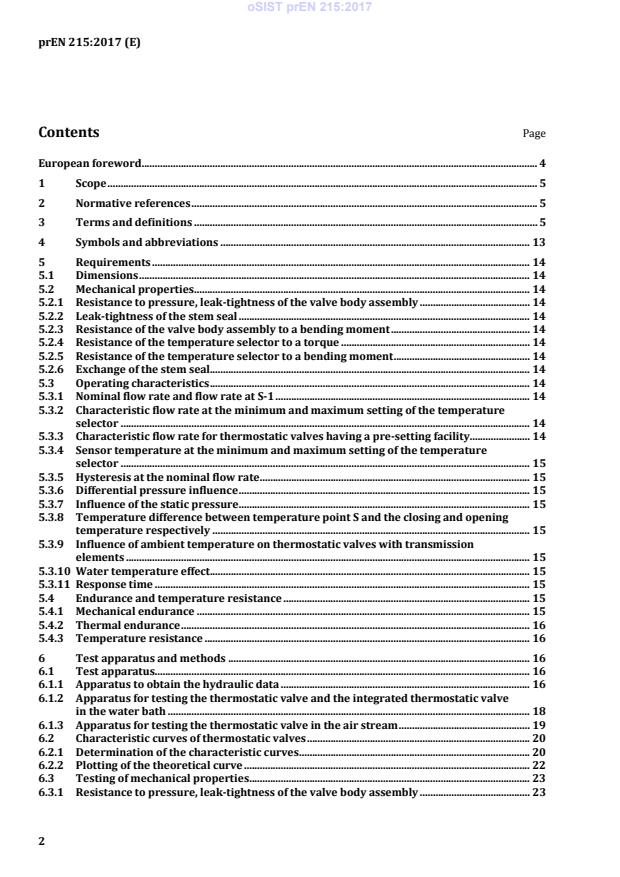

Contents Page

European foreword . 4

1 Scope . 5

2 Normative references . 5

3 Terms and definitions . 5

4 Symbols and abbreviations . 13

5 Requirements . 14

5.1 Dimensions . 14

5.2 Mechanical properties . 14

5.2.1 Resistance to pressure, leak-tightness of the valve body assembly . 14

5.2.2 Leak-tightness of the stem seal . 14

5.2.3 Resistance of the valve body assembly to a bending moment . 14

5.2.4 Resistance of the temperature selector to a torque . 14

5.2.5 Resistance of the temperature selector to a bending moment . 14

5.2.6 Exchange of the stem seal. 14

5.3 Operating characteristics . 14

5.3.1 Nominal flow rate and flow rate at S-1 . 14

5.3.2 Characteristic flow rate at the minimum and maximum setting of the temperature

selector . 14

5.3.3 Characteristic flow rate for thermostatic valves having a pre-setting facility. 14

5.3.4 Sensor temperature at the minimum and maximum setting of the temperature

selector . 15

5.3.5 Hysteresis at the nominal flow rate . 15

5.3.6 Differential pressure influence . 15

5.3.7 Influence of the static pressure . 15

5.3.8 Temperature difference between temperature point S and the closing and opening

temperature respectively . 15

5.3.9 Influence of ambient temperature on thermostatic valves with transmission

elements . 15

5.3.10 Water temperature effect. 15

5.3.11 Response time . 15

5.4 Endurance and temperature resistance . 15

5.4.1 Mechanical endurance . 15

5.4.2 Thermal endurance . 16

5.4.3 Temperature resistance . 16

6 Test apparatus and methods . 16

6.1 Test apparatus. 16

6.1.1 Apparatus to obtain the hydraulic data . 16

6.1.2 Apparatus for testing the thermostatic valve and the integrated thermostatic valve

in the water bath . 18

6.1.3 Apparatus for testing the thermostatic valve in the air stream . 19

6.2 Characteristic curves of thermostatic valves . 20

6.2.1 Determination of the characteristic curves . 20

6.2.2 Plotting of the theoretical curve . 22

6.3 Testing of mechanical properties . 23

6.3.1 Resistance to pressure, leak-tightness of the valve body assembly . 23

6.3.2 Leak-tightness of the valve closed mechanically by means of the protection cap. . 24

6.3.3 Leak-tightness of the stem seal . 24

6.3.4 Resistance of the valve body assembly to a bending moment . 25

6.3.5 Resistance of the temperature selector to a torque . 26

6.3.6 Resistance of the temperature selector to a bending moment . 27

6.4 Testing of operating characteristics . 27

6.4.1 Characteristic data . 27

6.4.2 Endurance tests and temperature resistance test . 30

6.5 Test schedule . 31

7 Technical information to be published by the manufacturer . 33

Annex A (normative) Thermostatic Radiator Valves - Dimensions and details on connection . 35

A.1 General . 35

A.2 Dimensions . 35

A.3 Connection details . 37

A.4 Materials for body, tailpiece and nut . 37

A.5 Designation . 38

A.6 Marking (This marking does not cover possible certification marking) . 38

A.7 CA Value Calculation . 38

Annex B (informative) Degree of turbulence of the air current in a room . 39

Annex C (informative) Test block for thermostatic integrated valves . 40

Bibliography . 41

European foreword

This document (prEN 215:2017) has been prepared by Technical Committee CEN/TC 130 “Space

