SIST EN 15698-2:2025

(Main)District heating pipes - Bonded twin pipe systems for directly buried hot water networks - Part 2: Factory made fitting and valve assemblies of steel service pipes, polyurethane thermal insulation and a casing of polyethylene

District heating pipes - Bonded twin pipe systems for directly buried hot water networks - Part 2: Factory made fitting and valve assemblies of steel service pipes, polyurethane thermal insulation and a casing of polyethylene

This document specifies requirements and test methods for fitting and steel valve assemblies of factory made thermally insulated bonded twin pipe assemblies for hot water networks in accordance with EN 13941-1, comprising two steel service pipes, in most cases steel fittings and/or steel valves, steel components, polyurethane (PUR) foam thermal insulation and one casing of polyethylene.

NOTE Steel components can be e.g. fixing bars.

The twin pipe assembly can also include the following additional elements: measuring wires, spacers and diffusion barriers.

This document covers the following assemblies:

- fittings: bends, T-pieces and reducers;

- valves for main line.

This document applies to fitting assemblies with an internal pressure of at least 1,6 MPa and steel valve assemblies with a maximum internal pressure of 2,5 MPa.

Fernwärmerohre - Doppelrohr-Verbundsysteme für direkt erdverlegte Fernwärmenetze - Teil 2: Werkmäßig gefertigtes Verbundformstück und vorgedämmte Absperrarmatur, bestehend aus Stahl-Mediumrohr, einer Wärmedämmung aus Polyurethan und einer Ummantelung aus Polyethylen

Dieses Dokument legt Anforderungen und Prüfverfahren für Verbundformstück- und Stahlarmaturbaueinheiten von werkseitig hergestellten, gedämmten Doppelrohrbaueinheiten für Fernwärmenetze in Übereinstimmung mit EN 13941 1 fest, die aus zwei Stahl-Mediumrohren, in den meisten Fällen Stahl-Formstücken und/oder Stahl-Armaturen, Bauteilen aus Stahl, einer Schaumstoffwärmedämmung aus Polyurethan (PUR) und einer Ummantelung aus Polyethylen bestehen.

ANMERKUNG Bauteile aus Stahl können z. B. Verbindungsstege sein.

Die Doppelrohrbaueinheit kann darüber hinaus die folgenden zusätzlichen Bauteile umfassen: Messdrähte, Abstandhalter und DiffusionsbarrierenN1.

Dieses Dokument behandelt die folgenden Baueinheiten:

Formstücke: Bögen, T Stücke und Reduzierstücke;

Armaturen für die Hauptleitung.

Dieses Dokument gilt für Verbundformstückbaueinheiten mit einem Innendruck von mindestens 1,6 MPa und für Stahl-Armaturbaueinheiten mit einem maximalen Innendruck von 2,5 MPa.

Tuyaux de chauffage urbain - Systèmes bloqués de bitubes pour les réseaux d'eau chaude enterrés directement - Partie 2: Assemblages de raccords et d'appareils de robinetterie manufacturés pour tube de service en acier, isolation thermique en polyuréthane et tube de protection en polyéthylène

Le présent document définit les exigences et les méthodes d’essai applicables au raccord et aux appareils de robinetterie en acier d’assemblages de bitubes manufacturés isolés thermiquement pour réseaux d’eau chaude conformément à l’EN 13941-1, comprenant deux tubes de service en acier, dans la plupart des cas des raccords en acier et/ou des appareils de robinetterie en acier, des composants en acier, une isolation thermique en mousse de polyuréthane (PUR) et une protection en polyéthylène.

NOTE Les composants en acier peuvent être, par exemple, des barres de fixation.

L’assemblage de bitubes peut également comprendre les éléments supplémentaires suivants : des câbles de mesure, des entretoises et les barrières anti-diffusion.

Le présent document couvre les assemblages suivants :

- les raccords : les coudes, les coudes en T et les réductions ;

- les appareils de robinetterie pour la ligne principale.

Le présent document s’applique aux assemblages de raccords ayant une pression interne d'au moins 1,6 MPa et aux assemblages d’appareils de robinetterie en acier ayant une pression interne maximale de 2,5 MPa.

