SIST EN 1806:2006

(Main)Chimneys - Clay/ceramic flue blocks for single wall chimneys - Requirements and test methods

Chimneys - Clay/ceramic flue blocks for single wall chimneys - Requirements and test methods

This European Standard specifies the requirements for clay/ceramic flue blocks with solid walls or walls with vertical perforations including bonding and non-bonding blocks and their fittings. Non-bonding flue blocks which have insulation in the vertical perforations or attached to the outer walls are also covered by this standard. This standard specifies the performance requirements for factory-made flue blocks.

When they are installed, they will form a part of a multi-wall chimney or a complete chimney which will serve to convey products of combustion from fireplaces or heating appliances to the atmosphere.

This standard includes components used for domestic and industrial chimneys which are not structurally independent (free-standing). Testing, marking and inspection requirements are covered by this standard.

NOTE 1 Flue blocks covered by this standard are manufactured in three forms :

a) single flue ;

b) multi-flue ;

c) flue/ventilation combination.

NOTE 2 Flue blocks may have flues which are either circular, square or rectangular. The joints may have a locating feature such as a rebate.

Abgasanlagen - Keramik - Formblöcke für einschalige Abgasanlagen - Anforderungen und Prüfmethoden

Diese Europäische Norm legt die Anforderungen für Keramik-Formblöcke mit massiven oder vertikal gelochten Wandungen einschließlich eingebundener oder nicht eingebundener Formblöcke und deren Formstücke fest. Nicht eingebundene Formblöcke mit einer Dämmung in der vertikal gelochten Wandung oder an den äußeren Oberflächen der Außenwände werden ebenfalls in dieser Norm berücksichtigt. Diese Norm legt die Leistungsanforderungen für werkmäßig hergestellte Formblöcke fest.

Nach ihrem Einbau bilden die Formblöcke einen Teil einer mehrschaligen Abgasanlage oder eine komplette Abgasanlage, die zur Ableitung von Verbrennungsprodukten von Feuerstätten an die Außenluft bei Unterdruck verwendet wird.

Diese Norm beinhaltet Bauteile für Haus- und industrielle Abgasanlagen, die nicht freistehend sind. Sie enthält ferner Anforderungen an die Prüfung, Kennzeichnung und Qualitätskontrolle.

ANMERKUNG 1 Keramik-Formblöcke nach dieser Norm werden in drei Arten hergestellt:

a) Formblöcke mit einem Zug,

b) Formblöcke mit mehreren Zügen,

c) Formblöcke für ein Luft-Abgassystem.

ANMERKUNG 2 Keramik-Formblöcke können runde, quadratische oder rechteckige Züge haben. Die Formstücke können Verbindungstechnik beinhalten, z. B. Falz.

Conduits de fumée - Boisseaux en terre cuite/céramique pour conduits de fumée simple paroi - Exigences et méthodes d'essai

La présente Norme européenne spécifie les exigences concernant les boisseaux en terre cuite/céramique munis de parois pleines ou de parois à alvéoles verticales, y compris les boisseaux harpés ou non et leurs accessoires. Les boisseaux (non harpés) qui présentent un isolant dans les alvéoles verticales ou fixé sur les parois extérieures sont également couverts par la présente norme. La présente norme spécifie les exigences de performance des boisseaux fabriqués en usine.

Lorsqu'ils sont installés, ils constituent soit une partie d’un conduit de fumée multiparois soit un conduit de fumée complet destiné à évacuer dans l'atmosphère, les produits de combustion produits par les cheminées ou les générateurs de chaleur.

Cette norme comprend les composants à usage domestique et les conduits de fumée industriels qui ne sont pas structurellement indépendants (auto-stables). Les exigences d'essais, de marquage et d'inspection sont couvertes par la présente norme.

NOTE 1 Les boisseaux couverts par la présente norme sont fabriqués selon trois formes :

a) simple conduit ;

b) multi-conduits ;

c) combinaison conduit de fumée/conduit de ventilation.

NOTE 2 Les boisseaux peuvent avoir des conduits circulaires, carrés ou rectangulaires. Les joints peuvent posséder un dispositif de fixation tel qu'une feuillure.