heating appliances without integral heat sources”, the secretariat of which is held by UNI.

This document is currently submitted to the CEN Enquiry.

This document will supersede EN 215:2004.

This European Standard can be used as a reference for a CEN/CENELEC Certification Mark System on

radiator valves.

1 Scope

This European Standard specifies definitions, requirements and test methods for thermostatic radiator

valves (referred to hereafter as thermostatic valves).

This standard applies to two port thermostatic valves with or without pre-setting facility and

thermostatic integrated valves with or without pre-setting facility for fitting to radiators in wet central

heating installations up to a water temperature of 120 °C and a nominal pressure of PN 10.

This standard further specifies the dimensions, the materials and the connection details of four series of

straight and angle pattern thermostatic radiator valves of nominal pressure ≤ PN 10.

This standard can be used as reference in a CEN/CENELEC Certification Mark System on thermostatic

radiator valves.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

EN 1982, Copper and copper alloys - Ingots and castings

EN 12164, Copper and copper alloys - Rod for free machining purposes

EN 12168, Copper and copper alloys - Hollow rod for free machining purposes

EN 12420, Copper and copper alloys - Forgings

EN 12449, Copper and copper alloys - Seamless, round tubes for general purposes

prEN 15316-2, Heating systems and water based cooling systems in buildings - Method for calculation of

system energy requirements and system efficiencies - Part 2: Space emission systems (heating and cooling)

EN ISO 228-1, Pipe threads where pressure-tight joints are not made on the threads - Part 1: Dimensions,

tolerances and designation (ISO 228-1)

ISO 7-1, Pipe threads where pressure-tight joints are made on the threads - Part 1: Dimensions, tolerances

and designation

ISO 965-1, ISO general purpose metric screw threads - Tolerances - Part 1: Principles and basic data.

ISO 7268, Pipe components - Definition of nominal pressure.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

thermostatic radiator valve

thermostatic head assembly and thermostatic valve assembly or the thermostatic integrated valve

assembly

Note 1 to entry: See Figure 1 for components of the thermostatic radiator valve.

Key

A thermostatic head assembly 5 valve seat

B valve body assembly 6 union nut

1 sensor 7 tailpiece

2 temperature selector 8 valve stem

3 temperature selector scale 9 stem seal

4 valve disc 10 flow direction arrow

Figure 1 — Schematic drawing of the assembly of a thermostatic valve with integral sensor

3.1.1

sensor

part of the thermostatic valve that senses the temperature (controlled value)

Note 1 to entry: See Figure 2.

3.1.2

transmission unit

part of the thermostatic valve that converts a change of temperature or pressure of the sensor into a

linear movement of the valve stem

Note 1 to entry: See Figure 2.

3.1.3

transmission element

part of the thermostatic valve (e.g. capillary) that transmits the volume or pressure changes from the

sensor or temperature selector to the transmission unit

Note 1 to entry: See Figure 2.

