SIST EN 15266:2025

(Main)Stainless steel pliable corrugated tubing kits for gas installation pipework with an operating pressure up to 0,2 MPa (2 bar)

Stainless steel pliable corrugated tubing kits for gas installation pipework with an operating pressure up to 0,2 MPa (2 bar)

This document specifies the requirements for material, design, manufacture, testing, marking and documentation of stainless steel pliable corrugated gas tubing kits for gas installation pipework with a maximum allowable pressure (PS):

- less than or equal to 0,5 bar within a nominal size range from DN 10 to DN 50 (class 1); and

- less than or equal to 2 bar within a nominal size range from DN 10 to DN 25 (class 2).

This document applies to stainless steel pliable corrugated gas tubing kits used for 1st, 2nd and 3rd family gases (see EN 437) in residential, commercial and industrial gas installations to be installed outdoors or indoors at a temperature range from –20 °C to +60 °C.

This document does not apply to:

- pliable tubing without cover;

- corrugated safety metal hose assemblies for connection to moveable appliances.

NOTE This document does not cover the installation aspects of stainless steel pliable corrugated gas tubing kits.

Nichtrostende biegbare Wellrohrbausätze für Gasleitungsanlagen mit einem Arbeitsdruck bis 0,2 MPa (2 bar)

Dieses Dokument legt die Anforderungen an Werkstoff, Auslegung, Herstellung, Prüfung, Kennzeichnung und Dokumentation von nichtrostenden biegbaren Wellrohrbausätzen für Gasinstallationsrohrleitungen mit einem maximal zulässigen Druck (PS) fest:

- kleiner oder gleich 0,5 bar in einem Nennweitenbereich von DN 10 bis DN 50 (Klasse 1); und

- kleiner oder gleich 2 bar in einem Nennweitenbereich von DN 10 bis DN 25 (Klasse 2).

Dieses Dokument ist anwendbar für nichtrostende biegbare Wellrohrbausätze für Gase der 1., 2. und 3. Familie (siehe EN 437) in häuslichen, gewerblichen und industriellen Gasinstallationen, die im Freien oder in Innenräumen in einem Temperaturbereich von −20 °C bis +60 °C installiert werden.

Dieses Dokument ist nicht anwendbar für:

- biegbare Rohrbausätze ohne Ummantelung;

- gewellte Sicherheits-Schlauchleitungen aus Metall für den Anschluss von beweglichen Geräten.

ANMERKUNG Dieses Dokument behandelt keine Anforderungen bezogen auf den Einbau von nichtrostenden biegbaren Wellrohrbausätzen für Gas.

Kits de tuyaux onduleux pliables en acier inoxydable pour les installations intérieures à gaz avec une pression de service inférieure ou égale à 0,2 MPa (2 bar)

Le présent document définit les exigences relatives au matériau, à la conception, à la fabrication, aux essais, au marquage et à la documentation des kits de tuyaux onduleux pliables en acier inoxydable pour les installations intérieures de gaz dont la pression maximale de service (MOP) admissible est :

- inférieure ou égale à 0,5 bar avec une plage de diamètres nominaux allant du DN 10 au DN 50 (classe 1) ; et

- inférieure ou égale à 2 bar avec une plage de diamètres nominaux allant du DN 10 au DN 25 (classe 2).

Le présent document s'applique aux kits de tuyaux onduleux pliables en acier inoxydable destinés à être utilisés avec les première, deuxième et troisième familles de gaz (voir EN 437) dans les installations de gaz résidentielles, commerciales et industrielles à installer à l'extérieur ou à l'intérieur à une température comprise entre −20 °C et +60 °C.

Le présent document ne s'applique pas :

- aux tuyaux pliables sans gaine de protection ;

- aux tuyaux métalliques flexibles onduleux de sécurité pour le raccordement d'appareils mobiles.

NOTE Le présent document ne traite pas des aspects liés à l'installation des kits de tuyaux onduleux pliables en acier inoxydable pour le gaz.

Upogljivi valoviti cevni kompleti iz nerjavnega jekla za plinske napeljave z delovnim tlakom do 0,2 MPa (2 bara)

Ta evropski standard določa zahteve za materiale, načrtovanje, izdelavo, preskušanje, označevanje in dokumentiranje upogljivih valovitih cevnih kompletov iz nerjavnega jekla za plinske napeljave z največjim delovnim tlakom (MOP):

– 0,5 bara v razponu nazivnih velikosti od DN 10 do DN 50 (razred 1); in

– 2 bara v razponu nazivnih velikosti od DN 10 do DN 25 (razred 2).

Ta dokument se uporablja za upogljive valovite cevne komplete iz nerjavnega jekla za uporabo plinov iz 1., 2. in 3. družine v skladu s standardom EN 437 v stanovanjskih, poslovnih ter industrijskih plinskih napeljavah, ki so namenjeni za notranjo ali zunanjo namestitev v temperaturnem območju od –40 °C do +60 °C.

Ta dokument se ne uporablja za:

⎯ upogljive cevi brez obloge;

⎯ valovite varnostne kovinske cevne priključke za premične naprave.

OPOMBA: Ta dokument ne zajema vidikov namestitve upogljivih valovitih cevnih kompletov iz nerjavnega jekla.

General Information

- Status

- Published

- Public Enquiry End Date

- 05-Dec-2023

- Publication Date

- 12-Jan-2025

- Technical Committee

- I13 - Imaginarni 13

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 06-Jan-2025

- Due Date

- 13-Mar-2025

- Completion Date

- 13-Jan-2025

Relations

- Effective Date

- 19-Jan-2023

Overview

EN 15266:2024 - Stainless steel pliable corrugated tubing kits for gas installation pipework with an operating pressure up to 0,2 MPa (2 bar) - defines requirements for the design, materials, manufacture, testing, marking and documentation of stainless steel pliable corrugated tubing (PLT) kits used in gas installation pipework. The standard covers kits intended for 1st, 2nd and 3rd family gases (see EN 437) in residential, commercial and industrial installations, for use outdoors or indoors between −20 °C and +60 °C. It applies to two pressure/size classes:

- Class 1: PS ≤ 0.5 bar, DN 10 to DN 50

- Class 2: PS ≤ 2.0 bar, DN 10 to DN 25

EN 15266:2024 supersedes the 2007 edition and focuses on product performance and safety; it does not cover on-site installation procedures.

