SIST EN 13438:2014

(Main)Paints and varnishes - Powder organic coatings for hot dip galvanised or sherardised steel products for construction purposes

Paints and varnishes - Powder organic coatings for hot dip galvanised or sherardised steel products for construction purposes

This European Standard specifies performance requirements for organic coating powders and powder organic coatings as applied to finished articles (hot dip galvanised or sherardised steel products) for construction purposes. Hot dip galvanised steel products can be articles that have been batch hot dip galvanised (hot dip galvanised after fabrication) or articles consisting of continuously hot dip galvanised sheet which is then subsequently fabricated.

This European Standard does not set out any performance requirements for the powder coating process itself. Guidance on cleaning and pretreatment of the hot dip galvanised or sherardised steel products prior to powder coating is provided.

This European Standard does not apply to articles with zinc-aluminium coatings or aluminium-zinc coatings, or to continuously hot dip galvanised wire. This standard does not apply to organic coating powders and powder organic coatings as applied to hot dip galvanised or sherardised steel products (i.e. duplex coated articles) for which there are specific standards, which might include additional requirements or requirements which are different from those of this standard.

Beschichtungsstoffe - Pulverbeschichtungen für feuerverzinkte oder sherardisierte Stahlerzeugnisse für Bauzwecke

Diese Europäische Norm legt Leistungsanforderungen an organische Pulverlacke und organische Pulverbeschichtungen fest, die auf fertige Gegenstände (feuerverzinkte oder sherardisierte Stahlerzeugnisse) aufgetragen wurden und für Bauzwecke vorgesehen sind. Feuerverzinkte Stahlerzeugnisse können Gegenstände sein, die stückverzinkt (nach der Herstellung feuerverzinkt) wurden oder aus kontinuierlich feuerverzinktem Band oder Blech bestehen, welches anschließend verarbeitet wurde.

Diese Europäische Norm legt keine Leistungsanforderungen an den Prozess des Pulverbeschichtens selbst fest. Anforderungen an die Reinigung und Vorbehandlung der feuerverzinkten oder sherardisierten Stahlerzeugnisse vor dem Pulverbeschichten werden festgelegt.

Diese Europäische Norm gilt nicht für Gegenstände mit Zink-Aluminium-Überzügen oder Aluminium-Zink-Überzügen sowie für kontinuierlich feuerverzinkten Draht. Diese Norm gilt nicht für organische Pulverlacke und organische Pulverbeschichtungen, die auf feuerverzinkte oder sherardisierte Stahlerzeugnisse aufgetragen werden (d. h. Duplex-beschichtete Gegenstände), für die es spezifische Normen gibt und in die zusätzliche Anforderungen aufgenommen sind oder von den Anforderungen in dieser Norm abweichen.

Peintures et vernis - Revêtements de poudre organique pour produits en acier galvanisé à chaud ou shérardisé utilisés dans la construction

La présente Norme européenne spécifie les exigences de performance des poudres de revêtement organiques et des revêtements de poudre organique appliqués sur des produits finis (produits en acier galvanisé à chaud ou shérardisé) utilisés dans la construction. Les produits en acier galvanisé à chaud peuvent être des articles qui ont été galvanisés à chaud au trempé (après fabrication) ou des tôles d’acier galvanisé à chaud en continu, qui passent ensuite en fabrication.

La présente Norme européenne ne définit pas d’exigences de performance pour le procédé d’application du revêtement de poudre. Elle fournit des recommandations relatives au nettoyage et au prétraitement des produits en acier galvanisé à chaud ou shérardisé avant l’application du revêtement de poudre.

La présente Norme européenne ne s’applique pas aux articles revêtus de zinc-aluminium ou d’aluminium zinc, ni au fil d’acier galvanisé à chaud en continu. La présente norme ne s’applique pas aux poudres de revêtement organiques ni aux revêtements de poudre organique appliqués sur des produits en acier galvanisé à chaud ou shérardisé (c’est-à-dire des produits duplex) pour lesquels il existe des normes spécifiques qui peuvent inclure des exigences supplémentaires ou des exigences différentes de celles fournies dans la présente norme.