3.1.4

thermostatic element

section containing all parts that are filled with the expansion medium

EXAMPLE Sensor, transmission element and transmission unit, shown as cross hatched parts in Figure 2.

Key

1 sensor

2 transmission element

3 transmission unit

Figure 2 — Thermostatic element

3.1.5

protection cap

device that protects the valve stem and thread before the initial fitting of the thermostatic head

assembly

3.2

types of thermostatic head assembly

3.2.1

thermostatic valve with integral sensor

valve where the sensor, transmission unit and temperature selector constitute an assembly which is

incorporated with the valve body assembly

Note 1 to entry: See Figure 3.

Figure 3 — Thermostatic valve with integral sensor

3.2.2

thermostatic valve with integral temperature selector and with remote sensor

valve where the temperature selector is incorporated within the valve but the sensor is separated from

the transmission unit, and there is a transmission element between the sensor and the transmission

unit

Note 1 to entry: See Figure 4.

Figure 4 — Thermostatic valve with integral temperature selector with remote sensor

3.2.3

thermostatic valve with the remote sensor incorporating the selector

valve where the sensor and temperature selector assembly is mounted remotely from the valve body

assembly and from the transmission unit, and there is a transmission element between the sensor and

the transmission unit

Note 1 to entry: See Figure 5.

Figure 5 — Thermostatic valve with the remote sensor incorporating the selector

3.2.4

thermostatic valve with remote sensor and remote selector

valve where both the sensor and the temperature selector are separate from each other and from the

valve body assembly with transmission unit, and there is a transmission element between the sensor

and the transmission unit and between the temperature selector and the transmission unit

Note 1 to entry: See Figure 6.

Figure 6 — Thermostatic valve with remote sensor and remote selector

3.2.5

thermostatic valve with pre-setting

valve where a reduced flow rate can be obtained by means of mechanical pre-adjustment incorporated

in the valve body assembly

3.2.6

type of thermostatic integrated valve

embedded valve including valve seat

Note 1 to entry: See Figure 7.

Key

1 garniture

2 integrated valve assembly

3 packing seal

Figure 7 — Example of valve integrated in a radiator

3.3

types of connections

examples of connections used to fit the valve to the radiator and to the pipe work

Note 1 to entry: See Figure 8.

Key

a) internal pipe thread and cone seated union

b) compression fitting and cone seated union

c) washered union connections

d) compression fittings

e) integrated valve

Figure 8 — Types of radiator valve connections

3.4

operating characteristics

3.4.1

characteristic flow rate

q

m, s

water flow rate that is obtained at a temperature of point S-2K, and at a differential pressure of 10 kPa

(0,1 bar), at any desired setting

3.4.2

nominal flow rate

q

m, N

characteristic flow rate for an intermediate setting of the temperature selector according to 6.2.1.3.

Note 1 to entry: The nominal flow rate for thermostatic valves having a pre-setting facility is that obtained

when the pre-setting facility is inoperative.

3.4.3

maximum flow rate

q

m, max

maximum water flow rate that can be obtained at a differential pressure of 10 kPa (0,1 bar)

3.4.4

hysteresis

temperature difference between the opening and closing curves obtained at the same flow rate

Note 1 to entry: See Figure 9.

Note 2 to entry: If the opening and the closing curves cross each other the value of the hysteresis will be

measured at 1 K P-deviation.

Key

q flow rate a opening curve S temperature point S

m

°C water bath temperature b closing curve

c theoretical curve

d hysteresis

e closing temperature

f opening temperature

Figure 9 — Explanatory graph of characteristic curves

3.4.5

differential pressure influence

difference between the temperature points S on the theoretical closing curves obtained at different

differential pressures

Note 1 to entry: See Figure 9.

3.4.6

influence of static pressure

temperature difference between two closing curves plotted at different static pressures at the same

flow rate

3.4.7

water temperature effect

difference in sensor temperatures which is equivalent to the flow rate deviation caused by a change of

temperature of the water flowing through the valve

3.4.8

influence of ambient temperature on thermostatic valves with transmission elements

temperature difference obtained at the same flow rate between two opening curves, one recorded with

and one without temperature difference between sensor and transmission unit

Note 1 to entry: Valves according to 3.2.2 to 3.2.4.