Dimniki – Keramične tuljave za enoslojne dimnike – Zahteve in preskusne metode

General Information

- Status

- Published

- Publication Date

- 30-Sep-2006

- Technical Committee

- POZ - Požarna varnost

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 01-Oct-2006

- Due Date

- 01-Oct-2006

- Completion Date

- 01-Oct-2006

- Directive

- 89/106/EEC - Construction products

Relations

- Effective Date

- 01-Oct-2006

Overview

EN 1806:2006 - published by CEN - specifies requirements and test methods for clay/ceramic flue blocks for single-wall chimneys. The standard covers factory-made flue blocks with solid walls or vertical perforations, including bonding and non-bonding blocks, insulation within perforations or attached to outer walls, and associated fittings. When installed, these flue blocks form part of multi-wall chimneys or complete chimneys that convey combustion products from fireplaces and heating appliances to atmosphere. Components for domestic and industrial chimneys that are not structurally independent are included. The standard also addresses testing, marking and inspection requirements.

Key Topics and Technical Requirements

EN 1806:2006 organizes technical content around performance, dimensional tolerances and laboratory tests. Key topics include:

- Types and forms: single-flue, multi-flue, and flue/ventilation combination blocks; circular, square or rectangular flues; joint locating features (e.g., rebates).

- Materials and insulation: requirements for flue block materials and insulation - shape, thermal conductivity and heat resistance considerations for non-bonding blocks.

- Dimensional tolerances: internal transverse dimensions, height, angles, straightness, squareness, joints and insulation thickness tolerances.

- Mechanical performance: proof load testing for straight and angle blocks and sections with inspection openings.

- Gas tightness and thermal shock: initial and final gas-tightness testing and thermal shock resistance protocols.

- Durability tests: condensate resistance, corrosion resistance, water absorption, bulk density, abrasion resistance, flow resistance, thermal resistance and freeze/thaw.

- Fire resistance: internal-to-external and external-to-external fire resistance assessments, including soot fire testing.

- Conformity and quality control: initial type testing, factory production control, sampling procedures, marking, labelling and packaging.

- Test methods and procedures: detailed test descriptions and annexes for thermal resistance calculations, coefficient of friction, and sampling for inspection.

Applications and Who Uses EN 1806:2006

EN 1806:2006 is essential for stakeholders involved in the design, manufacture, testing and installation of chimney components:

- Manufacturers of clay/ceramic flue blocks and fittings - to design products that meet performance and marking requirements.

- Testing laboratories - to perform standardized proof load, gas-tightness, thermal shock, corrosion and durability tests.

- Specifiers, architects and engineers - to select compliant flue blocks for domestic and industrial chimneys.

- Installers and building inspectors - to verify product conformity and correct marking/packaging.

- Regulatory authorities and certification bodies - for evaluation of conformity and factory production control.

Related Standards

EN 1806:2006 supersedes EN 1806:2000 and sits alongside other CEN standards for chimneys and ceramic building products. For complete compliance, consult national transpositions and complementary European standards covering chimney systems, installation and safety.

Frequently Asked Questions

SIST EN 1806:2006 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Chimneys - Clay/ceramic flue blocks for single wall chimneys - Requirements and test methods". This standard covers: This European Standard specifies the requirements for clay/ceramic flue blocks with solid walls or walls with vertical perforations including bonding and non-bonding blocks and their fittings. Non-bonding flue blocks which have insulation in the vertical perforations or attached to the outer walls are also covered by this standard. This standard specifies the performance requirements for factory-made flue blocks. When they are installed, they will form a part of a multi-wall chimney or a complete chimney which will serve to convey products of combustion from fireplaces or heating appliances to the atmosphere. This standard includes components used for domestic and industrial chimneys which are not structurally independent (free-standing). Testing, marking and inspection requirements are covered by this standard. NOTE 1 Flue blocks covered by this standard are manufactured in three forms : a) single flue ; b) multi-flue ; c) flue/ventilation combination. NOTE 2 Flue blocks may have flues which are either circular, square or rectangular. The joints may have a locating feature such as a rebate.