Barve in laki - Praškasti organski premazi za izdelke iz vroče pocinkanega ali difuzijsko pocinkanega jekla za gradbeništvo

General Information

- Status

- Published

- Public Enquiry End Date

- 24-Apr-2012

- Publication Date

- 12-Mar-2014

- Technical Committee

- IBLP - Paints and varnishes

- Current Stage

- 6060 - National Implementation/Publication (Adopted Project)

- Start Date

- 25-Feb-2014

- Due Date

- 02-May-2014

- Completion Date

- 13-Mar-2014

Relations

- Effective Date

- 01-Apr-2014

Overview

EN 13438:2013 - Paints and varnishes: Powder organic coatings for hot dip galvanised or sherardised steel products for construction purposes - is a European Standard published by CEN that specifies performance requirements for powder coating materials and finished powder-coated articles used on hot dip galvanised or sherardised steel in construction. The standard focuses on coating performance (appearance, durability and resistance) rather than prescribing the powder coating process itself. It also provides guidance on cleaning and pretreatment of substrates prior to coating.

Key topics and requirements

EN 13438:2013 covers technical topics and test methods for powder organic coatings applied to hot dip galvanised or sherardised steel. Key items include:

- Scope and exclusions: Applies to batch or continuously galvanised sheet subsequently fabricated; excludes zinc‑aluminium or aluminium‑zinc coatings and continuously galvanised wire. Duplex systems may be covered by other specific standards.

- Coating powder requirements: Identification, storage and performance requirements for powders and finished coatings.

- Surface and appearance: Requirements and tests for colour, gloss, surface appearance and film thickness.

- Adhesion and mechanical resistance: Tests for adhesion, resistance to scratching, resistance to deformation and mortar resistance.

- Durability and environmental resistance: Tests for weathering, humidity, sulfur dioxide, salt spray, and permeability.

- Test methods and annexes: Normative and informative annexes describe methods for preparing test panels, sampling, and specific test procedures (Annexes A–D). Annex B gives guidance on cleaning and pretreatment; Annex C offers process guidelines; Annex E covers care and protection of coated components.

- Conformity and certification: Requirements for certificates of conformity and summary of required tests.

Applications and users

EN 13438 is intended for stakeholders involved in the specification, production and testing of powder-coated galvanised or sherardised steel used in construction, including:

- Architects and specifiers choosing cladding, façade elements, railings, profiles and building components

- Fabricators, galvanisers and sherardisers preparing substrates for powder coating

- Powder coating applicators and manufacturers ensuring film performance

- Testing laboratories and certification bodies conducting performance tests and issuing conformity documents

- Building owners and asset managers who require durable, decorative duplex systems

This standard helps ensure durable, corrosion-resistant, and aesthetically consistent powder coatings on galvanised or sherardised steel used in construction applications.

Related standards

- EN 15773 - Guidance for duplex systems (recommended to be used alongside EN 13438)

- Relevant EN/ISO test standards referenced within EN 13438 for colour, gloss and mechanical tests

Keywords: EN 13438:2013, powder organic coatings, hot dip galvanised, sherardised, powder coated, construction, pretreatment, adhesion, salt spray, weathering.

Frequently Asked Questions

SIST EN 13438:2014 is a standard published by the Slovenian Institute for Standardization (SIST). Its full title is "Paints and varnishes - Powder organic coatings for hot dip galvanised or sherardised steel products for construction purposes". This standard covers: This European Standard specifies performance requirements for organic coating powders and powder organic coatings as applied to finished articles (hot dip galvanised or sherardised steel products) for construction purposes. Hot dip galvanised steel products can be articles that have been batch hot dip galvanised (hot dip galvanised after fabrication) or articles consisting of continuously hot dip galvanised sheet which is then subsequently fabricated. This European Standard does not set out any performance requirements for the powder coating process itself. Guidance on cleaning and pretreatment of the hot dip galvanised or sherardised steel products prior to powder coating is provided. This European Standard does not apply to articles with zinc-aluminium coatings or aluminium-zinc coatings, or to continuously hot dip galvanised wire. This standard does not apply to organic coating powders and powder organic coatings as applied to hot dip galvanised or sherardised steel products (i.e. duplex coated articles) for which there are specific standards, which might include additional requirements or requirements which are different from those of this standard.