3.4.9

response time

time taken for a change of flow rate after a step-change of air temperature

Note 1 to entry: This change of flow rate corresponds to a pre-determined temperature difference in accordance

with 6.4.1.13.

3.5

technical definitions

3.5.1

sensor temperature

measured temperature of the sensor

Note 1 to entry: In the test it is the same as the temperature of the water bath.

3.5.2

differential pressure

Δp

difference of pressure between valve inlet and valve outlet

3.5.3

closing curve and opening curve

curves showing the functions of the water flow versus sensor temperature at constant differential

pressure when the valve is closing and opening respectively and at the same temperature selector

setting

Note to entry: See Figure 9.

3.5.4

closing temperature and opening temperature

sensor temperatures obtained from the closing and opening curves respectively for zero flow

Note 1 to entry: See Figure 9.

3.5.5

theoretical curve

straight line which passes through the points 0,5 q and 0,25 q on the characteristic curve

m s m s

Note 1 to entry: Construction shall be according to 6.2.2.

Note 2 to entry: See Figure 9.

3.5.6

temperature point S

point of intersection of the theoretical curve with the abscissa q = 0

m

Note 1 to entry: According to 6.2.2.

Note 2 to entry: See Figure 9.

4 Symbols and abbreviations

Table 1 — Symbols and abbreviations

Symbol Explanation Unit

q

Flow rate kg/h

m

qm,N Nominal flow rate kg/h

qm,s Characteristic flow rate kg/h

qm,max Maximum flow rate kg/h

q at maximum setting of the

m s

qm,s,max kg/h

temperature selector

q at minimum setting of the

m s

qm,s,min kg/h

temperature selector

q

m,x1 Auxiliary flow rates for measuring the

kg/h

response time

qm,x2

Sensor temperature which corresponds

t

°C

s

to the characteristic flow rate

t at maximum setting of the

s

ts,max °C

temperature selector

t at minimum setting of the

s

ts,min °C

temperature selector

S Temperature point °C

Δp Differential pressure Pa

K Temperature difference Kelvin

5 Requirements

5.1 Dimensions

Dimensions and connection details for some types of radiator valves are given in Annex A.

5.2 Mechanical properties

5.2.1 Resistance to pressure, leak-tightness of the valve body assembly

During the test according to 6.3.1, there shall be no leak from the connections nor through the wall of

the body.

5.2.2 Leak-tightness of the stem seal

The stem seal shall show no leakage of air during the test according to 6.3.3.

5.2.3 Resistance of the valve body assembly to a bending moment

The valve shall withstand the load according to 6.3.4 without permanent functional impairment, and

shall fulfil the requirements of the subsequent tests.

Permanent deformation shall not be taken into account.

5.2.4 Resistance of the temperature selector to a torque

No damage or permanent deformation shall be visible after the test according to 6.3.5.

5.2.5 Resistance of the temperature selector to a bending moment

No damage or permanent deformation shall be visible after the test according to 6.3.6.

5.2.6 Exchange of the stem seal

It shall be possible to exchange the stem seal and/or the insert without draining the heating installation

in which the valve is mounted.

5.3 Operating characteristics

5.3.1 Nominal flow rate and flow rate at S-1

The nominal flow rate declared by the manufacturer shall not vary by more than 10 % for flow rates

> 33 kg/h and by more than 3 kg/h for flow rates ≤ 33 kg/h from the value determined in the test

specified in 6.4.1.1.

The plotted flow rate S -1 K shall not be more than 70 % of the nominal flow rate. For presettable

valves, the 70 % are only valid for the maximum pre-setting position.

5.3.2 Characteristic flow rate at the minimum and maximum setting of the temperature selector

This flow rate qm,s determined according to 6.4.1.5 shall be within the following ranges:

• at maximum setting: q ≥ 0,8q

m,s,max m,N;

• at minimum setting: 1,2q ≥ q ≥ 0,5q

m,N m,s,min m,N.