This European Standard specifies the requirements for clay/ceramic flue blocks with solid walls or walls with vertical perforations including bonding and non-bonding blocks and their fittings. Non-bonding flue blocks which have insulation in the vertical perforations or attached to the outer walls are also covered by this standard. This standard specifies the performance requirements for factory-made flue blocks. When they are installed, they will form a part of a multi-wall chimney or a complete chimney which will serve to convey products of combustion from fireplaces or heating appliances to the atmosphere. This standard includes components used for domestic and industrial chimneys which are not structurally independent (free-standing). Testing, marking and inspection requirements are covered by this standard. NOTE 1 Flue blocks covered by this standard are manufactured in three forms : a) single flue ; b) multi-flue ; c) flue/ventilation combination. NOTE 2 Flue blocks may have flues which are either circular, square or rectangular. The joints may have a locating feature such as a rebate.

SIST EN 1806:2006 is classified under the following ICS (International Classification for Standards) categories: 91.060.40 - Chimneys, shafts, ducts; 91.100.25 - Terracotta building products. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 1806:2006 has the following relationships with other standards: It is inter standard links to SIST EN 1806:2001. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 1806:2006 is associated with the following European legislation: EU Directives/Regulations: 305/2011, 89/106/EEC; Standardization Mandates: M/105. When a standard is cited in the Official Journal of the European Union, products manufactured in conformity with it benefit from a presumption of conformity with the essential requirements of the corresponding EU directive or regulation.

SIST EN 1806:2006 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Chimneys - Clay/ceramic flue blocks for single wall chimneys - Requirements and test methodsConduits de fumée - Boisseaux en terre cuite/céramique pour conduits de fumée simple paroi - Exigences et méthodes d'essaiAbgasanlagen - Keramik - Formblöcke für einschalige Abgasanlagen - Anforderungen und PrüfmethodenTa slovenski standard je istoveten z:EN 1806:2006SIST EN 1806:2006en91.100.25Ceramic building products91.060.40Dimniki, jaški, kanaliChimneys, shafts, ductsICS:SIST EN 1806:20011DGRPHãþDSLOVENSKI

STANDARDSIST EN 1806:200601-oktober-2006

EUROPEAN STANDARDNORME EUROPÉENNEEUROPÄISCHE NORMEN 1806July 2006ICS 91.060.40; 91.100.25Supersedes EN 1806:2000

English VersionChimneys - Clay/ceramic flue blocks for single wall chimneys -Requirements and test methodsConduits de fumée - Boisseaux en terre cuite/céramiquepour conduits de fumée simple paroi - Exigences etméthodes d'essaiAbgasanlagen - Keramik - Formblöcke für einschaligeAbgasanlagen - Anforderungen und PrüfmethodenThis European Standard was approved by CEN on 19 June 2006.CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this EuropeanStandard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such nationalstandards may be obtained on application to the Central Secretariat or to any CEN member.This European Standard exists in three official versions (English, French, German). A version in any other language made by translationunder the responsibility of a CEN member into its own language and notified to the Central Secretariat has the same status as the officialversions.CEN members are the national standards bodies of Austria, Belgium, Cyprus, Czech Republic, Denmark, Estonia, Finland, France,Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania,Slovakia, Slovenia, Spain, Sweden, Switzerland and United Kingdom.EUROPEAN COMMITTEE FOR STANDARDIZATIONCOMITÉ EUROPÉEN DE NORMALISATIONEUROPÄISCHES KOMITEE FÜR NORMUNGManagement Centre: rue de Stassart, 36

B-1050 Brussels© 2006 CENAll rights of exploitation in any form and by any means reservedworldwide for CEN national Members.Ref. No. EN 1806:2006: E