This European Standard specifies performance requirements for organic coating powders and powder organic coatings as applied to finished articles (hot dip galvanised or sherardised steel products) for construction purposes. Hot dip galvanised steel products can be articles that have been batch hot dip galvanised (hot dip galvanised after fabrication) or articles consisting of continuously hot dip galvanised sheet which is then subsequently fabricated. This European Standard does not set out any performance requirements for the powder coating process itself. Guidance on cleaning and pretreatment of the hot dip galvanised or sherardised steel products prior to powder coating is provided. This European Standard does not apply to articles with zinc-aluminium coatings or aluminium-zinc coatings, or to continuously hot dip galvanised wire. This standard does not apply to organic coating powders and powder organic coatings as applied to hot dip galvanised or sherardised steel products (i.e. duplex coated articles) for which there are specific standards, which might include additional requirements or requirements which are different from those of this standard.

SIST EN 13438:2014 is classified under the following ICS (International Classification for Standards) categories: 25.220.60 - Organic coatings; 87.040 - Paints and varnishes. The ICS classification helps identify the subject area and facilitates finding related standards.

SIST EN 13438:2014 has the following relationships with other standards: It is inter standard links to SIST EN 13438:2006. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

SIST EN 13438:2014 is available in PDF format for immediate download after purchase. The document can be added to your cart and obtained through the secure checkout process. Digital delivery ensures instant access to the complete standard document.

Standards Content (Sample)

2003-01.Slovenski inštitut za standardizacijo. Razmnoževanje celote ali delov tega standarda ni dovoljeno.Beschichtungsstoffe - Pulverbeschichtungen für feuerverzinkte oder sherardisierte Stahlerzeugnisse für BauzweckePeintures et vernis - Revêtements de poudre organique pour produits en acier galvanisé à chaud ou shérardisé utilisés dans la constructionPaints and varnishes - Powder organic coatings for hot dip galvanised or sherardised steel products for construction purposes87.040Barve in lakiPaints and varnishes25.220.60Organske prevlekeOrganic coatingsICS:Ta slovenski standard je istoveten z:EN 13438:2013SIST EN 13438:2014en,fr,de01-april-2014SIST EN 13438:2014SLOVENSKI

STANDARDSIST EN 13438:20061DGRPHãþD

EUROPEAN STANDARD NORME EUROPÉENNE EUROPÄISCHE NORM

EN 13438

September 2013 ICS 25.220.60 Supersedes EN 13438:2005English Version

Paints and varnishes - Powder organic coatings for hot dip galvanised or sherardised steel products for construction purposes

Peintures et vernis - Revêtements de poudre organique pour produits en acier galvanisé à chaud ou shérardisé utilisés dans la construction

Beschichtungsstoffe - Pulverbeschichtungen für feuerverzinkte oder sherardisierte Stahlerzeugnisse für Bauzwecke This European Standard was approved by CEN on 19 July 2013.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national standards may be obtained on application to the CEN-CENELEC Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation under the responsibility of a CEN member into its own language and notified to the CEN-CENELEC Management Centre has the same status as the official versions.