Key Topics and Requirements

The standard provides detailed, testable requirements across these technical areas:

- Materials & manufacture: stainless steel corrugated hose construction, covers, seals and PLT fittings.

- Design requirements: nominal sizes (DN), wall thickness, threads, fittings (end fittings, couplings, tees, manifolds), bend radius and supports.

- Performance tests: tightness, bending performance, crushing resistance, stability under pressure, wear of outer cover, impact and penetration resistance, pull-out resistance, chemical resistance, low-temperature behavior, ageing.

- Fire performance: tightness in case of fire and reaction-to-fire tests (single-flame source, SBI).

- Electrical conductivity: requirements for continuity/earthing where applicable.

- Marking & documentation: mandatory labelling, assembly instructions and factory production control (FPC) guidance (Annex C).

- Exclusions: PLT without cover and corrugated safety metal hoses for movable appliance connections.

Applications and Users

EN 15266 is essential for:

- Manufacturers designing and certifying stainless steel pliable corrugated tubing kits.

- Product designers & R&D verifying compliance with material, mechanical and fire-resistance requirements.

- Quality managers & testing laboratories carrying out the specified performance tests and FPC.

- Specifiers, procurement teams and compliance officers selecting compliant components for gas installation pipework.

- Installers and contractors - for product selection and verification - while noting that installation practices must follow local regulations (installation is outside the scope of EN 15266).

Related Standards

Commonly referenced standards include:

- EN 437 (family gases / appliance test gases)

- EN 1775 (gas pipework for buildings)

- EN ISO 10380 (corrugated metal hoses)

- EN 1363-1 / EN 13501-1 / EN ISO 11925-2 (fire testing and classification)

Keywords: EN 15266:2024, stainless steel pliable corrugated tubing, PLT kits, gas installation pipework, corrugated tubing kits, pressure classes, DN sizes, gas supply standards.

Frequently Asked Questions

SIST EN 15266:2025 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Stainless steel pliable corrugated tubing kits for gas installation pipework with an operating pressure up to 0,2 MPa (2 bar)". This standard covers: This document specifies the requirements for material, design, manufacture, testing, marking and documentation of stainless steel pliable corrugated gas tubing kits for gas installation pipework with a maximum allowable pressure (PS): - less than or equal to 0,5 bar within a nominal size range from DN 10 to DN 50 (class 1); and - less than or equal to 2 bar within a nominal size range from DN 10 to DN 25 (class 2). This document applies to stainless steel pliable corrugated gas tubing kits used for 1st, 2nd and 3rd family gases (see EN 437) in residential, commercial and industrial gas installations to be installed outdoors or indoors at a temperature range from –20 °C to +60 °C. This document does not apply to: - pliable tubing without cover; - corrugated safety metal hose assemblies for connection to moveable appliances. NOTE This document does not cover the installation aspects of stainless steel pliable corrugated gas tubing kits.

This document specifies the requirements for material, design, manufacture, testing, marking and documentation of stainless steel pliable corrugated gas tubing kits for gas installation pipework with a maximum allowable pressure (PS): - less than or equal to 0,5 bar within a nominal size range from DN 10 to DN 50 (class 1); and - less than or equal to 2 bar within a nominal size range from DN 10 to DN 25 (class 2). This document applies to stainless steel pliable corrugated gas tubing kits used for 1st, 2nd and 3rd family gases (see EN 437) in residential, commercial and industrial gas installations to be installed outdoors or indoors at a temperature range from –20 °C to +60 °C. This document does not apply to: - pliable tubing without cover; - corrugated safety metal hose assemblies for connection to moveable appliances. NOTE This document does not cover the installation aspects of stainless steel pliable corrugated gas tubing kits.

SIST EN 15266:2025 is classified under the following ICS (International Classification for Standards) categories: 23.040.01 - Pipeline components and pipelines in general; 77.140.75 - Steel pipes and tubes for specific use; 91.140.40 - Gas supply systems. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 15266:2025 has the following relationships with other standards: It is inter standard links to SIST EN 15266:2007. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 15266:2025 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

SLOVENSKI STANDARD

01-marec-2025

Upogljivi valoviti cevni kompleti iz nerjavnega jekla za plinske napeljave z

delovnim tlakom do 0,2 MPa (2 bara)

Stainless steel pliable corrugated tubing kits for gas installation pipework with an

operating pressure up to 0,2 MPa (2 bar)

Nichtrostende biegbare Wellrohrbausätze für Gasleitungsanlagen mit einem

Arbeitsdruck bis 0,2 MPa (2 bar)

Kits de tuyaux onduleux pliables en acier inoxydable pour les installations intérieures à

gaz avec une pression de service inférieure ou égale à 0,2 MPa (2 bar)

Ta slovenski standard je istoveten z: EN 15266:2024

ICS:

77.140.75 Jeklene cevi in cevni profili Steel pipes and tubes for

za posebne namene specific use

91.140.40 Sistemi za oskrbo s plinom Gas supply systems

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.