Cevi za daljinsko ogrevanje - Poviti dvocevni sistemi za neposredno vkopana vročevodna omrežja - 2. del: Tovarniško izdelan sestav fitingov in ventilov iz jeklene cevi, poliuretanske toplotne izolacije in zunanjega polietilenskega plašča

Ta dokument določa zahteve in preskusne metode za sestave fitingov in ventilov tovarniško izdelanih toplotno izoliranih dvocevnih sestavov za vročevodna omrežja v skladu s standardom EN 13941-1, ki so sestavljeni iz dveh jeklenih cevi (v večini primerov jeklenih fitingov) in/ali ventilov, jeklenih sestavnih delov, poliuretanske (PUR) toplotne izolacije in zunanjega polietilenskega plašča. OPOMBA: Jekleni sestavni deli so lahko npr. pritrditvene palice. Dvocevni sestav lahko vključuje tudi naslednje dodatne elemente: merilne žice, distančnike in difuzijske pregrade. Ta dokument zajema naslednje sestave: – fitingi: kolena, T-komadi in reducirni priključki; – ventili za glavni vod. Ta dokument se uporablja za sestave fitingov z notranjim tlakom vsaj 1,6 Mpa in sestave jeklenih ventilov z notranjim tlakom vsaj 2,5 MPa.

General Information

- Status

- Published

- Public Enquiry End Date

- 26-Sep-2023

- Publication Date

- 08-Apr-2025

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 08-Apr-2025

- Due Date

- 13-Jun-2025

- Completion Date

- 09-Apr-2025

Relations

- Effective Date

- 18-Jan-2023

Overview

EN 15698-2:2025 is a CEN European standard for district heating pipes covering factory-made bonded twin pipe systems for directly buried hot water networks. It specifies requirements and test methods for fitting and steel valve assemblies composed of two steel service pipes, polyurethane (PUR) thermal insulation and a single polyethylene casing. The standard governs prefabricated bends, T-pieces, reducers and main-line valves intended for long-term buried operation and aligns with system design requirements in EN 13941-1.

Key topics and technical requirements

- Scope of assemblies: fittings (bends, T-pieces, reducers) and valves for main line in bonded twin pipe systems.

- Component makeup: steel service pipes, steel fittings/valves, steel components (e.g., fixing bars), PUR foam insulation, and one polyethylene casing. Optional elements: measuring wires, spacers, diffusion barriers.

- Pressure ratings: fitting assemblies designed for internal pressures of at least 1.6 MPa; steel valve assemblies up to 2.5 MPa.

- Performance and manufacturing controls: requirements for welding of steel parts, casing and polyethylene welding, surface conditions, dimensional tolerances, end alignment, and distance between flow and return pipes.

- Durability and thermal performance: clauses on expected thermal life, long-term temperature resistance, and thermal conductivity of the insulation.

- Mechanical integrity: resistance to axial forces, bending moments and valve stem/end-of-stem construction rules.

- Quality assurance and testing: defined test methods, marking, inspection guidance and documentation requirements (referencing EN 10204 for inspection documents).

- Environmental considerations: waste treatment and recycling guidance provided in informative Annex B; example assemblies in Annex C.

Applications

- Design, production and factory assembly of prefabricated fittings and valve units for directly buried hot water district heating networks.

- Specification documents for utilities, district heating system designers, and large infrastructure projects requiring certified bonded twin pipe components.

- Manufacturing quality control, third‑party testing laboratories and product conformity assessment to ensure thermal performance, mechanical strength and long-term serviceability.

Who should use this standard?

- Pipe system manufacturers and fabricators of bonded twin pipe fittings and valves.

- System designers, engineering consultants and project specifiers for district heating.

- Installation contractors and asset owners responsible for long-term operation and maintenance.

- Certification bodies, testing laboratories and procurement teams evaluating compliance.

Related standards

- EN 15698-1 (factory made twin pipe assemblies)

- EN 13941-1 (design of insulated bonded single & twin pipe systems)

- EN 253, EN 448, EN 488 series (related bonded pipe and valve requirements)

- EN 17248 (terms and definitions)

EN 15698-2:2025 ensures consistent safety, thermal efficiency and interoperability of factory-made fittings and valve assemblies used in modern district heating networks.