CEN members are the national standards bodies of Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMITÉ EUROPÉEN DE NORMALISATION EUROPÄISCHES KOMITEE FÜR NORMUNG

CEN-CENELEC Management Centre:

Avenue Marnix 17,

B-1000 Brussels © 2013 CEN All rights of exploitation in any form and by any means reserved worldwide for CEN national Members. Ref. No. EN 13438:2013: ESIST EN 13438:2014

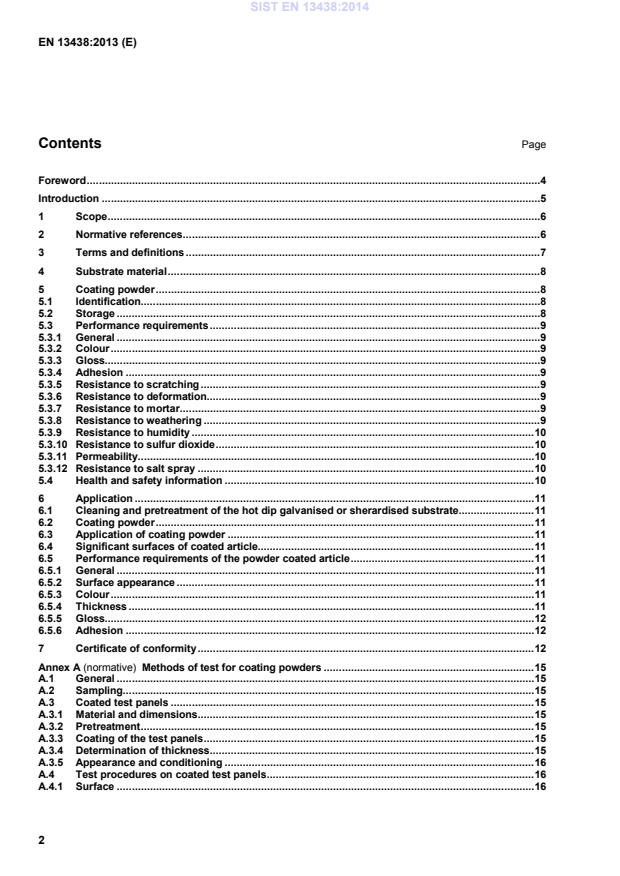

Methods of test for coating powders . 15 A.1 General . 15 A.2 Sampling . 15 A.3 Coated test panels . 15 A.3.1 Material and dimensions . 15 A.3.2 Pretreatment . 15 A.3.3 Coating of the test panels . 15 A.3.4 Determination of thickness . 15 A.3.5 Appearance and conditioning . 16 A.4 Test procedures on coated test panels . 16 A.4.1 Surface . 16 SIST EN 13438:2014

Guidance on cleaning and pretreatment processes . 19 B.1 Cleaning . 19 B.2 Pretreatment . 19 B.3 Types of pretreatment . 19 B.3.1 Conversion and drying of the conversion coating (chemical pretreatment) . 19 B.3.2 Mechanical pretreatment. 20 Annex C (informative)

Guidelines on the powder coating process . 21 Annex D (normative)

Methods of test for powder coatings . 22 D.1 General . 22 D.2 Test piece preparation . 22 D.3 Test procedures on finished articles . 22 D.3.1 Surface appearance . 22 D.3.2 Colour . 22 D.3.3 Thickness . 22 D.3.4 Gloss . 22 D.3.5 Adhesion . 22 D.4 Test procedures on test panels . 23 Annex E (informative)

Guidelines on the care and protection of powder coated hot dip galvanised or sherardised steel components . 24 E.1 Packing and handling. 24 E.2 Tapes . 24 Bibliography . 25

EN ISO 11664-4 (see A.4.2) and replacement of ISO 1518 with EN ISO 1518-1 (see A.4.5); k) Annex B has been edited to clarify references to "cleaning" and "pretreatment" and the content reduced; l) the possibility of an adhesion test on finished article now included in Annex D (see D.3.5); m) the content of Annex E has been reduced – reference has been made to EN 15773 for further information. According to the CEN-CENELEC Internal Regulations, the national standards organizations of the following countries are bound to implement this European Standard: Austria, Belgium, Bulgaria, Croatia, Cyprus, Czech Republic, Denmark, Estonia, Finland, Former Yugoslav Republic of Macedonia, France, Germany, Greece, Hungary, Iceland, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Norway, Poland, Portugal, Romania, Slovakia, Slovenia, Spain, Sweden, Switzerland, Turkey and the United Kingdom. SIST EN 13438:2014