EN 15266

EUROPEAN STANDARD

NORME EUROPÉENNE

December 2024

EUROPÄISCHE NORM

ICS 23.040.01 Supersedes EN 15266:2007

English Version

Stainless steel pliable corrugated tubing kits for gas

installation pipework with an operating pressure up to

0,2 MPa (2 bar)

Kits de tuyaux onduleux pliables en acier inoxydable Nichtrostende biegbare Wellrohrbausätze für

pour les installations intérieures de gaz avec une Gasleitungsanlagen mit einem Arbeitsdruck bis

pression de service inférieure ou égale à 0,2 MPa 0,2 MPa (2 bar)

(2 bar)

This European Standard was approved by CEN on 18 November 2024.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this

European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references

concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN

member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by

translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management

Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia,

Finland, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway,

Poland, Portugal, Republic of North Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and

United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATIO N

EUROPÄISCHES KOMITEE FÜR NORMUN G

CEN-CENELEC Management Centre: Rue de la Science 23, B-1040 Brussels

© 2024 CEN All rights of exploitation in any form and by any means reserved Ref. No. EN 15266:2024 E

worldwide for CEN national Members.

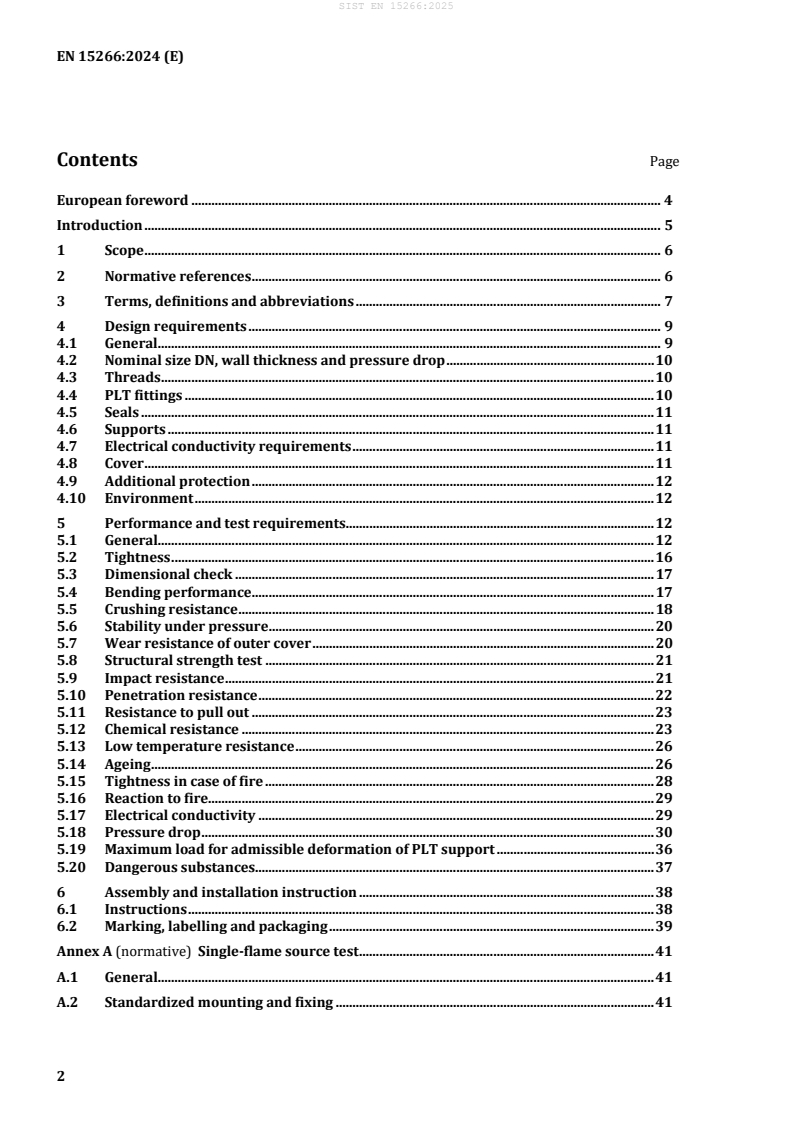

Contents Page

European foreword . 4

Introduction . 5

1 Scope . 6

2 Normative references . 6

3 Terms, definitions and abbreviations . 7

4 Design requirements . 9

4.1 General. 9

4.2 Nominal size DN, wall thickness and pressure drop . 10

4.3 Threads . 10

4.4 PLT fittings . 10

4.5 Seals . 11

4.6 Supports . 11

4.7 Electrical conductivity requirements . 11

4.8 Cover . 11

4.9 Additional protection . 12

4.10 Environment . 12

5 Performance and test requirements. 12

5.1 General. 12

5.2 Tightness . 16

5.3 Dimensional check . 17

5.4 Bending performance . 17

5.5 Crushing resistance . 18

5.6 Stability under pressure . 20

5.7 Wear resistance of outer cover . 20

5.8 Structural strength test . 21

5.9 Impact resistance . 21

5.10 Penetration resistance . 22

5.11 Resistance to pull out . 23

5.12 Chemical resistance . 23

5.13 Low temperature resistance . 26

5.14 Ageing . 26

5.15 Tightness in case of fire . 28

5.16 Reaction to fire. 29

5.17 Electrical conductivity . 29

5.18 Pressure drop . 30

5.19 Maximum load for admissible deformation of PLT support . 36

5.20 Dangerous substances. 37

6 Assembly and installation instruction . 38

6.1 Instructions . 38

6.2 Marking, labelling and packaging . 39

Annex A (normative) Single-flame source test . 41

A.1 General. 41

A.2 Standardized mounting and fixing . 41

A.3 Test definition . 41

A.4 Test duration . 41

Annex B (normative) Thermal attack by a single burning item . 43

Annex C (informative) Factory Production Control . 44

C.1 General . 44

C.2 FPC recommendations for all manufacturers . 44

C.3 Manufacturer’s specific FPC system recommendations . 45

Bibliography . 47

European foreword

This document (EN 15266:2024) has been prepared by Technical Committee CEN/TC 342 “Metal hoses,

hose assemblies, bellows and expansion joints”, the secretariat of which is held by SNV.