5.3.3 Characteristic flow rate for thermostatic valves having a pre-setting facility

For thermostatic valves having a pre-setting facility, the characteristic flow rate declared by the

manufacturer for an intermediate setting of the temperature selector according to 6.2.1.3 and for each

specified pre-setting position shall not vary by more than the tolerance declared by the manufacturer

from the values determined in the test specified in 6.4.1.3.

5.3.4 Sensor temperature at the minimum and maximum setting of the temperature selector

This sensor temperature ts determined according to 6.4.1.6 shall be within the following range:

• 5 °C ≤ t ≤ 32 °C.

s

5.3.5 Hysteresis at the nominal flow rate

The hysteresis determined according to 6.4.1.7 shall not be greater than 1 K and not exceed the value

declared by the manufacturer by more than 0,2 K.

5.3.6 Differential pressure influence

The differential pressure influence determined according to 6.4.1.8 shall not be greater than 1 K and not

exceed the value declared by the manufacturer by more than 0,3 K.

If the measured value is negative (e.g. in case of opposite flow direction) it shall be documented as

absolute value.

5.3.7 Influence of the static pressure

The influence of the static pressure determined according to 6.4.1.9 shall not be greater than 1 K.

5.3.8 Temperature difference between temperature point S and the closing and opening

temperature respectively

The temperature difference between temperature point S and the closing and opening temperature

respectively determined according to 6.4.1.10 shall not be greater than 0,8 K.

5.3.9 Influence of ambient temperature on thermostatic valves with transmission elements

The influence of the ambient temperature determined according to 6.4.1.11 shall not be greater than

1,5 K.

5.3.10 Water temperature effect

The effect that is caused by a change of the temperature of the water flowing through the valve of 30 K

and which is determined according to 6.4.1.12 shall not be greater than:

• 1,5 K for thermostatic valves with the sensor incorporated according to 3.2.1;

• 0,75 K for thermostatic valves with the transmission elements according to 3.2.2 to 3.2.4

and not exceed the value declared by the manufacturer by more than 0,3 K.

5.3.11 Response time

The response time determined according to 6.4.1.13 shall not exceed 40 min and the value declared by

the manufacturer by more than 7 min.

5.4 Endurance and temperature resistance

5.4.1 Mechanical endurance

The values of the sensor temperatures at the nominal flow rate before and after the mechanical

endurance test according to 6.4.2.1 shall not vary by more than 2 K.

The nominal flow rate determined after the mechanical endurance test shall not vary by more than

± 20 % from that determined before the endurance test.

5.4.2 Thermal endurance

The values of the sensor temperatures at nominal flow rate before and after the thermal endurance test

according to 6.4.2.2 shall not vary by more than 2 K.

The nominal flow rate determined after the thermal endurance test shall not vary by more than ± 20 %

from that determined before the endurance test.

5.4.3 Temperature resistance

The values of the sensor temperatures at nominal flow rate before and after the temperature resistance

test according to 6.4.2.3 shall not vary by more than 1,5 K.

The nominal flow rate determined after the temperature resistance test shall not vary by more than

± 20 % from that determined before the temperature resistance test.

6 Test apparatus and methods

6.1 Test apparatus

6.1.1 Apparatus to obtain the hydraulic data

Use a test circuit with the functions shown in Figure 10 to obtain the hydraulic data of the valve.

Key

1 test sample 8 differential pressure controller

2 flow meter F 9 differential pressure meter

3 xy recorder R 10 measuring points for differential pressure

(x = temperature, y = flow rate)

4 heater 11 temperature sensor

5 temperature controller 12 temperature meter

6 temperature sensor 13 device for maintaining the pressure in the system by means of

an expansion vessel

7 circulating pump 14 test block for thermostatic integrated valve (Examples for

dimension see Annex C)

Figure 10 — Schematic layout of the test circuit to obtain the hydraulic data of the thermostatic

valve and the thermostatic integrated valve

Table 2 — Dimensional pipe characteristics

Nominal size Pipe thread Internal diameter d

a

DN mm

8 1/4 10

10 3/8 10

15 1/2 13

20 3/4 20

25 1 25

a

See EN ISO 6708.