Frequently Asked Questions

SIST EN 15698-2:2025 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "District heating pipes - Bonded twin pipe systems for directly buried hot water networks - Part 2: Factory made fitting and valve assemblies of steel service pipes, polyurethane thermal insulation and a casing of polyethylene". This standard covers: This document specifies requirements and test methods for fitting and steel valve assemblies of factory made thermally insulated bonded twin pipe assemblies for hot water networks in accordance with EN 13941-1, comprising two steel service pipes, in most cases steel fittings and/or steel valves, steel components, polyurethane (PUR) foam thermal insulation and one casing of polyethylene. NOTE Steel components can be e.g. fixing bars. The twin pipe assembly can also include the following additional elements: measuring wires, spacers and diffusion barriers. This document covers the following assemblies: - fittings: bends, T-pieces and reducers; - valves for main line. This document applies to fitting assemblies with an internal pressure of at least 1,6 MPa and steel valve assemblies with a maximum internal pressure of 2,5 MPa.

This document specifies requirements and test methods for fitting and steel valve assemblies of factory made thermally insulated bonded twin pipe assemblies for hot water networks in accordance with EN 13941-1, comprising two steel service pipes, in most cases steel fittings and/or steel valves, steel components, polyurethane (PUR) foam thermal insulation and one casing of polyethylene. NOTE Steel components can be e.g. fixing bars. The twin pipe assembly can also include the following additional elements: measuring wires, spacers and diffusion barriers. This document covers the following assemblies: - fittings: bends, T-pieces and reducers; - valves for main line. This document applies to fitting assemblies with an internal pressure of at least 1,6 MPa and steel valve assemblies with a maximum internal pressure of 2,5 MPa.

SIST EN 15698-2:2025 is classified under the following ICS (International Classification for Standards) categories: 23.040.07 - Pipeline and its parts for district heat; 23.040.10 - Iron and steel pipes; 23.060.01 - Valves in general; 91.140.10 - Central heating systems. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 15698-2:2025 has the following relationships with other standards: It is inter standard links to SIST EN 15698-2:2020. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 15698-2:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-junij-2025

Cevi za daljinsko ogrevanje - Poviti dvocevni sistemi za neposredno vkopana

vročevodna omrežja - 2. del: Tovarniško izdelan sestav fitingov in ventilov iz

jeklene cevi, poliuretanske toplotne izolacije in zunanjega polietilenskega plašča

District heating pipes - Bonded twin pipe systems for directly buried hot water networks -

Part 2: Factory made fitting and valve assemblies of steel service pipes, polyurethane

thermal insulation and a casing of polyethylene

Fernwärmerohre - Doppelrohr-Verbundsysteme für direkt erdverlegte Fernwärmenetze -

Teil 2: Werkmäßig gefertigtes Verbundformstück und vorgedämmte Absperrarmatur,

bestehend aus Stahl-Mediumrohr, einer Wärmedämmung aus Polyurethan und einer

Ummantelung aus Polyethylen

Tuyaux de chauffage urbain - Systèmes bloqués de bitubes pour les réseaux d'eau

chaude enterrés directement - Partie 2: Assemblages de raccords et d'appareils de

robinetterie manufacturés pour tube de service en acier, isolation thermique en

polyuréthane et tube de protection en polyéthylène

Ta slovenski standard je istoveten z: EN 15698-2:2025

ICS:

23.040.07 Cevovodi za daljinsko Pipeline and its parts for

ogrevanje in njihovi deli district heat

23.040.10 Železne in jeklene cevi Iron and steel pipes

91.140.10 Sistemi centralnega Central heating systems

ogrevanja

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 15698-2

EUROPEAN STANDARD

NORME EUROPÉENNE

March 2025

EUROPÄISCHE NORM

ICS 23.040.07 Supersedes EN 15698-2:2019

English Version

District heating pipes - Bonded twin pipe systems for

directly buried hot water networks - Part 2: Factory made

fitting and valve assemblies of steel service pipes,

polyurethane thermal insulation and one casing of

polyethylene

Tuyaux de chauffage urbain - Systèmes bloqués de Fernwärmerohre - Doppelrohr-Verbundsysteme für

bitubes pour les réseaux d'eau chaude enterrés direkt erdverlegte Fernwärmenetze - Teil 2:

directement - Partie 2: Assemblages de raccords et Werkmäßig gefertigte Formstück- und

d'appareils de robinetterie manufacturés pour tubes de Armaturbaueinheiten, bestehend aus Stahl-

service en acier, isolation thermique en polyuréthane Mediumrohr, einer Wärmedämmung aus Polyurethan

et tube de protection en polyéthylène und einer Ummantelung aus Polyethylen

This European Standard was approved by CEN on 27 January 2025.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION

EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2025 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 15698-2:2025 E

worldwide for CEN national Members.