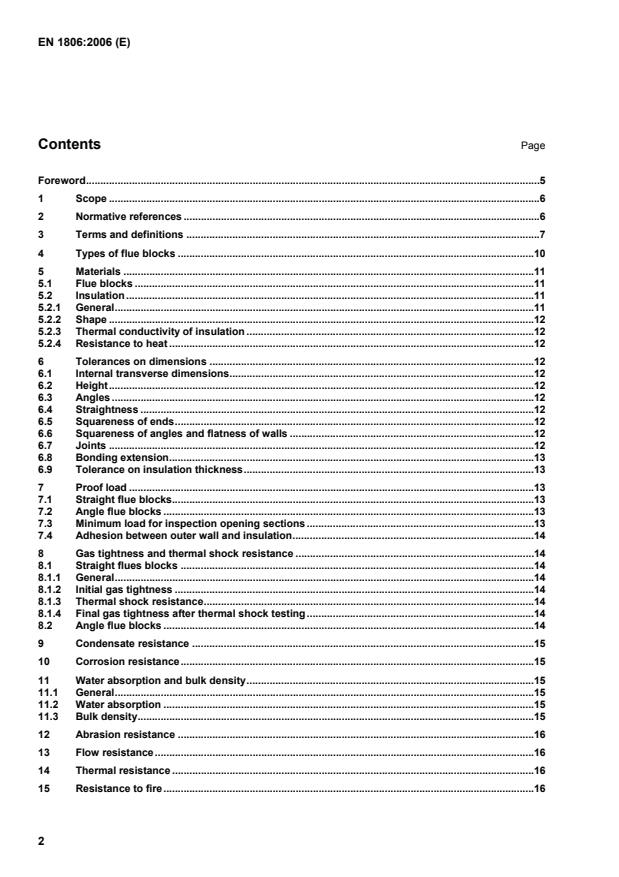

Measurement of the coefficient of friction of chimneys.39 Annex B (normative)

Thermal resistance.41 B.1 Method 1 : simplified calculation for flue blocks without cavities.41 B.2 Method 2 : thermal resistance of flue blocks with or without cavities.41 B.2.1 General.41 B.2.2 Data.42 B.2.3 Specific conditions for the cavities.43 B.2.4 Calculations.46 B.3 Method Approximate thermal resistance values.46 Annex C (normative)

Sampling procedures for an AQL of 10 % and Inspection Level S2.47 C.1 Acceptability determination.47 C.1.1 General.47 C.1.2 Single sampling.47 C.1.3 Double sampling.47 C.2 Normal inspection.47 C.3 Normal to reduced inspection.49 C.4 Reduced to normal inspection.49 C.5 Tightened inspection.49 C.6 Tightened to normal inspection.50 C.7 Discontinuation of inspection.50 Annex ZA (informative)

Clauses of this European Standard addressing the provisions of EU Construction Products Directives.51 ZA.1 Scope and relevant characteristics.51 ZA.2 Procedure of attestation of conformity of clay/ceramic flue blocks.54 ZA.2.1 System of attestation of conformity.54 ZA.2.2 EC certificate and declaration of conformity.54 ZA.3 CE Marking and labelling.55 Bibliography.59

angle flue block flue blocks designed to facilitate a change in angle of the axis of a flue (see Figure 2). 3.2

bonding extension part of a flue block which is designed to be bonded into adjacent masonry walls, and forms no part of the chimney 3.3

bonding flue block flue blocks designed to be built wholly or partially into a masonry wall and having a bonding extension

Bonding flue block Non-bonding flue block Figure 1 — Examples of flue block shape 3.4

entry flue block flue block connecting the chimney to the connecting flue pipe or the chimney to the appliance (see Figure 6)

Figure 2 — Examples of angle flue block 3.5

family group of products for which the test for one or more characteristics from any one product within the family are valid for all other products within the family 3.6

flue blocks with attached insulation flue blocks with insulation factory-fitted to the outer walls (see Figure 5).

Figure 3 — Examples of transfer flue blocks 3.7 flue blocks with insulation in vertical perforations flue blocks with perforations within the wall specially designed to house rigid insulation (see Figure 4).

Figure 4 — Example of flue block with insulation in vertical perforations 3.8

nominal height numerical designation of the height in millimetres of a standard flue block excluding any projecting spigot, which is a convenient round number NOTE For a bonding flue block, this is the co-ordinating height which equates to the nominal height of masonry building blocks for walls into which such a flue block is designed to be built.

Figure 5 — Example of flue block with attached insulation

nominal size numerical designation of size which is a convenient round number equal to or approximately equal to either: the internal diameter in millimetres of flue blocks with circular section flue; or the internal width in millimetres of flue blocks with square section flue; or the internal width and breadth in millimetres of the internal transverse dimensions of flue blocks with rectangular section flue.