This European Standard does not set out any performance requirements for the powder coating process itself. Guidance on cleaning and pretreatment of the hot dip galvanised or sherardised steel products prior to powder coating is provided. This European Standard does not apply to articles with zinc-aluminium coatings or aluminium-zinc coatings, or to continuously hot dip galvanised wire. This standard does not apply to organic coating powders and powder organic coatings as applied to hot dip galvanised or sherardised steel products (i.e. duplex coated articles) for which there are specific standards, which might include additional requirements or requirements which are different from those of this standard. 2 Normative references The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references, the latest edition of the referenced document (including any amendments) applies.

EN 10346, Continuously hot-dip coated steel flat products — Technical delivery conditions EN 13811, Sherardizing — Zinc diffusion coatings on ferrous products — Specification EN ISO 1461, Hot dip galvanized coatings on fabricated iron and steel articles — Specifications and test methods (ISO 1461) EN ISO 1518-1, Paints and varnishes — Determination of scratch resistance — Part 1: Constant loading method (ISO 1518-1) EN ISO 1519, Paints and varnishes — Bend test (cylindrical mandrel) (ISO 1519) EN ISO 2178, Non-magnetic coatings on magnetic substrates — Measurement of coating thickness — Magnetic method (ISO 2178) EN ISO 2409, Paints and varnishes — Cross-cut test (ISO 2409) EN ISO 2808, Paints and varnishes — Determination of film thickness (ISO 2808) EN ISO 2810, Paints and varnishes — Natural weathering of coatings — Exposure and assessment (ISO 2810) EN ISO 2813, Paints and varnishes — Determination of specular gloss of non-metallic paint films at 20°, 60° and 85° (ISO 2813) EN ISO 3231, Paints and varnishes — Determination of resistance to humid atmospheres containing sulfur dioxide (ISO 3231) EN ISO 3668, Paints and varnishes — Visual comparison of the colour of paints (ISO 3668) EN ISO 4618:2006, Paints and varnishes — Terms and definitions (ISO 4618:2006) SIST EN 13438:2014

[SOURCE: EN ISO 4618:2006, 2.108] 3.2 conversion coating layer produced on a hot dip galvanised or sherardised steel surface by a chemical treatment 3.3 powder coating dry film obtained by application and fusing of a coating powder 3.4 coating powder solvent-free coating material in powder form which, after fusing and possible curing, gives a continuous film 3.5 test piece single item, representative of the work being processed 3.6 significant surface part of the coated article on which the coating is essential for serviceability of the article 3.7 specifier person specifying the performance requirements for the coating and significant surfaces of the article 3.8 coating applicator company responsible for applying the coating powder onto a substrate 3.9 substrate surface to which a coating material is applied or is to be applied

NOTE EN 15773 and EN ISO 12944-4 provide some guidance on surface conditions that might be encountered on post fabrication hot dip galvanised or sherardised articles. To achieve optimum quality of finished product, sharp edges on the fabrication should be avoided (see EN ISO 14713-2 and EN ISO 14713-3). 5 Coating powder 5.1 Identification The following information shall be made available by the supplier for each consignment of coating powder: a) manufacturer; b) trade name; c) colour; d) gloss level; e) type of resin; f) batch number; g) box number; h) product reference code; i) date of manufacture; j) date of despatch. 5.2 Storage The coating powder, after storage in unopened containers for a maximum period indicated by the manufacturer, calculated from the date of dispatch by the manufacturer, shall still conform to 5.3. If no maximum permissible storage period is indicated by the manufacturer, the coating powder shall, after storage in unopened containers for up to 12 months from the date of despatch by the manufacturer, conform to 5.3. The storage temperature shall not exceed 25 °C unless otherwise specified by the coating powder manufacturer. SIST EN 13438:2014

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...