This European Standard shall be given the status of a national standard, either by publication of an

identical text or by endorsement, at the latest by June 2025, and conflicting national standards shall be

withdrawn at the latest by June 2025.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. CEN shall not be held responsible for identifying any or all such patent rights.

This document supersedes EN 15266:2007.

In comparison with the previous edition, the following technical modifications have been made:

— operating pressure up to 0,2 MPa (2 bar).

Any feedback and questions on this document should be directed to the users’ national standards body.

A complete listing of these bodies can be found on the CEN website.

According to the CEN-CENELEC Internal Regulations, the national standards organisations of the

following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia,

Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Germany, Greece, Hungary, Iceland, Ireland,

Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Republic of North

Macedonia, Romania, Serbia, Slovakia, Slovenia, Spain, Sweden, Switzerland, Türkiye and the United

Kingdom.

Introduction

This document contains the general safety requirements relating to the safety of persons, animals, and

property and the protection of their environment.

The requirements of this document concern designers, manufacturers, suppliers and importers of

stainless steel pliable corrugated gas tubing kits for gas installation pipework.

Installation and mandatory strength and tightness tests before commissioning should consider the local

application regulations where they exist.

This document is applicable to:

— new installation pipework;

— replacements of existing installations; or

— extensions to existing installations.

Stainless steel pliable corrugated gas tubing kits can be used in conjunction with other approved gas

pipework.

This document defines performance requirements for the products to be placed on the European

Economic Area EEA.

1 Scope

This document specifies the requirements for material, design, manufacture, testing, marking and

documentation of stainless steel pliable corrugated gas tubing kits for gas installation pipework with a

maximum allowable pressure (PS):

— less than or equal to 0,5 bar within a nominal size range from DN 10 to DN 50 (class 1); and

— less than or equal to 2 bar within a nominal size range from DN 10 to DN 25 (class 2).

This document applies to stainless steel pliable corrugated gas tubing kits used for 1st, 2nd and 3rd family

gases (see EN 437) in residential, commercial and industrial gas installations to be installed outdoors or

indoors at a temperature range from –20 °C to +60 °C.

This document does not apply to:

— pliable tubing without cover;

— corrugated safety metal hose assemblies for connection to moveable appliances.

NOTE This document does not cover the installation aspects of stainless steel pliable corrugated gas tubing

kits.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

EN 1363-1:2020, Fire resistance tests — Part 1: General requirements

EN 1775:2007, Gas supply — Gas pipework for buildings — Maximum operating pressure less than or equal

to 5 bar — Functional recommendations

EN 10028-7, Flat products made of steels for pressure purposes — Part 7: Stainless steels

EN 10088-3, Stainless steels — Part 3: Technical delivery conditions for semi-finished products, bars, rods,

wire, sections and bright products of corrosion resistant steels for general purposes

EN 10226-1, Pipe threads where pressure tight joints are made on the threads — Part 1: Taper external

threads and parallel internal threads — Dimensions, tolerances and designation

EN 10242, Threaded pipe fitting in malleable cast iron

EN 12164, Copper and copper alloys — Rod for free machining purposes

EN 12165, Copper and copper alloys — Wrought and unwrought forging stock

EN 13501-1:2018, Fire classification of construction products and building elements — Part 1:

Classification using data from reaction to fire tests

EN 13823, Reaction to fire tests for building products — Building products excluding floorings exposed to

the thermal attack by a single burning item

EN ISO 228-1, Pipe threads where pressure-tight joints are not made on the threads — Part 1: Dimensions,

tolerances and designation (ISO 228-1)

EN ISO 6509-1, Corrosion of metals and alloys — Determination of dezincification resistance of copper

alloys with zinc — Part 1: Test method (ISO 6509-1)

EN ISO 7369:2020, Pipework — Metal hoses and hose assemblies — Vocabulary (ISO 7369:2020)

EN ISO 9227, Corrosion tests in artificial atmospheres — Salt spray tests (ISO 9227)

EN ISO 10380:2012, Pipework — Corrugated metal hoses and hose assemblies (ISO 10380:2012)

EN ISO 11925-2, Reaction to fire tests — Ignitability of products subjected to direct impingement of flame

— Part 2: Single-flame source test (ISO 11925-2)

ISO 6957, Copper alloys — Ammonia test for stress corrosion resistance

3 Terms, definitions and abbreviations

For the purposes of this document, the terms and definitions given in EN ISO 7369:2020 and

EN 1775:2007, and the following apply.

3.1

pliable tubing

PLT

corrugated tubing capable of being bent easily by hand a limited number of times, incorporating an outer

cover applied by the manufacturer at the time of production

3.2

PLT kit

pliable tubing with its related components obtained or specified from one manufacturing entity having

design and performance responsibility for the kit

3.3

bend radius

radius measured to the centre line of the pliable tubing

3.4

PLT fitting

unique fitting using mechanical attachment methods, in which tightness is achieved with or without seals,

excluding other joining methods such as welding, brazing, soldering or gluing

3.4.1

end fitting

PLT fitting intended to join pliable tubing to an external component

3.4.2

coupling

PLT fitting intended to join two sections of pliable tubing

3.4.3

tee

PLT fitting to join three sections of pliable tubing

3.4.4

manifold

PLT fitting designed to join 4 or more sections of pliable tubing

3.5

seal

any part intended to provide tightness within a PLT fitting

3.6

additional protection

outer sheath intended to protect the connection between the pliable tubing and a PLT fitting or eventual

damage occurred to the cover during or after installation of the pliable tubing from corrosion or

mechanical damage

Note 1 to entry: This sheath has the same chemical resistance as the cover.