The flow measurement accuracy shall be at least:

— ± 3 % of the measured value for flow rates > 33 kg/h;

— ± 1 kg/h for flow rates ≤ 33 kg/h.

The pressure differential measurement accuracy shall be at least:

— ± 1 % of the measured value.

By means of a controller it shall be possible to maintain a differential pressure, when measured across

the inlet and outlet pressure tappings of the test sample, at a value between 10 and 60 kPa (0,1 and

0,6 bar) and constant within ± 2 %. Furthermore, it shall be possible to apply a constant inlet pressure

of 100 kPa (1 bar) ± 2 % or of 1 000 kPa (10 bar) ± 2 % at the inlet pressure tapping of the sample.

At the inlet of the test circuit there is a water temperature measuring point.

It shall be possible to keep the water temperature constant within ± 0,2 K at a chosen temperature

between 50 °C and 80 °C.

6.1.2 Apparatus for testing the thermostatic valve and the integrated thermostatic valve in the

water bath

Use a circuit functionally as shown in Figure 11 for testing the thermostatic valve and the thermostatic

integrated valve in the water bath. Totally immerse the thermostatic element in the water bath, e. g. at

the level which is specified by the manufacturer, ensuring that the water is continuously mixed and

circulated around the thermostatic element.

It shall be possible to change the temperature smoothly by means of a control device. The rate of change

shall be 3 K/h. The temperature of the water bath shall be measured and recorded with an accuracy of

± 0,2 K and the temperature change in the bath with an accuracy of ± 0,03 K.

For the test according to 6.2.1.5, two water baths shall be used.

Key

1 water bath 8 temperature controller

2 stirrer 9 temperature sensor

3 temperature sensor 10 thermostatic head assembly

4 temperature meter 11 thermostatic element

5 xy recorder 12 test circuit according to Figure 10

(x = temperature, y = flow rate)

6 water bath heater 13 testblock for thermostatic integrated

valve (Dimensions see Annex C)

7 water bath cooler

Figure 11 — Schematic layout of the test apparatus for the water bath

6.1.3 Apparatus for testing the thermostatic valve in the air stream

Use a testing equipment consisting of two air ducts, each having a symmetrical cross sectional area of at

least 0,36 m (Figure 12). The thermostatic valve shall be placed in the centre of one duct with the axis

of the thermostatic head with integral sensor mounted in a horizontal position, unless otherwise

specified by the manufacturer. Thermostatic valves with transmission elements in accordance with

3.2.2 to 3.2.4 shall be mounted in a position as declared by the manufacturer.

Air shall pass across the thermostatic valve in an upward direction. A device shall effect rapid transfer

of the thermostatic valve from one duct to the other.

The inside wall of the measuring duct shall be protected against radiated heat. The temperature and

velocity profiles in the duct at test level shall be uniform over at least 80 % of the cross section. During

the test, the air stream shall be controlled by a measuring device having an adequate measuring

accuracy. The air temperature shall be maintained constant to ± 0,1 K.

The connection pipes shall not be in the air stream in front of the test sample. They shall be thermally

insulated.

The air temperature change shall be measured with a maximum uncertainty of measurement of

± 0,03 K. The temperature sensor shall be insulated against radiation.

The airflow shall be turbulent. The air velocity, shall be adjusted to obtain a mean velocity of

+0,05

0,1 m/s m/s.

The standard deviation, calculated from velocity variations, by statistical methods and compared to the

mean value, or the degree of turbulence, shall be within 30 % to 50 % (see Annex B).

Key

1 test sample

2 fan

3 duct installations for obtaining a smooth flow profile and for generating turbulence

4 calibrated venturi

5 differential pressure gauge F

6 heat exchanger

7 temperature controlled water circuit

8 temperature meter

Figure 12 — Schematic layout of the air test apparatus

6.2 Characteristic curves of thermostatic valves

6.2.1 Determination of the characteristic curves

6.2.1.1 General

Use the curves 1 to 7 according to Figure 13 for the assessment of the performance of thermostatic

valves.