Figure 6 — Example of entry flue block 3.10

non-bonding flue block flue blocks designed not to be built into a masonry wall with a bonding extension 3.11 straight flue block flue blocks designed to be used in a vertical section of a chimney having the ends perpendicular to the axis of the flue (see Figure 1). 3.12

transfer flue block flue block which changes the cross-section of the flue from rectangular to circular (see Figure 3). 4 Types of flue blocks Clay/ceramic flue blocks shall be designated according to Clause 19. A non-exhaustive list of abbreviated designation for clay/ceramic flue blocks, according to temperature, pressure, sootfire resistance and condensate resistance (wet and dry conditions) is given in Table 1.

type

pressure resistance conditions pressure leakage rate

working°C test °C

Pa m3

.s-1.m–2 x10-3 FB1 N2 Non-bonding 600 1 000 N2 Yes Dry 20 3 FB1 N1 Non-bonding 600 1 000 N1 Yes Dry 40 2 FB2 N2 Non-bonding 600 700 N2 No Dry 20 3 FB2 N1 Non-bonding 600 700 N1 No Dry 40 2 FB3 N2 Non-bonding 400 500 N2 No Dry & wet 20 3 FB3 N1 Non-bonding 400 500 N1 No Dry & wet 40 2 FB4 N2 Non-bonding 300 350 N2 No Dry & wet 20 3 FB4 N1 Non-bonding 300 350 N1 No Dry & wet 40 2 FB5 N2 Non-bonding 200 250 N2 No Dry & wet 20 3 FB5 N1 Non-bonding 200 250 N1 No Dry & wet 40 2 FB6 Bonding 300 350 N2 No Dry 20 3 NOTE A flue block may be designated in one or more types provided that it complies with the appropriate requirements of each type. 5 Materials 5.1 Flue blocks Flue blocks shall be manufactured from suitable clay/ceramic material which, when fired, meet the performance requirements given in this standard. Flue blocks may be unglazed or glazed on the interior and/or exterior. When glazed, they need not be glazed on the jointing surfaces. 5.2 Insulation 5.2.1 General All information on reaction to fire shall be made available according to the relevant European product standard.

= χ . H . G/ 100

(1) where F is the minimum load in kN;

χ is the safety factor equal to 5;

H is the height of chimney in m;

G is the weight per metre in kg/m.

The flue block which forms part of a multi-wall chimney shall not be tested for the distance to combustible materials. The flue block that forms a chimney shall be tested for the distance to combustible materials. For the latter, the distance to combustible material shall be declared in accordance with 18.8. The manufacturer may declare a distance to combustible material that reflects installation practice in individual member states' regulations. The surface temperature of the combustible material shall be equal to or less than 100 °C for an ambient air temperature of 20 °C. NOTE This distance should not be less than the distance under normal operating conditions. 15.2 External to external For complete chimneys which convey products of combustion to the atmosphere, the resistance to fire external to external shall be evaluated according to the provision valid in the intended place of use of the flue blocks until a European test method is available. 16 Resistance to freeze/thaw When subject to regulation, the freeze/thaw resistance of the flue block shall be tested according to EN 14297. The product shall not present any damage of type 7, 8, 9 and 10 in accordance with EN 14297:2004, Table 1.

Relevant requirements clauses Initial type testing Factory production control Item 17.2

17.4 Straight flue blocks 7.1,8, 9, 10, 13,12, 14, 15 and 16 6.1, 6.2, 6.4, 6.5, 6.6 and 11 Angle blocks 7.2, 8.2, 10 and 16 6.1, 6.3, and 11 Sampling and testing of any batch shall be completed prior to removal from the works and shall be in accordance with ISO 2859-1 at an AQL of 10 % and inspection level S2. Isolated batches of units shall be assessed in accordance with tightened inspection procedures, with a maximum batch size of 1 200 (see Annex C). Batches rejected under the sampling procedure specified above may be resubmitted once, after removal of units with previously undetected visible defects, under the tightened inspection procedures, in respect only of the defect that caused initial rejection.

Key H Nominal height of the flue block in mm L Test length of the flue block in mm D Deviation from straightness in mm H - L = 50 mm Figure 7 — Terms for deviation

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...