EXAMPLE Wrapping tape or heat shrink tube

3.7

PLT support

element used to attach the PLT kit to the structure of the building

3.8

rated flow rate

flow rate at a given pressure drop, under standard reference conditions

3.9

family

group of products produced by one manufacturer for which test results for one product of that group are

representative of characteristics for the whole group

3.10

1st, 2nd and 3rd family gases

group of gaseous fuels with similar burning behaviour linked together by a range of Wobbe indices

Note 1 to entry: See EN 437:2021, Table 1.

Note 2 to entry: These gases are commonly referred to as manufacturer gases, natural gas and liquified petroleum

gases.

[SOURCE: EN 437:2021, 3.18, modified with Note 2 to entry]

3.11

installation pipework

pipework downstream of the point of gas delivery terminating at the appliance inlet connection

3.12

cover

tubular outer sheath applied to the corrugated pipe by the manufacturer and intended to improve the

resistance of the pipe to external corrosion and mechanical damage

3.13

maximum allowable pressure

PS

maximum pressure for which the equipment is designed, as specified by the manufacturer, and defined

at a location specified by him

4 Design requirements

4.1 General

4.1.1 Additional components

Where additional components are required to complete the PLT kit, these components shall be provided

or specified by the kit manufacturer.

4.1.2 Materials

The material for the pliable tubing (see Table 1) shall be austenitic stainless steel and the grade shall be

chosen according to long term suitability for the gas conveyed, the environment, the conditions under

which it will be used and the suitability for fabrication, e.g. welding, cold forming, etc. as appropriate. Due

regard shall be taken of the quality of the gas conveyed, possible variation in the composition, and

possible development of corrosive agents both internally and externally.

NOTE 1 Examples of possible corrosive agents include:

— internal: combinations of sulphur, oxygen, moisture, etc.;

— external: coastal and general environmental influence, building materials, etc.

NOTE 2 The material of the pliable tubing directly affects the safety of the works (building and civil engineering)

in which the tubing kit is installed and the durability performance of the tubing kit itself.

4.1.3 Cover, PLT fittings and PLT supports

PLT fittings shall provide a gas-tight connection to the pliable tubing. PLT fittings, whether surface

finished or not, shall be manufactured from materials listed in Table 1.

Table 1 — Materials

Component Material

Austenitic Stainless steel according to EN 10028-7: 1.4306, 1.4404, 1.4401, 1.4541,

Pliable tubing

1.4571

a

Cover Synthetic material

Additional

b

Synthetic material

protection

Stainless steel according to EN 10088-3, copper alloys according to EN 12164 and

PLT fittings

c

EN 12165

Stainless steel according to EN 10088-3, copper alloys according to EN 12164 and

c

EN 12165

PLT

manifold/tees

Malleable cast iron according to EN 10242 types W 400-05; W 350-04; B 350-10 or

B 300-06

Supports Metallic corrosion resistant material

a

see 4.8

b

see 4.9

c

A material containing at least 57 % copper and not more than 3,5 % lead for copper PLT fittings, PLT

manifolds and tees is an example of the percentages presenting an appropriate resistance against stress

corrosion cracking and dezincification.

The choice of material for pliable tubing should relate to the composition of the gas conveyed and the

external environment (see Table 2, adapted extract from EN ISO 10380:2012).

Table 2 — Typical classification of materials for corrosion resistance

Corrosion Description Material Grade Examples

Resistance Class

1.4306

Basic corrosion

A Stainless steels

resistance

1.4541

1.4404

Good corrosion

B Mo-alloyed stainless steels 1.4401

resistance

1.4571

NOTE For example, the addition of biogas can increase oxygen and moisture content.

4.2 Nominal size DN, wall thickness and pressure drop

The nominal size of a PLT kit shall be selected from the DN given in EN ISO 10380:2012, Table 1.

The nominal size range shall be from DN 10 to DN 50.

The minimum bore size of the pliable tubing shall be at least 98 % of the nominal size DN in mm.

The manufacturer shall declare the related pressure drop (see 5.18) for each nominal size DN (see 5.3).

For direct burial if not stipulated in local installation standards, the minimum wall thicknesses values as

included in the following Table 3 shall apply.

Table 3 — Nominal size DN, min. inner diameter and min. wall thickness

DN 10 DN 12 DN 15 DN20 DN25 DN32 DN40 DN50

Min. inner diameter (mm) 9,8 11,8 14,7 19,6 24,5 31,4 39,2 49,0

Min. wall thickness (mm) 0,18 0,18 0,20 0,25 0,25 0,30 0,30 0,30

4.3 Threads

Male end fittings shall have terminating threads according to EN 10226-1 or any national standard.

Male or female end fittings shall have terminating threads according to EN ISO 228-1 or any national

standard.

Integrated threads within the mechanical attachment of the PLT fittings shall not be compatible for

EN 10226-1 nor EN ISO 228-1.

4.4 PLT fittings

4.4.1 General

PLT fittings shall provide a gas-tight connection to the pliable tubing. PLT fittings, whether surface

finished or not, shall be manufactured from materials listed in Table 1. Copper alloys shall be selected

from EN 12164 and/or EN 12165 and shall contain at least 57 % copper and not more than 3,5 % lead.

4.4.2 Stress corrosion

All fittings and components of copper alloy shall be resistant to stress corrosion.

Stress corrosion resistance shall be determined in accordance with ISO 6957 (pH 9,5) or any more

stringent national standard.

4.4.3 Dezincification

All copper alloys components shall resist dezincification.

If an alloy contains more than 10 % of zinc, its corrosion behaviour shall be assessed according to

EN ISO 6509-1.

4.5 Seals

Where seals and sealing materials for metallic threaded joints are used in the PLT kit, they shall be

suitable for gas and selected from the appropriate European Standards when permitted by the national

regulation or technology e.g. EN 549, EN 682, EN 751-1, EN 751-2 and EN 751-3 and taking into account

the different temperature ranges.