These curves are plotted using the test apparatus as described in 6.1.1 and 6.1.2.

Unless specified differently in the following clauses, the measurements shall be carried out with a static

pressure at the inlet of the valve of 100 kPa (1 bar) ± 10 % and with a differential pressure of

10 kPa (0,1 bar) ± 2 %. The temperature of the water flowing through the thermostatic valve shall be

maintained at 50 °C ± 2 °C. The water bath temperature shall not vary by more than 3 K/h.

For all the characteristic curves which are measured at an intermediate setting of the temperature

selector, this intermediate setting shall be obtained in the closing direction.

6.2.1.2 Opening curve at minimum setting of the temperature selector (curve no. 1) and at

maximum setting (curve no. 2)

Adjust to the minimum setting. Starting with a temperature of at least 2 K above the opening

temperature, decrease the sensor temperature to 3 K below the opening temperature and plot the

opening curve. Now adjust to the maximum setting and repeat the procedure given for the minimum

setting above.

6.2.1.3 Opening curve at an intermediate setting of the temperature selector (curve no. 3)

Choose a mean setting of the temperature selector for which the opening temperature on the opening

curve is between 20 °C and 24 °C. Start with a temperature of at least 2 K above the opening

temperature. Decrease the sensor temperature to 6 K below the opening temperature and plot the

opening curve.

6.2.1.4 Closing curve at an intermediate setting of the temperature selector (curve no. 4)

The setting of the temperature selector remaining unchanged, start from a temperature of at least 4 K

below the opening temperature. Increase the sensor temperature up to 1 K above the closing

temperature and plot the closing curve.

6.2.1.5 Opening curve for thermostatic valves with transmission elements in accordance with

3.2.2 to 3.2.4 at an intermediate setting of the temperature selector (curve no. 5)

The setting of the temperature selector remaining unchanged, immerse the transmission unit with 1 m

of its transmission element in a second water bath. This shall be at a constant temperature of

10 K ± 0,1 K above that sensor temperature, at which the nominal flow rate is obtained. The remainder

of the transmission element, the sensor, and for thermostatic valves according to 3.2.4 the remote

temperature selector as well shall be immersed in the first water bath.

Starting with the temperature of at least 2 K above the opening temperature, decrease the sensor

temperature to 3 K below the opening temperature and plot the opening curve.

6.2.1.6 Closing curve at an intermediate setting of the temperature selector and at a differential

pressure greater than 10 kPa (0,1 bar) (curve no. 6)

For thermostatic valves with integral sensor, plot the closing curve at a differential pressure of 60 kPa

(0,6 bar) ± 2 % immediately after the measurement as described in 6.2.1.4 and in the same way.

For thermostatic valves with transmission elements according to 3.2.2 to 3.2.4, plot the same curve

after the measurement as described in 6.2.1.5.

If the maximum permissible differential pressure declared by the manufacturer is less than

60 kPa (0,6 bar), the test shall be carried out at that differential pressure.

6.2.1.7 Closing curve at an intermediate setting of the temperature selector and at a static

pressure of 1000 kPa (10 bar) (curve no. 7)

In the same way as described in 6.2.1.4 and immediately after the measurement described in 6.2.1.6,

plot the closing curve at a static pressure of 1 000 kPa (10 bar) ± 2 %.

Key

A flow rate, q

m

B water bath temperature, °C

C hysteresis

D differential pressure effect

E effect of the static pressure

F difference of sensor temperatures at minimum and maximum setting

G influence of ambient temperature on thermostatic valves with transmission elements

Figure 13 — Characteristic curves of thermostatic valves

6.2.2 Plotting of the theoretical curve

This procedure is used for any plotted opening and closing curve. It is effected by the following iterative

steps (see Figure 14):

1) The linear part of the curve is extended to meet the abscissa q = 0 (point 1 ) or the tangent is

m 1

drawn through the point of inflexion;