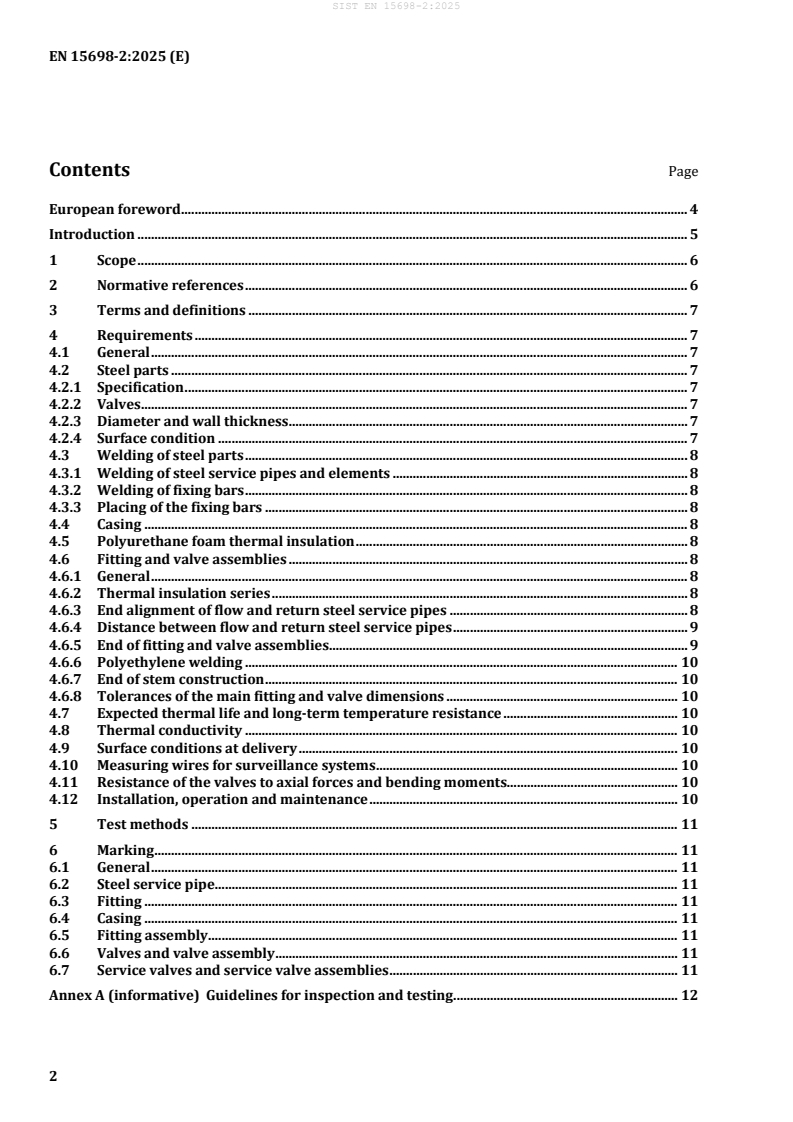

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms and definitions . 7

4 Requirements . 7

4.1 General . 7

4.2 Steel parts . 7

4.2.1 Specification . 7

4.2.2 Valves. 7

4.2.3 Diameter and wall thickness . 7

4.2.4 Surface condition . 7

4.3 Welding of steel parts . 8

4.3.1 Welding of steel service pipes and elements . 8

4.3.2 Welding of fixing bars . 8

4.3.3 Placing of the fixing bars . 8

4.4 Casing . 8

4.5 Polyurethane foam thermal insulation . 8

4.6 Fitting and valve assemblies . 8

4.6.1 General . 8

4.6.2 Thermal insulation series . 8

4.6.3 End alignment of flow and return steel service pipes . 8

4.6.4 Distance between flow and return steel service pipes . 9

4.6.5 End of fitting and valve assemblies. 9

4.6.6 Polyethylene welding . 10

4.6.7 End of stem construction . 10

4.6.8 Tolerances of the main fitting and valve dimensions . 10

4.7 Expected thermal life and long-term temperature resistance . 10

4.8 Thermal conductivity . 10

4.9 Surface conditions at delivery . 10

4.10 Measuring wires for surveillance systems . 10

4.11 Resistance of the valves to axial forces and bending moments. 10

4.12 Installation, operation and maintenance . 10

5 Test methods . 11

6 Marking . 11

6.1 General . 11

6.2 Steel service pipe . 11

6.3 Fitting . 11

6.4 Casing . 11

6.5 Fitting assembly . 11

6.6 Valves and valve assembly . 11

6.7 Service valves and service valve assemblies . 11

Annex A (informative) Guidelines for inspection and testing . 12

Annex B (informative) Waste treatment and recycling . 14

Annex C (informative) Examples of twin pipe fitting assemblies . 15

Bibliography . 18

European foreword

This document (EN 15698-2:2025) has been prepared by Technical Committee CEN/TC 107

“Prefabricated district heating and district cooling pipe system”, the secretariat of which is held by DS.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by September 2025, and conflicting national standards shall

be withdrawn at the latest by September 2025.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 15698-2:2019.

— alignment with the structure of EN 253;

— in alignment with the other standards of CEN/TC 107, explanatory information has been included in

Annex B.

The EN 15698 series, under the title District heating pipes — Bonded twin pipe systems for directly buried

hot water networks, is currently composed of the following parts:

— Part 1: Factory made twin pipe assembly of steel service pipes, polyurethane thermal insulation and one

casing of polyethylene;

— Part 2: Factory made fitting and valve assemblies of steel service pipes, polyurethane thermal insulation