PLT kit components shall be resistant to any corrosive agent reasonable foreseen in the field of the

declared intended use.

They shall be durable to climatic conditions according to 5.14.

4.6 Supports

Supports shall be made of materials mechanically and chemically nonaggressive with the other

components of the PLT kit with which they are in contact.

Supports shall be designed to carry the designed load for a minimum of 30 min in case of fire. The

standard temperature/time curve shall be as given in EN 1363-1:2020, Figure 7.

The manufacturer shall supply installations instructions that give the correct support design for the kit

supplied. The instructions shall also emphasize the need to design the support fixings to the structure in

such a way that maintains the integrity of the system in case of fire for a period not less than the period

for which the supports are designed to carry the system load.

4.7 Electrical conductivity requirements

PLT kit components shall be electrically conductive, see 5.17.

The manufacturer should advise in his installation instructions that equipotential bonding should be in

accordance with local application regulations.

4.8 Cover

The cover shall satisfy the tests according to 5.4, 5.7, 5.12, 5.13, 5.14 and 5.16.

If the materials of the cover contain corrosive agents or ingredients such as sulphur or chlorine, such

agents shall not be released during manufacturing process or during intended service conditions.

The cover shall be a synthetic polymer or elastomer with a total chloride content not exceeding 50 ppm.

For direct burial if not stipulated in local installation standards, the cover shall have a minimum thickness

of 0,5 mm.

For the purpose of safety, the prevailing colour of the cover shall be: yellow, e.g. RAL 1004, 1016, 1018.

4.9 Additional protection

The additional protection must be convenient to the specifications of the manufacturer.

The additional protection shall satisfy the tests according to 5.12, 5.13, and 5.14.

The additional protection shall be a synthetic polymer or elastomer with a total chloride content not

exceeding 50 ppm.

If the additional protection is a heat shrink tube, the tube shall have a minimum thickness of 0,5 mm after

shrinkage.

If the additional protection is a wrapping tape, the finished thickness on the applied area shall be

minimum 0,5 mm.

The manufacturer of the PLT-kit shall supply installation instructions that specifies the overlap to be

applied for the tape or the maximum temperature for the shrinkable tube.

For the purpose of safety, the prevailing colour of the additional protection shall be: yellow, e.g. RAL 1004,

1016, 1018.

4.10 Environment

PLT kit components shall be resistant to any corrosive agent reasonably foreseen in the conditions of the

declared intended use.

They shall be durable to climatic conditions according to 5.14.

They shall withstand a temperature range of –20 °C to 60 °C.

In case any country needs a lower temperature class, it should be specified by the country;

The manufacturer should advise in his installation instructions that, where exposed, sections of PLT kits

can be protected against excessive mechanical force that can cause damage. Casing/trunking can be used

to fulfil this requirement.

5 Performance and test requirements

5.1 General

5.1.1 Introduction

The number and the type of PLT kit samples to be tested, the tests and the compliance criteria shall be as

given in the following Table 4.

Initial type testing shall be performed on samples of PLT kits representative of the manufactured types,

and shall be chosen at random from either a production lot, or in the absence of available lots assemblies

representative of the production from the market.

Unless otherwise specified, the number and type of samples of PLT kits to be tested, the tests and

compliance criteria are as given in Table 4.

Table 4 — Number of units and compliance criteria for initial testing

Type test Nominal Requirement Sample Quantity Assessment Compliance criteria

size or clause type method

families

to be

tested

Bending

All sizes 5.4.1 1 2 5.4.2 Tightness

performance

Crushing Tightness, maximum

All sizes 5.5.1 1 4 5.5.2

resistance deformation

Stability under Tightness, elongation

All sizes 5.6.1 1 1 5.6.2

pressure level

Wear resistance

All sizes 5.7.1 see 5.7 1 5.7.2 No full penetration

of outer cover

Structural

All sizes 5.8.1 1 1 5.8.2 Tightness

strength

Impact Tightness, maximum

X / Y / Z 5.9.1 2 1 5.9.2

resistance deformation

Penetration Tightness, maximum

All sizes 5.10.1 1 1 5.10.2

resistance deformation

Resistance to

All sizes 5.11.1 1 1 5.11.2 Tightness

pull out

Chemical Tightness, no

Y 5.12.1 2 3 5.12.2

resistance detrimental effect

Low

Tightness, no

temperature Y 5.13.1 2 1 5.13.2

detrimental effect

resistance

Tightness, no

Ageing X / Z 5.14.1 2 2 5.14.2

detrimental effect

Tightness in Permissible leakage

X / Y / Z 5.15.1 2 2 5.15.2

case of fire level

Euroclass

Reaction to fire X / Z 5.16.1 see Annexes A and B

classification

Electrical

X / Y / Z 5.17.1 2 2 5.17.2 -

conductivity

see see see

Tables Tables Tables Pressure drop

Pressure drop 5.18.1 5.18.3

12 and 12 and 12 and statement

13 13 13

Maximum load

Admissible

for admissible X / Z 5.19.1 - 2 5.19.2

deformation

deformation

The results of all tests shall be recorded and held by the manufacturer for at least 10 years.

If any nominal size fails one of the tests within the test sequence schedule given in 5.1.3, Table 6, then all

samples of that nominal size will be deemed to have failed to meet the type test requirements of this

document.

Unless otherwise specified in this document:

— all dimensions shall be in mm;

— the tests shall be carried out with the cover in place;

— the tests performed will qualify the other sizes in the same family as specified in Table 5.

Tests results shall only apply to components of the same design and same material.

Table 5 — Test requirements

Nominal size Family Qualified diameters DN

a

to be tested

DN 12 X DN 10 - DN 12 - DN 15

DN 25 Y DN 20 - DN 25 - DN 32

DN 50 Z DN 40 - DN 50

a

If these sizes are not available, the largest DN in the relevant family shall be tested.