2) At a temperature of 2 K below the intersection (point 1 ) point 2 is obtained and the corresponding

1 1

water flow rate (point 3 ) is determined;

3) Point 4 is obtained at 50 % and point 5 at 25 % of the water flow rate at point 3 ;

1 1 1

4) Join point 4 and 5 and continue to cut the abscissa (q = 0) at point 6 ;

1 1 m 1

5) Repeat the process starting from point 6 until further repetition does not result in a shift in point 6;

this final point is designated by S;

6) The water flow rate at a temperature 2 K lower is q ;

m,s

7) The line through the final points of 50 % and of 25 % of q on the characteristic curve and S on the

m,s

abscissa is the theoretical curve.

Key

q flow rate

m

°C water bath temperature

Figure 14 — Plotting of the theoretical curve and of point S

6.3 Testing of mechanical properties

6.3.1 Resistance to pressure, leak-tightness of the valve body assembly

The test shall be carried out as shown in Figure 15.

Tighten the union nut of the tailpiece piece for the connection to the radiator (cone seated union shown

in Figure 7) with a torque given in Table 3 and shut the valve on the radiator side. The tightening torque

for other connections shall be according to the manufacturer's instructions.

Subject the valve in the open position, to a static water pressure of the next higher nominal pressure

(see ISO 7268), compared to the nominal pressure of the valve body assembly. The temperature of the

water shall be 20 °C ± 10 °C. Check after 1 min whether water leaks from the connections or through the

wall of the body.

Figure 15 — Testing of pressure resistance of the valve body

Table 3 — Tightening torques for the tailpiece nut

a

Nominal size Size of thread Tightening torque

Nm

15 mm copper tube fitting 1/4 40

DN 8 3/8 40

DN 10 1/2 40

DN 15 3/4 60

DN 20 1 80

DN 25 100

a

See EN ISO 6708.

6.3.2 Leak-tightness of the valve closed mechanically by means of the protection cap.

This test shall be carried out only if the manufacturer declares that the valve can be shut-off by means

of the protection cap against a pressure, which he declares.

Mount the valve body assembly in the test apparatus shown in Figure 15 so that it remains open on the

radiator side. Shut the valve by means of the protection cap. Apply a static water pressure equal to the

pressure declared by the manufacturer. The temperature of the water shall be 20 °C ± 10 °C. Check after

1 min whether water has escaped past the valve disc.

6.3.3 Leak-tightness of the stem seal

The test shall be carried out as shown in Figure 16. The valve shall be blanked off on the radiator side

and immersed in water. Apply an air pressure of 20 kPa (0,2 bar) ± 10 %. After 1 min, operate the stem

5 times. Check the leak-tightness of the stem seal.

Figure 16 — Testing of leak-tightness of the stem seal

6.3.4 Resistance of the valve body assembly to a bending moment

The test shall be carried out as shown in Figure 17. Tighten the union nut of the tailpiece piece

according to Table 3. Apply a force F at the end of the pipe and perpendicular to its axis for 30 s. F shall

result in a bending moment as specified in Table 4.

After this test, check the leak tightness by the method specified in 6.3.1.

Permanent deformation shall not be taken into account.

Key

1 straight-through valves

2 right-angle valves

Figure 17 — Testing of bending strength of the valve body assembly

Table 4 — Bending moments for testing thermostatic valves

a

Nominal size Size of thread Bending moment in Nm

15 mm copper tube fitting 1/4 20

DN 8 3/8 80

DN 10 1/2 100

DN 15 3/4 120

DN 20 1 180

DN 25 220

a

See EN ISO 6708.

6.3.5 Resistance of the temperature selector to a torque

The test shall be carried out as shown in Figure 18 with water at a temperature of 90 °C ± 2 °C and a

static pressure of 100 kPa (1 bar) flowing through the valve body assembly. After a period of at least

20 min for thermal equilibrium to be reached, set the temperature selector at the minimum stop

position. Apply for 30 s a force that results in a torque of 7 Nm without any transverse force in the

direction of the stop.

Finally, the temperature selector is set to the maximum stop position and the test is carried out

accordi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...