and one casing of polyethylene (this document).

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

Other standards from CEN/TC 107 are:

— EN 253, District heating pipes — Bonded single pipe systems for directly buried hot water networks —

Factory made pipe assembly of steel service pipe, polyurethane thermal insulation and a casing of

polyethylene

— EN 448, District heating pipes — Bonded single pipe systems for directly buried hot water networks —

Factory made fitting assemblies of steel service pipes, polyurethane thermal insulation and a casing of

polyethylene

— EN 488-1, District heating pipes — Bonded single pipe systems for directly buried hot water networks

— Part 1: Factory made steel shut-off valve assembly for steel service pipes, polyurethane thermal

insulation and a casing of polyethylene;

— EN 488-2, District heating and district cooling pipes — Bonded pipe systems for directly buried hot and

cold water networks — Part 2: Factory made steel valve assembly for steel service pipes, polyurethane

thermal insulation and a casing of polyethylene

— EN 489-1, District heating pipes — Bonded single and twin pipe systems for buried hot water

networks — Part 1: Joint casing assemblies and thermal insulation for hot water networks in

accordance with EN 13941-1

— EN 13941-1, District heating pipes — Design and installation of thermal insulated bonded single and

twin pipe systems for directly buried hot water networks — Part 1: Design

— EN 13941-2, District heating pipes — Design and installation of thermal insulated bonded single and

twin pipe systems for directly buried hot water networks — Part 2: Installation

— EN 14419, District heating pipes — Bonded single and twin pipe systems for buried hot water

networks — Surveillance systems

— EN 15632 (all parts), District heating pipes — Factory made flexible pipe systems

— EN 15698-1, District heating pipes — Bonded twin pipe systems for directly buried hot water

networks — Part 1: Factory made twin pipe assembly of steel service pipes, polyurethane thermal

insulation and one casing of polyethylene

— EN 17248, District heating and district cooling pipe systems — Terms and definitions

— EN 17414 (all parts), District cooling pipes — Factory made flexible pipe systems

— EN 17415 (all parts), District cooling pipes — Bonded single pipe systems for directly buried cold water

networks

— EN 17878 (all parts), District heating pipes — Factory made flexible pipe systems with a lower

temperature profile

Waste management and recycling of materials is dealt with in Annex B.

Examples of twin pipe fitting assemblies are shown in Annex C.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...