The tests shall be performed under ambient conditions. If not otherwise indicated, the following

tolerances shall apply:

— atmospheric pressure: (±0,1) mbar;

— flow rate: (±3) %;

— temperature above 125 °C: (±10) °C;

— dimensions: (±0,1) mm;

— air pressure: (±5) %;

— ambient temperature: (±1) °C;

— time: (±0,1) %;

— sample length: (–1/+3) %.

5.1.2 Type of PLT kit samples

The PLT kit samples used in the following tests shall be assembled in accordance with the manufacturers’

instructions (with additional protection applied for the tests according to 5.12, 5.13 and 5.14)

If the installation instruction of the manufacturer prescribes both; wrapping tape or heat shrink tube as

an additional protection; then both shall not be mixed on the same sample. The quantity of PLT kit

samples used in the tests according to 5.12, 5.13 and 5.14 shall then be adapted.

Prior to assembling, each length of the pliable tubing shall be tested according to 5.3. Depending on the

test, Type 1 sample (see Figure 1) or Type 2 sample (see Figure 2) shall be used.

Type 1:

End fitting – pliable tubing – end fitting

Dimensions in millimetres

Figure 1 — PLT sample Type 1

Type 2:

End fitting – pliable tubing – coupling – pliable tubing – end fitting

Dimensions in millimetres

Figure 2 — PLT sample Type 2

5.1.3 Test sequence schedule

Table 6 gives the sequence to be followed for each test.

Table 6 — Test sequence schedule

Test Tests to verify the Test sequence Clause of this

characteristics document

1 2 3 4 5

A Tightness test A - - - - 5.2

B Dimensional check B - - - - 5.3

C Bending performance B A C A - 5.4

D Crushing resistance B A D A B 5.5

E Stability under pressure B A E A - 5.6

Wear resistance of outer

F F - - - - 5.7

cover

G Structural strength B A G A - 5.8

H Impact resistance B A H A - 5.9

I Penetration resistance B A I A - 5.10

J Resistance to pull out B A J A - 5.11

K Chemical resistance A K A - - 5.12

L Low temperature resistance A L A - - 5.13

M Ageing A M A - - 5.14

N Tightness in case of fire A N A - - 5.15

O Reaction to fire O - - - - 5.16

P Electrical conductivity P - - - - 5.17

Q Pressure drop A Q - - - 5.18

Maximum load for

R R - - - - 5.19

admissible deformation

Example

Test H is preceded by tests B and A and followed by test A.

5.2 Tightness

5.2.1 Tightness for test samples

5.2.1.1 Requirements

The PLT kit shall be tight when tested in accordance with the method given in 5.2.1.2.

The initial tightness test shall be performed with the cover in place. For the final tightness test, the cover

shall be removed in order that it does not contribute to the achievement of the tightness.

5.2.1.2 Test method

When held under water and containing air at a pressure of air at a pressure of 2 bar for class 1, and a

pressure of 3 bar for class 2, the leakage rate of a test sample shall not exceed 10 cm /h.

−3

NOTE A helium leakage rate not exceeding (7x 10 ) mbar l/s is equivalent to the above requirement.

5.2.2 Tightness for FPC

5.2.2.1 Requirements

The PLT shall be tight when tested in accordance with the method given in 5.2.2.2.

The tightness test shall be performed just prior to the cover being applied.

Any operation after the cover being applied which may influence the tightness shall require retesting

with the cover in place.

5.2.2.2 Test method

When held under water and containing air at a pressure of air at a pressure of 2 bar for class 1 and a

pressure of 3 bar for class 2, the leakage rate of a PLT shall not exceed 10 cm /h per 25 m.

−3

NOTE A helium leakage rate not exceeding (7x 10 ) mbar l/sec is equivalent to the above requirement.

5.3 Dimensional check

5.3.1 Requirements

When subjected to the following test method, every sample length of pliable tubing shall show no sign of

inner diameter restriction.

5.3.2 Test method

A metal sphere or gauge, calibrated to (98 +0/–0,5) % of the DN shall pass through the length.

5.4 Bending performance

5.4.1 Requirements

After being bent through 12 cycles in accordance with 5.4.2, PLT samples shall be leak tight when tested

in accordance with 5.2.1.2 and there shall be no visible cracks in the cover.

5.4.2 Test method

The samples shall be subjected to a bend test as shown in Figure 3. With one end rigidly fixed the other

shall be moved to a starting position A in a circular arc around a former having a radius calculated from

the bend radius (pliable test) as given in EN ISO 10380:2012, Table 6 type 3, until the tubing is in intimate

contact with the full length of the arc of the former.

Throughout the test, the sample shall be pressurized with air at MOP according to the DN and class.

The PLT sample shall be bent 12 times through an arc of 180°, the first cycle comprises one bend starting

in a position A moving through B to the end position C, the second cycle being a movement from position

C through B to the end position A.

The longitudinal seam weld shall be located in accordance with position 3 (see Figure 3). If helical

welding is used, the orientation of the weld shall be ignored.

The test frequency shall be between 8 cycles/min and 12 cycles/min.

Side view

Key

r former radius

R bend radius

1 pressure sensor

2 end fittings

3 weld seam orientation

Figure 3 — Bending test configuration

5.5 Crushing resistance

5.5.1 Requirements

When tested in accordance with 5.5.2, the bore size of the pliable tubing shall not be reduced by more

than 15 % of its nominal size DN, and it shall remain tight.

5.5.2 Test method

The internal diameter shall be determined by using the method described in 5.3.2 before the crushing

test.

The corrugated part of the PLT kit sample shall be placed on a hard flat support surface. A load of

4000 N shall be gradually applied on a square steel plate of 150 mm side positioned on the PLT kits

sample. After a stabilization time of 5 min, the load shall be removed.

— subject 2 samples of Type 1 to a crushing test as shown in Figure 4;

— subject 2 samples of Type 1 to a crushing test as shown in Figure 5.

The seam of the PLT kit sample shall be at right angle to the direction of the load. If helical welding is

used, the orientation of the weld shall be ignored.

Carry out the tightness test given in 5.2.1.2.

Following the test, the bore size of the pliable tubing shall be confirmed by using the method given in

5.3.2 but using a sphere or a gauge calibrated to 85 % of that used in the original dimensional test.

−05,

Dimensions in millimetres

Key

1 crushing direction

2 seam weld

3 steel plate

Figure 4 — Crushing test configuration 1

Dimensions in millimetres

Key

1 crushing direction

2 seam weld

3 steel plate

Figure 5 — Crushing test configuration 2

NOTE In the crushing test configuration 2 the protection of the fitting is removed.

5.6 Stability under pressure

5.6.1 Requirements

When subjected to an internal pressure following the test method described in 5.6.2 a PLT kit sample

shall remain tight when tested in accordance with 5.2.1.2 and the permanent elongation after the release

of the pressure shall not exceed 3 %.

5.6.2 Test method

The length of the PLT kit sample shall be measured on a flat surface and recorded. With one of its ends

free and the other one plugged to a pressure device, the PLT kit sample shall be gradually pressurized to

the strength test pressure (STP) but to a minimum of 3 bar or higher, as declared by the manufacturer.

The pressure shall be maintained for 5 min. Following the release of the pressure the length shall be re-

measured.

Strength test pressure before commissioning should consider local and/or national regulations where

they exist.

5.7 Wear resistance of outer cover

5.7.1 Requirements

When subjected to the test described in 5.7.2, the cover shall not be fully penetrated.

5.7.2 Test method

The test method shall consist of the following steps:

1) a 100 mm length of pliable tubing with its cover in place shall be mounted between centres and

rotated with the crest of a corrugation under the test head (see Figure 6);

2) adjust the apparatus to apply a force of 30 N to the test head and rotate the tubing through

(350° ± 5°), at a surface speed of (35 ± 8) mm/s;

3) the cover shall be visually examined for perforation.

Key

r 0,5 mm

1 Test head

Figure 6 — Test configuration of wear resistance outer cover

NOTE Radius r of the test head is to be checked and recorded at each test report.

5.8 Structural strength test

5.8.1 Requirements

When subjected to an internal pressure following the test method described in 5.8.2 a PLT kit sample

shall remain tight when tested in accordance with 5.2.1.2.

Elongation of the PLT kit sample is acceptable.

5.8.2 Test method

Subject the unrestrained sample to an internal pressure of 15 bar in a straight position for a period of

(300 +10/–0) s.

If this test is carried out using water, the sample shall be dried prior to the tightness test.

5.9 Impact resistance

5.9.1 Requirements

A PLT kit sample subjected to an impact of 30 J applied onto its PLT coupling shall remain tight when

tested in accordance with 5.2.1.2.

5.9.2 Test method

Each end fitting shall be secured in a fixed support and the sample shall not touch anything during the

impact.

The seam of the PLT kit sample shall be at right angle to the direction of the load. If helical welding is

used, the orientation of the weld shall be ignored.

A mass of 5 kg as given in detail A, shall be dropped from a height of 600 mm onto the PLT coupling, see

Figure 7.

Dimensions in millimetres

Key

1 mass

2 guide tube with a loose fit

3 PLT coupling

Figure 7 — Impact test

NOTE Protections of fittings are removed.

5.10 Penetration resistance

5.10.1 Requirements

When subjected to the test method as described in 5.10.2, a PLT kit sample of type 1 shall remain tight

when tested in accordance with 5.2.1.2.

5.10.2 Test method

A striker of a mass of 5 kg as given in detail A, shall be dropped from a height of 300 mm onto the PLT

close to the fitting (20 mm from its insert into the fitting or the nut), see Figure 8.

The seam of the pliable tubing at the point of impact shall be at right angles to the direction of force.

Dimensions in millimetres

Key

1 striker

2 guide tube with a loose fit

3 seam zone

Figure 8 — Penetration resistance test configuration

NOTE Protections of fittings are removed.

5.11 Resistance to pull out

5.11.1 Requirements

When subjected to the test method described in 5.11.2 a PLT kit sample shall remain tight.

5.11.2 Test requirements

An axial load of 100 times DN in N (e.g. 3200 N for DN 32) shall be gradually applied to the sample at a

rate of 50 to 100 N/s and the full load shall be maintained for 10 min. After release of the load, the sample

shall be tested in accordance with 5.2.1.2.

5.12 Chemical resistance

5.12.1 Requirements

When subjected to the corrosion tests described in 5.12.2, PLT kit samples shall show:

— no visual signs of blistering or cracking on the pliable tubing cover and additional protection;

— no visual signs of corrosion or cracking on the pliable tubing with its cover and additional protection

removed;

— and no visual signs of corrosion on the PLT fittings, which could affect the safe performance of the

product.

The PLT kit samples shall remain tight when tested in accordance with 5.2.1.2.

5.12.2 Test method

5.12.2.1 General

For each test, a PLT kit sample shall be bent over a cylindrical former whose diameter is calculated using

the radius given in EN ISO 10380:2012, Table 6 type 3, to obtain a U bend sample as shown in Figure 9.

The sample shall be partially immersed in the appropriate solution for the specified time. The sample

shall be fitted with additional protection.

NOTE After the test, it would be advised to disconnect the sample in order to check that there is no test fluid

inside, which could cause a leak at a later stage.

Dimensions in millimetre

Key

1 plugged end fitting

2 additional protection

3 coupling

4 test solutions, given in Tables 7 and 8

R

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...